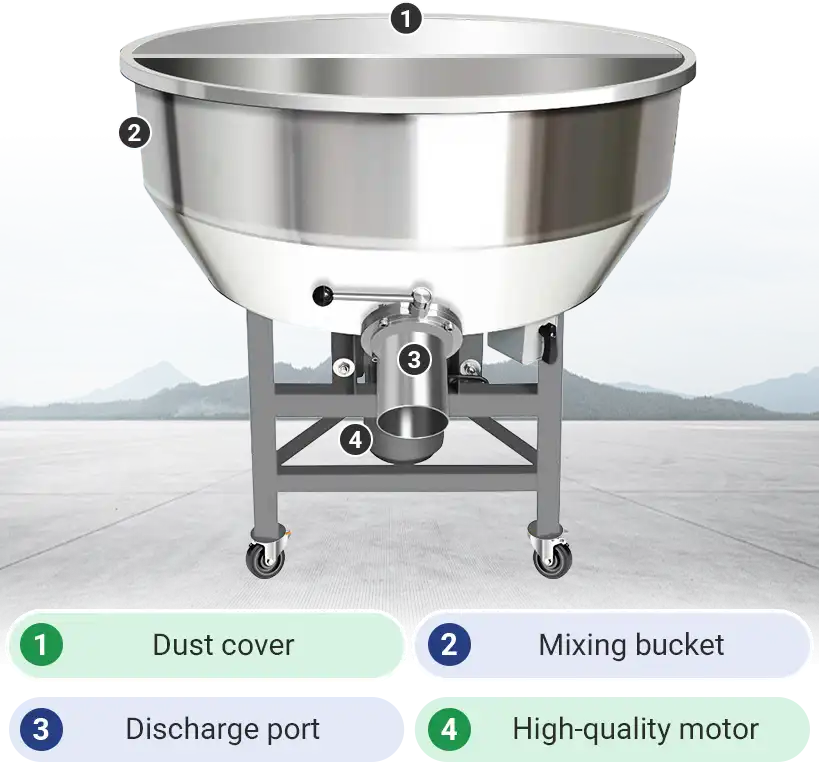

Feed Mixer

This vertical feed mixer is a popular choice among small to medium farms for efficient dry feed blending. It uses a vertical screw to lift materials from the bottom to the top, allowing them to fall and mix evenly in cycles.

The open-top design makes manual loading easy and lets you monitor mixing in real time. The bottom discharge is smooth and clog-free. Its compact build and simple operation make it ideal for spaces with limited room or lower budgets.

For dry feed mixing, the standard carbon steel model works well. For wet or high-moisture materials, or if regular cleaning is needed, the stainless steel material is a better long-term option with easier maintenance and longer durability.

Video

Product Parameters

| Model |

Each stirring (kg) |

Volume (L) | Host power (kw) | Machine size (mm) | Weight (kg) |

| 30 | 35 | 58 | 3 | 580*580*500 | 22 |

| 50 | 70 | 130 | 3 | 690*690*900 | 52 |

| 120 | 120 | 210 | 3 | 890*890*920 | 56 |

| 150 | 180 | 280 | 3 | 1040*1040*920 | 74 |

| 200 | 230 | 360 | 3 | 1140*1140*950 | 80 |

| 300 | 310 | 480 | 4.5 | 1290*1290*920 | 120 |

| 500 | 550 | 890 | 4.5 | 1490*1490*930 | 180 |

FAQ?

What materials can it mix?

This mixer handles all kinds of powders and granules, such as livestock feed, plastic pellets, seasonings, fertilizers, and chemical materials. The stainless-steel model also works well with wet, salty, or high-moisture materials for more demanding tasks.

How long does one mixing cycle take?

Typically 3–4 minutes for dry feed and 4–5 minutes for wet materials, depending on volume and type.

What's the difference between stainless steel and carbon steel?

Stainless steel offers better corrosion resistance, easier cleaning, and longer lifespan. It's ideal for wet mixing, frequent cleaning, or hygiene-sensitive use. In the long run, it saves time and reduces maintenance costs.

Why doesn't the machine come with a power plug?

Since power setups vary by user, the mixer is shipped without a plug to allow safe and flexible connection based on your needs.

Will it leak during mixing?

No. The tank is made in one piece with a sealed discharge outlet. It won't leak, even when mixing wet materials, keeping your workspace clean.

Can this mixer connect directly to a pellet mill?

Yes. The discharge outlet can connect to a screw or bucket conveyor, allowing direct feeding into a pelletizer or packaging unit without modifications.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.