Water Drop Hammer Mill

The water drop hammer mill is widely used in feed, grain, food, pharmaceutical, and chemical industries. It efficiently handles granular, block, and fibrous materials, making it ideal for continuous industrial use.

Its unique chamber design improves material flow, reduces air resistance and wear, and ensures better grinding efficiency and uniform output.

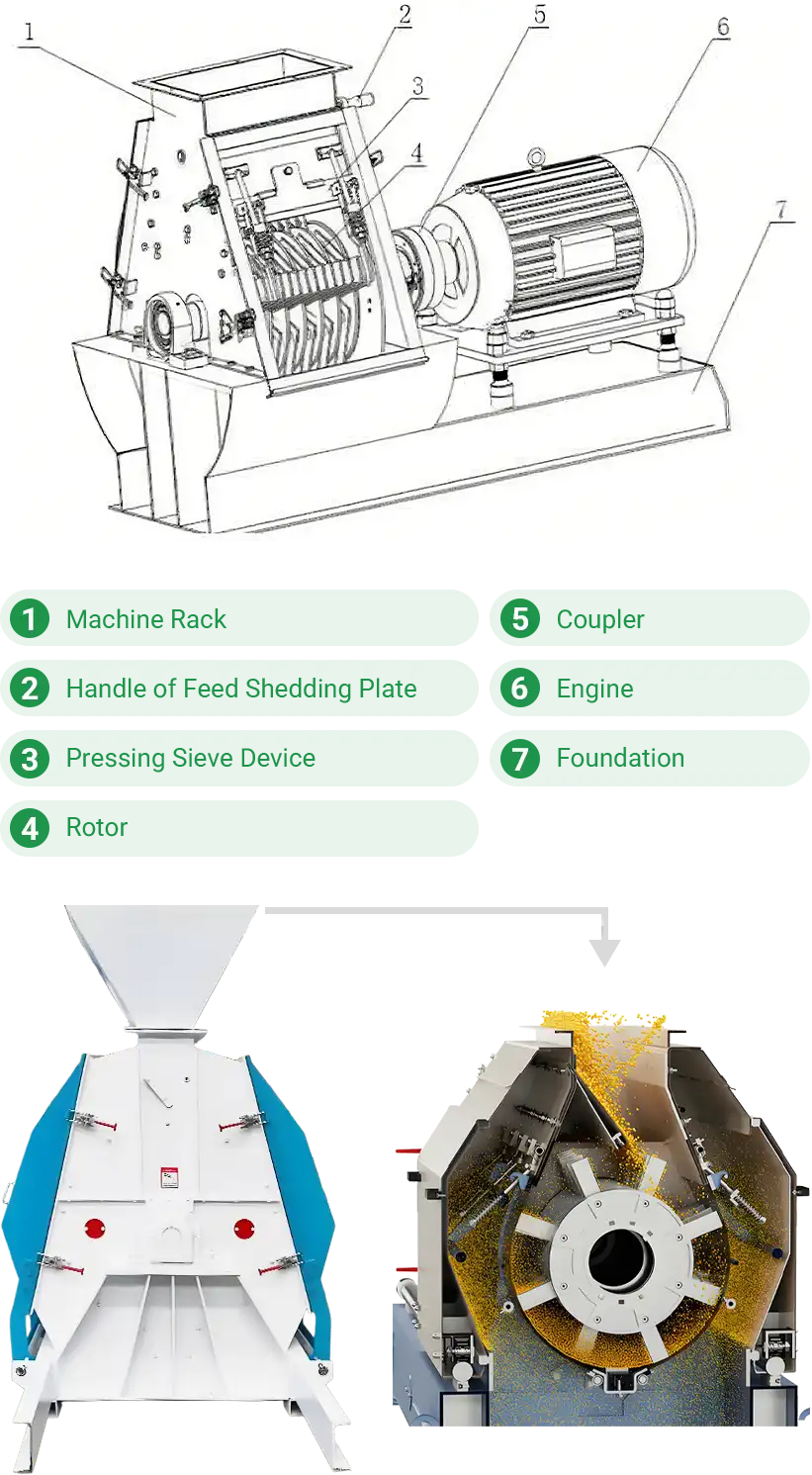

The water drop hammer mill consists of an inlet, hammers, rotor, screen, and discharge outlet.

The motor drives the rotor to spin at high speed. Material enters from the top and is gradually crushed by hammer impact and friction. Fine particles pass through the screen with the help of centrifugal force and airflow, while larger ones remain for further grinding until they reach the required size.

The screen size controls the final particle size for consistent output. By adjusting the hammer length and its gap with the screen, the machine can switch between fine and coarse grinding as needed.

Video

Product Parameters

| Model | Power (KW) |

Capacity (T/H) Coarse Grinding ≥Φ3.0mm |

Capacity (T/H) Fine Grinding ≤Φ2.5mm |

| SFSP56*30 | 22 | 1-3 | 0.5-1.5 |

| SFSP56*36 | 22/30 | 3-5 | 0.8-2.5 |

| SFSP56*40 | 30/37 | 4-6 | 1-3 |

| SFSP60*38 | 30/37 | 5-8 | 1-4 |

| SFSP60*45 | 45/55 | 7-12 | 1.5-6 |

| SFSP60*60 | 75/90 | 13-18 | 2.5-8 |

| SFSP60*75 | 90/110 | 16-22 | 3-10 |

FAQ?

How is it different from other hammer mills?

The water drop hammer mill is easy to adjust for different grinding needs. Its U-shaped chamber improves material flow, helps prevent clogging, and boosts efficiency. With low vibration and a compact, durable design, it's built for steady, long-term use.

What materials can this machine process?

It's ideal for grinding corn, wheat, soybean meal, cottonseed meal, grass powder, straw, sawdust, and other granular, block, or fibrous materials.

How do I choose the right screen size?

Screen size depends on the desired particle size. For livestock and poultry feed, Ø2.5–Ø4.0 mm is common. For aquatic feed, finer sizes like Ø0.8–Ø2.0 mm are recommended to ensure better digestion.

How often do wear parts need to be replaced?

Hammer blades usually last over 1,000 hours with normal use. Screens typically need replacement every 600–800 hours, depending on material type and working conditions.

Is there anything to watch out for when using?

Like other hammer mills, the water drop type produces some noise during operation. It's not suitable for materials that are too wet, sticky, or elastic. Regular inspection and maintenance are needed to keep it running smoothly over time.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.