Counterflow Cooler & Screener

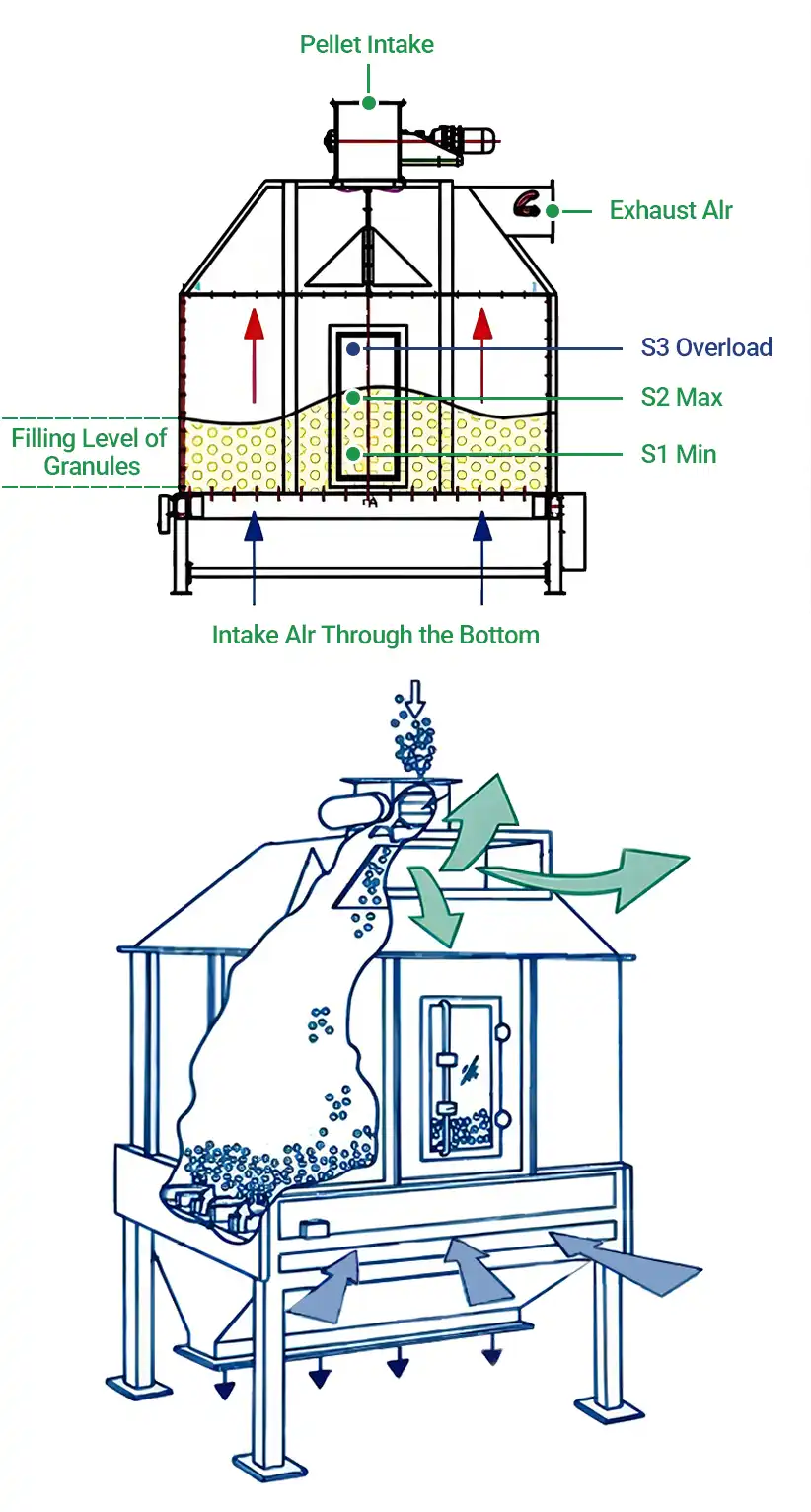

Fresh pellets are usually hot (70–90°C) and moist. Without timely cooling and screening, they can deform, mold, or break during transport, affecting overall quality. This counterflow cooler and screener quickly reduces temperature and moisture, removes fines, and makes pellets more stable and easier to store.

It uses a counterflow cooling system where cool air moves upward against the flow of pellets. This ensures even, gentle cooling that removes heat and moisture more effectively. After cooling, a vibrating screen separates dust and broken pellets, leaving clean, uniform final products ready for packing. Rejected material can be reused for pelleting, helping reduce waste.

The machine is easy to operate, runs reliably, and works well with pellet mills, conveyors, and other equipment. It's suitable for both feed and biomass pellet plants, supporting efficient, continuous production.

Video

Product Parameters

| Model | Capacity (T/H) | Trough Volume (m3) | Power (kW) |

| NL2.5 | 5 | 2.5 | 0.75+0.55 |

| NL4 | 10 | 4 | 1.5+0.55 |

| NL5 | 12 | 5 | 1.5+0.55 |

| NL6 | 15 | 6 | 1.5+0.55 |

| NL8 | 20 | 8 | 1.5+0.55 |

| NL10 | 25 | 10 | 1.0+0.75 |

| NL12 | 30 | 12 | 1.5+0.75 |

FAQ?

Will it clog or cause pellets to stick inside?

Rarely. It has an adjustable discharge system and level sensors to keep material flowing smoothly. The inner chamber is smooth with no dead corners, so buildup is unlikely. For high-moisture pellets, pre-drying helps improve stability.

Does it have dust removal?

Yes. There's a dust outlet that connects to a bag filter or vacuum fan. The sealed chamber and negative pressure design help keep dust from escaping.

Is the screen easy to change?

Yes. The screen uses a quick-release design and the chamber has a cleaning port, making maintenance simple.

Does the fan consume a lot of power? Is it noisy?

No. It uses energy-efficient, low-noise centrifugal fans. With shock pads and sound insulation, the noise stays around 70–75 dB, within industrial standards.

Can it connect to my current equipment?

Yes. Discharge height and connections can be customized. In most cases, no major changes are needed. Just share your equipment size and layout, we'll provide a matching solution.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.