Homemade Corn Pellets: Easy, Low cost and Effective

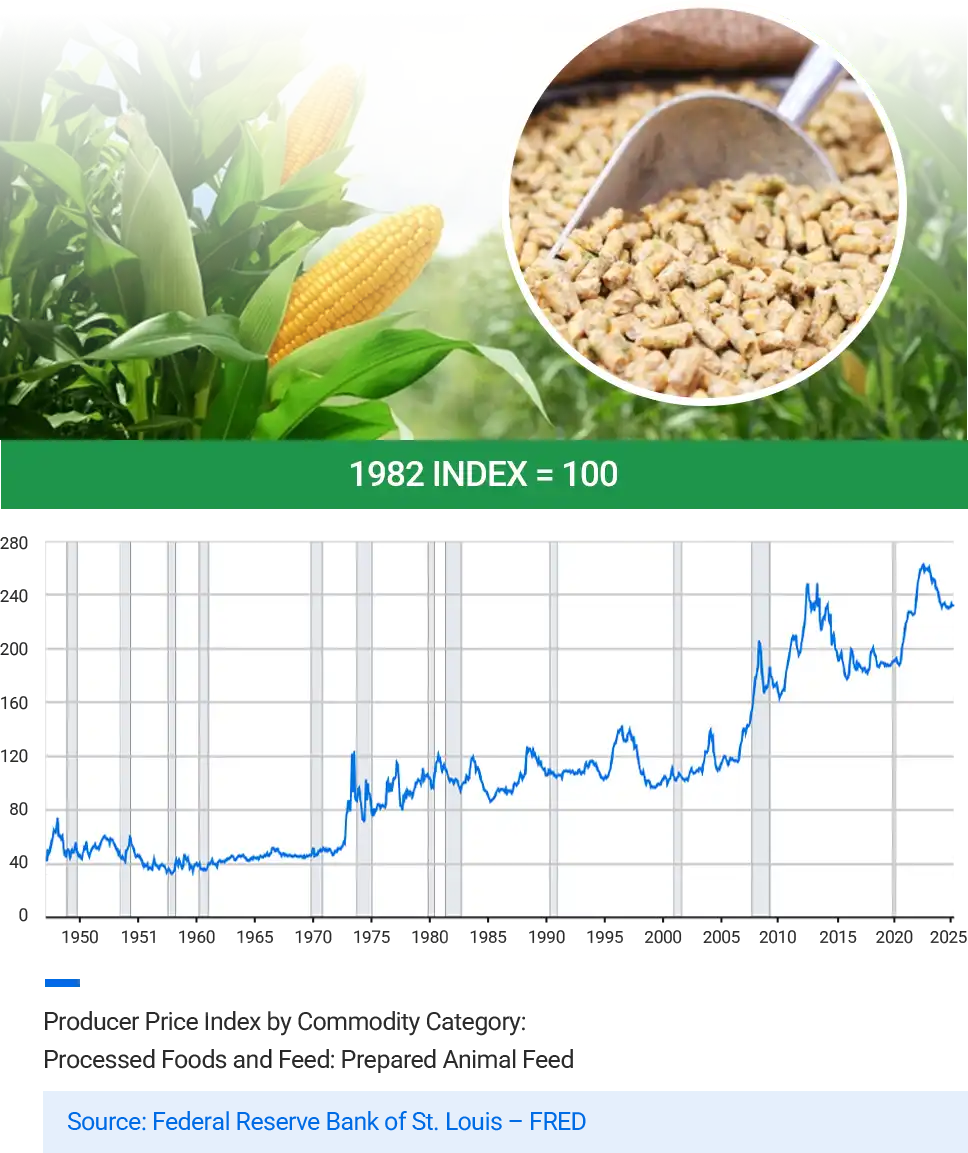

Feed usually accounts for over 60% of farming costs, and in some cases, over 70%. With prices rising, many farmers are turning to homemade pellet feed. Corn is one of the most common and cost-effective options. It's nutritious, easy to get, and works well for pelleting.

Once processed, the pellets are easier to store, transport, and feed. Making your own corn pellets helps cut costs and allows flexible formulas based on your animals' needs. It's a practical way to boost efficiency.

Why Corn Works Well for Pellet Production

Corn is a common feed crop that's easy to source. Its by-products are also useful in feed. It's widely used for pelleting thanks to its good nutrition, simple structure, and ease of processing.

Abundant and Affordable

Corn is one of the most widely grown crops in the world. In regions like China, Africa, and Southeast Asia, it's planted on a large scale with high yearly output. Raw materials such as corn kernels, cobs, and stalks are easy to find and reasonably priced. Whether farmers grow their own or buy local by-products, corn helps cut material costs and improve the economics of pellet production.

Balanced Nutrition

Corn is widely used in pellet feed as a base ingredient due to its good energy value and palatability. According to the FAO report Poultry Feed Availability and Nutrition in Developing Countries (AL705E-2013), corn and its by-products typically make up 40%–60% of poultry and livestock feed, making it a key high-energy source.

Corn kernels contain over 60% starch and are rich in protein, fat, fiber, and minerals. They're suitable for most animals. Corn cobs are high in fiber but low in protein, often used in ruminant feed to improve structure and density. Corn stalks also contain coarse fiber and some protein, making them a common roughage for cattle and sheep.

| Material | Key Use | Animals |

| Kernels | High energy feed base | Poultry, pigs, cattle, sheep |

| Cobs | Fiber filler | Cattle, sheep, rabbits |

| Stalks/Straw | Roughage | Cattle, sheep, horses |

Good Pelletizing Properties

Corn-based materials are easy to crush and have a suitable particle structure, making them ideal for pelletizing. Whole corn is rich in starch, which acts as a natural binder during steam conditioning. This helps form dense and durable pellets. Crushed and dried corn cobs and stalks are loose and breathable, making them easy to compress into stable and high-quality pellets.

Well-Suited for Pelleting

Corn materials are easy to grind and have a structure well-suited for pelleting. Corn kernels are rich in starch, which helps binding during steam conditioning, making the pellets dense and durable. Cobs and stalks, once crushed and dried, are light and porous, making them easy to compress into stable pellets.

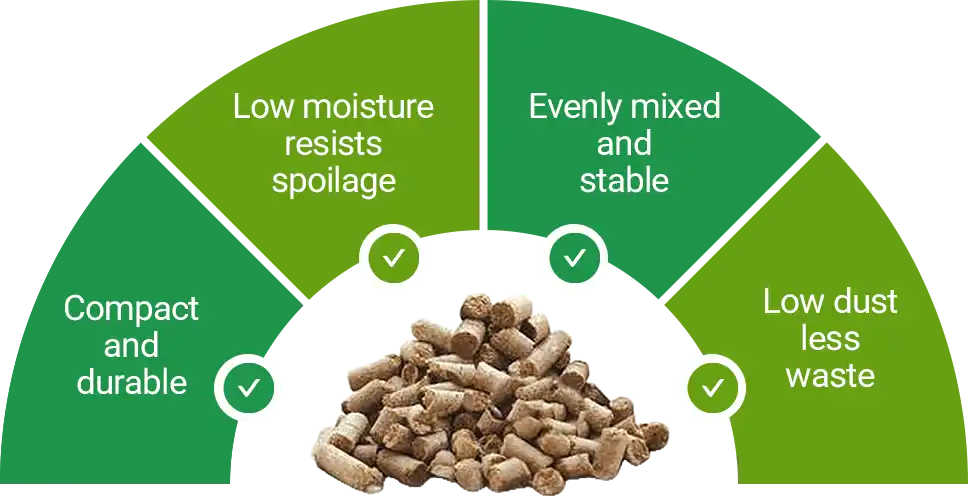

| Aspect | Corn Pellets | Corn Powder |

| Form | Compact and durable | Loose and fragile |

| Storage | Low moisture, resists spoilage | Spoils easily |

| Nutrition | Evenly mixed and stable | Separates |

| Feeding | Low dust, less waste | Dusty, higher feed loss |

Corn is suitable for feed, and its by-products like cobs and stalks can be made into biomass fuel pellets. They are dense, burn steadily, and can replace some traditional fuels.

Flexible Feed Formulation

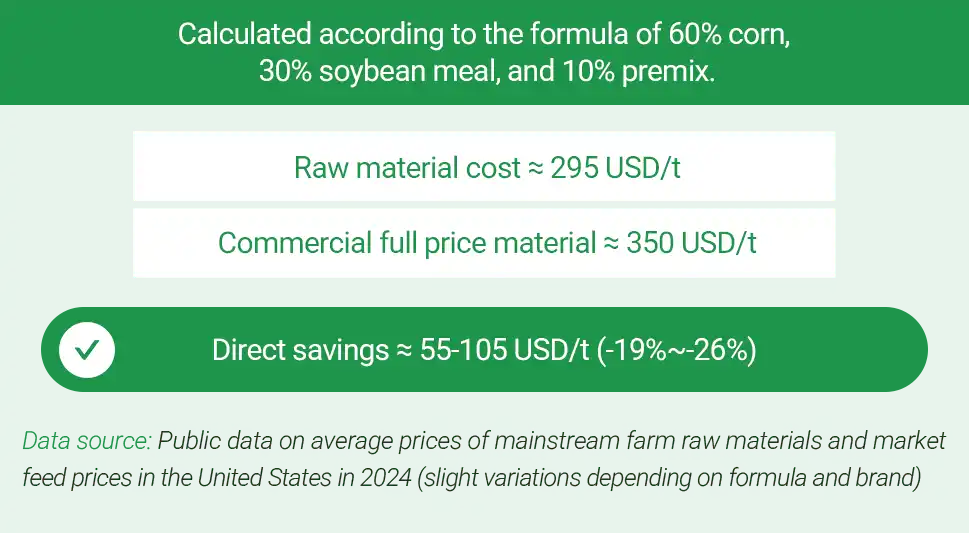

Corn works well with other ingredients like soybean meal, wheat bran, grass powder, and premix. By adjusting the corn ratio during pelleting, you can tailor the formula for different animals and growth stages. This helps improve feed performance and efficiency.

Corn Pellet Feed Production Steps

Making corn pellets at home is not complicated. The process generally includes the following steps:

1. Raw Material Preparation

Use dry, mold-free corn as the main raw material. A sheller can separate the kernels from the cobs, making it easier to handle and mix later. Kernels can go straight to grinding, while the separated cobs should be crushed into smaller pieces before further grinding.

Corn stalks should be sun-dried after harvest, with moisture kept below 15%. Before grinding, cut them into shorter pieces, usually within 3 to 5 cm, to make processing easier.

Grinding size directly affects pellet quality

- Corn kernels are best ground into fine powder around 0.5 mm. This helps produce firm pellets with good palatability.

- Due to their fibrous structure, corn stalks and cobs can be ground to 1–2 mm. It's best not to exceed 3 mm, as this can cause poor pellet formation and increase die wear.

If using all three materials, grind them separately first, then mix them according to the needed ratio.

2. Mixing and Formulation

After grinding, corn serves as the main energy source in the feed. However, using corn alone may not provide balanced nutrition. To improve the overall feed value, it's recommended to add ingredients like soybean meal, wheat bran, oils, and minerals. Mix thoroughly to ensure a balanced formula with good palatability and digestibility.

Here are basic feed ratios. You can adjust them as needed.

| Animal | Suggested Ratio (%) |

| Poultry (chickens/ducks) | Corn 55–65, soybean meal 20–25, bran 5–10, oil 2–5, minerals 2–3 |

| Pigs | Corn 60–70, soybean meal 15–20, bran 5–10, by-products 0–5, minerals 2–3 |

| Beef cattle | Corn 70–90, forage 10–30, minerals as needed |

| Dairy cows | Corn 30–50, forage/straw 30–50, minerals as needed |

Source: Poultry Feed Formulation & Nutrient Requirements of Dairy Cattle

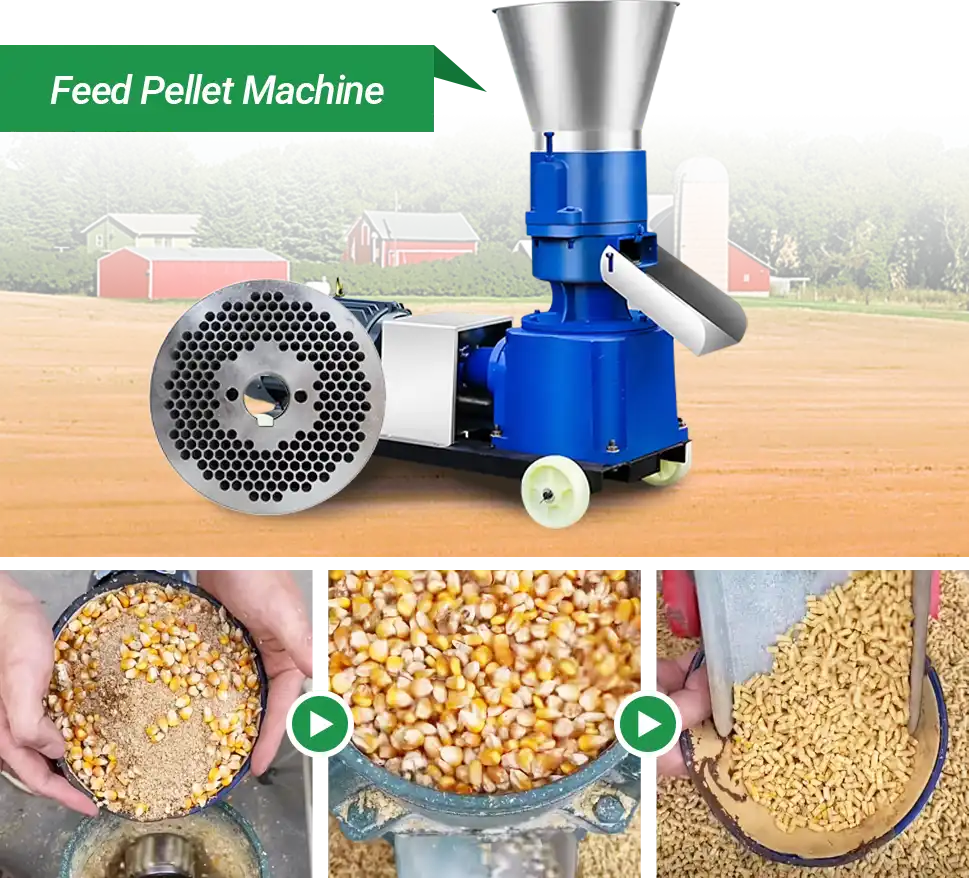

3. Pelleting

Pelleting is the core step in the process. It directly affects pellet density, forming rate, and feed palatability.

The pellet machine uses rollers to press the mixed material into the die holes. Under pressure and friction, dense pellets are formed. As they exit the die, they break off naturally or are cut into uniform lengths. During pelleting, the material can reach 60–80°C. This helps kill some bacteria and reduce anti-nutritional factors, making the feed safer and easier to digest.

Die size can be adjusted to match the feeding habits of different animals.

| Animal | Recommended Pellet Size (mm) |

| Chicks | 2.0 – 2.5 |

| Adult chickens / ducks | 3.0 – 4.0 |

| Pigs | 4.0 – 6.0 |

| Beef cattle | 6.0 – 8.0 |

| Dairy cows | 5.0 – 6.0 |

| Sheep / goats | 4.0 – 6.0 |

| Rabbits | 3.0 – 4.0 |

| Fish (floating type) | 1.5 – 3.0 |

| Young poultry | 1.0 – 2.0 |

4. Cooling and Screening

Fresh pellets are hot and contain some moisture, so they should be cooled quickly to avoid mold.

This can be done with natural air or a counterflow cooler. In hot, humid areas or with larger output, mechanical cooling is a better choice. For small batches, natural cooling and manual screening are enough.

For small batches, natural cooling and manual screening are enough.

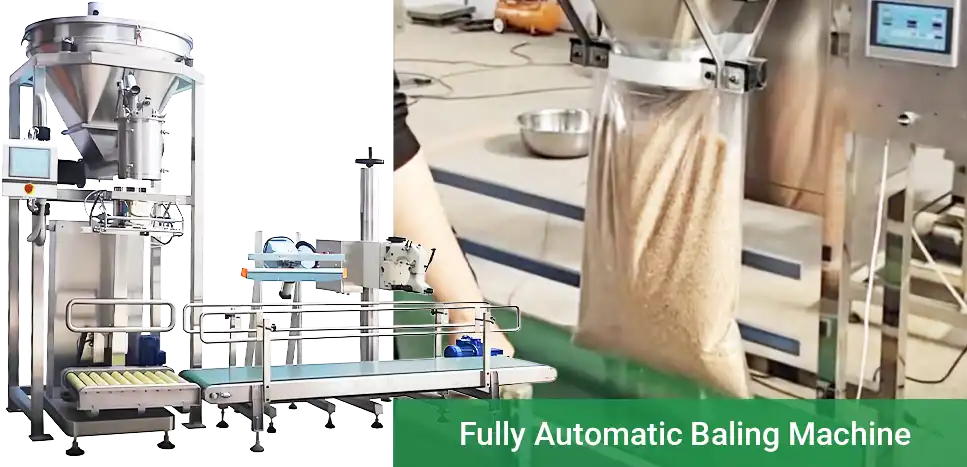

5. Packing and Storage

Cooled pellets can be used directly for daily feeding. For sale or long-term storage, packing machines can help with handling and transport.

Store the feed in a dry, well-ventilated place and protect it from moisture and pests to extend shelf life.

Pellet Line for Small and Medium Feed Plants

To improve efficiency and reduce labor, we offer complete corn feed pellet production lines for small farms and feed businesses. The recommended setup includes:

| Step | Equipment |

| Pre-cleaning | Drum screen + magnet (opt.) |

| Threshing | Corn thresher |

| Cob crushing | Crusher |

| Grinding | Hammer mill |

| Mixing | Horizontal mixer |

| Pelleting | KD-400 pellet mill |

| Cooling | Cooler + screener |

| Packing | Weighing packer (opt.) |

| Conveying | Screw / bucket elevator (opt.) |

This compact line is easy to operate and efficiently handles corn grinding, mixing, pelletizing, cooling, and packing. With a high level of automation, it reduces labor and is ideal for daily use in small and medium farms or feed plants.

Start Corn Pellet Production at Low Cost

For users with limited budget or space, a single animal feed pellet mill is enough to process corn feed. You can prepare the raw materials manually and feed them directly into the machine. While output is lower and more manual work is needed, it's still a practical choice for home use or small-scale farming.

| Model | Power (kw) | Capacity(kg/h) |

| 150 | 4.5 | 80-150 |

| 160 | 4.5 | 130-200 |

| 210 | 7.5 | 200-300 |

| 230 | 11 | 250-400 |

| 260 | 15 | 300-500 |

| 300 | 22 | 500-700 |

| 400 | 37 | 900-1200 |

Relevant Cases:400kg/h Corn Feed Pellet Machine at Uganda Farm

Our machine is designed for practicality and offers the following benefits:

- Compact and easy to move, takes up little space

- Works with corn, bran, soybean meal, straw and more

- Strong build and long-lasting die

- Compatible with electric, diesel or PTO power

- Die sizes available from 2.5 to 8 mm

- One-year warranty with spare parts and quick support

If you have any questions about choosing a machine or setting up a production line, feel free to reach out. We'll recommend a solution based on your actual needs.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.