6 Quick Checks to Prevent Biomass Pellet Machine Overheating

Long runs can cause biomass pellet machines to overheat, lowering pellet quality, speeding up wear, and even causing shutdowns. This affects both flat die and ring die models. To help you stay on top of it, here are six quick checks to identify and fix overheating during daily production.

Pellet Mill Overheating Causes

For raw materials, improper moisture content, excess impurities, or high fiber levels with inadequate crushing can overload the pelletizing process.

Improper operation is another key factor, such as running at full load for too long, overfeeding right after startup, or poor ventilation. For new dies, lack of proper lubrication during the break-in period can cause increased friction, leading to faster temperature rise.

Biomass pellet machines can overheat from friction and pressure during long, high-load operation, impacting output and lifespan. Regular checks help catch issues early, reducing downtime and maintenance. Note that flat die and ring die mills have different structures, so check priorities may differ.

1. Bearings & Lubrication

During prolonged operation, bearings and rollers are prone to overheating. Lack of lubrication can cause noise, reduced output, and even jams. Many users find overheating is due to delayed or incorrect lubrication.

Check the oil level and quality of the lubricant first.

Oil Level and Quality Check

Check the oil level and quality by listening for unusual sounds, checking bearing temperature, and reviewing lubrication records.

For ring die biomass machine, high bearing temperatures (>80°C) or sharp friction sounds suggest insufficient lubrication.

For flat die mills, rotate the roller by hand after stopping. If it feels stiff or resistant, lubrication is likely inadequate. Replace the grease if it's black, thin, or contaminated.

Maintenance Tips

Check grease levels and oil supply lines daily. Follow the manufacturer's oiling schedule. For high-load production, add oil every shift (8-12 hours) and regularly check grease to prevent overheating.

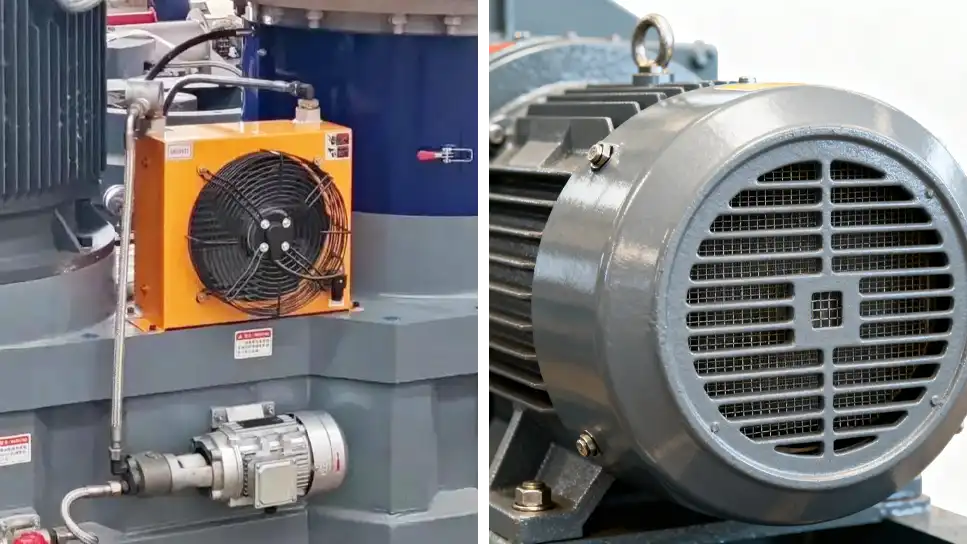

2. Ventilation & Cooling Check

Both ring die and flat die pellet mills generate heat during high-speed compression. Without proper cooling check and ventilation, heat builds up around the die cavity, motor, and gearbox.

For ring die pellet mills, inspect the gearbox vents, and use a flashlight to check the die cavity cooling ducts for dust or debris after stopping. For flat die equipment, look at the motor vents and covers for buildup.

When the machine runs, listen for even fan noise and feel the airflow. Weak airflow usually means dust on the blades, which needs cleaning.

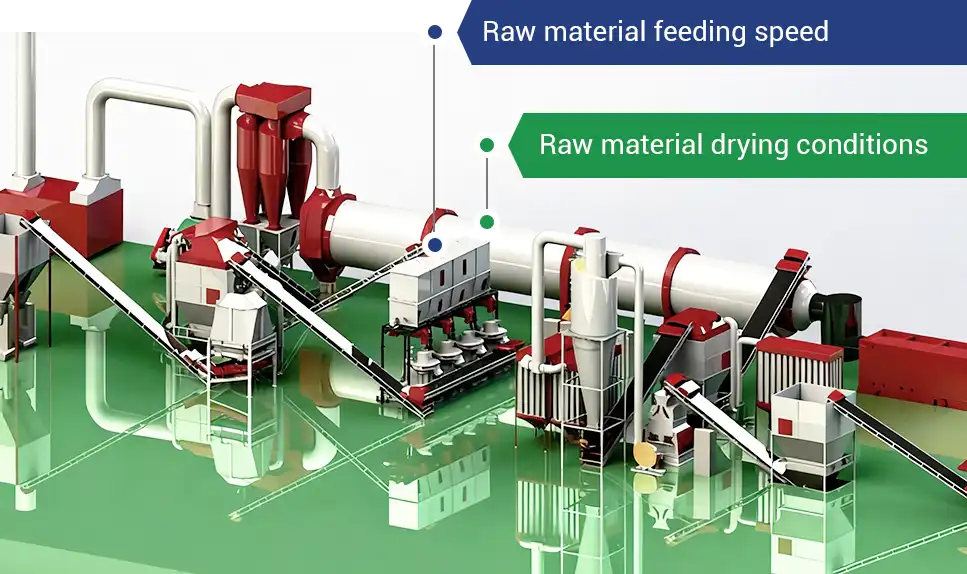

3. Feeding Speed & Raw Material Condition

Inconsistent feeding speed or improper moisture and temperature levels in raw materials can increase compression resistance, raising the machine's load and temperature.

For ring die mills, ensure the moisture (10%-15% for wood chips and straw) and temperature are within the recommended range. Excess moisture can clog the die, while too little can make the fibers too hard, increasing friction.

For flat pellet machines, feed the material evenly to prevent sudden load changes and ensure smooth operation.

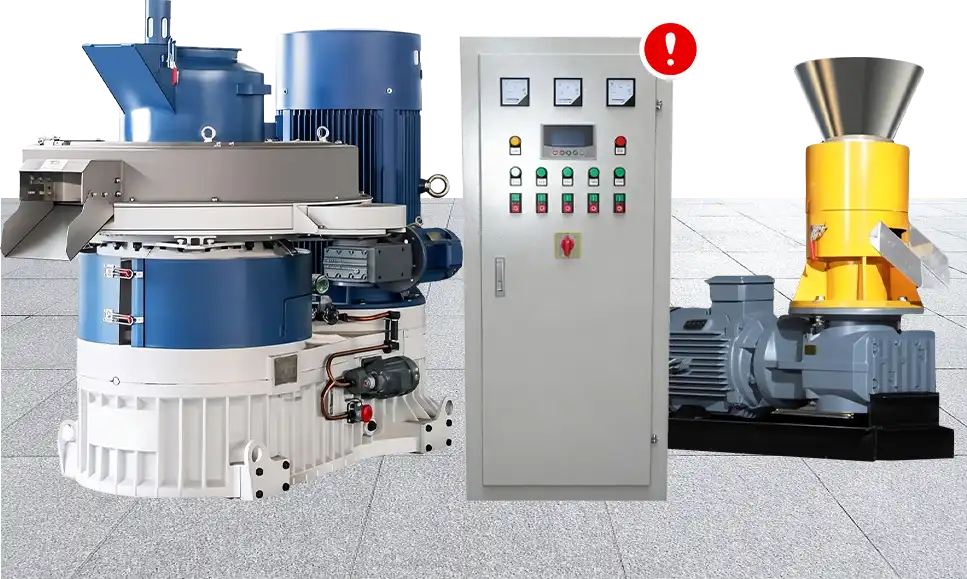

4. Load monitoring & Sound

Changes in load and operational sounds are key indicators of the pellet machine's condition. A sudden rise in load or unusual sounds usually signals increased friction and resistance inside the machine.

Load monitoring regularly for both ring die and flat die mills. A rising current in ring die mills may signal raw material issues, die clogging, or poor lubrication. For flat die mills, sudden current spikes or abnormal sounds may indicate uneven feeding, die blockages, or wear. Immediate inspection is key to avoid damage.

Stable sounds and current readings are normal. Any sudden changes or unusual noises should prompt an immediate shutdown for inspection.

5. Die Inspection & Compression Ratio

The die is key to pellet formation, and its condition affects material flow. If the compression ratio doesn't match the material or mold jam, it can hinder flow, increase friction, and raise energy use and temperature(Ismail, 2023).

Ensure the die compression ratio matches the material, especially when switching materials.

For ring die mills, after a power outage, open the inspection port and use a flashlight to check for clogged holes, deformed channels, or uneven wear.

If blockages or residue are found, gently clear them with a thin wire. For clumps, use a wooden stick or plastic scraper, avoiding metal tools that could damage the die. The same method can be used for flat die mills.

For more details on material compression ratios and blockage issues, see the article below.

Pellet Machine Die Jam: Causes and Solutions

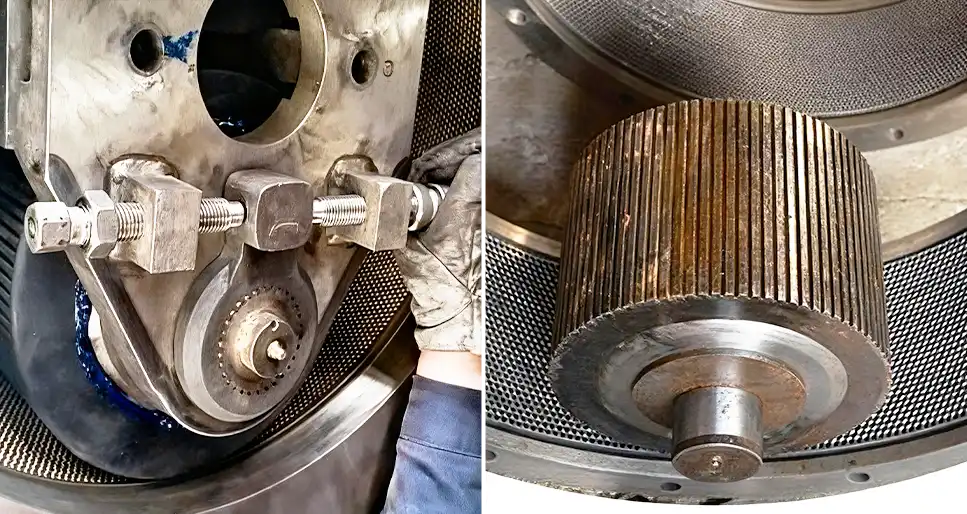

6. Roller Wear

Worn, cracked, or uneven rollers can block material flow through the die, increasing friction and raising the die temperature, which may also cause bearing overheating.

Power off the machine and clean the die cavity for safety.

Check the roller for grooves, cracks, or wear. For flat die mills (without material), check for sticking, wobbling, or uneven resistance.

Finally, check the pressure adjustment to ensure even pressure on both sides to prevent overheating.

Flat Die vs. Ring Die Inspection Focus

Flat die and ring die pellet mills have structural differences, so their inspections vary. Below is a comparison of the checks for each type.

| Area | Flat Die Pellet Mill | Ring Die Pellet Mill |

| Lubrication | Roller and main bearings | Roller and main bearings |

| Cooling | Motor vents, covers | Gearbox vents, cooling fan |

| Feeding | Even feeding, avoid overloading | Check moisture and temperature |

| Load | Watch for sudden current spikes | Monitor gradual current rise |

| Die | Check for blockages or roughness | Inspect for wear and deformation |

| Roller | Check for cracks or uneven wear | Check for wear and pressure adjustment |

By adding these 6 quick checks to your routine pellet mill maintenance, you can prevent most overheating issues. With proper lubrication, cooling, and feeding management, you'll extend the life of the die and rollers while keeping production running smoothly.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.