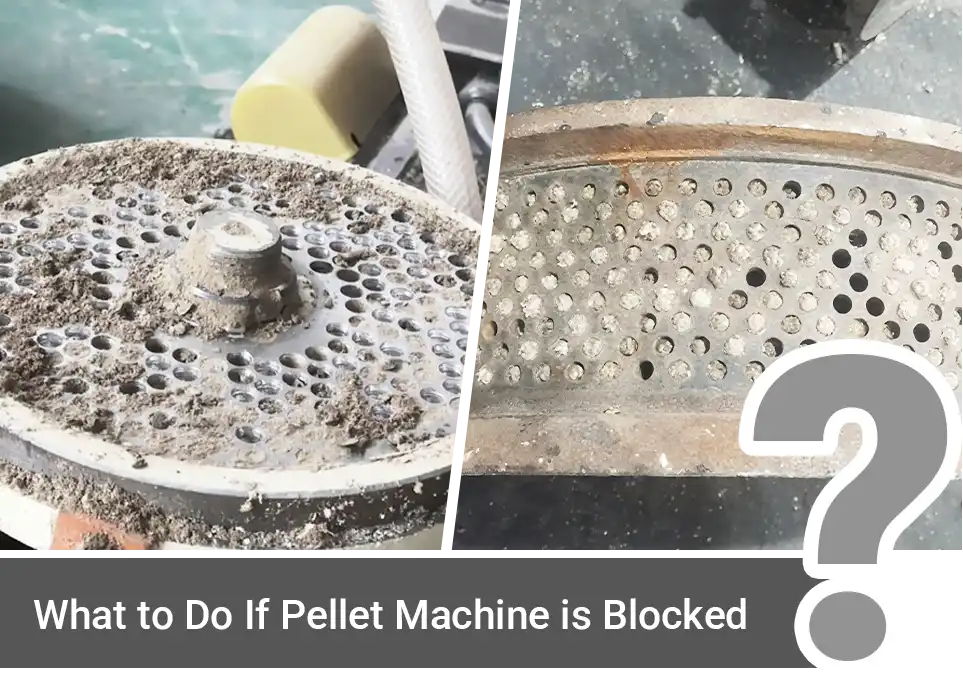

Pellet Machine Die Jam: Causes and Solutions

Pellet mill blockage is a common problem that can reduce output, waste raw materials, and in severe cases damage equipment. This guide explains the causes from three aspects: operation, equipment, and raw materials, and provides several practical die maintenance solutions to help prevent and resolve blockages, improving efficiency and productivity.

Raw Material Factors

The choice of pellet die or pellet press die affects how raw materials flow through the machine. In feed mill die setups, fine materials require different compression settings than coarse biomass.

1. Improper moisture control

Moisture directly affects the compressibility of raw materials. Too much moisture causes a sticky layer in the die, leading to blockages and mold fouling. Too little moisture results in weak pellets that don't form properly. This issue is more noticeable in hot weather or with hygroscopic powders.

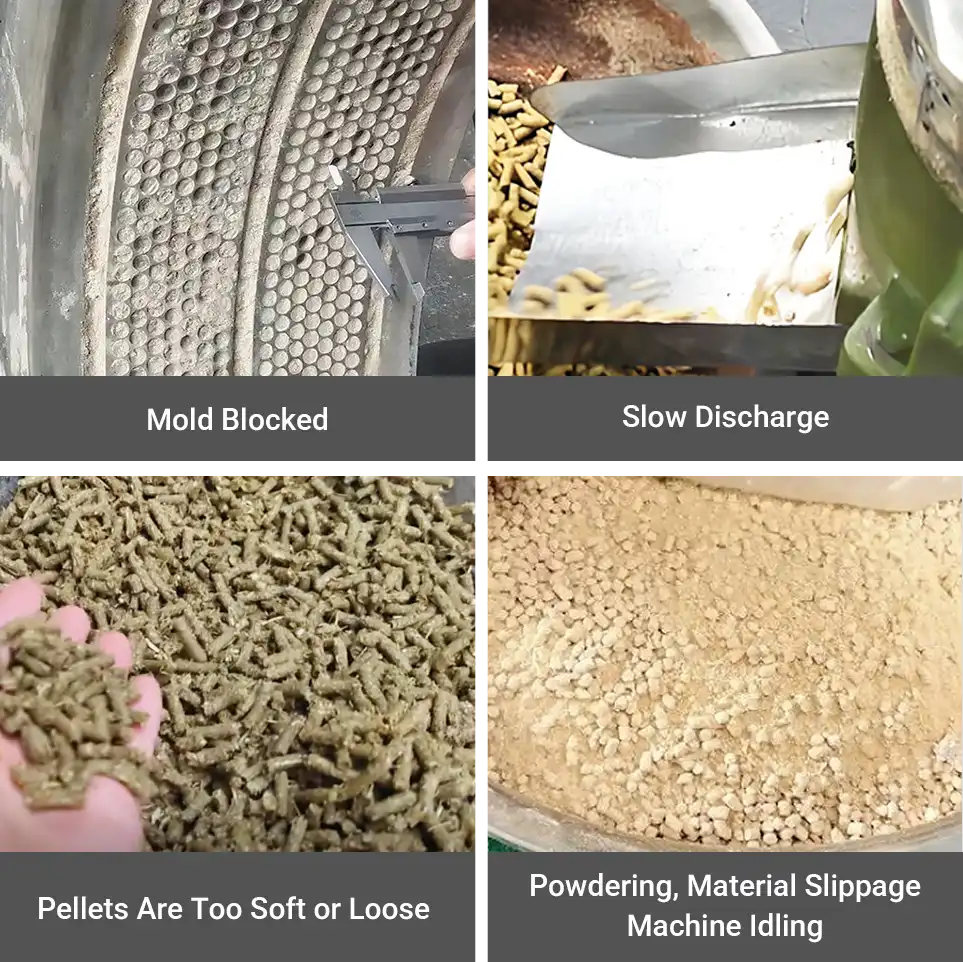

Common Issues

- Die jam after a few minutes, slowing down output.

- Pellets are soft, loose, and break easily.

- Powder falls off, or material slips, causing idle equipment.

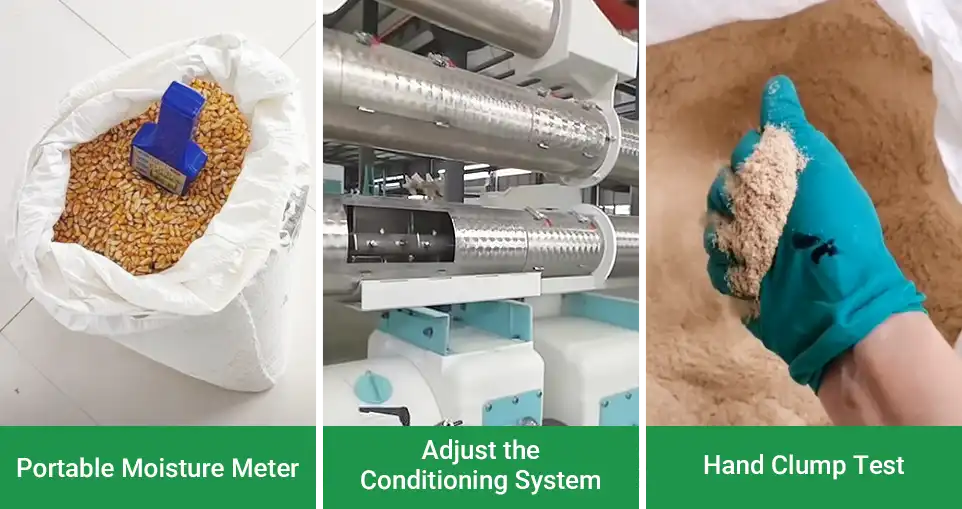

Solution

Test moisture levels before production using a portable meter. Maintain moisture between 8% and 12% (12% to 15% for flat dies). For ring die mills, adjust steam and water. For small flat die mills, squeeze the material. If it forms a ball and breaks apart easily, the moisture is correct.

2. Large raw material size / uncrushed

Coarse materials like straw, husks, and hay are too large and fibrous to pass through die holes smoothly, affecting flow and compression. This is especially problematic in ring die pellet mills, where uncrushed materials reduce conditioning efficiency and uniformity.

Common Issues

- Roller vibration causes inconsistent or stopped output.

- Frequent blockages that require cleaning.

- Lower pellet efficiency, reduced molding rate, and higher load.

- Large particles blocking the screw feeder and buildup in the die chamber (for ring die feed pellet mill die).

Solution

Ring die mills need finer, uniform raw materials. Using a continuous grinding and mixing system helps improve efficiency and stability. For small pellet mills, crush coarse materials like hay or corn cobs to 2-5mm first to avoid blockages and improve pellet formation.

3. Excess coarse fiber content

Coarse fibrous materials (like grass powder, bagasse, peanut shells) are hard to compress and have a loose structure, making it difficult to form an effective extrusion path during the molding process. Their strong toughness causes them to wrap around the rollers or get stuck in the die exit.

Typical Issues

- High compression resistance, heavy machine noise, and rough operation.

- Frequent die jam, causing misshaped or unformed pellets.

Solution

If your raw materials are mainly grass powder or shells, mix in corn flour, wheat bran, or soybean meal, and use dies with holes of 6mm or larger. Using only coarse materials without mixing will likely cause blockages. For ring die mills, adjust the die compression ratio and conditioning time.

4. Uneven raw material mixing

Differences in density and particle size can cause uneven mixing, leading to layering during feeding. This results in inconsistent material flow, uneven pressure on the die, and potential blockages or unstable molding. This is most common when mixing by hand or without proper mixing equipment.

Common Issues

- Significant differences in pellet shape and hardness within the same batch.

- Inconsistent output, with roller speed fluctuating.

- Local die jam and uneven pellet formation over time.

Solution

Mix the materials using a mixer for 3-5 minutes. If mixing by hand, don't let the materials sit too long to avoid layering. Keep high-density ingredients (like fish meal or mineral powder) at 10%-20% of the total mix to ensure smooth compression.

5. Contaminants or hard objects

Foreign objects like corn cobs, stones, metal pieces, or plastic ropes can easily clog the die or jam the rollers, affecting output and potentially damaging the motor, bearings, or die. These issues are especially common when materials are manually fed or stored outdoors.

Common Issues

- Sudden stop of equipment with motor overload alarms.

- Die holes clogging repeatedly, difficult to clear after cleaning.

- Roller surface damage, with abnormal noise or vibration during operation.

Solution

Before storing raw materials, it's recommended to screen or use a magnet to remove impurities, which helps reduce the risk of blockages and equipment damage. Manual feeding or outdoor storage increases the chance of foreign objects like stones, metal shavings, or plastic, so extra care is needed.

Operational Factors

Poor operating practices can lead to die jam or even a complete ring die pellet machine clog. Routine pellet mill maintenance helps keep your system running smoothly.

1. Incorrect startup and shutdown

Many users start feeding material before the machine reaches the right temperature, making compression difficult. Shutting down by cutting power directly causes the material in the die to harden, leading to blockages on the next startup.

Solution

Let the machine run idle for 2-3 minutes before feeding to preheat the die.

For flat die mills, if not used for a while, add a small amount of vegetable oil mixed with wheat bran or corn flour to lubricate the die. For ring die mills, preheating is enough to stabilize the die temperature and prevent blockages.

2. Uneven or excessive feeding

This often happens with small flat die pellet mills when manual feeding is inconsistent, or large amounts of material are dumped at once. This causes material buildup, leading to fluctuating roller load and die blockages, especially with light powders or loose mixtures.

Solution

Use continuous and steady feeding. Small machines can be paired with a screw feeder or simple buffer hopper to control the feeding pace and avoid sudden impacts on the die.

3. Incorrect roller gap adjustment

Intermittent material output, fluctuating motor load, slipping rollers, or sharp noises are common signs of improper roller gap settings.

Solution

When first using the equipment, set the roller gap (0.1–0.3 mm) based on the die and material type, following the manufacturer's guidance. If output is unstable or the load fluctuates, adjust the gap to prevent friction. Regular pellet mill maintenance and trial runs help catch and fix gap issues early.

Equipment and Mold Issues

Both pellet mill dies and pellet mill rollers wear over time. Inspecting the pellet mill die and roller assembly, including the die core roller, ensures consistent pressure and feed.

1. Rough mold hole walls

New molds often have small burrs or rough hole walls. This is common for flat-die machines during first use and can cause feeding blockages or pressing difficulties.

Solution

Before first use, run a mix of bran or cornmeal with a little vegetable oil through the machine for 5–10 minutes. This will smooth the hole walls and reduce the risk of clogging or jamming.

2. Mold or roller wear

With long use, mold holes may go out of shape and roller teeth can wear down. This lowers pressure, feeds unevenly, and easily causes clogging, especially during heavy or continuous work.

Solution

Check mold and roller wear regularly. Replace the mold promptly if holes are deformed or rollers are slipping.

3. Die Compression ratio mismatch

The pellet mill die compression ratio, often calculated using a pellet mill die compression ratio formula, affects pellet density and durability. Choose a ratio and die size that match your raw material.

Solution

Select a mold compression ratio suited to the material. Use short stroke molds for coarse fibers and high ratio molds for fine feed. Ring die users should ensure the mold matches the material.

| Material Type | Examples | Recommended L/D Ratio |

| Fine powdered feed | Corn meal, soybean meal, premix | 12:1 – 14:1 |

| High oil content | Cottonseed meal, rapeseed meal, rice bran | 10:1 – 12:1 |

| Coarse fiber feed | Alfalfa meal, cotton stalk meal, hay meal | 6:1 – 10:1 |

| Hard materials | Rice husk, coconut shell, sunflower hulls | 5:1 – 8:1 |

| Biomass fuel | Sawdust, bamboo powder, straw | 6:1 – 10:1 |

| Sinking aqua feed | Fish meal, corn meal, soybean meal, premix | 12:1 – 14:1 |

Data from About Compression Ratio of Ring Die & Feed Pelleting Reference Guide

By selecting the right pellet mill die, performing regular die maintenance, and adjusting your compression ratio, you can prevent downtime and improve production efficiency.

If you experience ongoing die blockage during production, you're welcome to reach out to us for technical support and equipment advice.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.