How to Set Up a Cattle Feed Pellet Production Line

Starting a cattle feed pellet line is about more than machines. You also need to plan the formula, process, and layout. Farm size and whether you raise beef or dairy cattle will shape the right setup. This article walks you through the steps from planning to production.

Set Clear Goals and Plan Ahead

Before building, set clear goals. Decide on the output, cattle type, and whether the feed is for your own herd or for sale. These choices affect equipment, process, and budget.

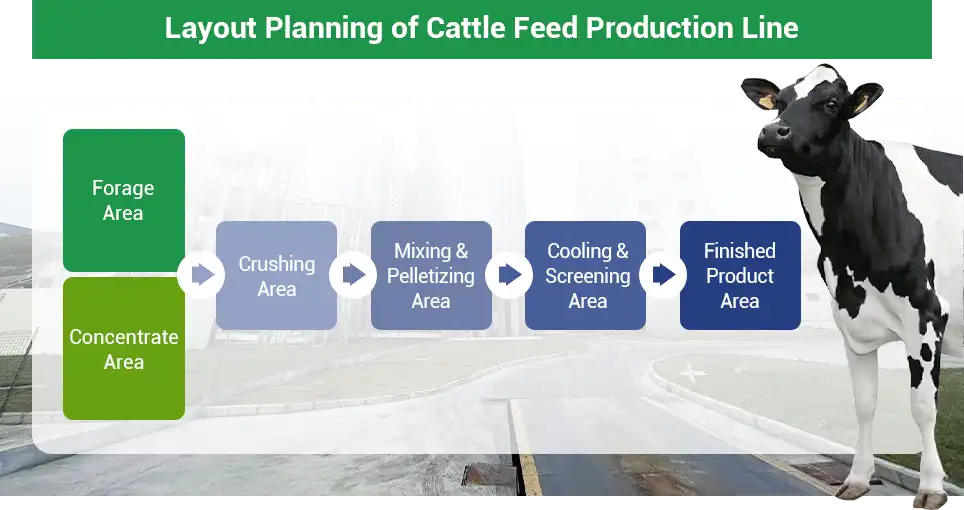

Plant Layout

The layout of a cattle feed pellet line should consider raw materials, plant size, and workflow.

In larger plants, areas are divided for raw materials, grinding, mixing, pelleting, cooling, and storage. Forage and concentrates are stored separately to avoid contamination, and a straight flow reduces handling.

Because forage dust is common, a dust collector is advised at the grinding stage. Bigger lines also need three-phase power for stable operation.

Cattle Needs and Feed Formulas

Beef and dairy cattle need different feeds.

When planning a pellet line, first decide if it's for beef fattening or dairy production, as this guides both formulas and raw materials.

Beef feed focuses on energy for weight gain, while dairy cows need balanced protein, minerals, and trace elements to maintain milk yield. In general, beef rations use more concentrates, and dairy feed relies more on forage, which also affects equipment choices.

For more feed formulas, you can check the guide in the blog below.

Beef Cattle Feeding Differences in Growing and Fattening Diets

Dairy Cow Nutrition and Feeding Guide for Each Stage

Process Flow and Equipment Setup

A cattle feed pellet line usually runs through key stages: receiving, cleaning, grinding, batching, mixing, pelleting, cooling, screening, and packaging.

The setup differs for beef and dairy cattle. Beef feed aims at weight gain, while dairy feed focuses on balanced nutrition. These needs affect pellet size, process steps, and equipment choice.

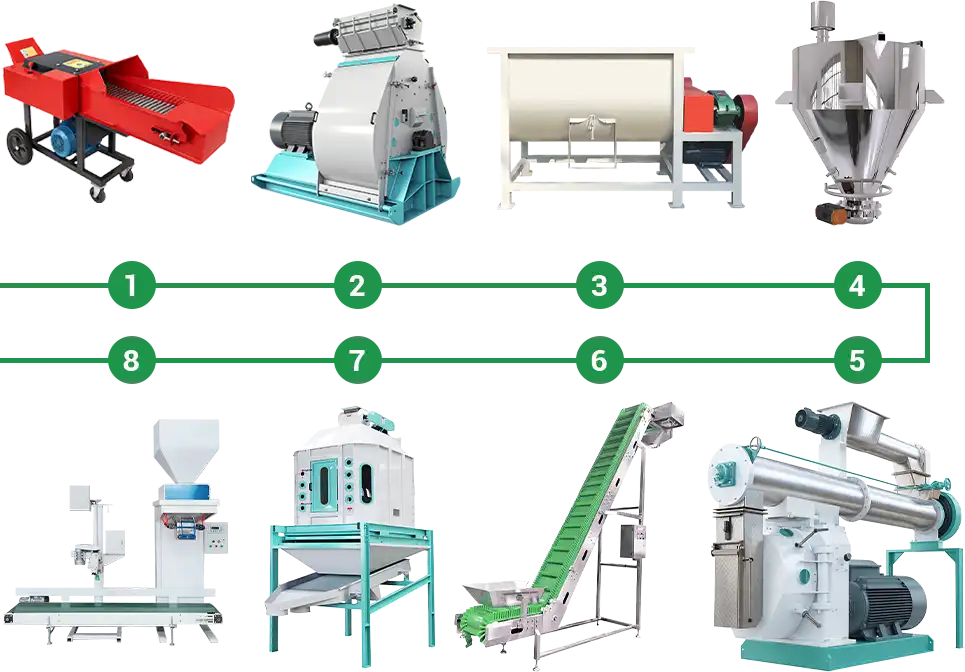

Basic production flow

Receiving & Cleaning → Grinding → Batching & Weighing → Mixing/Conditioning → Pelleting → Cooling → Screening → Packaging or Bulk

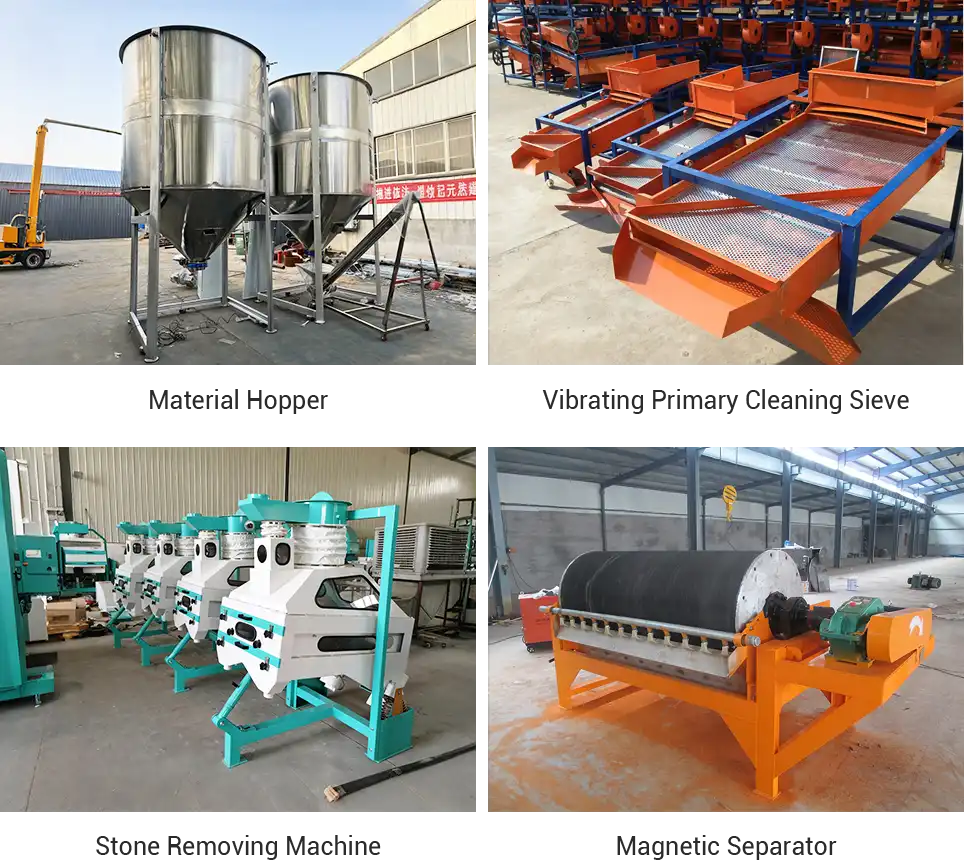

1. Material Preprocessing and Cleaning

Cattle feed uses both forage and concentrates, so materials should be received and stored separately.

- Concentrates such as corn and soybean meal work best in sealed bins or bags for easy loading.

- Forage is bulky and dusty, so it should be stacked in ventilated areas with simple dust control.

Before grinding, all raw materials must be cleaned to remove stones, metal, or other debris. Forage may carry strings or plastic, while concentrates can contain iron scraps or small stones. If not cleared, these impurities can damage equipment and reduce pellet quality.

Recommended Equipment

| Equipment | Purpose |

| Silo | Temporary storage and classified feeding |

| Vibrating Pre-Cleaner | Removes large and light impurities |

| Destoner | Clears stones, clods, and heavy debris |

| Magnetic Separator | Removes iron scraps and metal impurities |

2. Grinding

Grinding

Grinding makes feed easier to eat and helps it mix more evenly.

Forage such as alfalfa, straw, and fresh grass has long fibers and should be roughly ground. Concentrates like corn and soybean meal need a stable fineness, usually around 800–1200 microns.

Particle size affects pellet quality. If too coarse, pellets are hard to press; if too fine, energy use rises and pellets turn loose. Adjust the grind to suit beef or dairy cattle needs.

Suggested Grinding Equipment

| Equipment | Purpose |

| Chaff Cutter (with crushing option) | Coarse chopping of high-fiber forage |

| Self-priming Grinder | Small-scale grain grinding with auto feeding |

| Hammer Mill | Grinding concentrates for small to medium output |

| Water-drop Hammer Mill | Higher efficiency and finer grinding of concentrates |

| Air Delivery System (optional) | Reduces dust during processing |

3. Batching and Mixing

After grinding, ingredients should be measured by cattle type, keeping the right forage-to-concentrate ratio.

Use multi-silo batching to weigh materials separately. For formulas with liquids like molasses or oil, mixers with spraying devices ensure even blending and prevent clumps.

Dairy rations with more forage may pile up, so a forced-turning or double-shaft paddle mixer is recommended for smooth mixing.

Suggested Mixing Equipment

| Equipment | Purpose |

| Single-silo Batching System | For simple concentrate formulas, small-scale on-farm use |

| Multi-silo Auto Batching | Precise multi-ingredient ratios, continuous production |

| Vertical Mixer | Mixing small batches of raw materials |

| Horizontal Mixer | Even mixing, suitable for adding liquids like molasses or oil |

| Liquid Adding System | Sprays molasses, oil, and other liquids evenly into the mix |

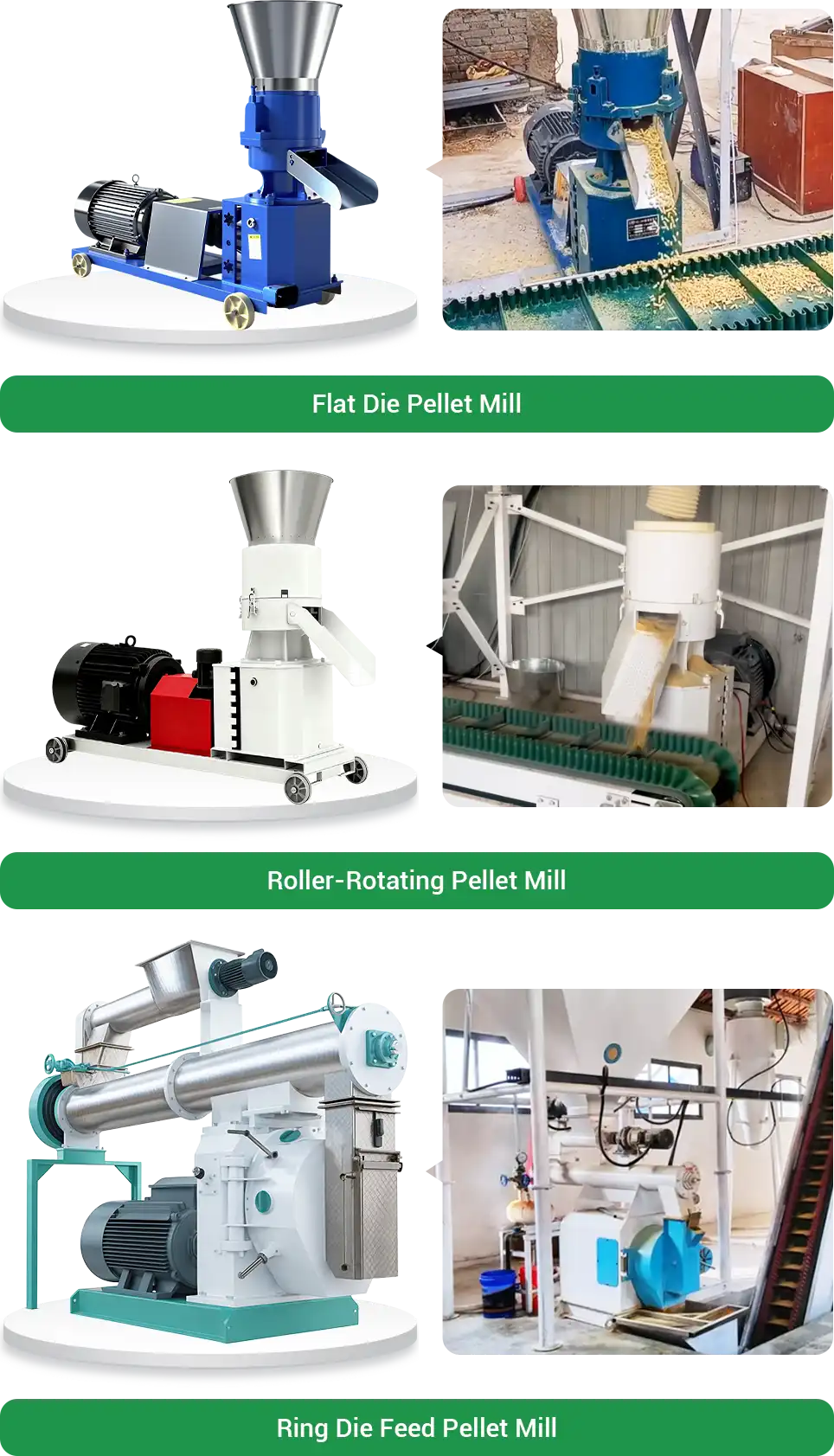

4. Pelleting

Pellet mill choice has a direct impact on feed quality and output. Selection depends on daily capacity, forage ratio, and whether the feed is for beef or dairy cattle.

Flat die pellet mills suit users making less than 1 ton per day. They are compact and easy to run. For larger or commercial lines, ring die pellet mills handle continuous, heavy-duty work more efficiently.

Pellet diameter should also match cattle needs at different growth stages.

Recommended Pellet Machines

| Equipment | Purpose |

| Flat Die Pellet Mill | Efficient pressing of standard concentrate feed |

| Roller-driven Pellet Mill | High-efficiency pressing of high-fiber forage |

| Ring Die Pellet Mill | Large-scale, continuous industrial production |

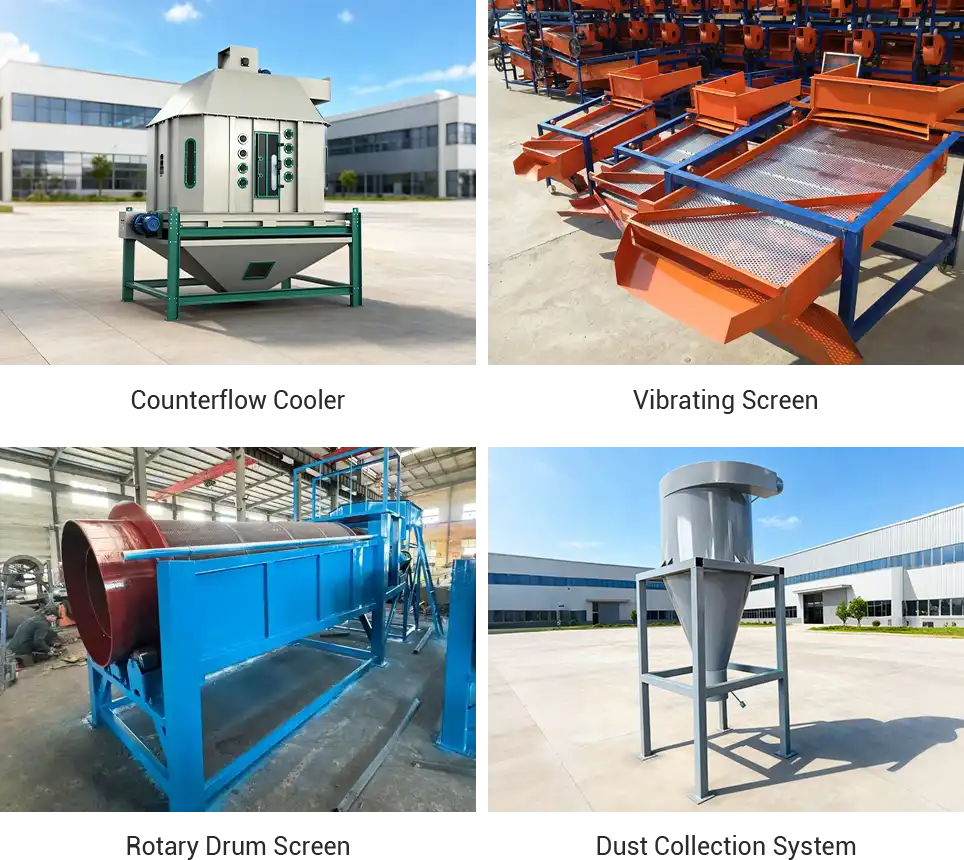

5. Cooling and Screening

Pellets can reach 80–90°C during pressing. If not cooled in time, they may crack, mold, or absorb moisture again. Dairy feed, with higher forage and liquid content, needs stricter control to keep moisture under 13.5%.

After cooling, pellets should be screened to remove fines and dust. Excess fines not only hurt appearance but also make cattle picky, leading to uneven intake. For beef, this slows weight gain; for dairy cows, it can disturb rumen function and lower milk yield.

Suggested Cooling & Screening Equipment

| Equipment | Purpose |

| Counterflow Cooler | Efficient cooling and moisture reduction |

| Air Cooling System (small lines) | Simple design, used for small-batch pellet cooling |

| Vibrating Screen | High-precision screening of pellets and fines |

| Rotary Drum Screen | Low power use, ideal for high-capacity prescreening |

| Dust Collection System | Controls dust and improves workshop environment |

6. Weighing and Packaging (if for sale)

This step is mainly for market sales. Automatic weighing and packing ensure accurate bag weight, making feed easier to transport, store, and sell. Moisture-proof and insect-proof bags also help extend shelf life.

For self-use or small farms, bulk storage or a finished feed silo can be used instead, but protection against moisture and pests is still important.

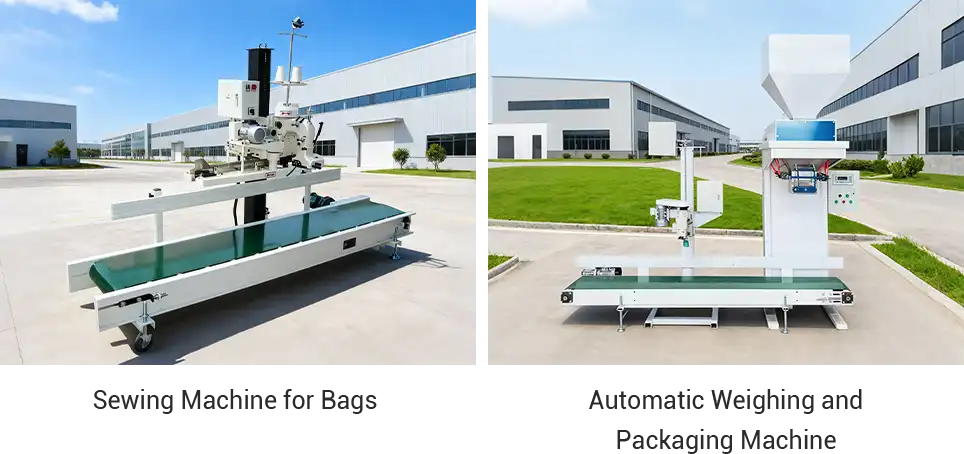

Suggested Weighing & Packing Equipment

| Equipment | Purpose |

| Finished Feed Silo | Stores pellets for bulk use or manual bagging |

| Bag Sewing Machine | Seals bags after manual filling |

| Automatic Weighing & Packing Machine | Weighs, bags, and seals in one unit |

Production Line Setup Reference

1. Small-Scale Basic Line

Equipment Included

Chaff Cutter,Vertical Mixer,Rotating Roller Pellet Mill,Screw Conveyor (for auxiliary feeding).

2. Full Commercial Production Line

Equipment Included

Chaff Cutter,Water-Drop Hammer Mill,Horizontal Mixer (Twin Paddle),Buffer Silo,Ring Die Feed Pellet Mill,Belt Conveyor,Counterflow Cooler with Screening and Dust Collection,Automatic Weighing and Packing Machine.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.