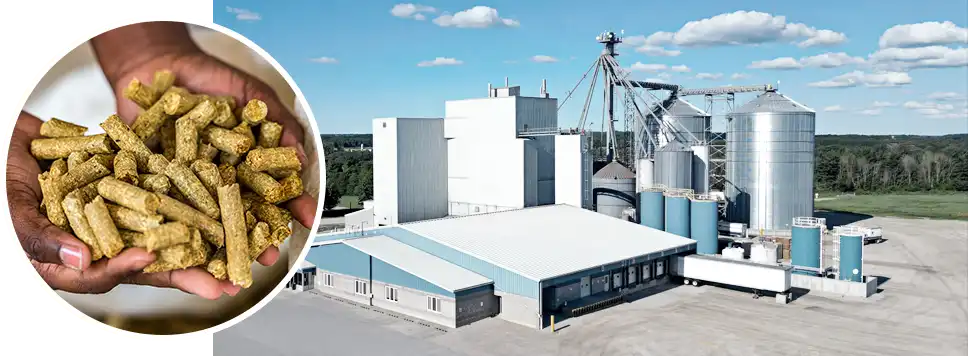

How Much to Build a Livestock Feed Mill (2025)

The global animal feed market was worth $595 billion in 2023, and it's expected to reach $850 billion by 2032, representing a steady annual growth rate of 4.5%. Livestock feed is a key part of this market, with significant potential for steady growth.

While the livestock feed industry looks promising, many still worry that the investment required is too high, which can discourage potential entrants. However, is the initial investment required to start a livestock feed plant truly that high?

Investment Insights: A Closer Look at the Costs of Livestock Feed Plants

The cost of setting up a feed processing plant depends on its production capacity.

Kawise Machinery offers a budget table for plants with capacities between 1 and 10 tons per hour, which is a great reference during the planning phase:

| Capacity | Recommended Floor Area | Budget Range | Total Power | Installation & Commissioning Time | Payback Period |

| 1-2 tons/hour | 300-500 m2 | $12,000-$45,000 | 47-75 kW | 7-15 days | 1-2 years |

| 3-4 tons/hour | 300-700 m2 | $47,000-$100,000 | 53-165 kW | 15-20 days | 1-2 years |

| 4-6 tons/hour | 400-800 m2 | $70,000-$250,000 | 68-259 kW | 20-40 days | 1-3 years |

| 8-10 tons/hour | 800-2,000 m2 | $100,000-$300,000 | 125-410 kW | 45-60 days | 1-3 years |

It's important to note that the table above shows the investment budget related to machinery (actual costs may vary depending on specific equipment configurations).

When starting a feed processing plant, additional operational and compliance-related expenses must also be considered. Below are some common startup costs, excluding equipment:

| Startup Cost Category | Description | Min Amount ($) | Max Amount ($) |

| Raw Material Procurement | Purchase high-quality materials and maintain initial stock | 30,000 | 100,000 |

| Licensing and Certification | Obtain necessary permits, licenses, and compliance certifications | 5,000 | 20,000 |

| Labor and Recruitment | Hire skilled employees and cover recruitment expenses | 20,000 | 80,000 |

| Marketing and Branding | Develop branding, advertising, and promotional strategies | 10,000 | 50,000 |

| Logistics and Distribution | Set up transportation, fleet management, and delivery systems | 15,000 | 60,000 |

| Technology Systems | Invest in production management tech and data analysis tools | 8,000 | 30,000 |

| Insurance and Risk Management | Secure comprehensive insurance and risk management plans | 7,000 | 25,000 |

| Total (Estimated Range) | 95,000 | 365,000 | |

Starting a fully operational feed processing plant does require an initial investment, but the actual costs can vary.

One of the key factors is optimizing the process design: it directly impacts equipment configuration, energy efficiency, and overall operating costs, making it a core element in determining the payback period.

Core Production: Process Flow Analysis

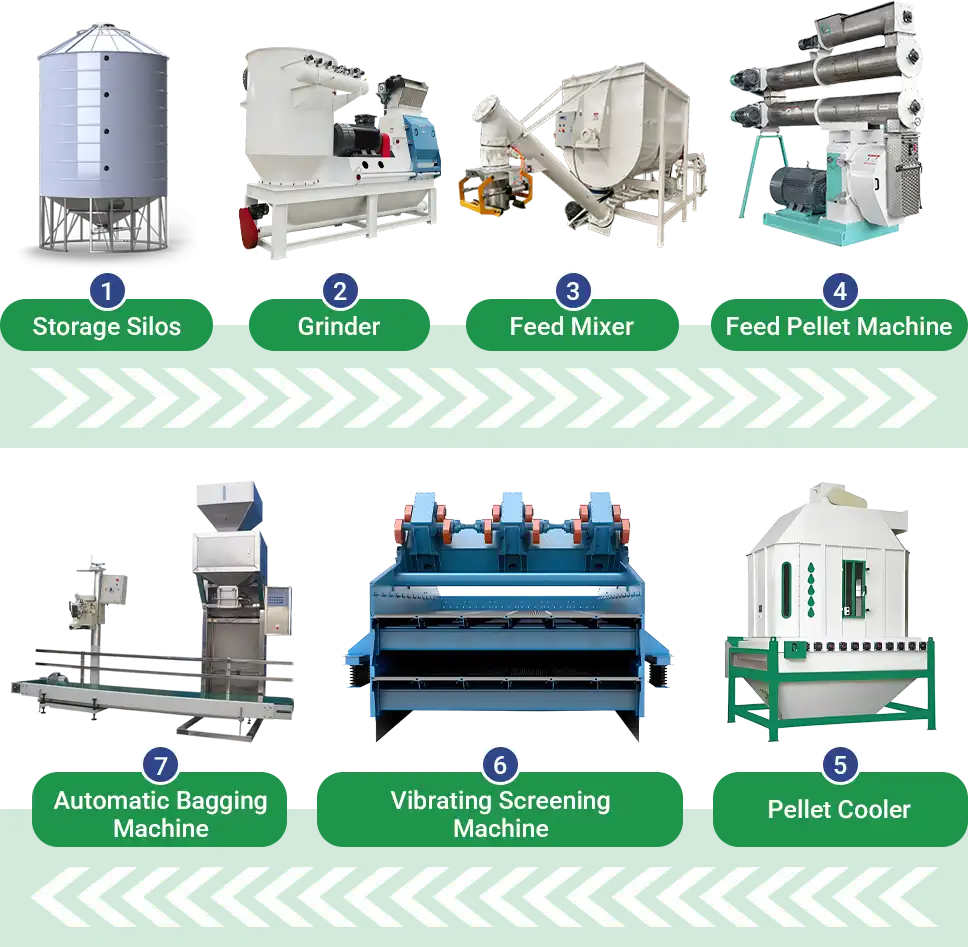

The quality and efficiency of feed production largely depend on the scientific design of the processing flow. A standard livestock feed mill typically includes the following production stages:

1.Raw Material Storage (Silos)

Raw materials like grains and soybean meal are sent to silos for temporary storage. They are then sorted initially to prepare them for continuous production.

2.Raw Material Grinding (Crusher)

Coarse materials are ground to a controlled particle size, which helps improve mixing uniformity and pelletizing efficiency.

3.Mixing (Feed Mixer)

Various raw materials, nutritional additives, and other functional ingredients are thoroughly mixed to ensure even nutrient distribution.

4.Pelletizing (Feed Pellet Mill)

Raw materials are compressed through rollers and molds in the machine to form feed pellets, making it the core step of the production line.

5.Cooling (Pellet Cooler)

Newly formed pellets are cooled to room temperature for storage and to reduce the risk of breakage.

6.Screening (Vibratory Screener)

Separates unformed fine powder or broken pellets to improve product consistency and appearance.

7.Packaging (Automatic Bagging Machine)

The machine automatically measures, portions, and seals finished pellets. This improves factory efficiency and makes storage and transportation easier.

The process outlined above provides the basic framework for livestock feed pellet production. However, during plant setup, it can be adjusted to suit specific conditions. A well-designed production line can improve efficiency and profitability in several ways:

- Saving Space: A compact layout and functional zoning can help reduce land use, especially in areas with high land costs.

- Controlling Budget: Select equipment based on production capacity goals to avoid overcapacity or underutilization, preventing unnecessary waste.

- Optimizing Labor: Introducing automation, particularly in material handling and packaging, can significantly cut labor costs and improve operational efficiency.

From Concept to Reality: Planning the Perfect Feed Plant

To ensure a more efficient investment and smoother project progress, focus on the following key aspects before setting up your plant:

- Define Production Capacity Goals: This is the foundation of your plan, determining equipment selection and initial investment size.

- Site Selection: Choose a suitable location based on land costs, transportation access, and utility availability.

- Raw Material and Sales Channels: Ensure a stable raw material supply and clearly define your sales regions and target customers.

- Level of Automation: Based on your budget and workforce, determine the appropriate level of production automation.

- Seek Professional Support: Work with equipment suppliers or industry consultants to get customized plans and accurate quotes, helping to avoid costly trial-and-error.

A Trusted Partner: Kawise Case Study

Choosing a reliable partner is crucial during plant setup. As a leading feed equipment supplier in China, Kawise Machinery has completed numerous livestock feed pellet plant projects worldwide. These projects showcase our expertise and professional strength.

Tanzania 2-4t/h Cattle Feed Plant

Located in Tanzania, this plant has a production capacity of 2-4 tons per hour. It primarily serves the client's own farm and nearby ranches for cattle feed supply. The raw materials include corn, wheat, rice bran, cottonseed cake, and sunflower seed cake, among others. The production process includes: Grinding → Mixing → Pelletizing → Cooling → Packaging.

During the planning phase, we selected the appropriate equipment models based on the client's actual capacity needs, avoiding overcapacity. Additionally, we optimized the equipment layout according to the plant structure, ensuring a compact design that keeps the land area within a reasonable range. These adjustments helped the client save on initial investment, reduce operating costs, and achieve better cost performance.

Vietnam 8-10t/h Hog Feed Plant

Capacity: 8-10 tons per hour

Location: Vietnam

Raw Materials: Corn, rice bran, soybean meal, premix, etc.

Final Feed: Hog feed pellets

Project Design: Five-story steel structure plant

This project was custom-designed by Kawise Machinery for a client in Vietnam. The production line adopts a five-story layout, equipped with a full set of machines including crushers, mixers, pellet mills, coolers, screens, and packaging equipment. It also features an automatic batching system, electrical control panels, and dust and impurity removal systems, achieving both capacity and automation improvements.

During the planning phase, we worked closely with the client to understand their production needs and plant conditions. We optimized the equipment layout on each floor, reducing material handling distance and enhancing operational convenience. The compact design and clear structure of the plant significantly reduced civil engineering costs and daily operational energy consumption.

Building a livestock feed plant does require some investment, but it's not as high as often imagined. With proper planning and smart choices, costs can be controlled while achieving a high return on investment. If you're considering starting your own feed plant, feel free to contact us for a personalized project plan and quote.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.