Softwood Pellet Production: Value, Market & Setup Guide

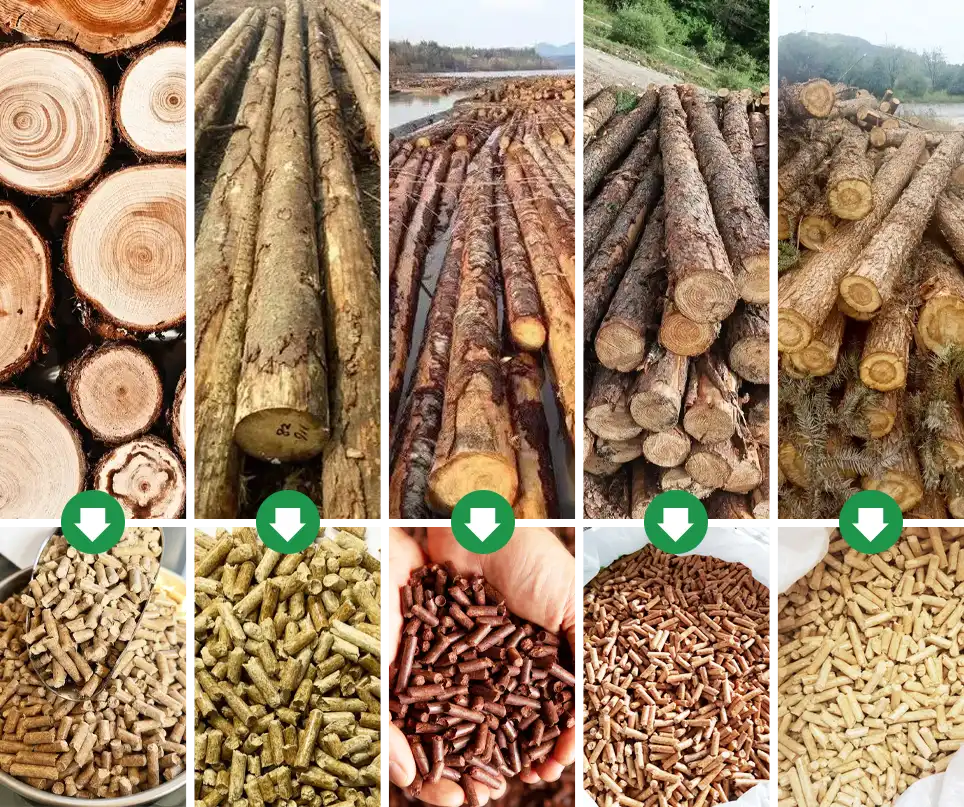

Softwood pellets, made from coniferous sawdust like pine, spruce, and hemlock, deliver high heat, low ash, and form easily. They're easier to source and cheaper to process than hardwood pellets, making them a cost-effective choice for heating, boilers, and pet bedding. This article covers their key properties and production value.

What Is Softwood

Softwood pellets are solid biofuel made by compressing sawdust from coniferous trees like pine, spruce, and hemlock using pellet machines. As a type of wood-based biomass pellet, they feature a dense surface and stable structure, typically measuring 6–10 mm in diameter and 10–30 mm in length.

Softwood contains more natural resin, giving the pellets higher heat value and good compressibility. This results in high forming efficiency, uniform shape, and strong durability. Compared to hardwood, softwood has lower density and longer fibers, making it easier to dry and grind. This makes it a popular choice for pellet production.

Performance of Different Softwood Pellet

Softwood comes from a wide range of sources, and sawdust from different coniferous trees can produce pellets with varying properties. Below is a brief comparison of some common softwood materials.

Performance Reference Table

Different conifer species show noticeable differences in calorific value, ash content, density, and moisture level.

| Tree Species | Calorific Value (MJ/kg) | Ash Content (%) | Density (kg/m3) | Moisture (%) |

| Pine | 19.0–20.0 | 0.5–1.0 | 650–750 | 6–8 |

| Spruce | 18.5–19.5 | 0.3–0.6 | 620–700 | 6–8 |

| Hemlock | 17.5–18.5 | 0.8–1.2 | 600–700 | 6–9 |

| Larch | 19.0–20.0 | 1.0–1.5 | 700–750 | 6–8 |

| Chinese Fir | 17.5–18.5 | 0.5–0.8 | 600–680 | 6–9 |

Source: Wood Fuel Handbook & FAO Handbook

Larch pellets offer high heat value but produce more ash, requiring better corrosion resistance from the burner. Spruce pellets burn cleanly with very low ash, making them ideal for premium household pellet stoves. Although Chinese fir has a lower heat value, its natural scent and moisture absorption make it popular in pet products.

* Specific values may vary depending on moisture content, impurities, and processing methods.

Hardwood vs Softwood Pellets

| Property | Softwood Pellets | Hardwood Pellets | Straw Pellets | Rice Husk Pellets |

| Calorific Value (MJ/kg) | 17.5–20 | 18–19.5 | 14–16 | 13–15 |

| Ash Content (%) | 0.3–0.7 | 0.5–1.0 | 4–8 | 15–20 |

| Combustion Efficiency | High | High | Medium | Low |

| Slagging Risk | Low | Low | High | Very High |

| Pelletizing Difficulty | Low | Medium | High | High |

Source: Agricultural Residues as Biomass Energy & ENplus Handbook Part 3

Softwood pellets have a slightly higher upper heat value. While they don't burn as long as hardwood, they ignite easily and produce less ash. Compared to other biomass materials, softwood offers a better balance of combustion efficiency and ease of use, making it suitable for continuous and large-scale operations, though the material cost tends to be higher.

Overall, softwood comes in many varieties, each with distinct traits in combustion, scent, and moisture absorption. These differences give softwood pellets a wide range of uses, from clean-burning fuel to pet products, with each tree species offering its own unique value.

Softwood Pellet Market Outlook

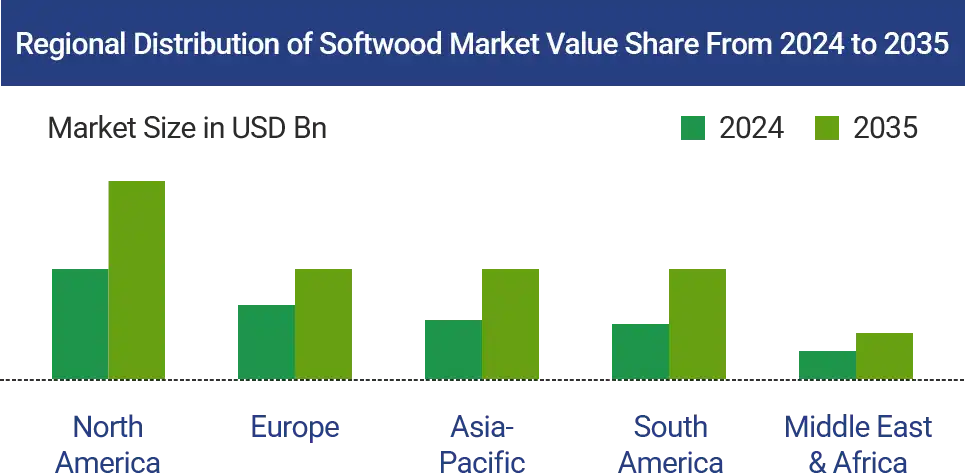

The global wood pellet market was valued at around USD 13.6 billion in 2024 and is expected to grow steadily at 16.4% per year from 2025 to 2034. By 2030, it's projected to exceed USD 24 billion. Softwood pellets, known for their high heat value and low ash content, have become the preferred choice for home heating and industrial boilers. In fact, softwood accounts for the largest share of the entire wood pellet market.

The softwood pellet industry is expanding across multiple regions. North America held the leading position in 2024, supported by abundant forest resources, strong export capacity, and widespread use of softwood in residential heating. At the same time, the Middle East and Africa are emerging as high-growth markets, fueled by urbanization, energy transitions, and growing demand for clean heating solutions.

Regional Market Share of Softwood Pellets (2024–2035)

In addition to North America and emerging markets, Asia-Pacific is showing strong momentum. Rapid industrial growth and policy support are opening up new demand, especially in power generation, heating, and packaging. The need for renewable fuels in the region continues to rise.

Overall, softwood pellets are gaining global traction as a biomass pellet fuel that combines clean combustion with environmental benefits. The market is entering a phase of structural growth, with a broader and more diverse landscape ahead.

How to Start Softwood Pellet Production

Softwood pellets burn well and are in high demand. They've become a key player in the biomass energy market. So, how do you get started in this field? Whether you're launching a new business or expanding production, the first step is to understand your raw materials, process, and equipment clearly.

Raw Material Access

The feasibility of a softwood pellet project starts with raw material availability-whether it's sufficient, easy to source, and stable.

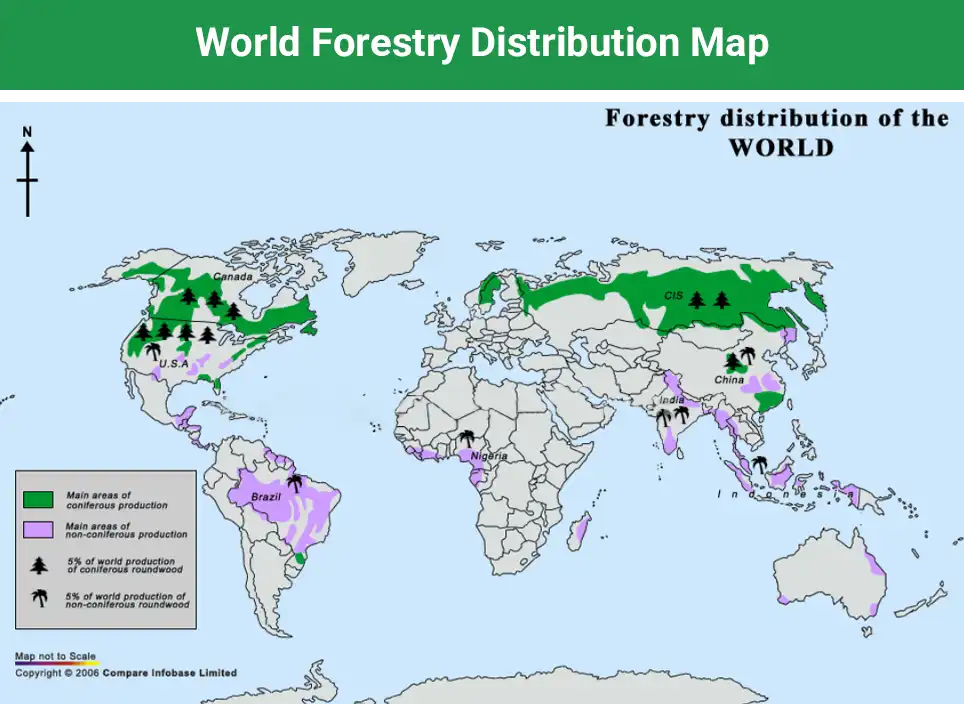

Pine, fir, spruce, and similar softwood species are widely found in North America, Europe, Russia, and parts of Asia and South America. The ease, cost, and quality of sourcing depend on local forestry development and the maturity of the wood processing industry.

When setting up a softwood pellet plant, choose a site near pine, fir, or spruce to easily source sawdust from local mills. Secure stable supply through long-term or recycling deals. For scattered or seasonal materials, use flexible storage or small collection points.

Set up basic systems like drying, crushing, and screening, and adjust sourcing based on local supply and plant scale to keep costs low and quality consistent.

Production Tips

- Start with small to medium capacity to keep investment and trial costs under control.

- Choose pellet machines with stable structure and easy operation, suited for softwood fiber.

- Plan proper discharge, cooling, and storage to prevent moisture buildup.

- For exports, prepare early for certified production standards and packaging.

- Set up basic quality checks to improve consistency and build trust with buyers.

Key Considerations

Keep raw material moisture between 12–15%. This helps pellets form better and reduces fines. Softwood has high resin content, so monitor die temperature during pelletizing. Overheating can cause burnt pellets, discoloration, or sticking. After pelletizing, allow full cooling and good ventilation to avoid cracking or moisture absorption.

Fine dust is common during processing and feeding. Use bag or pulse dust collectors to reduce cleanup and safety risks. Also, check key quality indicators like ash content, density, and pellet length regularly to maintain consistency.

Pellet Production Line Overview

Pine, fir, and spruce differ in structure, resin content, and fiber length, which influence pellet quality and equipment selection. Production scale also affects the setup and cost.

To help you choose the right solution, we've prepared several focused guides based on raw material and output needs.

Pine Pellets Market Insights and Production Line Setups

Softwood pellets offer a strong balance of performance, cost, and flexibility. With stable raw material access, efficient processing, and growing market demand, they provide a solid foundation for production.

If you're planning a pellet project or want to explore equipment options, cost estimates, or plant layout, we're here to help. Contact us for a tailored solution.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.