Screw Elevator

A screw conveyor is a device that uses the rotation of spiral blades to move materials forward continuously.

During the conveying process, gravity and friction between the materials and the casing drive the materials along the spiral blades. The conveyor then discharges them from the outlet.

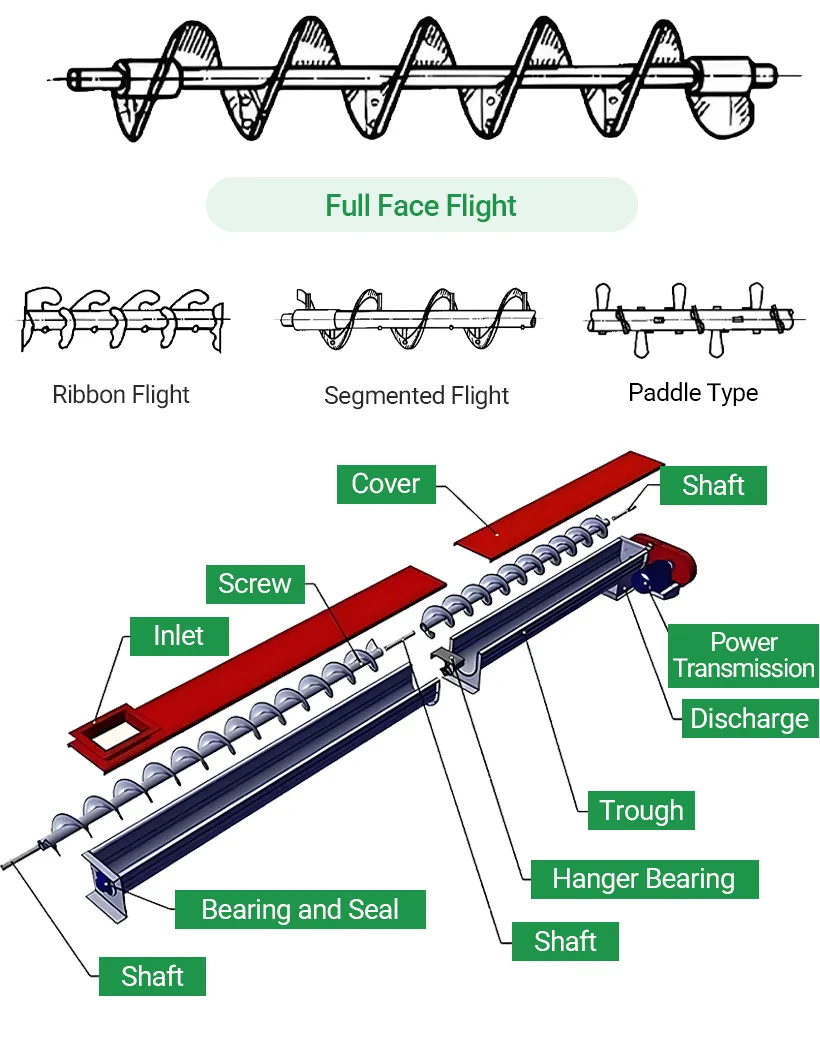

Depending on the characteristics of the material, the flights on the screw shaft can be designed as full face, segmented, or paddle types. These options can be selected and combined to enhance conveying efficiency and adaptability.

The Kawise screw conveyor features a compact design and consists of three main components: the conveyor body, drive unit, and inlet/outlet. It is highly adaptable, capable of efficiently and continuously conveying materials in powder, pellet, or small lump form.

The hopper and material rod are connected with flanges for easy assembly and maintenance. The interior is polished and smoothed to minimize material residue and adhesion, enhancing cleaning efficiency. Driven by a reduction motor, the conveyor operates smoothly with low noise, making it suitable for continuous operation. Its sealed design helps reduce dust and material contamination during the conveying process.

The specifications and models of the equipment can be customized to meet specific needs. Based on the size and application, optional casters can be added at the bottom for easier mobility. This equipment can meet the requirements of various industries and working conditions.

Video

Product Parameters

| Attributes | Range |

| Screw Diameter | 100mm-1000mm |

| Conveying Length | 3m-20m |

| Conveying Speed | 0.5m/s-2m/s |

| Conveying Capacity | 1t/h-100t/h |

| Conveying Angle | 30°- 60° |

| Power | 0.75KW-45KW |

FAQ?

What's the difference between solid, belt, and blade screw designs?

These three screw structures are designed to handle different types of materials.

Solid screws are suitable for dry powders and low-viscosity granules. Belt screws are better for moderately sticky materials in block form. Blade screws are used for tough, compressible, or easily entangled materials.

How is a screw conveyor different from other lifting equipment?

Screw conveyors, bucket elevators, and skirt belt conveyors each have distinct features in terms of structure, sealing performance, conveying angle, and space requirements. The table below shows a basic comparison:

| Equipment Type | Structure | Sealing | Conveying Angle | Space Requirement |

| Skirt Belt Conveyor | Open frame with skirted side walls | Poor | Steep or nearly vertical | Large floor space |

| Screw Conveyor | Enclosed casing with spiral blades | Good | Horizontal or slight incline | Compact layout |

| Bucket Elevator | Vertical structure with buckets | Moderate | Vertical only | Small footprint |

What factors affect the price of a custom screw conveyor?

The cost mainly depends on the material selected, with stainless steel being more expensive than carbon steel. Dimensions such as diameter and length will also influence the price. Motor options, including brand, explosion-proof design, or variable frequency drives, are another factor.

Any special customization will further affect the final quote.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.