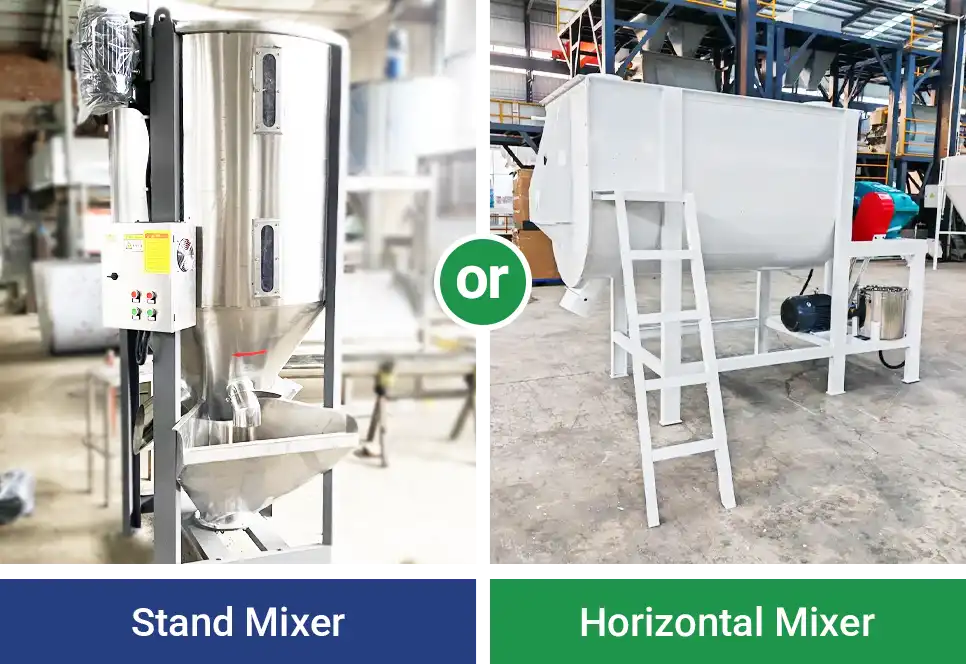

Vertical or Horizontal? How to Choose the Right Feed Mixer

Good feed mixing means better nutrition and healthier animals. If the mix isn't even, animals may pick at their food and grow slower. Vertical and horizontal mixer machines are the most common options, but choosing the right one isn't always easy. This guide breaks down their differences and helps you find the best fit for your farm.

Vertical Mixer

A vertical feed mixer usually includes a mixing barrel, screw auger, frame, and discharge outlet. It has a compact design and takes up little space, making it ideal for smaller areas. Common types include single-screw and single-shaft multi-screw models, which differ in how they mix and how evenly they do it.

Single-Screw

The machine uses a bottom motor to drive a vertical screw shaft. Feed is slowly lifted from the bottom to the top, then falls back down by gravity. This creates a continuous up-and-down flow that mixes the material.

Single-drive, Multi-screw

A single main shaft at the bottom drives two or more mixing blades. The screws push feed upward from different points, lifting, turning, and spreading the material. This creates a multi-point flow that blends ingredients of various sizes, densities, and moisture levels.

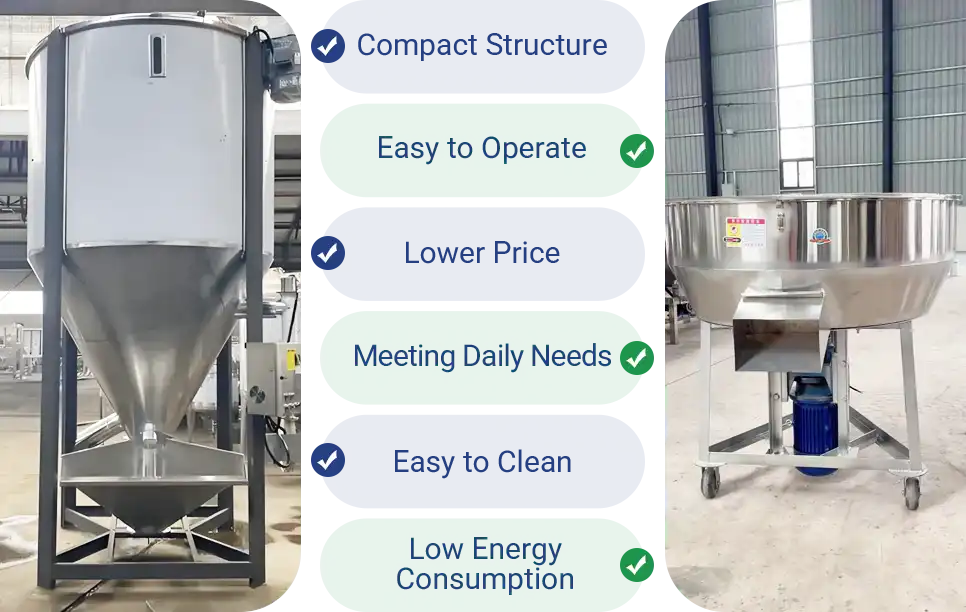

Main Advantages of Vertical Feed Mixers

- Compact design, saves space

- Easy to operate and maintain

- Lower cost, good value for small farms

- Ideal for small batches of dry feed

- Optional stainless steel for wet or fermented feed; easier to clean

- Low energy use, suitable for long-term use

Limitations

Single-screw mixers have only one mixing path, so they take longer to mix and discharge, with lower output. They're not ideal for frequent use or complex formulas, especially when dealing with oily or micro-ingredient-rich materials.

Multi-screw models improve mixing quality but still have low output, slow discharge, and are harder to clean. They also handle wet or granular materials less effectively.

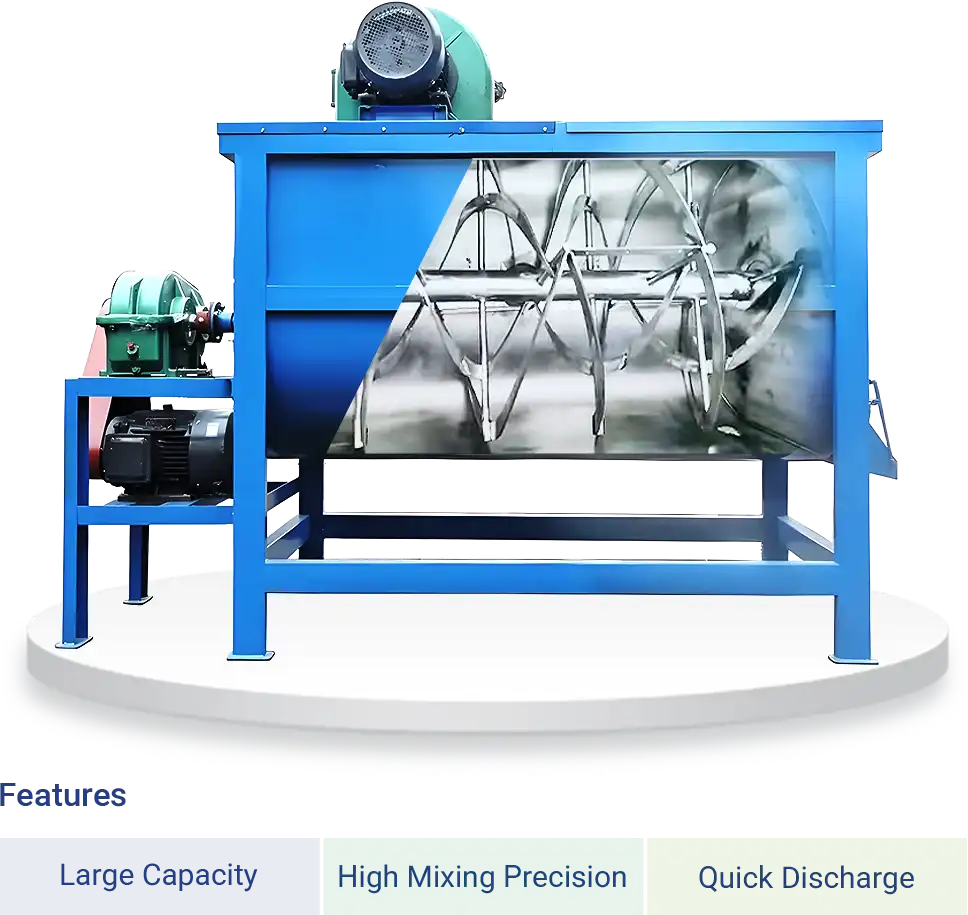

Horizontal Mixers

Compared to vertical models, horizontal mixers offer better mixing accuracy, faster processing, and quicker discharge.

Horizontal mixers use a horizontal drum with single or twin ribbon shafts. Materials are pushed and turned repeatedly inside the chamber, allowing fast and even mixing. They are well-suited for complex formulas and large-volume production.

For operations with higher hygiene or corrosion resistance needs, stainless steel versions are available. These are easier to clean and last longer.

Additives can be added easily. Most models feature side or bottom discharge, which makes unloading faster and cleaning more convenient. This type is ideal for frequent use and users who require high mixing accuracy.

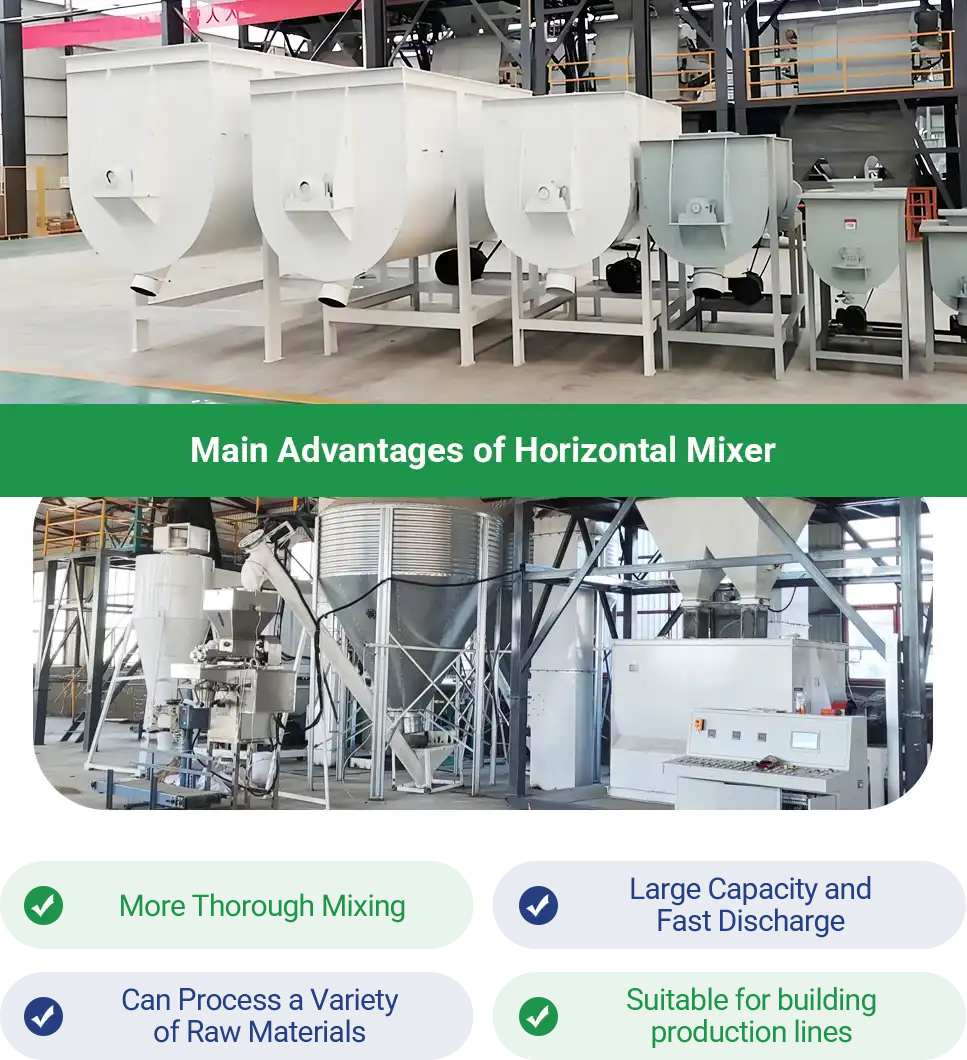

Advantages

- Mixes more thoroughly, ideal for feed with precise ratios

- Large capacity with fast discharge and high efficiency

- Handles various materials, including wet or fermented feed

- Easy to connect with conveyors for automated lines

Limitations

Horizontal mixers take up more space and require a suitable installation area. The internal structure is more complex, which can create hard-to-clean spots and make it harder to switch formulas quickly.

This equipment also has a higher manufacturing cost. The upfront investment is greater than that of vertical models, so it's important to evaluate based on your production scale and budget.

How to Choose the Right Mixer

When choosing a mixer, factors like farm size, feed type, operation style, and budget all matter. To ensure smoother and more efficient use later on, it's important to consider a few key points. Take time to weigh these before making a decision.

1. Daily Output and Batch Size

Daily feed output and batch size are key factors when choosing a mixer. Whether you're mixing small batches at home or running a feed plant, the machine should match your production needs. Here's a quick guide:

Small-scale use (100–500 kg/day)

Ideal for backyard farms or smallholders mixing poultry or pig feed. Choose a vertical or small horizontal mixer with a 100–300 kg batch capacity. These are simple, easy to use, and cost-effective.

Medium-scale use (500 kg–2 tons/day)

Best for mid-sized farms, cooperatives, or local feed mills handling multiple batches a day. A horizontal mixer with 500–1000 kg per batch is recommended. It offers better mixing and prevents layering.

Large-scale production (over 2 tons/day)

For large farms or feed plants, go with a horizontal mixer over 1000 kg per batch. These models support automated feeding, liquid spraying, and conveying. They save labor and boost efficiency.

Here's a quick reference table:

|

Daily Output |

Recommended Mixer |

Batch Size |

|

≤ 500 kg |

Vertical or small horizontal |

100–300 kg/batch |

|

500 kg – 2 tons |

Horizontal mixer |

500–1000 kg/batch |

|

≥ 2 tons |

Large horizontal with automation |

batch |

2. Feed Formulation and Material Type

The type of feed and its ingredients also affect mixer selection. Different materials require different mixing precision, methods, and machine setups.

Does your feed contain trace ingredients

Formulas with premix, trace minerals, or additives under 0.1 percent need higher mixing accuracy. A horizontal mixer, especially with twin-shaft paddles, is a better fit. It mixes more evenly and prevents separation or nutrient imbalance.

Powders, pellets, and extruded materials

1) Fine powders

Most mixers can handle them. However, if there's a big difference in material weight, a horizontal mixer is recommended to avoid layering.

2) Coarse particles, bran, or lightweight materials

Vertical mixers may cause uneven mixing due to material floating or sinking. A horizontal mixer blends better in this case.

3) Moist or extruded feed

A horizontal mixer with scraper paddles helps prevent sticking and clumping. Some models can also support liquid spraying.

If the feed includes oil, molasses, or water

Choose a horizontal mixer with a built-in spray system. Vertical mixers are not suitable for liquids. They often result in uneven mixing, material sticking, and blockages.

Mixer selection by feed type:

| Feed Type | Recommended Mixer |

| Trace ingredients like premix | Horizontal mixer |

| Mixed particle sizes or coarse feed | Horizontal mixer |

| Fine powders or grains | Vertical or horizontal mixer |

| With oil, water, or molasses added | Horizontal mixer with spray system |

| Extruded or moist materials | Horizontal mixer with scraper paddles |

3. Space and Layout Considerations

Mixer selection should match the actual site conditions. Poor layout can make feeding, operation, or maintenance more difficult later on.

Low ceiling

In barns or low-roof buildings, a horizontal mixer is recommended. It stands only 1.5 to 1.8 meters tall, supports ground feeding, and installs easily in limited-height spaces.

Limited floor space, enough headroom

A small vertical mixer works well in tight areas like corners or corridors. It's compact and space-saving. Just check if loading equipment can be used or if manual feeding is practical.

Multiple machines or automation needed

Choose horizontal mixers. Their layout makes it easy to connect with feeding, weighing, and packing systems, improving overall efficiency.

Frequent cleaning required

For oily or moist feed, use a horizontal mixer with an access door. It's easier to open and clean. Vertical mixers are harder to clean, especially at the bottom outlet.

4. For Easier Operation and Better Automation

If convenience and automation matter to you, a horizontal mixer is usually the better choice.

Its low-profile design makes loading and unloading easier. You don't need to lift materials too high, and it's much simpler to connect with other machines such as screw conveyors, pellet mills, or packaging equipment. Horizontal mixers can also support extra features like automatic weighing, timed mixing, variable speed control, and even full integration with a production line for easier workflow.

In comparison, vertical mixers are more basic. They are fine for simple mixing tasks but may not be the best fit for processes that require multiple steps or higher precision.

5. Budget and Operating Costs

Vertical mixers are simpler in design and cheaper to manufacture, which makes them more affordable. They're a good option for small farms or new users with limited budgets. With low power consumption and a small footprint, they also help reduce daily operating costs. For beginners, it's a cost-effective starting point.

Horizontal mixers require a higher initial investment, but they offer better performance in terms of mixing efficiency, consistency, and automation. They're well suited for medium to large farms or anyone looking to scale up and run continuously. In the long run, a horizontal mixer can reduce labor needs and improve productivity. When paired with a full production line, it can even lower overall operating costs.

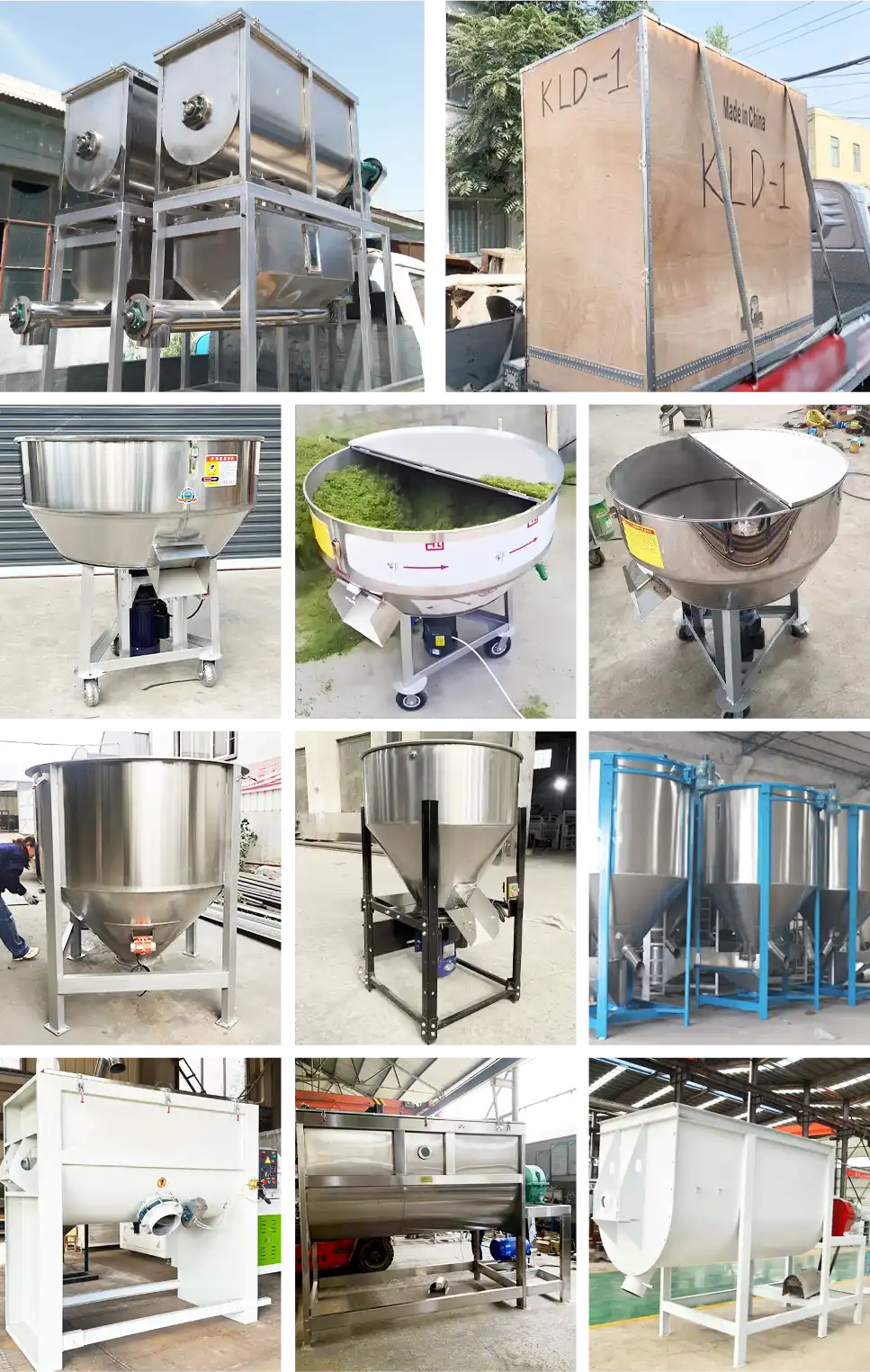

Vertical & Horizontal Feed Mixers for Sale

We offer vertical and horizontal feed mixers for farms of all sizes. Whether you need simple operation or high mixing efficiency, we have the right solution. All machines are factory-direct, reliable, and ready for delivery with full technical support.

Looking for a better feed mixing solution? We offer custom setups to fit your needs. Contact us today for a quote and tailored plan.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.