Powder vs Pellet Feed for Swine, which is Better?

In swine farming, feed choice directly affects growth performance, feeding efficiency, and daily management. To control costs, most farmers still use powder feed, often feeding it directly or wetting it to improve palatability and digestion. However, some farms are switching to pellet feed for better feeding efficiency. What are the differences between these two types of feed? Let's compare them across several aspects.

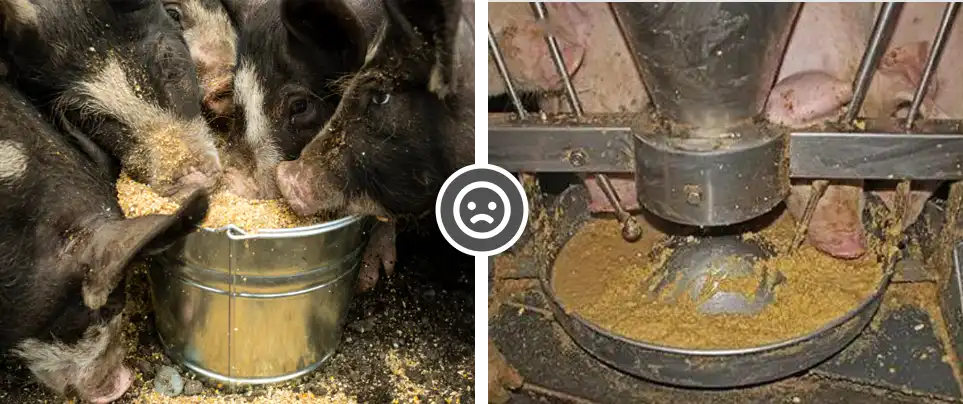

Common Forms and Usage of Powder Feed

Powder feed is the most traditional form, made by grinding and mixing ingredients like corn, soybean meal, bran, and premixes in specific proportions, then feeding it directly in powder form without any compression or shaping.

Its main advantages are low cost and ease of use, making it suitable for quick feeding. However, it has notable drawbacks, such as high dust, easy separation, and uneven nutrition, leading to feed waste. To improve palatability, reduce dust, and enhance digestion, some farmers mix the powder with water or other ingredients, or ferment it before use.

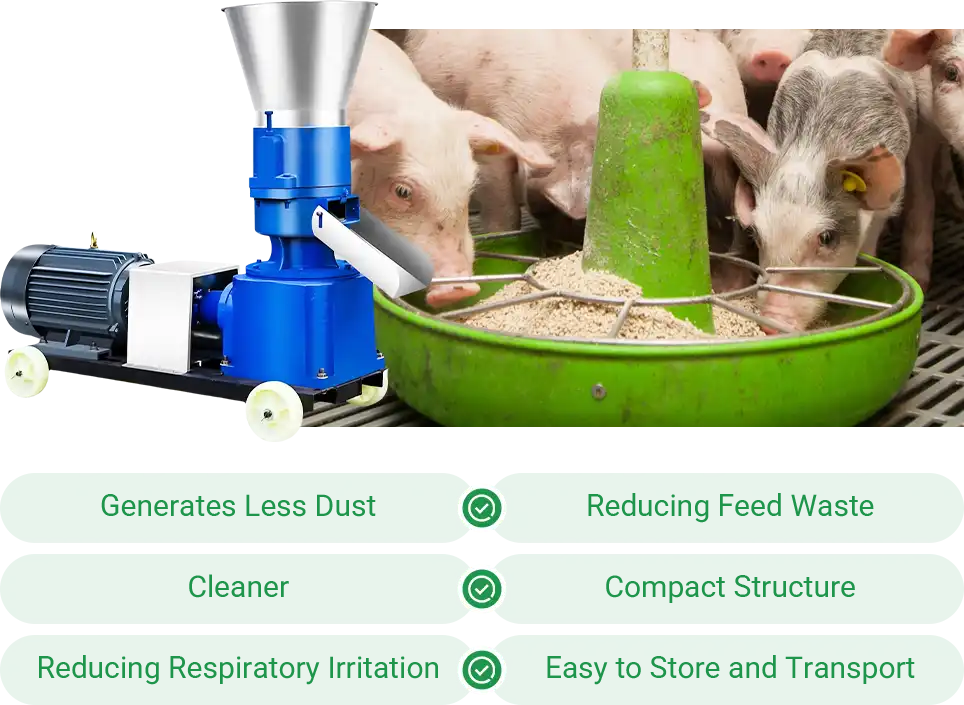

Features of Pellet Feed

Pellet feed is made by compressing prepared powder feed through a pellet mill under high temperature and pressure to form pellets with a specific shape and hardness. Some processes may also add moisture or steam for conditioning to improve the shaping effect.

Pellet feed generates less dust and is cleaner, reducing respiratory irritation and feed waste. Its compact structure makes it easy to store and transport without spoilage. The high-temperature, high-pressure process kills harmful bacteria like Salmonella and E. coli, improving farm safety.

However, relying on commercial pellets can be expensive. Many farmers opt for pellet mills to produce their own feed, allowing for flexible formulas and better cost control.

Comparison of Powder Feed and Pellet Feed

To provide a clearer comparison of their usage, we will analyze the key aspects that farmers are most concerned about.

Feeding Behavior

Powder and pellet feed each have distinct characteristics that affect pigs' palatability and feeding efficiency.

Powder feed is soft and easy to eat, making it suitable for weaned piglets or pigs with poor appetite. Some farmers add water or ferment it to improve taste. However, it tends to separate, creates dust, and can lead to picky eating and uneven intake, especially under free feeding. This often results in more waste and lower feeding efficiency, as pigs take longer to eat.

In comparison, pellet feed has a more compact structure and uniform pellets, leading to more focused and faster eating, reducing picky eating behaviors and improving group feeding order. Research has shown that using pellet feed can reduce pigs' average feeding time by 30–50%, increase daily feed intake by about 15%, and significantly improve overall feeding efficiency (Source: Poudel et al., Animal Feed Science and Technology, 2018). Additionally, pellet feed generates less dust, which helps protect pigs' respiratory health.

- Powder feed is better suited for piglets, is cost-effective, and offers flexibility, but its palatability and efficiency are limited.

- Pellet feed has better palatability and feeding concentration, making it ideal for large-scale, efficiency-focused farms.

Weight Gain and Feed Conversion Ratio

In terms of weight gain, pellet feed generally performs slightly better than powder feed. The compact structure and uniform nutrient distribution of pellet feed lead to more concentrated eating, reduce picky eating behaviors, and improve overall feed utilization. Research has shown that, compared to powder feed, pigs fed with pellets had an approximately 12% higher daily weight gain and an average feed conversion ratio (FCR) improvement of 0.2 (Rojas et al., Journal of Animal Science, 2016). This advantage is especially noticeable during the fattening stage.

Powder feed has its benefits in certain cases. It's easier for newly weaned piglets or pigs with weaker feeding abilities to eat due to its fine texture. Mixing it with water or fermenting it can enhance nutrient absorption. With proper management and balanced ingredients, powder feed can still promote good weight gain.

Feed Waste and Management

In pig farming, feed efficiency directly impacts profitability. The type of feed used affects waste levels and management burden, from transportation to feeding and pig feeding behavior.

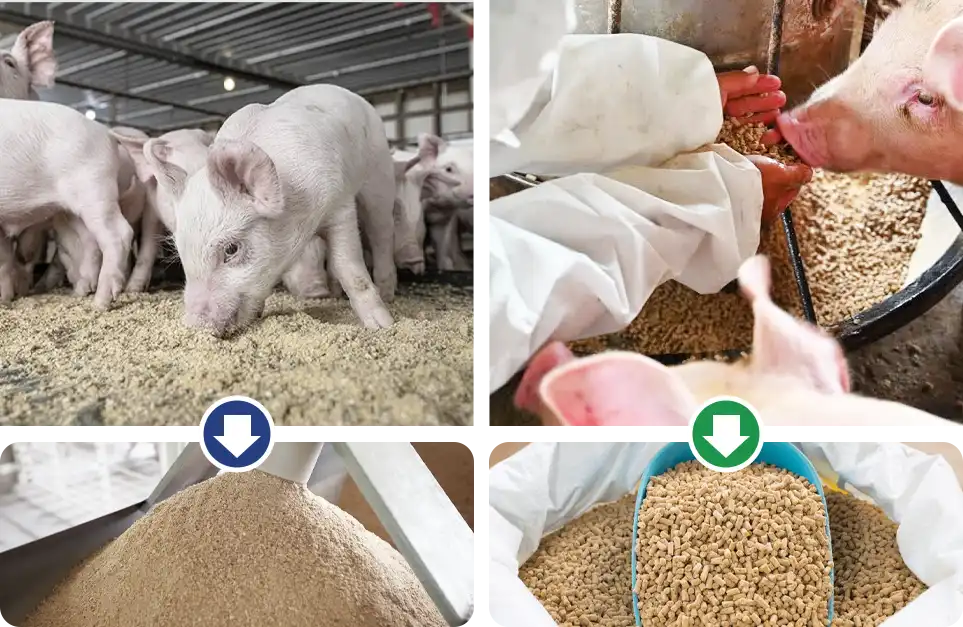

Spilled, Scattered, and Wasted Feed

When feeding powder feed, it's common for pigs to scatter or push feed out of the trough, especially in open feeders. Due to its loose texture and poor flowability, powder feed tends to spill, leading to waste and increased cleaning time. Studies show that during mixing and feeding, feed loss from spillage and wind can reach 5%–10%.

Pigs often push powder feed with their noses, especially if the taste isn't consistent, which can lead to waste. Powder feed also absorbs moisture easily, forming clumps in humid conditions or dirty troughs. Once it hardens, pigs may not eat it, causing leftovers and requiring more frequent cleaning, which adds to labor.

Mash Feed and Fermentation

In some pig farms, mash feed is still commonly used. Before feeding, ingredients like corn powder, soybean meal, and additives need to be mixed, sometimes with water or leftover food for fermentation. This process takes time and requires careful attention to the right ratios and timing.

For small to medium-sized farms, mixing takes about 1.5–2 hours daily. Fermentation requires extra preparation and constant monitoring of temperature and conditions to avoid spoilage. In hot weather, poorly managed feed can spoil, affecting intake and potentially requiring disposal of the entire batch. If equipment isn't cleaned properly, mold or contamination can occur, increasing farm risks.

Pellet Feed Feeding Performance

Compared to powder feeding, pellets are compressed and have moderate hardness, making them less likely to be pushed out of the trough or crushed, reducing visible waste. Many farmers report that after using pellet feed, the amount of feed left around the trough decreases significantly, and the frequency of cleaning the barn also drops. Studies show that pellet feed is generally more efficient than powder feeding, and its proper use can reduce feed waste by 10–30%.

Pellet feed generates little dust during feeding, which helps keep the air cleaner in the barn. Some farmers have noticed fewer cases of coughing and nasal discharge in pigs after switching to pellets. While ventilation and disease control also matter, reduced dust irritation is likely one contributing factor.

Pellets are more stable during feeding, helping reduce waste and improve feed efficiency. They also make daily management a bit easier. These benefits may not show up immediately, but over time they can lead to lower costs and better overall results.

Feed Types Recommendations

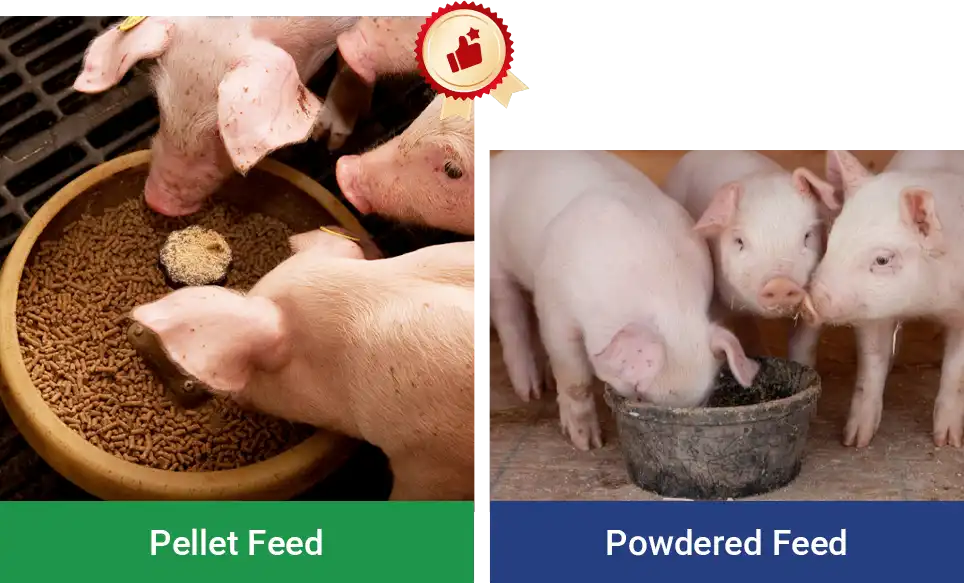

Pigs have different digestive needs and feeding habits at each growth stage. Younger pigs need easily digestible, palatable feed, while older pigs benefit more from feed that supports weight gain and efficiency. Choosing between powder and pellet feed should depend on the pig's stage and the farm's production scale.

For Different Growth Stages

| Growth Stage | Recommended Feed Type |

| Piglets / Nursery Pigs | Powder (Mash feed) |

| Growing Pigs (20–60kg) | Pellet feed |

| Fattening Pigs | Pellet feed |

| Market Pigs (before slaughter) | Mainly pellet feed, mix with powder feed |

During the early or weaning stage, many farmers mix powder feed with warm water to help piglets start eating and support digestion. As pigs grow into the weaning and fattening phases, pellet feed becomes a better choice, helping boost weight gain and lowering the risk of diarrhea.

For Different Farm Scenarios

| Farm Scenario | Recommended Feed Type |

| Small-scale farms (≤10 pigs) | Mainly powder feed, can switch to pellets |

| Small-scale farmers | Powder feed or homemade pellets |

| Medium-scale farms(≥50 pigs) | Primarily pellet feed |

| Large-scale farms (>100 pigs) | Homemade or commercially sourced pellet feed |

| Automated/Conveyor feed systems | Pellet feed (control pellet shape) |

| Specialized fattening farms | Mainly pellet feed, mix with powder feed towards the end |

Powder and pellet feed each have their pros and cons. The choice depends on farm size and management practices. If feed efficiency and long-term benefits are a priority, pellet feed is a better option.

For small farms, if powder feed causes waste and takes time to mix, making your own pellets is a simple and efficient option. A small pellet mill is easy to use and allows flexible feed formulas.For larger needs or commercial use, a custom production line can save labor, improve efficiency, and lower long-term costs.

Feel free to leave a message below if you have any questions about pellet mills or production lines.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.