How to Choose the Right Feed Grinder Machine

A grinder is essential equipment in feed and biomass processing. It reduces raw materials to the particle size required for mixing or pelleting. Since different grinders vary in structure and material suitability, proper selection should be based on raw material properties, processing goals, and production capacity.

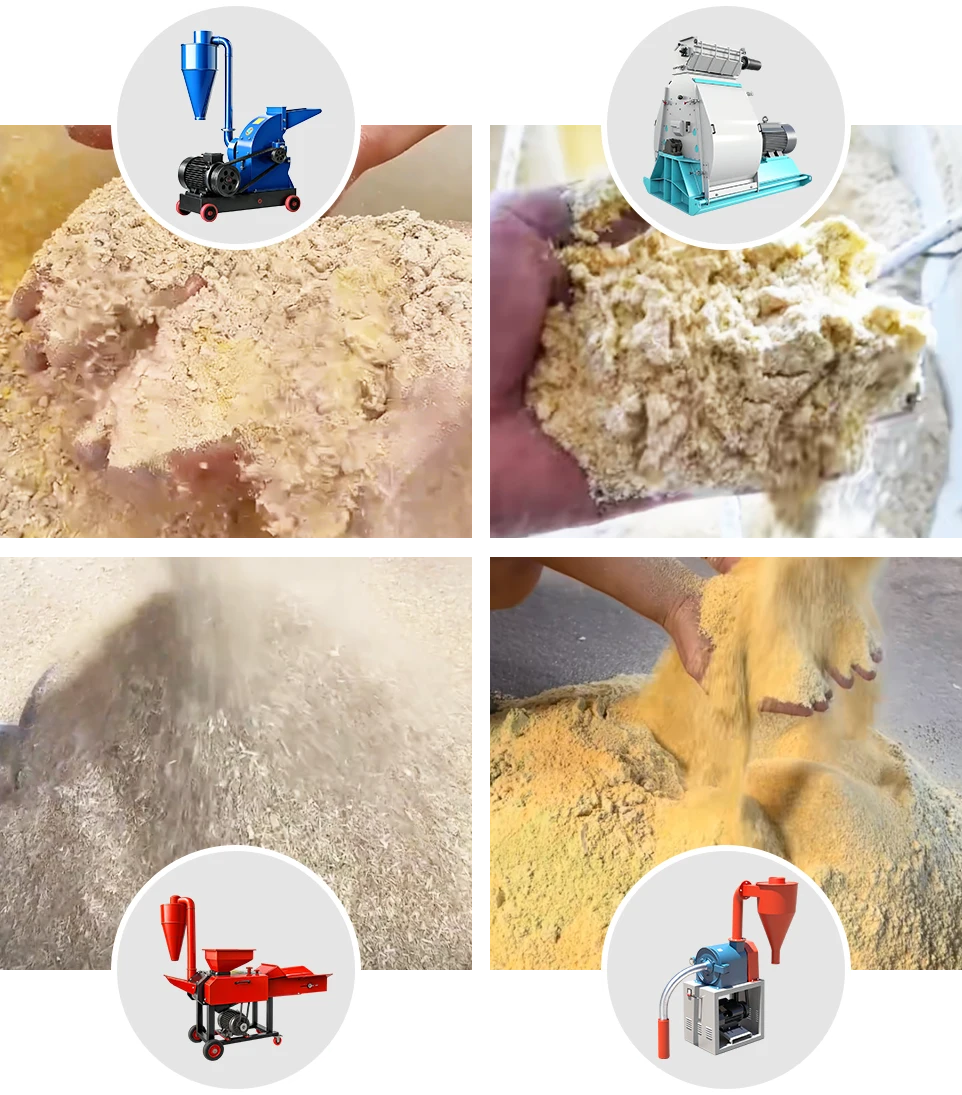

Common Types of Grinders

In feed processing, grinders are classified by their grinding method and force applied to the material. These differences affect material adaptability. Understanding them helps with proper machine selection.

Hammer mill

A hammer mill breaks materials through repeated impact from high-speed rotating hammers. It has a simple structure and is easy to operate and maintain. This type of machine is suitable for fast grinding of brittle materials.

Drop type hammer mill

A drop type hammer mill uses a specially designed chamber and hammer arrangement to keep materials inside the machine longer. This improves grinding stability and particle fineness. It supports continuous operation and is commonly used in medium to large production lines.

Chaff cutter grinder

This chaff cutter machine combines cutting and fiber processing with an added grinding function. It is mainly used for secondary grinding of chopped fibrous materials and can also handle basic grain grinding in the same unit.

Self-feeding tooth claw grinder

This grinder uses multiple tooth claws to crush materials through impact shear and friction. It is suitable for feed materials grains and agricultural by products. Optional self-feeding side or top inlets can be selected based on material characteristics.

Key Factors in Grinder Selection

In practice, grinder selection depends more on raw material properties, capacity, and output requirements than on the machine model. These factors define suitability for production use.

1. Raw material type

Grinder selection starts with material form, fiber length, hardness, and moisture content. These factors directly affect performance and efficiency.

| Equipment Type | Typical Materials |

| Hammer Mill | Corn, soybeans, rice, wheat |

| Drop Type Hammer Mill | Corn, wheat, soybeans, bran |

| Chaff Cutter Grinder | Grass, straw, limited grain |

| Tooth Claw Grinder | Corn, wheat, soybeans, dried chili, rapeseed |

Material adaptability varies across different machines, so equipment should be selected based on the specific materials to ensure efficient processing.

2. Confirm required particle size

Particle size is a key factor in the grinding process. In most cases, it is controlled by adjusting the screen hole size to achieve the desired fineness

| Equipment Type | Minimum Particle Size | Recommended Screen Size |

| Hammer Mill | 1 mm | 1.5–5 mm |

| Drop Type Hammer Mill | 0.8 mm | Livestock feed: 2.5–4 mm Aquafeed: 0.8–1.5 mm |

| Chaff Cutter Grinder | 2 mm | 10–30 mm |

| Tooth Claw Grinder | 0.2 mm | 3–50 mm |

Different grinder types offer different particle size ranges, so equipment selection should match the required output size.

3. Match capacity to production needs

Capacity is a key factor when selecting a grinder and should match the production scale.

Different applications require different output levels, so machine selection should focus on actual processing needs rather than maximum capacity.

| Equipment Type | Capacity (kg/h) | Output at Same Power |

| Hammer Mill | 300 – 4,000 | High |

| Drop Type Hammer Mill | 1,000 – 22,000 | Highest |

| Tooth Claw Grinder | 400 – 3,000 | Low |

| Chaff Cutter Grinder | 500 – 6,000 | High for grass materials |

Actual capacity may vary depending on machine model and material conditions.

4. Equipment cost and energy use

When selecting a grinder, consider not only the purchase price but also long-term operating costs.

| Equipment Type | Equipment Cost | Power Consumption |

| Hammer Mill | Low | Medium (4.5–37 kW) |

| Drop Type Hammer Mill | High | High (22–90 kW) |

| Chaff Cutter Grinder | Low | Low (4–7.5 kW) |

| Tooth Claw Grinder | Low | Low (4.5–11 kW) |

Power ranges are typical references. Actual energy use depends on the model, material, and operating conditions.

Choosing a grinder that matches your materials, capacity needs, and long-term costs is essential. The right machine improves efficiency and helps reduce operating costs over time.

If you need help with equipment selection, our team can offer practical advice based on your actual production needs.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.