How to Make Grass Pellets with Pellet Machine

Grass is a common feed, but direct feeding often wastes it. It can also absorb moisture, mold, and is difficult to store, making it hard to manage nutrition. Compressing grass into pellets is more efficient, cost-effective, and easier to handle. This article explains the pellet production process, suitable raw materials, and equipment selection to help you better utilize grass and boost farming efficiency.

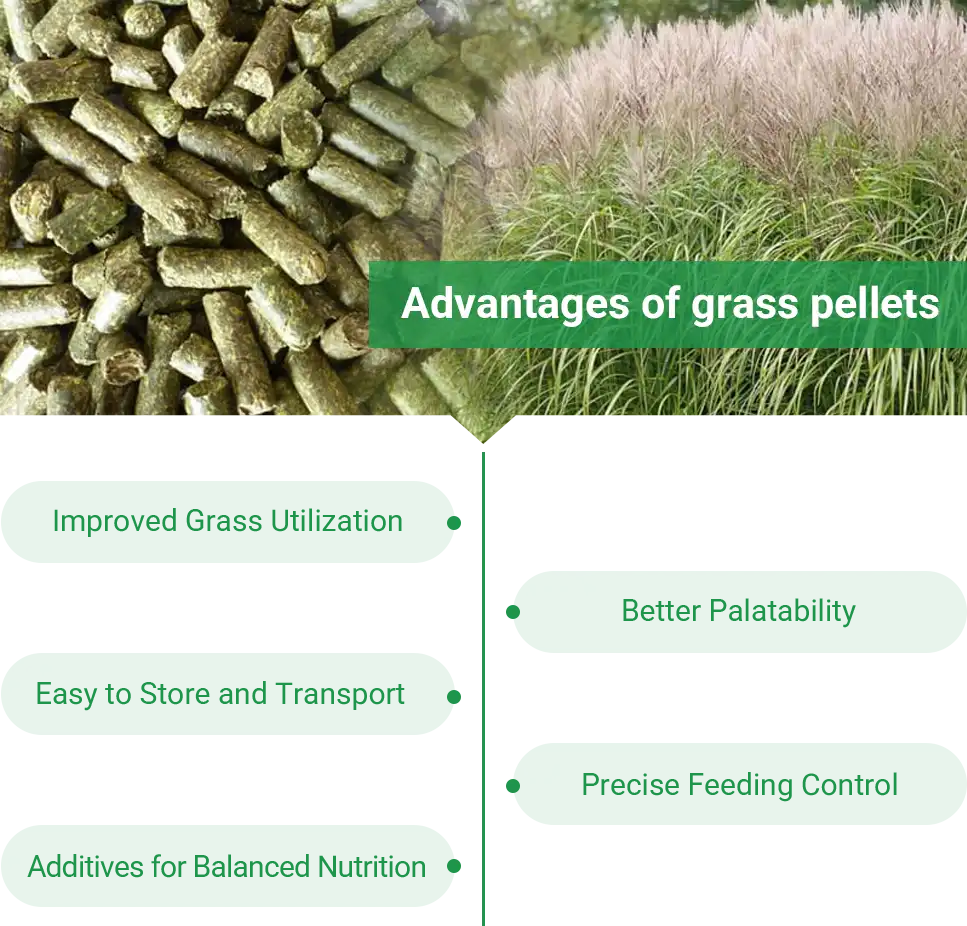

Why Turn Grass into Pellet Feed

Turning grass into pellets makes storage and transportation easier, while boosting feeding efficiency. Pellets are ideal for automated, precise feeding, reducing labor and simplifying management. They also break down fiber for better digestion and stable nutrition for ruminants, making them a practical choice for efficient farmers.

The specific advantages of pelletized grass include:

- Improved grass utilization, reducing waste

- Better palatability, increasing intake

- High density, easy to store and transport

- Precise feeding control, saving labor

- Easily mixes with concentrates and additives for balanced nutrition.

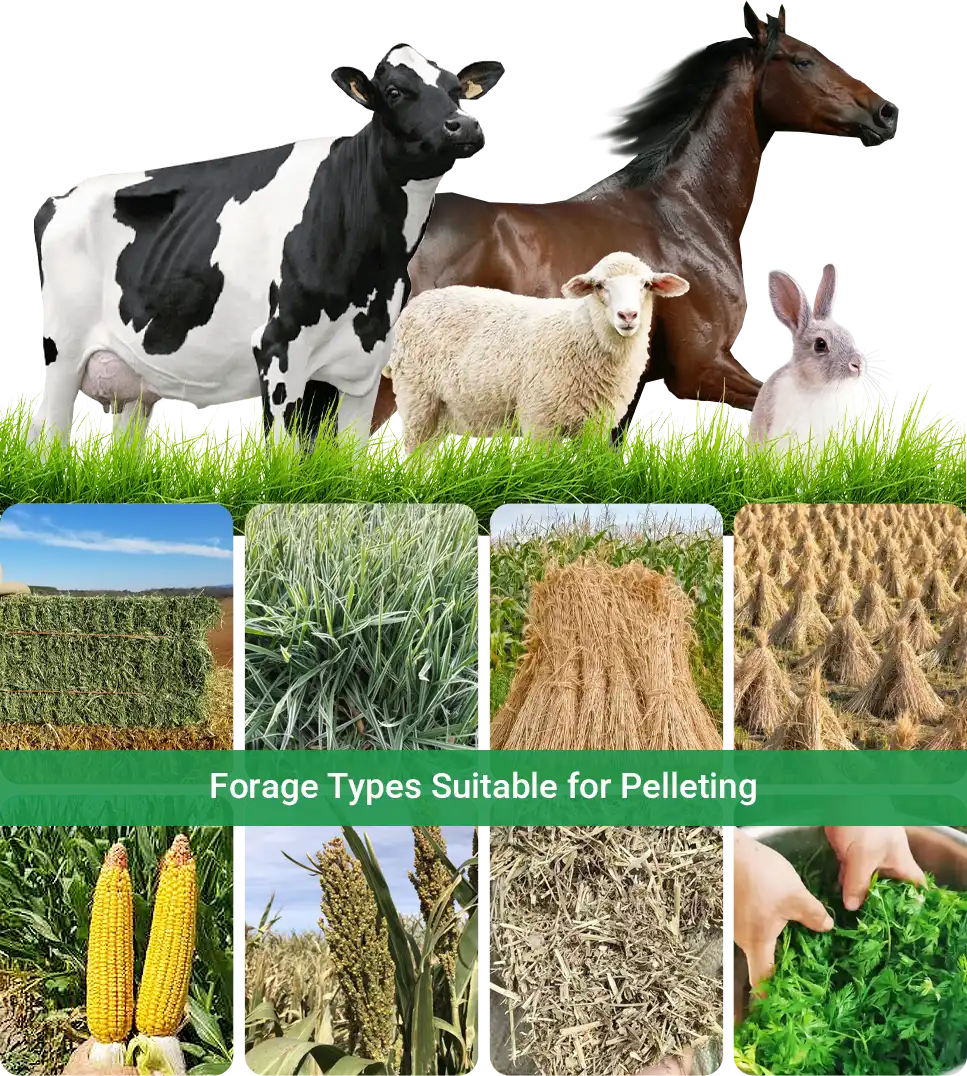

Types of Grass Suitable for Pelletizing

Pelletizing is an efficient and convenient method for processing forage and roughage. However, not all grasses are suitable for pellet production. Grass with moderate fiber, controllable moisture, and easy crushability are ideal for pelleting. Here are some common types of grass and raw materials suitable for this process:

| Grass Type | Common Raw Materials | Suitable Animals |

| Hay | Alfalfa hay, clover hay, ryegrass hay, oat hay, Timothy hay, Bermuda grass | Cattle, sheep, horses, rabbits |

| Straw | Corn straw, wheat straw, rice straw, sorghum straw | Cattle, sheep |

| Silage | Corn silage, sorghum silage, ryegrass silage | Cattle, sheep |

| Crop Vines | Peanut vines, soybean vines, sweet potato vines, sugarcane leaves, carrot leaves | Cattle, sheep, horses |

Note: Wet grass materials (such as fresh grass or freshly harvested forage) are difficult to pellet and should be properly dried or conditioned before processing.

Source: Alternative Feeds for Ruminants

Grass Pellet Production Guide

The key to making grass pellets is using a pellet mill to shape the crushed grass. The mill's stability and compression affect the pellet's density and consistency. Additional equipment for chopping, grinding, mixing, drying, and cooling is also needed to complete the process from raw material to pellets.

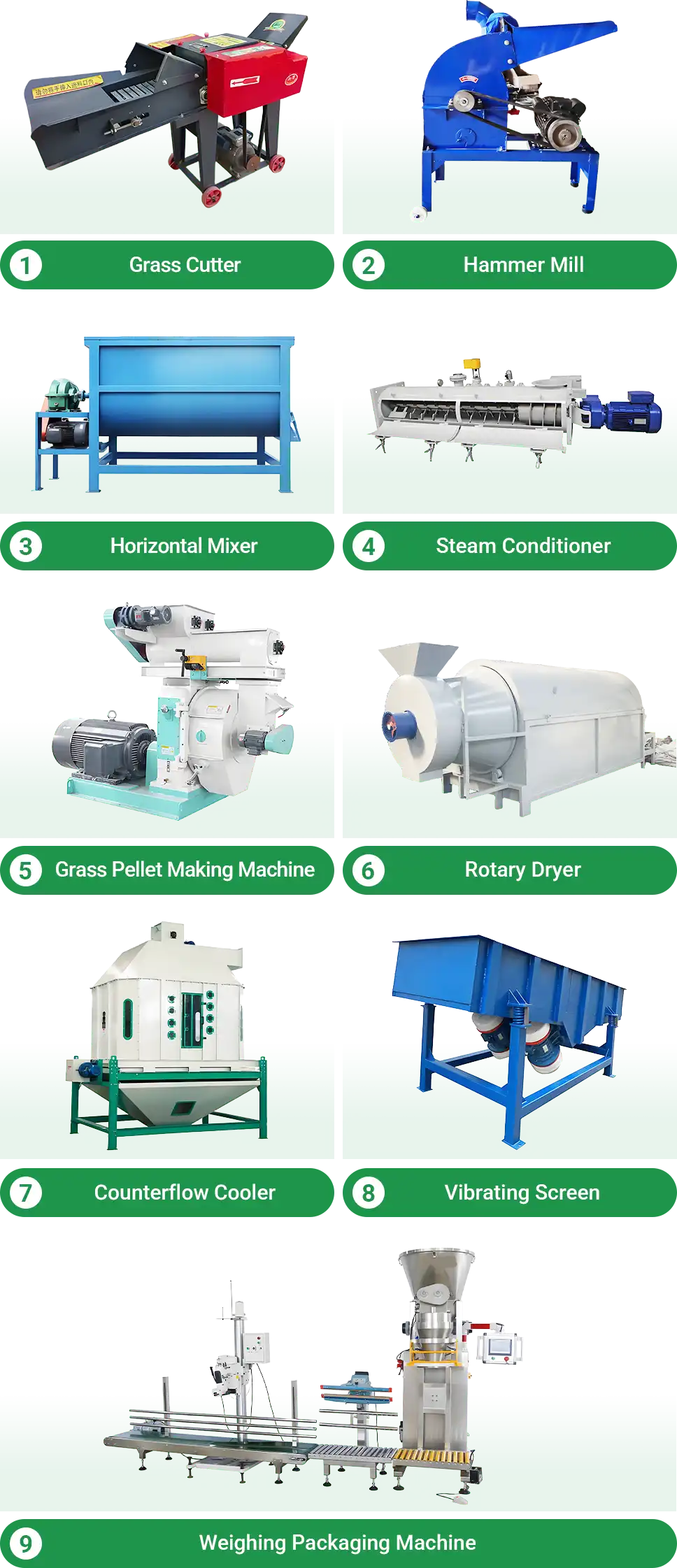

Required Equipment

Here is the equipment list for a complete grass pellet production line. The configuration can be adjusted based on actual production capacity and budget.

| Processing Stage | Required Equipment |

| 1. Raw Material Handling | Grass Cutter |

| 2. Grinding | Hammer Mill / Forage Grinder |

| 3. Mixing | Horizontal Mixer / Vertical Mixer |

| 4. Conditioning (Optional) | Steam Conditioner |

| 5. Pelletizing | Grass Pellet Making Machine |

| 6. Drying | Rotary Dryer / Hot Air Dryer |

| 7. Cooling | Counterflow Cooler |

| 8. Screening | Drum Screen / Vibrating Screen |

| 9. Packaging | Weighing Packaging Machine / Sewing Machine |

For small-scale farming or home users

There's no need to set up a full production line. Keeping only the essential equipment can save costs. Grass can be simply chopped, then processed with a small grinder before pelletizing. Mixing, cooling, and drying can be done manually or by air-drying.

The process is simple, low-cost, and suitable for daily use or small-scale production.

Step-by-Step Process

1. Chop the Grass

Use a grass cutter (such as a pull-type, drum-type, or vertical model) to cut baled grass into 5–8 cm pieces. If the pieces are too long, they may tangle in the grinder and slow down feeding. If it is too short, grinding becomes harder and uses more energy.

2. Grinding

Feed the chopped grass into a grinder. Use a screen size suited to your needs (3–5 mm is common). An ideal final size is around 1–4 mm.

For straw materials, keep the blades sharp and control moisture between 12–18%. Too dry causes dust; too wet can clog the machine.

3. Mixing Ingredients

Blend the ground grass with other ingredients to balance nutrition and improve pellet quality. Add based on the animal's growth stage and dietary needs:

- Cornmeal (for energy)

- Soybean meal or cottonseed meal (for protein)

- Wheat bran or rice bran (for palatability)

- Minerals or premix (for trace nutrients)

Load ingredients into the mixer. Mix for 3–6 minutes. For larger batches, use continuous mixing. Start with main powders like grass or corn, then add lighter materials like premix.

If needed, spray a small amount of water to improve mixing and reduce separation.

4. Conditioning (Optional)

Conditioning softens the grass powder by adding heat and moisture, making it easier to press into pellets.

Steam can be used to heat the material to 70–90°C and raise moisture to 16–18%. For coarse or dry grass, this step greatly improves pellet quality.

5. Pelletizing

Grass fibers are long and springy, which makes pelletizing more difficult. Pay close attention to die size, roller gaps, and feeding rate.

Choose the right die hole based on the animal. A compression ratio of at least 1:8 is recommended. Loose compression leads to powdery pellets, while tight compression can overload the machine.

Feed should be steady and even. A screw feeder is recommended for better control.

| Animal | Recommended Pellet Diameter (mm) |

| Sheep, Goats | 4–6 |

| Cattle (Beef, Dairy) | 6–10 |

| Horses | 8–10 |

| Rabbits | 4–6 |

| Deer | 6–8 |

| Donkeys, Mules | 8–10 |

If you're unsure about the equipment setup, feel free to contact us. We'll recommend the right solution based on your raw materials and production needs.

6. Drying

Fresh pellets have high moisture and should be dried to below 12% for storage. For larger output, use hot air or rotary dryer. For smaller batches or dry raw materials, air drying is also an option.

7. Cooling

After drying, pellets are still warm. Cool them to room temperature before packing. A counterflow cooler works well for large-scale use. For small batches, air cooling is fine, but keep the area ventilated to prevent moisture buildup.

8. Screening and Packing

To ensure consistency, use a screener to remove loose powder for reuse. Packing can be done with an automatic scale and bagging machine, or by hand.

FAQ

What animals can eat grass pellets?

Grass pellets are ideal for all herbivores, including cattle, sheep, horses, rabbits, deer, and donkeys. They can also supplement the diet of omnivores like geese and turkeys. Pellet size should match the animal, typically 6–10 mm.

Can grass pellets replace concentrate feed?

Not completely. Grass pellets mainly provide fiber and some energy, which are important for ruminants, but the nutrition is limited. You'll still need to add corn, soybean meal, and mineral premix for a balanced diet.

How do I know if the pellets are good quality?

Good pellets are firm, even in size, smooth on the surface, and don't break easily. They should have no cracks or strange smell.

Can grass pellets be stored long term? Will they mold?

Yes, if the moisture is below 12% and they're kept in a dry, well-ventilated place. Shelf life is 6 to 12 months. Use moisture-proof bags and avoid stacking directly on floors or walls, especially in humid areas.

Why do some pellets look darker or yellowish?

Darker color is usually caused by high drying temperatures or long pressing time. It can also be due to high sugar content or changes in the mix. Slight darkening is normal but burnt smell or blackening may indicate a problem with temperature or moisture control.

Grass Pellet Machine for Sale

If you're looking for a pellet machine to process hay, alfalfa, corn stalks, or other forage materials, we offer a range of machines to fit different output needs and budgets.

Flat Die Pellet Mill (Rotating Roller Type)

This model features a fixed die with rotating rollers, ideal for moist grass materials. It can pelletize without pre-mixing.

- High pressure, great for alfalfa, straw, and other fibrous materials

- Produces dense, firm pellets that hold their shape

- Stable structure, suitable for long working hours

- Recommended capacity: 200–1000 kg/h

Flat Die Pellet Mill (Rotating Die Type)

This model features fixed rollers and a rotating die. With a compact design and affordable price, it's suitable for pelleting dry grass powder mixed with concentrate feed.

- Small footprint, great for low-budget setups

- Easy to operate and maintain

- Best for dry, finely ground grass powder

- Recommended capacity: up to 500 kg/h

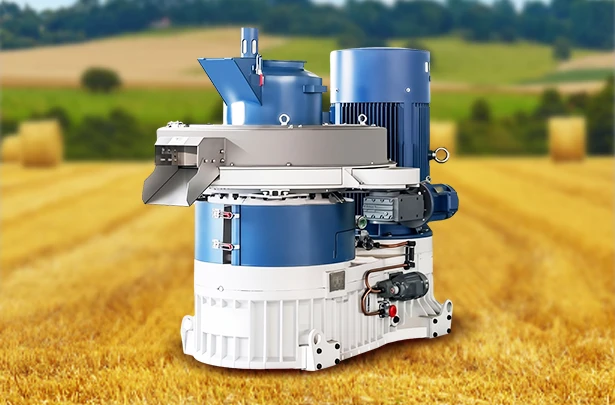

Ring Die Pellet Mill

Built for commercial and large-scale production, commonly used in feed plants, farms, and biomass projects.

- High output: 1–5 tons per hour

- Low energy use per ton, ideal for continuous production

- Optional steam conditioner for better pellet quality and digestibility

- Durable and suitable for full-automatic production lines

- Recommended for large farms, feed mills, or pellet processing plants

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.