Feed plays a major role in aquaculture success. The right pellet machine ensures stable, balanced feed that fish accept easily while improving pellet quality, buoyancy, and efficiency. Here shares some key tips for choosing the best machine for your farm.

How to Choose the Right Fish Feed Making Machine

Match Feed Type to Fish Feeding Habits

Different fish have different feeding behaviors, so pellet buoyancy, hardness, and size should match their habits. Fish feed is usually divided into sinking fish food pellets and floating fish food pellets, each made with a distinct structure and process.

1. Sinking Feed

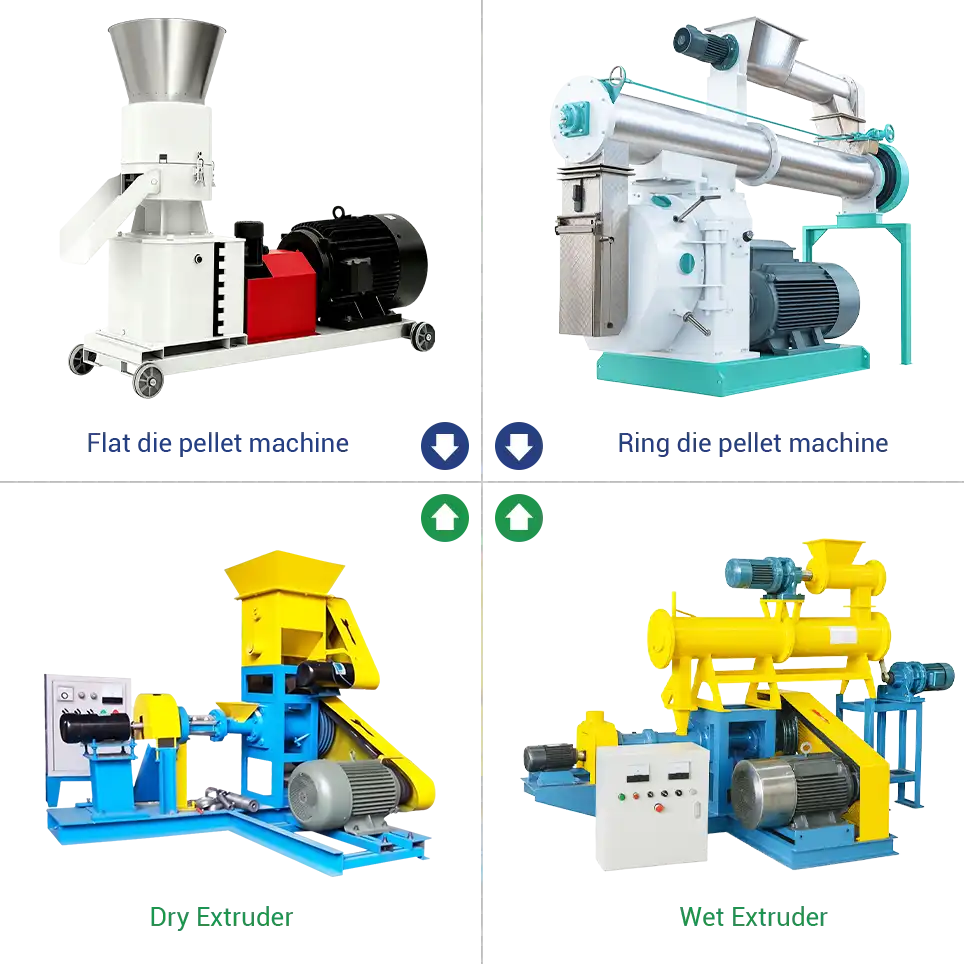

This type includes both hard and soft pellets, usually made with flat die (R type) or ring die pellet machines. The difference between "hard" and "soft" is not just about texture but depends on the ingredient ratio, pelleting method, degree of conditioning, and moisture content.

Soft Fishing Pellets

Soft feed pellets are formed under lower pressure and temperature, with a moisture content of around 20 to 30 percent. Some ingredients are only lightly cooked during processing. This method keeps the feed moist and tender, making it easier for fish to bite and digest.

A small amount of steam or hot water is added to lightly cook the material before pressing. This helps improve pellet shape and taste. Because the temperature stays low, nutrients like vitamins and amino acids are better preserved, keeping the feed more balanced.

Soft pellets have a tender texture, making them ideal for fish such as eels and trout that are sensitive to feed texture and have weaker digestion.

Soft pellets stay stable in water for only 20 to 40 minutes, so they're best for small farms or nursery use. To keep them fresh, they're usually made and fed right away.

Hard Pellets

Hard pellets are made under high pressure with about 10 to 13 percent moisture, then dried or air dried. The heat partly cooks the ingredients, improving starch and nutrient density.

They stay firm in water for one to two hours with little nutrient loss, ideal for bottom-feeding fish like carp, grass carp, and catfish. Hard pellets store well and suit large farms, though they take a bit more energy to make.

Soft Pellets vs Hard Pellets

| Category | Soft Pellets | Hard Pellets |

| Forming Method | Low pressure, partly cooked | High pressure, heat dried |

| Moisture | 20–30% | 10–13% |

| Texture | Soft, moist, easy to chew | Firm, dense, chewy |

| Fish Type | Eel, trout, young fish | Carp, grass carp, catfish |

| Water Stability | 20–40 min | 1–2 hrs+ |

| Storage & Cost | Short shelf life, low cost | Long shelf life, higher energy |

2. Floating Pellets

Floating or extruded feed is produced under high temperature and pressure in an extruder. Inside the screw chamber, strong shear and friction heat the material to about 120–160°C. When discharged, moisture quickly evaporates, creating a porous structure.

Compared with regular pellets, extruded feed is fully cooked, easy to digest, and stable in water for one to three hours. It reduces nutrient loss and feed waste, making it ideal for fish such as tilapia, bass, salmon, silver carp, and ornamental species that feed near the surface.

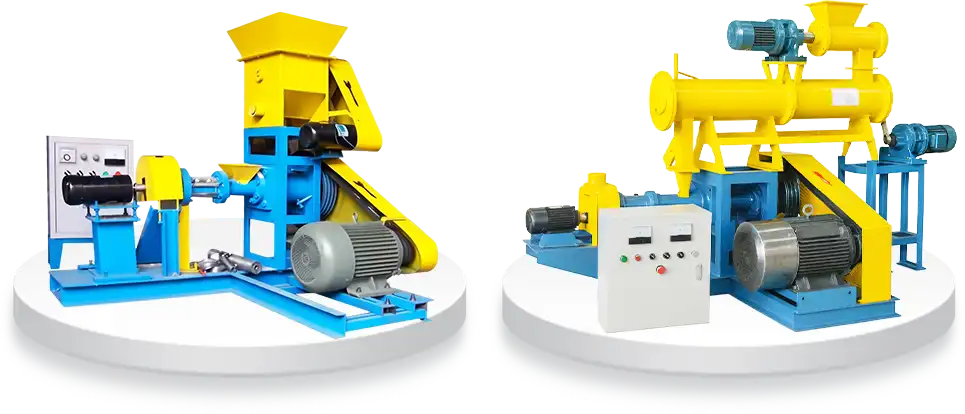

Extruders are classified into dry and wet types.

- Dry extruders use screw friction for heating, simple and low cost.

- Wet extruders use steam to preheat materials, making pellets more cooked and smooth.

Some wet extruders use twin screws to keep mixing even and output stable when handling high-fat or special ingredients. They are often used for premium feed formulas and can adjust feed density to make floating or slow-sinking pellets.

Define Production Goals and Capacity

A well-planned production capacity helps maintain efficiency while reducing energy use and maintenance costs.

| Application | Recommended Output (kg/h) |

| Labs, small fish farms, home use, small feed mills | 30–200 |

| Commercial farms, medium feed plants | 200–500 |

| Large feed factories, industrial production lines | 500–2,000+ |

At the same power level, pellet mills generally produce more than extruders, and wet extruders slightly outperform dry ones.

Suggestion

- Calculate daily feed needs and choose a machine with suitable hourly output.

- Keep some extra capacity for peak seasons or future growth.

- Choose models with replaceable dies or upgrade options for easy expansion.

Pellet Size and Length

Pellet size is a key factor in aquaculture and should match the species, growth stage, and mouth size of the fish. Using the wrong size can cause feed waste, stress the fish, and even lead to swallowing problems.

Use the guide below to choose the right pellet size for each fish species.

| Growth Stage | Pellet Diameter (mm) | Example Species |

| Fry | 0.8–1.2 | Tilapia, Carp |

| Juvenile | 1.5–2.5 | Catfish, Trout |

| Adult | 3.0–6.0 | Bass, Grouper, Grass Carp (up to 8 mm) |

Dta reference from: Nutrient Requirements of Fish and Shrimp

To improve feeding and reduce waste, pellet length is usually about twice its diameter. Smaller pellets require higher pressing force, finer grinding, and more precise dies.

As fish grow, you can adjust or change the die size to match their feeding habits and growth stage.

For young fish and shrimp that need softer feed, ingredients should be finely ground, usually with a hammer mill. Finer particles absorb steam better, making the mix easier to form and helping pellets stay stable in water.

Fish Feed Making Machine Selection Guide

| Type | Feed | Advantages | Limits |

| Flat Die Pellet Mill | Soft or hard sinking | Low cost, simple, versatile | Average water stability |

| Ring Die Pellet Mill | Hard sinking | High output, stable, long storage | Needs precise formula control |

| Dry Extruder | Floating | Tasty feed, easy to use | Low output, less oil mixing |

| Wet Extruder | Floating or slow sinking | High output, smooth pellets, top quality | Higher cost, needs steam system |

We produce high-quality fish feed machines in our own factory using durable alloy steel parts and copper motors.

We also provide full feed line solutions tailored to your needs.

Feel free to contact us for professional advice and a suitable quote for your farm.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.