Selling Feed Pellet Machines in Nigeria: A Profitable Opportunity

Pellet feed is now the most popular type in Nigeria's animal feed market. It offers better nutrition and is easier to store, handle, and transport. This trend is creating new opportunities for selling feed pellet machines, attracting interest from both farmers and dealers.

But is this business really profitable in Nigeria?

To answer that, we'll look at three key factors.

1.The Actual Demand for Feed Pellet Machines in Nigeria

To assess the profitability of feed pellet machines in Nigeria, we first need to determine whether they meet the local demand. We will analyze three key factors: livestock structure, raw material availability, and usage scenarios.

Livestock Structure

Nigeria boasts a rich variety of livestock, including poultry (chickens, turkeys, guinea fowls, ducks), ruminants (cattle, goats, sheep), pigs, rabbits, and working animals like camels, donkeys, and horses. Livestock farming has become an essential part of the local agricultural economy.

The table below shows the major livestock population in Nigeria (Source: Nigeria's First National Agricultural Sample Census, NASC):

| Livestock Type | Estimated Quantity |

| Chicken | 258.5 million |

| Goat | 124 million |

| Sheep | 49.1 million |

| Cattle | 58 million |

| Pig | 9.2 million |

(Rabbit farming is gradually emerging, though there are no authoritative statistics available. Camels, donkeys, and horses are mainly found in the northern arid and semi-arid regions, used for work and transport.)

The large livestock population has helped Nigeria's livestock sector generate an annual output value of approximately $32 billion, accounting for 5% of the national GDP. This foundation continues to drive the actual demand for efficient feed processing equipment.

Raw Material Availability

Feed pellet machines can process a wide range of raw materials, including grains (such as corn, guinea corn, and wheat), legumes (such as soybeans and peanut meal), tubers (like cassava powder), and by-products like hay, rice bran, and wheat bran. After grinding and mixing, these materials can be directly pelletized to meet the nutritional requirements of livestock and poultry.

Nigeria's total agricultural land area covers approximately 70.8 million hectares, with about 34 million hectares designated for arable land and 6.5 million hectares used for permanent crops. Key crops include corn, cassava, guinea corn, peanuts, and yams. Additionally, Nigeria is one of the leading soybean producers in West Africa.

These resources form a strong foundation for feed raw material supply, supporting local pellet production and helping reduce feed costs.

Usage Scenarios

Feed pellet machines in Nigeria are primarily used in two areas: on-farm production and feed processing plants, addressing specific needs in sectors like aquaculture and livestock farming.

On-Farm Production: Since feed costs account for around 70% of farming expenses, many small and medium-sized farms are investing in smaller feed pellet machines to make their own feed on-site.

Because of unreliable power supply in rural areas, many farmers opt for diesel-powered or manual machines. With high demand for poultry and pig feed, these machines typically produce anywhere from tens to hundreds of kilograms per hour, and are usually priced around one million Naira, which makes them a great deal.

For smaller, remote farms, feed pellet machines can process agricultural by-products locally, helping reduce waste and making feed more accessible. These farmers tend to prefer equipment that's simple, easy to maintain, and durable.

Feed Pellet Plants: Medium and large-scale feed mills are key users of feed pellet machines. These mills typically use industrial-grade equipment, such as ring die pellet mills, with production capacities of several tons per hour. They are specifically designed for mass production of poultry, ruminant, and aquaculture feed pellets.

To meet high production demands, feed mills prefer pellet machines that are high-output and stable, often paired with cooling and drying systems to ensure product quality.

In these applications, the reliability and continuous output capability of the equipment directly impact return on investment and are key factors in purchase decisions.

Aquaculture Farms and Fish Feed Pellet Production: Nigeria's annual fish consumption is around 2 million tons, with over 80% of it being imported. The low self-sufficiency rate has driven the growth of the local aquaculture industry. especially the rise of small and medium fish farms across the country.

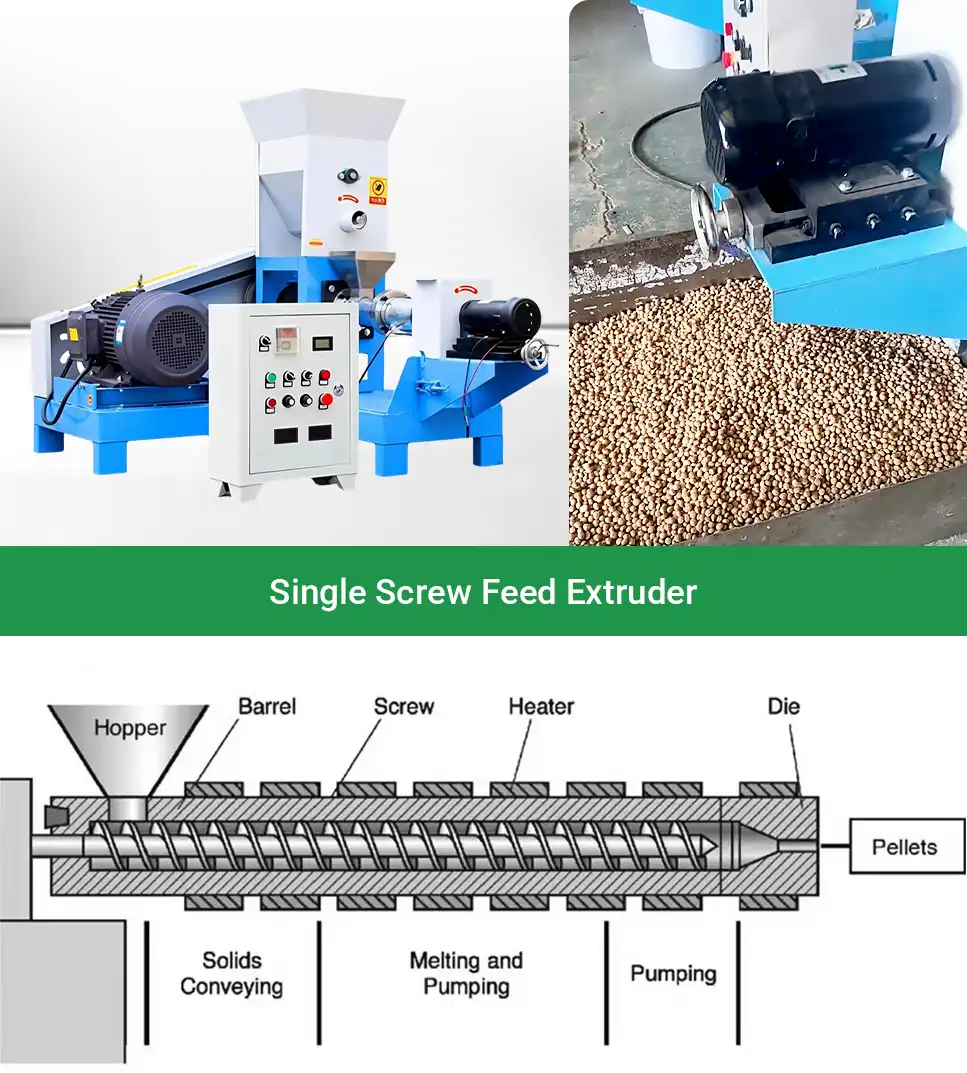

This growth has led to an increasing demand for floating and sinking fish feed pellets. While large farms use twin-screw extruders, smaller fish ponds tend to favor single-screw machines due to their affordability and ease of operation, becoming a new growth area in the pellet machine market.

This highlights the clear demand for feed pellet machines in Nigeria, with significant growth potential.

2.Competitive Landscape of the Feed Pellet Machine Market in Nigeria

Any promising market comes with competition, so understanding the competitive landscape of Nigeria's feed pellet machine market is a crucial step in assessing market entry feasibility.

Current Market Structure

Due to limited local production capacity, the Nigerian market remains dominated by imported equipment. Most of the pellet machines used by farmers and feed mills are sourced from China, India, Europe, or the U.S. Among these, Chinese and Indian manufacturers hold a clear advantage in the small to medium pellet machine market, thanks to their cost-effectiveness and wide range of models.

Additionally, around 75% of Nigeria's feed mills are located in the southwestern region, while the central and northern parts of the country have a more dispersed agricultural resource distribution, with farming activities scattered and weaker feed processing capacity.

This regional disparity leads to high feed transportation costs in some areas, making commercial feed harder to access. As a result, farmers in these regions rely more heavily on small to medium-sized pellet machines, creating new growth opportunities for equipment suppliers.

Market Key Players

Overseas Brands: Leading Chinese manufacturers like Zhengchang and Muyang offer a wide range of pellet mills, from flat die to ring die models. Their products are widely used in local medium and large feed processing projects, owing to their stable performance and established technical support.

Additionally, some smaller Chinese brands are gaining recognition in the local market due to their cost-effectiveness and reliable after-sales service, especially in the mid- to low-end segment.

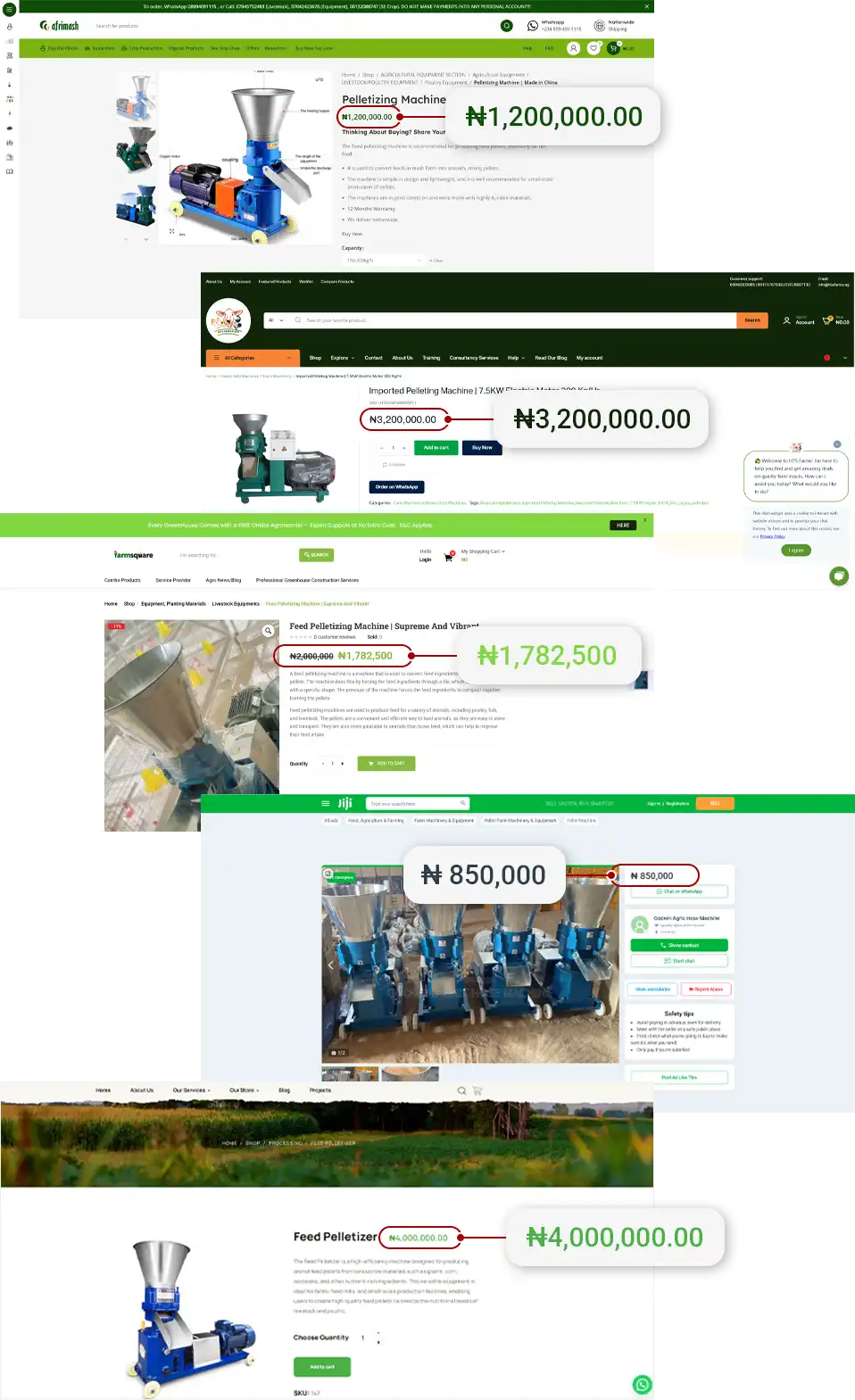

Local Distributors and E-commerce Platforms: Platforms such as Capsfeed, Obigodtools, and Afrimash have lowered procurement barriers. They address practical challenges such as transportation, customs clearance, and language issues.

Compared to direct imports, local procurement offers more flexibility, convenience, and quicker after-sales support.

Local Machinery Manufacturers: Companies like Funsab are building their own brands and sales systems, offering competitive prices. However, their equipment is mostly assembled locally, with key components imported.

The overall market exhibits the following characteristics:

- Highly Fragmented: Local suppliers are scattered, with numerous types and brands of equipment, varying product quality, and inconsistent after-sales and maintenance support.

- Price Sensitivity: Most buyers are price-sensitive, preferring simple, easy-to-operate, and maintain small to medium-sized imported pellet machines.

- Significant Quality Differences: Some locally assembled equipment is of lower quality, with insufficient compression and fast wear, making it difficult to compete with imported machines.

The market is still developing, with low competition and clear regional variations in demand, creating opportunities for new investors.

3.Is Selling Pellet Machines in Nigeria Profitable?

In a market with clear demand but limited competition, it is worth exploring whether pellet machine projects have significant profit potential in Nigeria.

The following analysis will focus on key cost factors, such as equipment procurement and logistics.

Equipment Procurement Costs

The cost of equipment primarily depends on the procurement channel. If purchased directly from Chinese manufacturers, the price of a small feed pellet machine (model 150) ranges from $320 - $400, which is approximately 488,000 - 610,000 Naira.

Shipping and Logistics

Shipping equipment from the manufacturing country to Nigeria is typically done via sea freight containers. For example, shipping from China, a 1-cubic meter wooden box can hold four 150-model feed pellet machines.

Based on current market conditions, shipping and clearance costs to Apapa/Lagos port in Nigeria are estimated at around $250 - $300 /cubic meter (approximately 38,000 - 45,800 Naira /cubic meter).

If using full containers, which have a capacity of approximately 33 cubic meters, the shipping and clearance cost is around $200 - $250 /cubic meter (approximately 30,500 - 38,000 Naira /cubic meter).

(Note: Shipping costs can fluctuate quickly, so for real-time quotes, please feel free to contact us for updated rates.)

Tariffs and Taxes

To encourage domestic agricultural production, Nigeria imposes a 0% import duty rate on agricultural equipment and machinery (HS Chapters 84, 85, 90). The standard VAT rate in Nigeria is 7.5%, but agricultural production materials, such as farm machinery and agricultural transport equipment, are exempt from VAT. Therefore, feed pellet machines imported into Nigeria are theoretically exempt from import duties, and VAT can also be waived, with only a small regulatory fee required.

Although there may be procedural and certification requirements in practice, the overall tax burden remains relatively low. For this analysis, we assume that tax expenses are either negligible or no more than 5% of the equipment's shipping cost, accounting for non-exempt miscellaneous fees.

Investment Profitability Analysis

Based on the above analysis, we will calculate the profitability for two scenarios:

If you purchase a small batch of 8 machines, at $380 per machine with shipping costs of $250 per cubic meter, the procurement cost would be:

8 * 380 + 250 * 2 = $3540 (approximately 5.4 million Naira).

Selling locally at $550 per machine, the total profit would be:

550 * 8 - 3540 = $860 (approximately 1.312 million Naira).

The average profit per machine would be:

860 / 8 = $107.5 per machine (approximately 163,900 Naira per machine).

The overall profit margin would be:

107.5 / 380 ≈ 28.29%.

If you purchase a large batch of 140 machines, at $320 per machine with shipping costs of $200 per cubic meter, the procurement cost would be:

140 * 320 + 200 * 33 = $51,400 (approximately 78.38 million Naira).

Selling locally at $550 per machine, the total profit would be:

550 * 140 - 51400 = $25,600 (approximately 39.04 million Naira).

The average profit per machine would be:

25,600 / 140 ≈ $182.86 per machine (approximately 278,900 Naira per machine).

The overall profit margin would be:

182.86 / 320 ≈ 57.14%.

(Note: All currency conversions are based on the exchange rate as of July 8, 2025.)

These profit calculations exclude operational costs, such as local rent, utilities, and labor. Therefore, if you already have a suitable location and sales experience in Nigeria, the profit potential will be substantial.

Overall, Nigeria's feed pellet machine market shows strong demand, low competition, significant profit potential, and considerable growth opportunities. It is a viable investment direction to consider.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.