Pellet Die Selection Guide for Feed and Biomass Pellet Mills

The die is the core of a pellet mill. Its accuracy affects efficiency and pellet quality. Choosing the right die means looking at raw material, scale, and process, not simply the price.

Die Types Selection

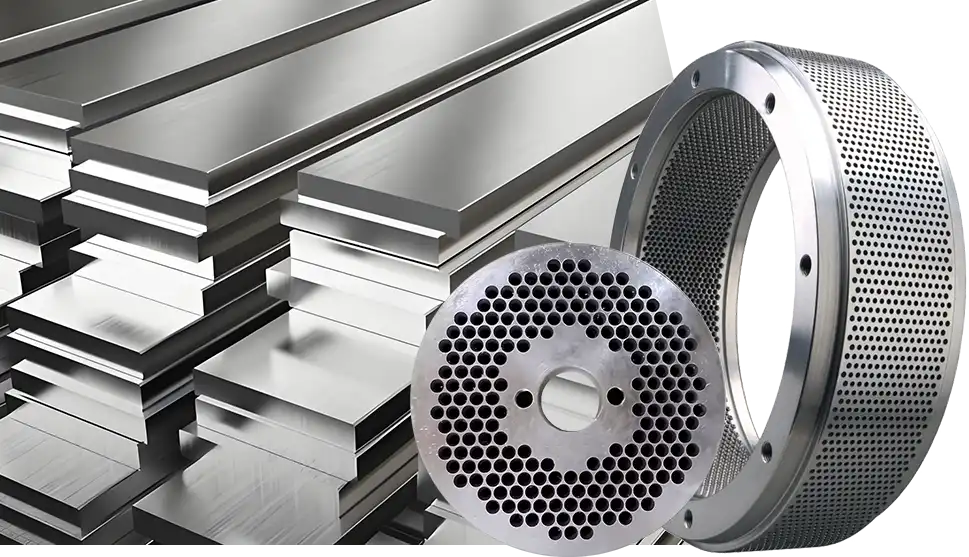

Dies are mainly divided into flat dies and ring dies. The two differ in structure and application.

Flat Die

Flat dies have a simple structure with horizontal installation. Material is pressed downward through the holes.

They are low cost, easy to replace, and flexible. Ideal for small production, frequent material changes, or trial runs.

Limitations include fewer holes, lower output, and reduced efficiency as the die wears.

Ring Die

Ring dies are used for large scale production. Material is evenly pressed into the holes by rollers.

They deliver high efficiency, stable pellets, lower energy use, and longer service life. Best for factories producing over ten thousand tons per year.

However, they require higher skill for replacement and adjustment, and initial cost is higher.

Selection Tips

- For small scale production or frequent formula changes, flat dies are more suitable.

- For continuous mass production, such as feed mills or biomass plants, ring dies offer better efficiency and stability.

Key Parameters for Die Selection

Dies are not universal parts. They must be designed for the raw material.

Fiber structure, moisture, ash, and binding properties all affect hole size, compression ratio, and hole shape.

If the die does not match the material, even strong power cannot prevent clogging, low output, or loose pellets.

Hole Size

Hole size decides pellet diameter.

- Larger holes give bigger pellets and higher throughput, but lower density and palatability.

- Smaller holes produce finer pellets but reduce output and need more power.

For Feed Pellet Die

| Animal / Stage | Hole Size (mm) |

| Chick starter | 1.5 – 2.0 |

| Poultry grower | 3.0 – 4.0 |

| Duck | 2.5 – 4.0 |

| Piglet | 2.5 – 3.0 |

| Finishing pig | 3.5 – 4.5 |

| Cattle / Sheep | 4.0 – 6.0 |

| Fish (sinking) | 2.0 – 3.0 |

| Shrimp | 1.0 – 2.0 |

| Rabbit | 3.0 – 4.0 |

For Biomass Pellet Die

| Raw Material | Hole Size (mm) |

| Wood (pine, hardwood, bamboo) | 6 – 8 |

| Crop residues (rice husk, palm shell, peanut shell) | 8 – 10 |

| Straw (wheat, corn) | 6 – 8 |

| Grass (alfalfa, napier) | 6 – 8 |

| By-products (corn cob, bagasse) | 6 – 8 |

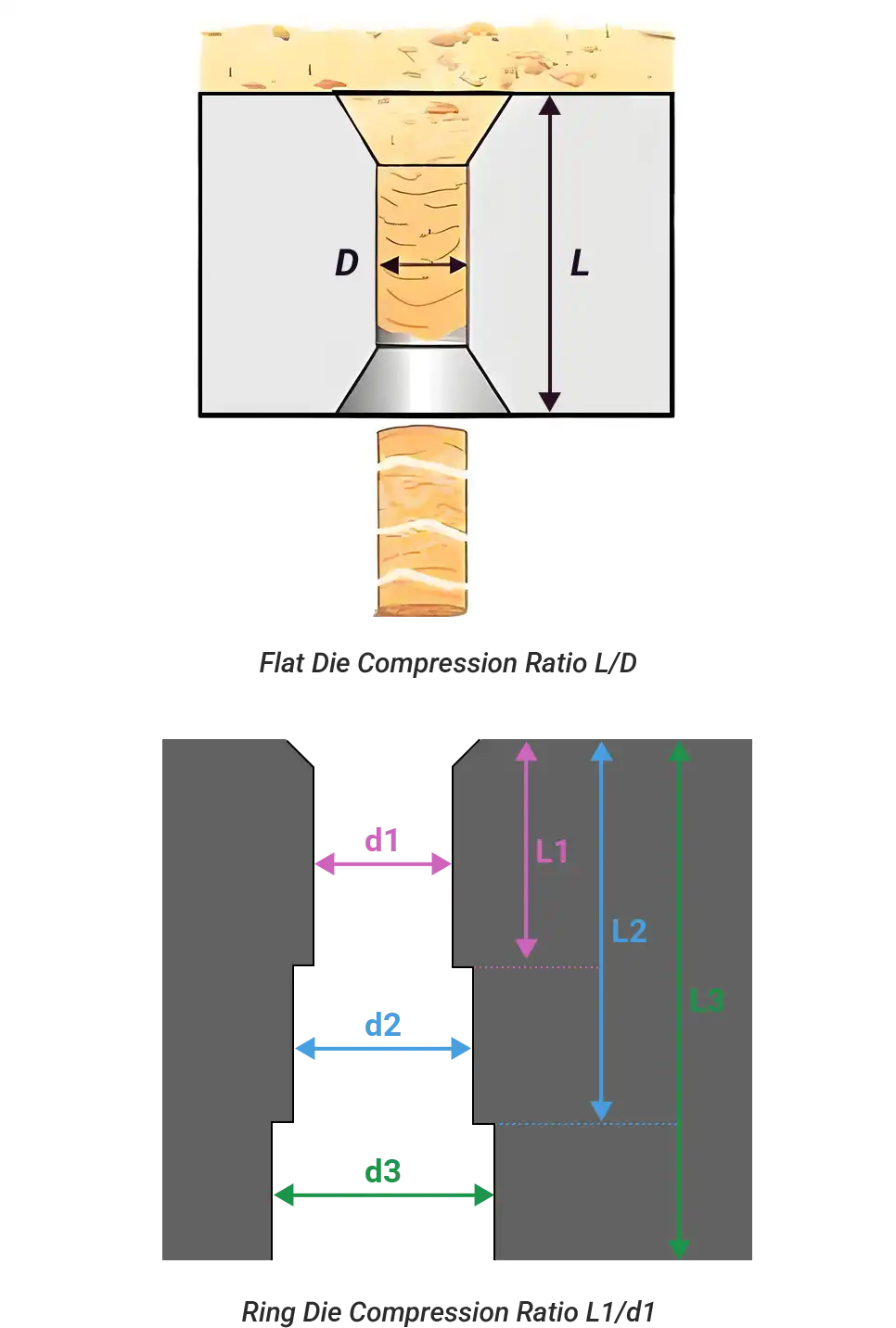

Compression Ratio

Compression ratio is the ratio of effective hole length to hole diameter (L/D). It defines how much material is compressed inside the die.

- Higher ratio: pellets are dense, hard, and durable, but resistance and energy use rise, and die wear is faster.

- Lower ratio: easier discharge with less energy, but pellets are loose and form poorly.

For Feed Pellet Die

| Material Type | Ratio Range |

| Poultry feed (chicken, duck) | 1:4 – 1:6 |

| Aquatic feed (fish, shrimp) | ≥ 1:12 |

| High fiber (alfalfa meal, soybean mix) | 1:7 – 1:9 |

| Mixed formula (pig, cattle, sheep) | 1:5 – 1:7 |

For Biomass Pellet Die

| Material Type | Ratio Range |

| Wood, bamboo | 1:7 – 1:8 |

| Rice husk, palm shell | 1:7 – 1:10 |

| Straw (wheat, corn) | 1:10 – 1:12 |

| Grass (alfalfa, napier) | 1:10 – 1:12 |

| Corn cob, bagasse | 1:8 – 1:10 |

| Cottonseed/peanut shell | 1:6 – 1:8 |

*If your material is not listed, check a similar type or contact us for advice.

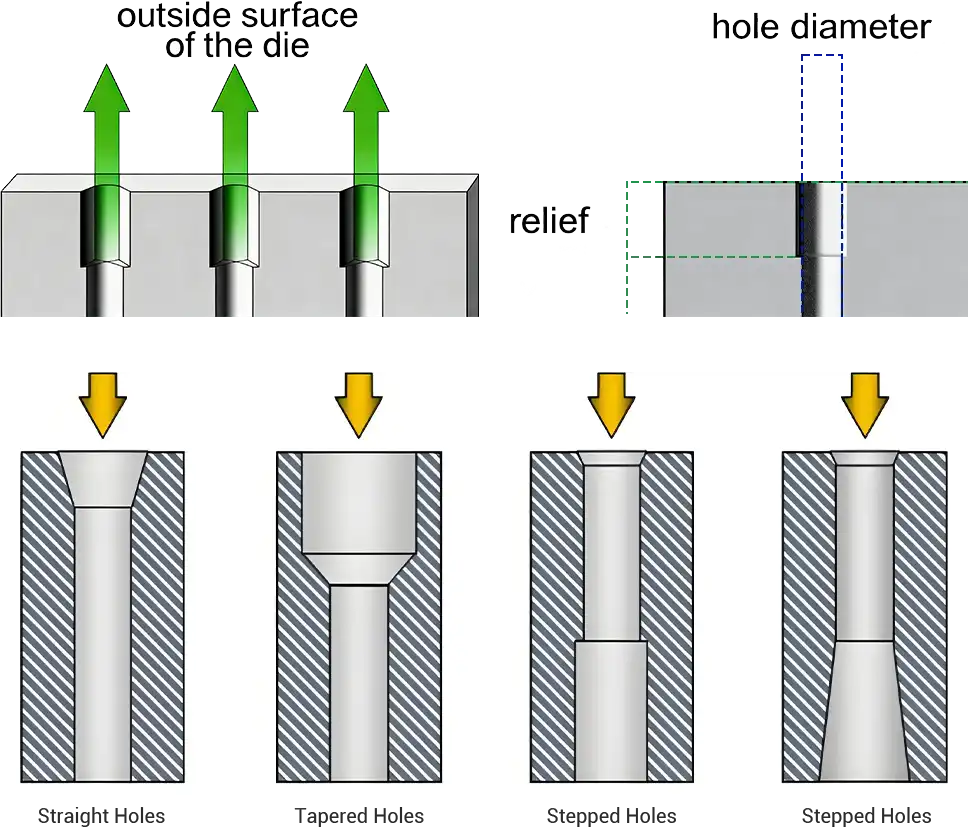

Die Hole Types

Common hole types include straight, stepped, and tapered.

At the outlet, a relief section can also be added. It is not a separate type but an auxiliary design.

- Straight holes are simple and efficient, best for low fiber raw materials

- Tapered holes improve feeding and reduce clogging at the inlet.

- Stepped holes strike a balance, making pellets denser without too much resistance.

Relief is an enlarged section at the die outlet. It reduces resistance and helps oily, fibrous or expanding materials discharge smoothly.

For Feed Pellet Die

| Feed Type | Hole Type |

| Poultry & livestock (chicken, duck, pig, rabbit) | Straight |

| Ruminant (cattle, sheep) | Straight + Relief |

| Aquatic sinking feed (fish, shrimp) | Long straight |

| Special formulas (high oil, high mineral, high fiber) | Stepped + Relief |

For Biomass Pellet Die

| Raw Material | Hole Type |

| Wood (sawdust, bamboo, shavings) | Straight |

| Crop straw (corn, wheat, cotton stalks) | Stepped |

| Grass (alfalfa, napier) | Stepped + Relief |

| Mixed residues (rice husk, peanut shell, nut shell) | Tapered |

| High moisture or gummy materials (bagasse, distillers' grains) | Inlet tapered |

Die Material Selection

Die material determines service life, pellet quality, and maintenance cost. Harder is not always better - the right choice depends on raw material, production load, and product requirements.

1. Carbon Steel

Low cost and easy to machine. Suitable when output is high and raw materials are not abrasive.

Weak in wear and corrosion resistance, so replacement is frequent.

2. Alloy Steel

The mainstream choice in the industry, such as 20CrMnTi and 42CrMo.

With proper heat treatment, it balances hardness and toughness. Best overall in service life and cost.

3. Stainless Steel

Grades include 304, 316, and 4Cr13. Excellent corrosion resistance, ideal for oily, salty, humid, or food grade use.

Less wear resistant than alloy steel and more costly. Better for special conditions, not as a general option.

4. Carbide or Surface Treated Dies

For abrasive materials such as rice husk and palm shell, carbide coating or alloy inserts are applied to extend die life, with higher cost but better value in specific use.

Die Material Recommend

For Feed Pellet Die

| Feed Type | Recommended Material |

| Pig, poultry (chicken, duck) | Alloy steel (42CrMo) |

| Ruminant (cattle, sheep) | Alloy steel (42CrMo) |

| Aquatic feed (high oil, high salt) | Stainless steel (304 / 316) |

For Biomass Pellet Die

| Raw Material Type | Recommended Material |

| Wood (pine, poplar) | Alloy steel (42CrMo) |

| High silica (rice husk, palm shell, coconut shell) | Alloy steel + carbide layer |

| Crop straw (corn, wheat) | Alloy steel (42CrMo) |

| High moisture organic (distillers' grains, bagasse) | Stainless steel (4Cr13) |

Die Craft and Precision

A die is not only about material and parameters. Processing accuracy is just as critical. Poor hole finishing or heat treatment will reduce both life and efficiency.

Hole Accuracy

Smooth and uniform holes reduce resistance and keep output stable. Rough edges or uneven size cause clogging and loose pellets.

How to check

Heat Treatment

Proper carburizing, quenching, and tempering give hardness, strength, and toughness. Good treatment makes the die wear resistant and less likely to crack. Poor treatment leads to fast wear or breakage.

How to check

Surface Finish

A smooth die surface keeps rollers running evenly and pellets forming well. Rough surfaces cause unstable roller movement, uneven wear, and lower efficiency.

How to check

Use and Maintenance

Ease of disassembly, cleaning, and upkeep directly affects die life.

New dies need running-in before regular use. Follow supplier instructions and use special abrasive material to clear residues and stabilize performance.

After daily production, press oily material through the die to prevent clogging and rust.

For long-term storage, keep the die in a dry, ventilated place.

Quick Reference Table

For Feed Pellet Die

| Raw Material Type | Hole Type | Hole Size (mm) | Compression Ratio | Material |

| Poultry feed (chicken, duck) | Straight | 2.5 – 4.0 | 1:4 – 1:6 | Alloy steel |

| Ruminant (cattle, sheep) | Straight + Relief | 4.0 – 6.0 | 1:7 – 1:9 | Alloy steel |

| Pig feed | Straight | 3.0 – 4.0 | 1:6 – 1:10 | Alloy steel |

| Aquatic feed (fish, shrimp) | Long straight | 1.0 – 3.0 | ≥ 1:12 | Stainless steel |

| Premix feed | Stepped + Relief | 3.0 – 4.0 | 1:5 – 1:7 | Stainless steel |

For Biomass Pellet Die

| Raw Material | Hole Type | Hole Size (mm) | Compression Ratio | Material |

| Wood (pine, poplar) | Straight | 6 – 8 | 1:7 – 1:8 | Alloy steel |

| Straw (corn, wheat) | Stepped | 6 – 8 | 1:10 – 1:12 | Alloy steel |

| Grass (alfalfa, napier) | Stepped + Relief | 6 – 8 | 1:10 – 1:12 | Alloy steel |

| Hard residues | Tapered | 8 – 10 | 1:7 – 1:10 | Carbide |

| Wet organics | Inlet tapered | 6 – 8 | 1:6 – 1:8 | Stainless steel |

*For reference only, subject to actual equipment and material.

Die selection should match your material, process and production goals. Hope this guide gives you useful reference, and you are welcome to share your needs with us.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.