Recycled Plastic Pellets: A Green Way to Profit

Plastic pellets are small granules made from various types of plastic. They are commonly used as raw materials in injection molding, extrusion, and blow molding.

A typical example is recycled plastic pellets, which are produced by processing plastic waste. These are also known as recycled granules or regrinds. The pellets are usually round or oval and have a consistent size, making them easy to transport and process.

Their use offers a more sustainable and eco-friendly solution for handling plastic waste.

Recycled Plastic Pellets: A Clean Win for the Environment and Economy

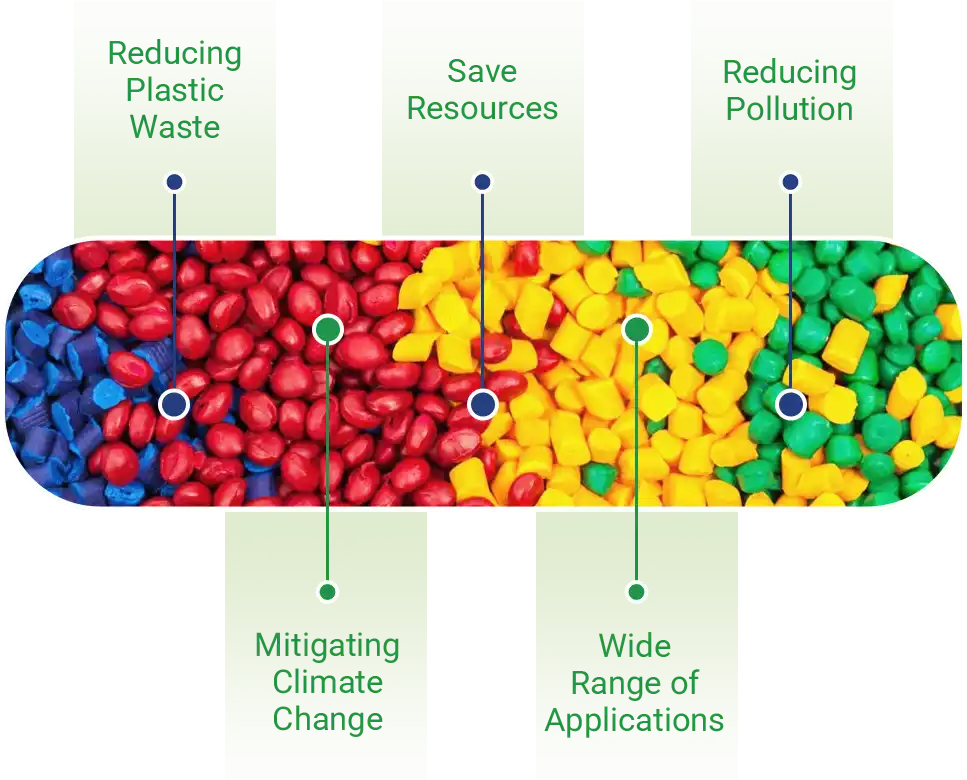

Traditionally, plastic waste has been managed through landfilling or incineration. These methods can pollute soil and oceans and, over time, may pose health risks to nearby communities. In contrast, turning plastic waste into pellets brings several clear benefits:

Reducing waste pollution: Recycling puts plastic waste back to use, reducing the amount sent to landfills or incinerated. It helps protect soil and water while saving landfill space.

Conserving resources and supporting a circular economy: As oil resources become scarcer and prices remain unstable, recycled plastic offers a more reliable material source. It also supports the shift toward a circular economy.

Minimizing environmental harm: Plastics take a long time to break down. If not properly managed, they can end up in habitats and oceans, putting wildlife at risk. Recycling helps reduce this plastic pollution.

Slowing climate change: PCR (post-consumer recycled) plastic uses at least 79% less energy and emits 67% fewer greenhouse gases. It's a cleaner, lower-impact choice.

In addition to these benefits, recycled plastic pellets are also showing strong potential for use across a wide range of industries.

How Recycled Plastic Pellets Are Used Across Industries

Recycled plastic pellets keep many of the important qualities of the original plastic, like strength, toughness, and durability. That's why they work well in many types of manufacturing-and help cut down on environmental impact at the same time.

1.Packaging Industry

Their light weight, strength, and heat resistance make them ideal for packaging. They meet common demands like durability, compression strength, and thermal stability. Recycled pellets are widely used to make bottles, containers, plastic bags, and films. They've become an essential material in the packaging sector.

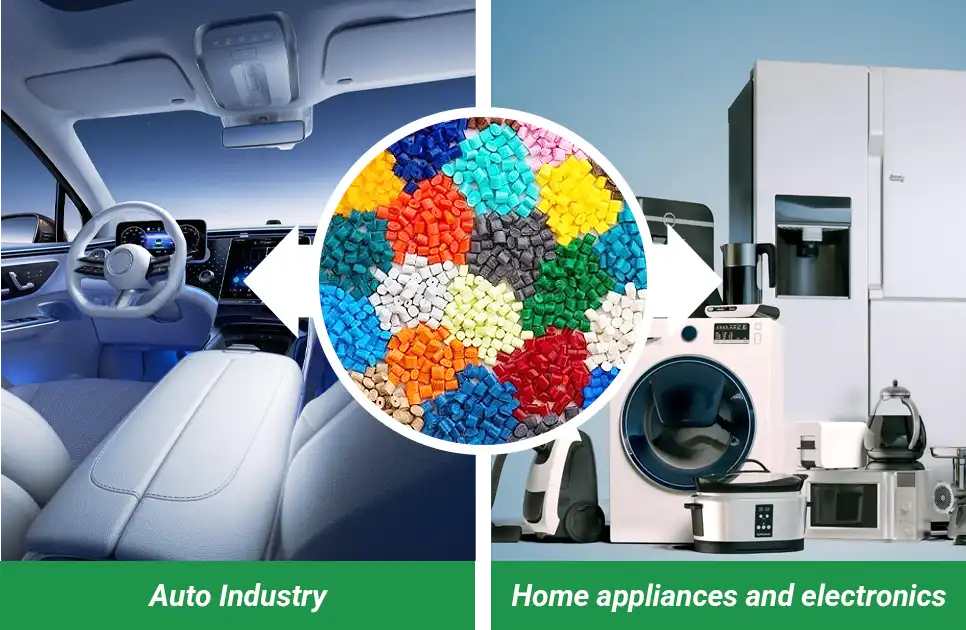

2.Automotive Industry

The automotive industry is a key user of recycled plastic. Plastic pellets are used to make many interior and exterior parts, including bumpers, dashboards, and seat frames. Their light weight helps cut vehicle weight and improve fuel efficiency. At the same time, their strength supports safety and long-term durability.

3.Home Appliances and Electronics

Recycled plastics are widely used for making casings for TVs, printers, routers, and similar devices. These products need materials that are strong, heat-resistant, and insulating. To meet these needs, recycled plastics are often blended with additives like reinforcements or flame retardants.

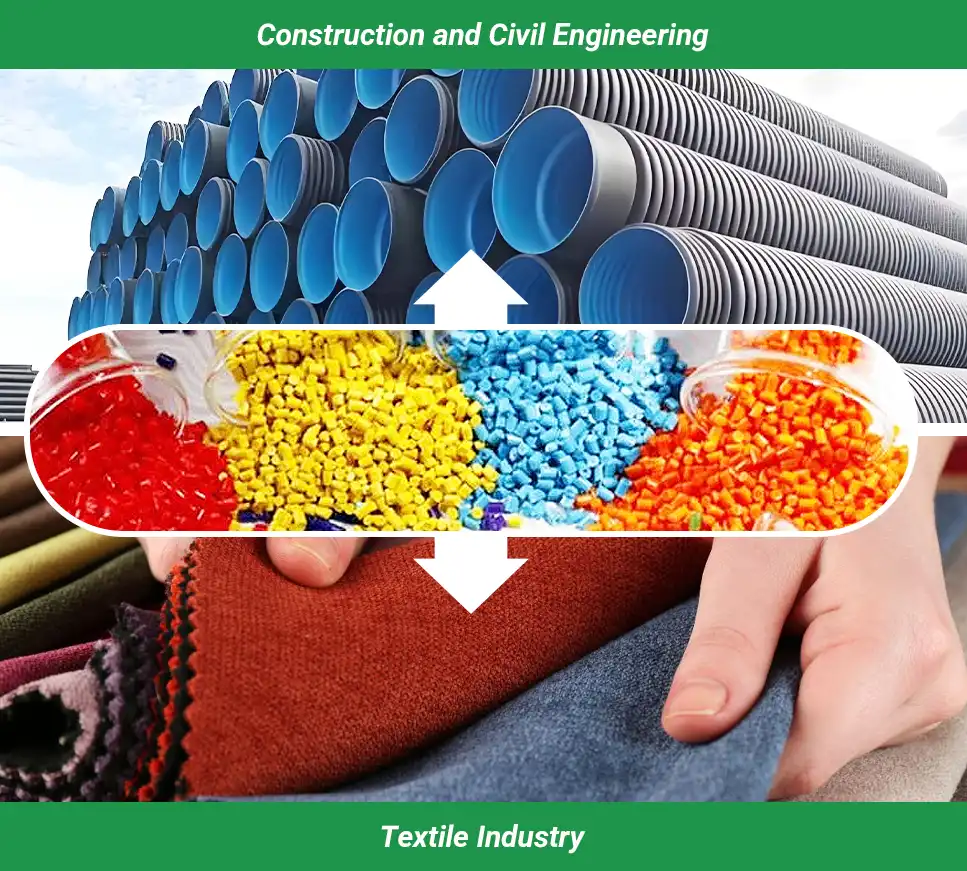

4.Construction and Civil Engineering

Recycled plastic pellets are lightweight, strong, and resistant to moisture and corrosion. They are commonly used to make pipes, panels, and structural parts. In many projects, they serve as a reliable alternative to traditional materials.

5.Textile Industry

Recycled plastic pellets can be turned into fibers and used across the textile industry. These fibers help produce eco-friendly polyester fabrics for clothes, shoes, and home items like blankets and carpets. Several major sports brands now offer sustainable apparel made from recycled plastic bottles.

How Recycled Plastic Pellets Are Made

Turning plastic waste into useful, eco-friendly pellets requires a clear and efficient process. The production of recycled plastic pellets typically involves six main steps:

1.Collection and Sorting

After collection, the plastic waste is sorted to remove non-plastic materials like metal, paper, and other debris.

Sorting methods include manual picking and automated systems, such as near-infrared detection, air separation, and water-based sorting.

Grouping plastics by resin type helps ensure the material is clean and consistent for the next stage.

2.Pre-treatment

Once sorted, the plastic is crushed into smaller pieces and then washed. Crushing makes cleaning easier, while washing removes dirt, labels, and other impurities. Cleaner input means higher-quality final pellets.

This stage typically uses a combination of crushers, washing units, dewatering machines, and dryers.

3.Melting and Extrusion

After washing, the plastic is fed into an extruder-usually a single-screw or twin-screw type. Inside, it's heated until fully melted. The molten plastic is then pushed through a die to form long, continuous strands.

4.Cooling and Pelletizing

These hot strands move through a water tank, where they are quickly cooled and shaped. Once cooled, they pass through an air dryer and enter the pelletizer, which cuts them into small, uniform pellets. This stage typically includes a cooling tank, air dryer, and pelletizer.

(Note: The washing, melting, and cooling steps can produce wastewater and gas emissions. Proper treatment systems should be in place to reduce environmental impact.)

5.Drying and Screening

The pellets are further dried and then screened to remove excess moisture and sort them by size. This step improves consistency and ensures the pellets meet quality standards.

6.Weighing and Packaging

Finally, the pellets are weighed and packed according to standard requirements. They are now ready for sale or further processing.

(Note: The equipment used may vary depending on the type and condition of the plastic. Some materials may not require every step in the process.)

Outlook for the Recycled Plastics Industry

Recycled plastics are essential to building a circular economy and lowering carbon emissions. As policies shift and demand grows, the industry is evolving quickly.

According to McKinsey, the global plastic recycling rate could reach 50% by 2030. As demand for recycled plastics grows, the industry may generate up to $60 billion in additional revenue in the coming years. This presents major opportunities for recyclers worldwide.

Countries like Malaysia, Thailand, and Vietnam are attracting more foreign investment to build modern recycling facilities. These nations are becoming key exporters of recycled plastic pellets in the region.

In contrast, areas such as Africa and South Asia still face major challenges in managing plastic waste. With the right investment in recycling infrastructure, these markets also plastic recycling help raise global recycling rates and support the continued growth of the industry.

Recycled plastic pellets are a practical way to reuse plastic waste. As technology improves and demand grows, they are being used in more industries and helping support both recycling and environmental protection.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.