The Best Chicken Feed Formula for Cost-Efficient Farming

In poultry farming, feed costs usually account for 65% to 75% of total expenses. While some large feed companies follow standardized formulas, many smaller producers deliver feed of inconsistent quality. This can result in slower chicken growth, reduced egg production, and even health issues or economic losses.

To better control feed quality and reduce production costs, more and more poultry farmers are choosing homemade chicken feed. This has become one of the most effective ways to improve farming efficiency.

Feed Formulas for Broilers, Layers, and Breeders

Chickens need different feeds at different growth stages. A good formula can boost survival rates and cut costs. Here are the feed formulas for broilers, layers, and breeder chickens:

Broiler Feed Formula

Formula 1 (for Rapid Weight Gain):

chick feed formula: 30% soybean meal, 5% fishmeal, 3% vegetable oil, 5% mineral/vitamin premix, 2% limestone and dicalcium phosphate.

broiler grower feed formula: 25% soybean meal, 5% wheat/barley, 4% vegetable oil, 5% mineral/vitamin premix, 1% limestone and dicalcium phosphate.

broiler finisher feed formula: 20% soybean meal, 5% vegetable oil, 5% wheat bran, 4% minerals, 1% limestone and dicalcium phosphate.

Formula 2 (Cost Balance and Basic Disease Prevention):

chick feed formula: 55% corn, 32% soybean meal, 5% fishmeal, 3% fats, 1.5% dicalcium phosphate, 1% limestone, 2.5% premix and additives.

broiler grower feed formula: 65% corn, 25% soybean meal, 5% canola meal, 2% fats, 1% dicalcium phosphate, 1% limestone, 1% premix and additives.

broiler finisher feed formula: 60.7% corn, 21% soybean meal, 4.5% canola meal, 5% cottonseed meal, 2% fishmeal, 3% vegetable oil.

Layer Feed Formula

Formula 1 (Eggshell Quality and Stable Egg Production):

Layer chick: 50% corn, 25% soybean meal, 15% wheat bran, 6% alfalfa hay, 1-1.5% oyster shell, 0.5% mineral premix, 0.5% salt.

Layer grower: 60% corn, 25% soybean meal, 5% wheat/barley, 4% vegetable oil, 5% mineral/vitamin premix, 1% limestone and dicalcium phosphate.

Egg laying cycle: 50% corn, 25% soybean meal, 15% wheat bran, 6% alfalfa hay, 3% oyster shell, 0.5% mineral premix, 0.5% salt.

Alfalfa hay can be replaced by wheat bran or straw powder, and oyster shell can be substituted with limestone, shell powder, or calcium phosphate. After replacement, make sure the feed still provides adequate fiber, calcium, and vitamins.

Formula 2 (Nutritionally Balanced, Rapid Growth):

Layer chick: 62% corn, 31% soybean meal, 3% wheat bran, 1.3% dicalcium phosphate, 1.2% limestone, 1.5% premix and additives.

Layer grower: 60% corn, 20% soybean meal, 10% wheat bran, 5% rapeseed meal, 1% dicalcium phosphate, 2% limestone, 2% premix and additives.

Egg laying cycle: 60% corn, 27% soybean meal, 3% wheat bran, 1.3% dicalcium phosphate, 8% limestone, 0.7% premix and additives.

Breeder Feed Formula

Chick stage: 56% corn, 28% soybean meal, 5% wheat bran, 3% fishmeal, 2% fats, 1.5% dicalcium phosphate, 1% limestone, 3.5% premix and additives.

Growing stage: 58% corn, 20% soybean meal, 16% wheat bran, 2% fishmeal, 1.5% dicalcium phosphate, 1% limestone, 1.5% premix and additives.

Breeding stage: 55% corn, 20% soybean meal, 10% wheat bran, 5% canola meal, 2% fats, 1% dicalcium phosphate, 5% limestone, 2% premix and additives.

Fishmeal can be replaced with meat and bone meal, blood meal, soybean meal, or canola meal. When doing so, use synthetic amino acid supplements to ensure protein quality and amino acid balance.

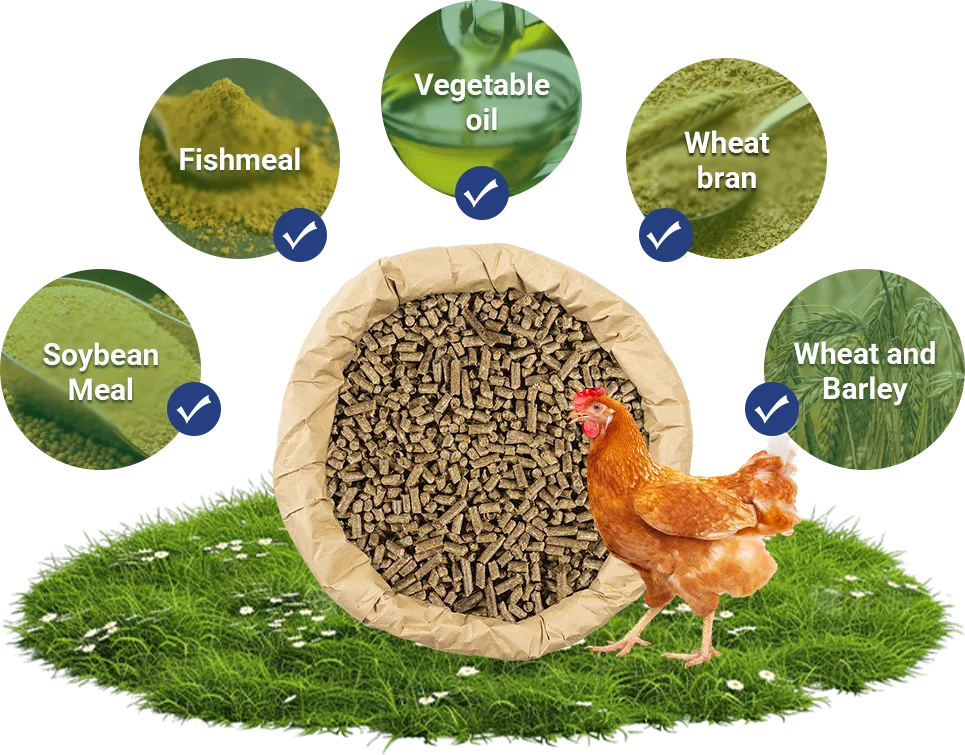

Nutritional Cornerstones: Key Ingredients and Functions in Chicken Feed

While chicken feed formulas may vary based on different farming needs, the following essential chicken feed ingredients must be included when creating a feed formula:

- Fat: Fat is an essential energy source. A balanced amount helps broilers gain weight quickly and enhances meat quality. For layers, a lack of fat in the feed can result in lower egg production.

- Minerals: Calcium plays a crucial role in both bones and teeth, and is also essential for eggshell formation. A calcium deficiency in the feed can lead to thinner eggshells in layers, causing breakage and significantly impacting egg production.

- Protein: High protein levels are crucial for muscle development in broilers. Sufficient protein is also essential for breeding hens. However, too much protein can reduce reproductive performance, so it's important to maintain a proper balance between energy and protein.

- Carbohydrates: High carbohydrate levels help promote weight gain. However, for breeders and layers, excessive carbohydrate intake can negatively impact health, so it should be controlled in moderation.

- Moisture: The moisture content in feed is 50% for adult chickens and 70% for chicks. If a chicken loses more than 20% of its body water, it can seriously affect its health and even cause death.

- Energy: Energy is essential for growth, egg production, and reproduction. Broilers need high-energy feed for rapid weight gain, while layers and breeders require a balanced amount of energy to maintain production and health.

- Vitamins: Vitamins are crucial for poultry's immune system, bone health, and normal metabolism. Vitamins A, D, E, and the B vitamins each play distinct roles, and deficiencies can impact poultry health and productivity.

Ingredient Overview: Nutritional Composition of Common Feed Ingredients

Different types of chicken feed raw materials offer different nutrients. Knowing their composition helps make better choices and improves feeding outcomes.

| Ingredients | Protein (%) | Fat (%) | Fibre (%) | |

| Grains | Wheat | 12 | 1.4 | 2.4 |

| Triticale | 15.4 | 1.2 | 2.5 | |

| Sorghum | 9 | 2.9 | 2.5 | |

| Barley | 11 | 1.7 | 1.7 | |

| Rye | 12.5 | 1.3 | 1.3 | |

| Oats | 10.5 | 4.7 | 11.6 | |

| Rice | 9 | 2.2 | 9.6 | |

| Corn | 9.5 | 3.6 | 2.3 | |

| Legumes | Peas | 25 | 1.2 | 5.6 |

| Beans | 22 | 1.5 | 4.6 | |

| Lentils | 23.5 | 1.4 | 4.3 | |

| Lupins | 32 | 8.4 | 12 | |

| Soybean - dry roasted | 35.7 | 19.7 | 5.8 | |

| Oilseeds | Canola (rape seed) | 18.7 | 44 | 8.5 |

| Flaxseed | 20.7 | 34.3 | 9.4 | |

| Sunflower | 14.8 | 44.6 | 16 | |

| Other components | Meatmeal | 50 | 20 | 1 |

| Bloodmeal | 80 | 1.9 | 1.3 | |

| Soybean meal | 46 | 1.6 | 5 | |

| Molasses | 4.2 | 0.5 | 0 | |

| Fishmeal | 60 | 9.2 | 0 | |

| Soy oil | 0 | 100 | 0 | |

| Tallow | 0 | 100 | 0 | |

Practical Operations: Key Considerations in Chicken Feed Preparation

In the actual preparation process, the following key factors should be considered:

- Raw Material Selection: Choosing locally grown feed ingredients (such as wheat, rice, and corn) helps reduce transportation costs. It also ensures freshness and improves adaptability, optimizing overall costs.

- Alternative Raw Materials: Some ingredients cannot fully replace others. For example, wheat can't replace corn, and plant-based proteins can't replace animal-based proteins. Supplements are needed to balance nutritional differences.

- Improving Nutritional Balance: In addition to basic ingredients, you should add premixes and supplements as needed to ensure a complete nutritional profile.

- Improving Absorption: Different protein sources have varying absorption rates. Animal-based proteins are typically absorbed more efficiently than plant proteins. A proper balance is needed to ensure chickens can effectively utilize the nutrients in the feed.

- Cost Efficiency: Optimizing feed formulas can reduce chicken feed production costs by 5-8%. Additionally, pellet feed can save 10-15% in manufacturing costs compared to ground feed, improving overall profitability.

Kawise: Making Feed Production More Efficient

Beyond feed formulation, the choice of production equipment and processes plays a key role in feed quality and efficiency. Kawise specializes in high-performance poultry feed machines and offers proven automated production lines widely used by farms and feed manufacturers.

Our production line integrates raw material handling, pelletizing, and packaging into a fully automated process. This significantly improves efficiency, reduces labor costs, and ensures product consistency. Whether for small-scale customization or large-scale production, we offer tailored solutions to help you adapt to market demand and stay competitive.

By working with us, you will receive exceptional technical support and expert services. We look forward to collaborating with you for a bright and successful future!

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.