Pine Pellets Market Insights and Production Line Setups

Pine is one of the most widely grown fast-growing trees in the world. During processing, up to 20–30% of its by-products, like sawdust and wood shavings, are available for use. These are often turned into fuel pellets. Thanks to its strong fiber structure, high lignin content, and low ash, pine also works well in absorbents and composite materials. Whether you want to use existing waste or start a new project, pine pellet production is worth considering.

Why Process Pine into Pellets

Pine is a common softwood with a natural scent, good moisture absorption, and is safe to use. However, it's often found as loose sawdust or scraps, which are hard to store, transport, or sell directly. Pelletizing turns it into dense, uniform pieces that are easier to pack and use. It boosts value and creates more ways to use it.

Benefits of Pine Pellets

- Meet market standards for cleanliness and size

- Easy to pack, store, and transport

- Low dust, clean to handle, and user-friendly

- Suitable for fuel, pet bedding, livestock, and gardening

- Make full use of wood waste and increase product value

Common Uses of Pine Pellets

Pine pellets are not just for heating and power. They're also widely used in pet care, livestock farming, and gardening. As demand grows for eco-friendly and natural products, wood pine pellets are moving beyond fuel into higher-value consumer markets.

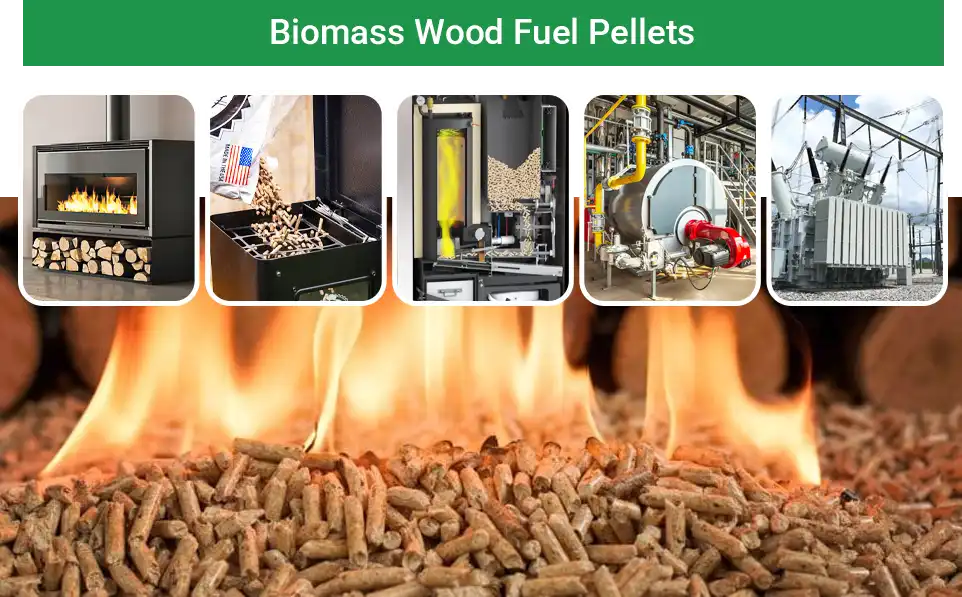

Biomass Wood Fuel Pellets

Pine pellets have high heat value, low ash, and stable shape. They burn efficiently and cleanly, making them ideal for fireplaces, BBQs, water heaters, industrial boilers, and power plants. With reliable performance and broad adaptability, they are widely used in Europe, Korea, and Japan, making pine one of the most common pellet fuels today.

| HHV (MJ/kg) | LHV (MJ/kg) | Ash Content | Moisture Content | Pellet Density |

| 19.0–20.5 | 17.5–19.0 | 0.3%–1.0% | 6%–10% | 600–700 kg/m3 |

Data from: Grand View Research

Higher Heating Value (HHV) refers to the total energy released during combustion, including the heat from condensing water vapor.

Lower Heating Value (LHV) is the usable energy in practice, excluding that condensation heat.

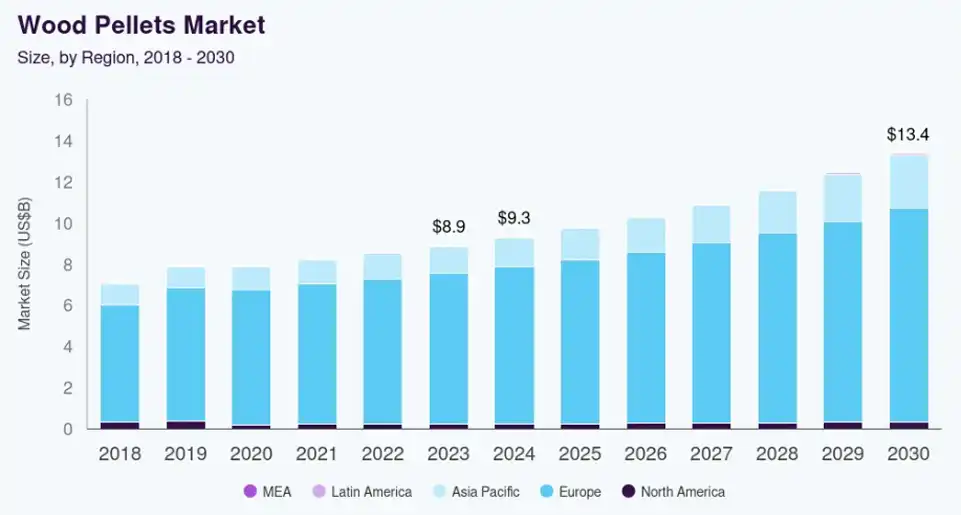

As demand for clean energy grows, the global wood pellet market continues to expand. By 2030, it is expected to exceed $13.3 billion, with an annual growth rate of 6%–7%. Among all sources, pine wood pellets remain a leading softwood option, playing a key role in the fuel pellet market.

Data from:Wood Pellets Market

Pine's advantage lies not only in its performance but also in its stable supply chain and wide availability, making it ideal for long-term production and export. Compared to crop straws or mixed materials, pine pellets offer better consistency, work well with most stoves, and have a higher chance of meeting certification standards.

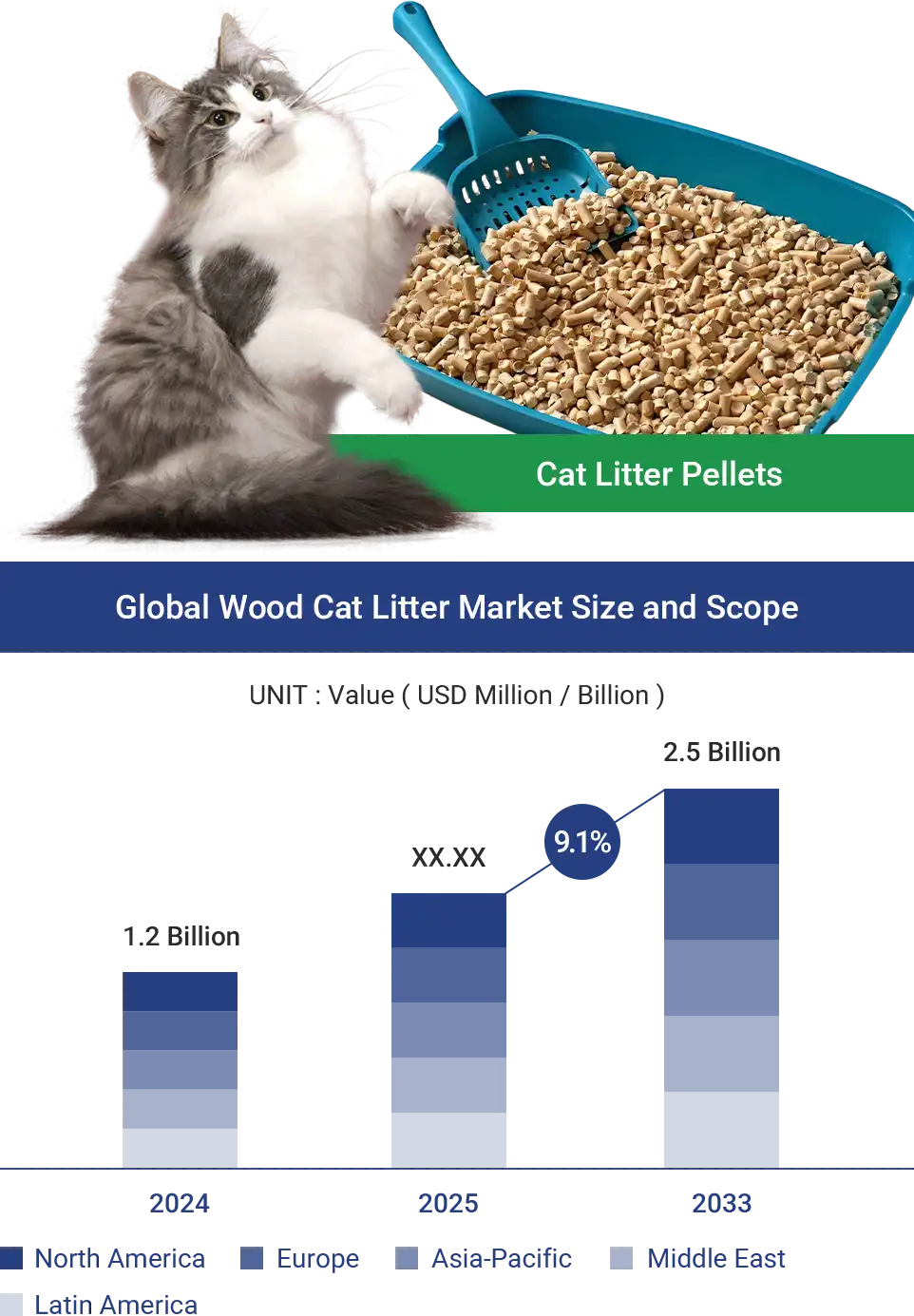

Cat Litter Pellets (High Value-Added Product)

Beyond heating, pine wood pellets are also widely used in pet products, especially as cat litter. Made without chemical additives, they carry a light natural wood scent and help neutralize odors from cat urine. When wet, the pellets break down into fine powder, locking in moisture and making cleanup easy.

Industry data shows that the global market for wood-based cat litter is growing at over 8% annually. With steady raw material supply and a better user experience, pine pellets are quickly becoming a popular alternative to traditional litter.

If you're interested in how cat litter is made, this article may be helpful: Make Biodegradable Cat Litter: Process & Equipment List.

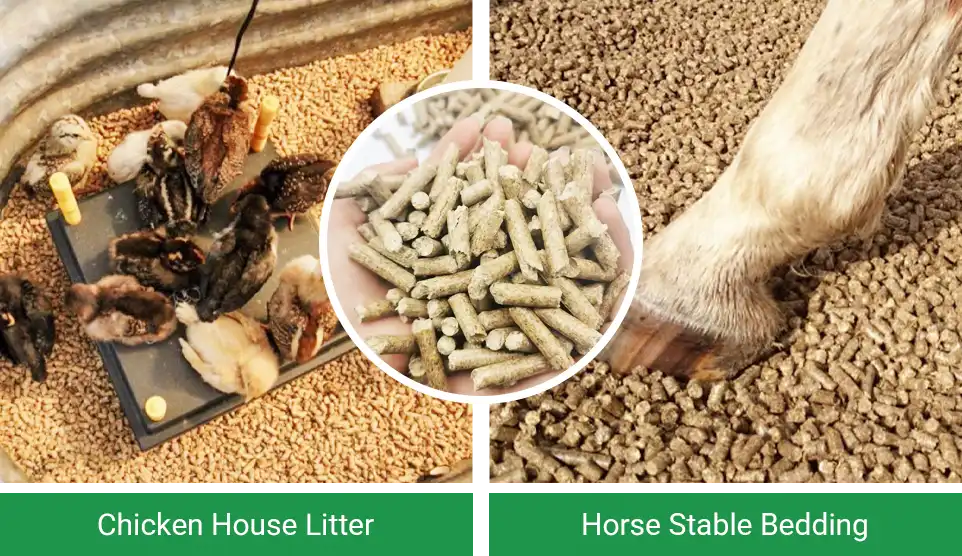

Livestock Bedding (Chicken Coops, Stables)

Pine pellets make clean and easy-to-use bedding for livestock. They absorb moisture quickly, lock in odors, and break down into powder after use. This helps keep the area dry and reduces ammonia and bacteria. Compared to husks or sawdust, pine wood pellets stay cleaner and are less likely to clump, which helps protect animals' feet. The natural wood scent is mild and pleasant. They're safe and ideal for chicken coops, pig pens, cattle barns, and especially horse stalls.

Pine pellets also work well for small pets like rabbits, hamsters, chinchillas, and guinea pigs. They're non-toxic, low in dust, soft underfoot, and gentle on the respiratory system. With strong absorbency and odor control, they're easy to clean and a popular choice for pet owners and breeders.

Garden Soil Additive

Pine wood pellets can also be used in gardening, either mixed into soil or as mulch. They improve aeration, drainage, and water retention while helping prevent soil compaction. As they break down, they release organic matter, support beneficial microbes, and boost soil health. Studies show wood materials can also enhance cation exchange capacity (CEC), improving nutrient retention and uptake.

Compared to loose sawdust, pellets are easier to spread, manage, and store. They're better suited for standard packaging and large-scale use. Pine pellets work well in flowers, vegetables, and fruit trees, making them a good fit for garden stores, nurseries, and home gardeners. With the rise of organic farming and home gardening, this market is growing fast and offers strong commercial potential.

Pine Pellet Production Line Setup

As pine pellets are used in more areas, market demand is becoming more diverse. Whether for livestock bedding, cat litter, or soil additives, users expect consistent size, cleanliness, and quality.

To meet these standards, a full production process is usually required, with matching equipment at each step. Below is a brief overview of the key machines involved in each stage.

Small-Scale Wood Pellet Production

This setup is ideal for users with access to raw materials who want to start small or expand gradually with low investment. It suits wood processors, farms, pet supply businesses, or small entrepreneurs looking to turn sawdust and scrap wood into value-added pellets.

Capacity: 1–4.5 T/H

Process Flow: Crushing Drying (optional) → Pelletizing → Cooling

Required Equipment

| Process Step | Main Equipment |

| Crushing | Wood Crusher / Hammer Mill |

| Drying (Optional) | Rotary Drum Dryer |

| Pelletizing | Flat Die Biomass Pellet Mill |

| Cooling | Storage Bin / Natural Air Cooling |

| Conveying | Screw Conveyor |

* Sawdust can be air-dried after crushing (keep moisture below 15%). Cooling can also be done naturally.

Suitable Raw Materials

Coarsely ground straw (corn, wheat, sorghum), forage grass, cotton stalks, peanut vines, rice straw, garden trimmings, coarsely ground rice husks, and animal manure (10–18% moisture). These materials are loose, fibrous, or high in impurities.

This small-scale production line is compact and easy to operate. It's ideal for quick startup and allows for gradual capacity expansion based on market demand. A practical choice for beginners or those looking to make use of existing raw materials.

Case Study:1T/H Small Wood Sawdust Pellet Production Line in China

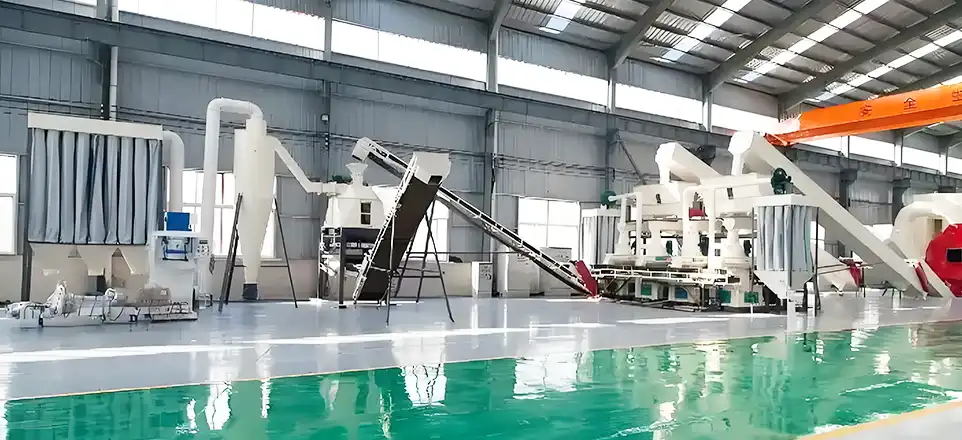

High-Capacity Wood Pellet Production Solution

For users with a steady supply of raw materials and plans to expand production, a ring die pellet line offers a more efficient and reliable option.

Compared to small-scale setups, this system delivers higher output, better pellet consistency, and more stable operation. It's well-suited for continuous production and bulk supply.

Capacity: 1–4.5 T/H

Process Flow: Raw Material Preparation → Crushing → Drying → Pelletizing → Cooling → Screening → Packaging

Main Equipment

| Process Step | Main Equipment |

| Raw Material Screening | Trommel Screen, Magnetic Separator |

| Coarse Crushing | Wood Chipper |

| Fine Crushing | Hammer Mill |

| Drying | Rotary Drum Dryer + Hot Air Furnace |

| Pelletizing | Ring Die Pellet Mill |

| Cooling | Rotary Cooler |

| Screening | Vibrating Screener or Trommel Screen |

| Dust Removal (Optional) | Bag Filter, Cyclone Dust Collector |

| Packaging | Automatic Packing Scale + Sewing Machine |

* Specific configurations can be adjusted or customized based on actual needs.

Suitable Raw Materials

Sawdust and wood shavings (from hardwoods and softwoods such as oak, pine, eucalyptus), bamboo powder, bagasse, finely ground corn stalks, corn cobs, coffee husks, peanut shells, rice husks (wear-resistant molds recommended), garden waste (after fine crushing), and dried animal manure (moisture ≤ 12%).

Customer Case

1T/H Cat Litter Production Line in China

Thailand Biomass Factory Boosts Output with New Pellet Line

3 T/H Corn Stalk Pellet Production Line in China

Choosing the right equipment means looking beyond specs. It's about matching your raw materials, output goals, budget, and plans.

We provide full pine pellet solutions from crushing to packaging. Suitable for different scales and uses, our machines are proven, easy to maintain, and customizable to help reduce costs while keeping production stable and consistent.

Planning to start a pine pellet project? Contact our team for tailored advice and a clear setup plan.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.