8 Common Biomass Fuel Pellets Compared

Biomass fuel pellets are small, dense cylinders made by compressing sawdust, straw, rice husks, and other agricultural or forestry waste under high pressure. They are widely used for home heating, industrial heat supply, and power generation.

Compared to fossil fuels like coal or natural gas, biomass pellets have higher energy density, produce less ash, and release fewer sulfur and nitrogen compounds. They are a cleaner and more efficient alternative.

In the early days, biomass pellets were mainly produced from forestry residues such as sawdust, bark, and branches. With rising demand for renewable energy, a wider range of agricultural waste is now used to make biomass pellets.

Today, there are eight common types of biomass fuel pellets, each made from a different raw material.

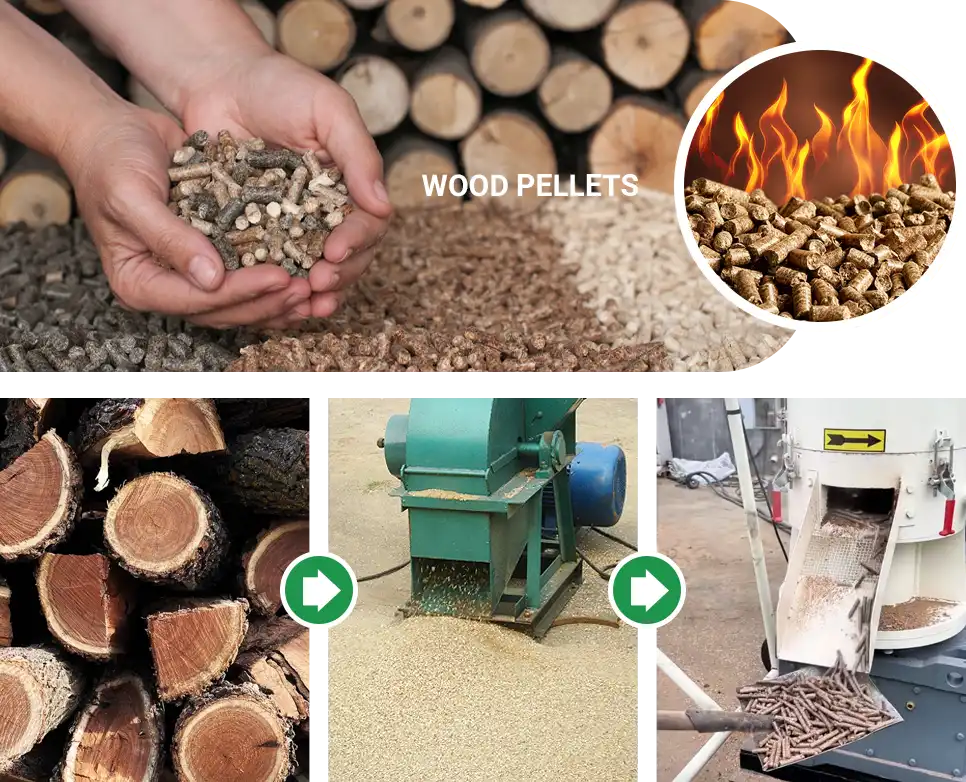

1.Wood Pellets

Wood pellets are the most widely used type of biomass fuel. They're typically made from sawdust or wood shavings that are dried, ground, and then compressed under heat and pressure into dense pellets.

Compared to other biomass pellets, wood pellets burn more steadily and work well with a wide range of heating systems.

Their calorific value typically ranges from 15.9 to 19.3 MJ/kg, with a low ash content of just 0.3% to 1%. That's why they remain one of the most popular biomass fuels today. Wood pellets are widely used for home heating, commercial heating, and power generation. They're especially effective in pellet stoves, hot air furnaces, and boilers-providing both efficiency and cleaner combustion.

2.Straw Pellets

Straw is one of the most common agricultural wastes used to make biomass fuel pellets. It's abundant, easy to collect, and often comes from crop residues like corn stalks, rice straw, and wheat straw. These materials are typically crushed, dried, and compressed into pellets.

Straw pellets usually have a lower calorific value than wood pellets, but still deliver usable energy-typically around 14–18 MJ/kg, depending on the crop type. They also tend to have a higher ash content, often around 5% even after pelletizing. This can lead to slagging at high temperatures. That's why straw pellets are mostly used for co-firing in industrial boilers, rural heating, or small-scale power generation.

In household pellet stoves, straw pellets work best with units equipped with strong ash removal systems. They can also be mixed with other pellet types to lower maintenance.

3.Paper Pellets

Waste rich in cellulose, such as used paper and pulp residue, can also be processed into fuel pellets. Thanks to their low cost and wide availability, paper pellets offer a budget-friendly alternative to traditional fuels.

They typically deliver 12 to 18 MJ/kg of energy, which is similar to straw-based pellets-and in some cases, even higher. However, their ash content is often higher than that of wood or straw pellets, depending on the paper quality. Clean paper without fillers, ink, or coatings tends to produce less ash. In contrast, low-quality or contaminated paper can lead to ash levels exceeding 5%.

Because of their energy output and ash content, paper pellets are mainly used in industrial boilers, often blended with other fuels.They're also a practical option for factories with access to paper waste, especially for small boiler systems. Paper pellets can also be used for power generation, but large-scale use requires proper combustion equipment and reliable ash handling systems.

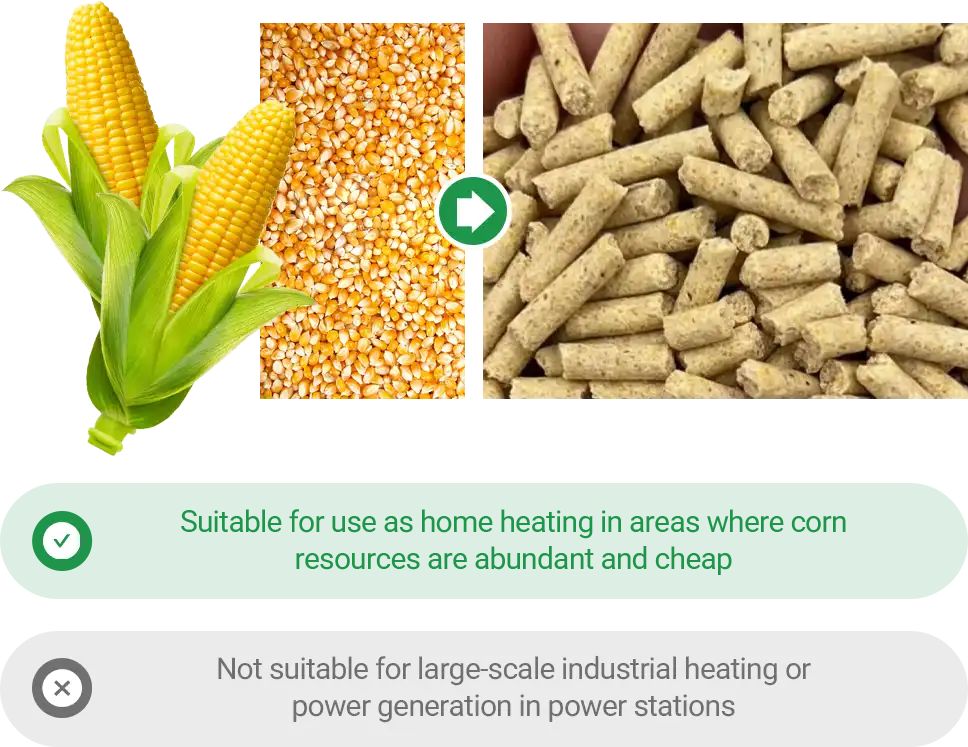

4.Corn Pellets

Most people know corn pellets as a type of animal feed. But with a fairly high energy value, around 16.3 MJ/kg, they can also be used as biomass fuel. Corn pellets typically have a low ash content of 1% to 1.5%.

However, the high sugar and oil content in corn can still cause slagging during combustion. That is why corn pellets work best in specialized corn stoves or multi-fuel systems equipped with stirring and ash removal features.

That said, corn is an edible crop and tends to be more expensive. Its price often fluctuates with the grain market. As a result, corn pellets are mainly used for home heating in regions where corn is abundant and affordable, such as the Midwestern United States. They are not ideal for large-scale industrial heating or power generation.

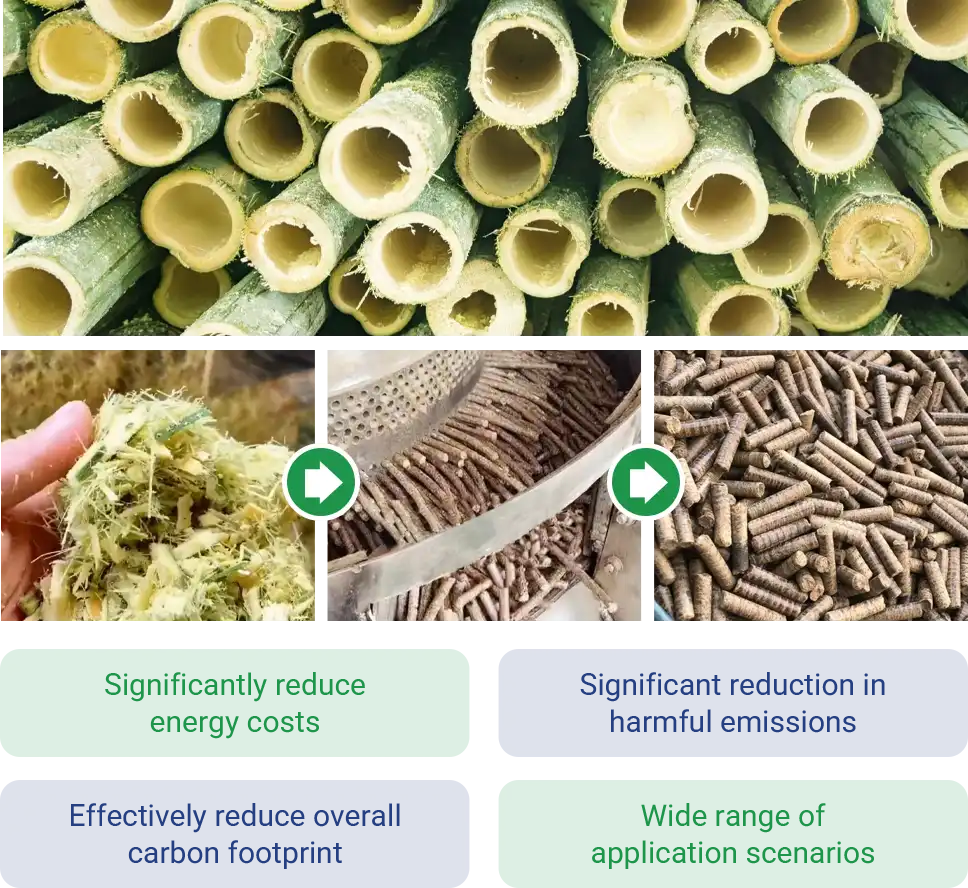

5.Bamboo Pellets

Bamboo is a fast-growing, woody grass that can be used as a sustainable biomass fuel. Bamboo pellets typically have a calorific value of 17 to 19 MJ/kg, with an ash content ranging from 0% to 1%.

They burn in a similar way to wood pellets. In most cases, they perform better than agricultural residues such as straw or grasses. Bamboo pellets can be used in many systems, such as industrial boilers, pellet stoves, fireplaces, commercial heaters, and biomass power plants.

In most cases, their price is close to that of regular wood pellets. In some regions, they can even be slightly cheaper. This is mainly because the market is still developing and use is limited to certain areas.

However, bamboo resources are often scattered, and transportation or collection costs may be higher in some areas. In regions where bamboo is abundant, such as China and Southeast Asia, bamboo pellets offer a clean and affordable fuel source.

6.Rice Husk Pellets

Rice husks are a major byproduct of the rice milling industry. Although they are naturally lightweight and have relatively low energy content, pelletizing them under high pressure increases both their density and combustion efficiency. This makes them a practical biomass fuel in the right setting.

Rice husk pellets typically deliver 15 to 16 MJ/kg of energy and have a high ash content of around 13%.

Because of this, they are not ideal for household heating. They are more often used in industrial boilers or biomass power systems with strong ash handling capabilities. In rice-producing areas, these pellets can be used locally as a low-cost and renewable source of energy.

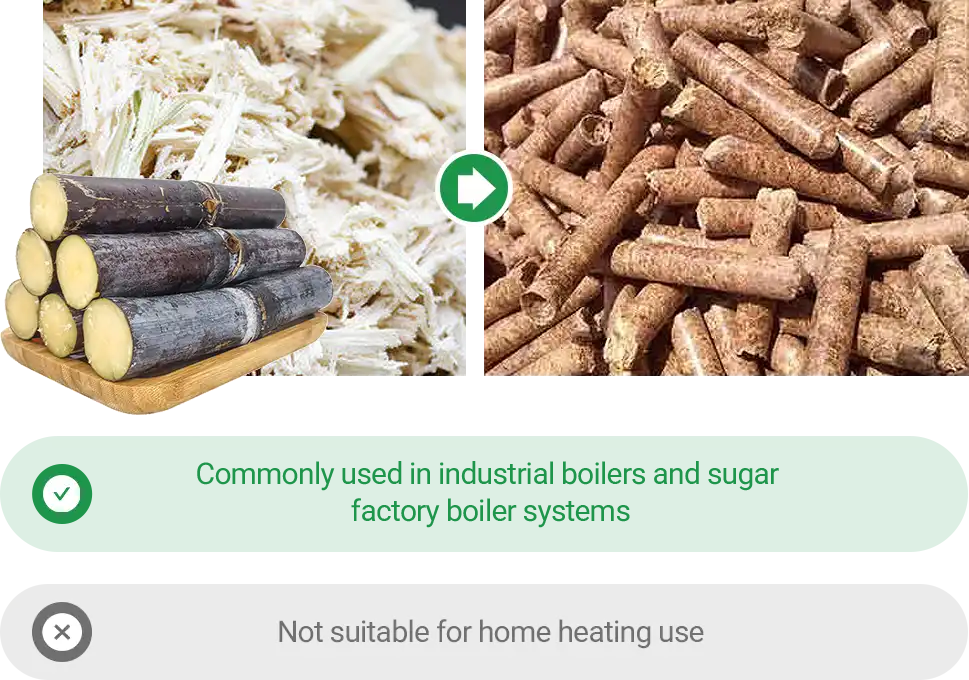

7.Bagasse Pellets

Bagasse is the fibrous material left after extracting juice from sugarcane or sorghum. Because it is widely available and cheap to collect, it is often used to make biomass fuel pellets.

Bagasse pellets provide a moderate energy output, usually between 14.2 and 17.6 MJ/kg. However, their ash content is relatively high, around 6.1%, which makes them less suitable for home heating.

They are mainly used in industrial boilers, especially in sugar mills where bagasse is already produced as a byproduct. In parts of Southeast Asia, these pellets are also exported to South Korea for use in power plants as a co-firing fuel.

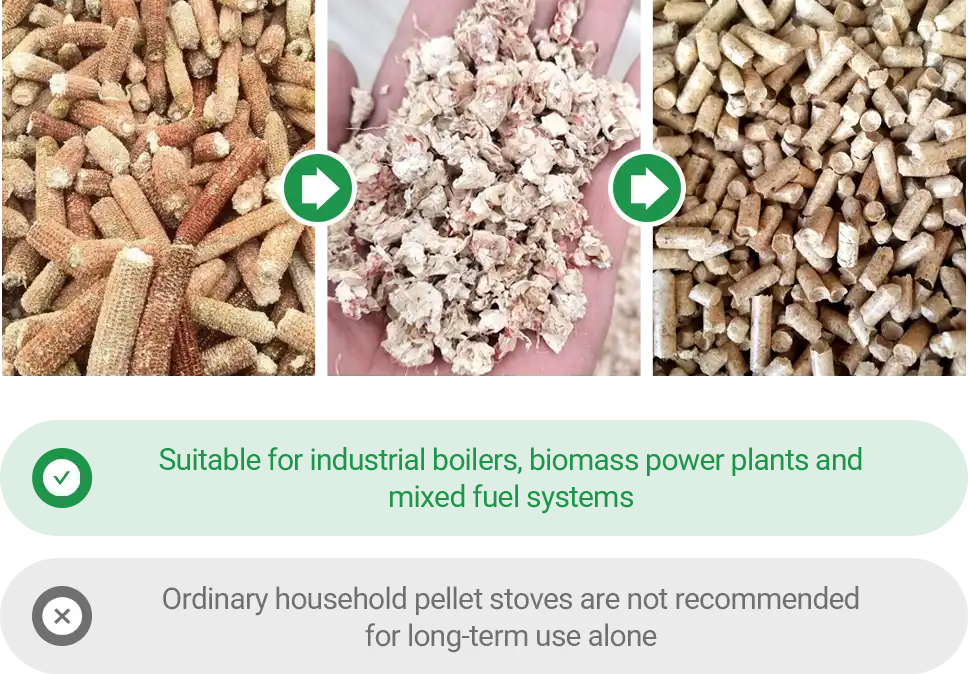

8.Corn Cob Pellets

Corn is one of the most widely grown crops worldwide, and its byproduct, corn cobs, is produced in large quantities. They are easy to collect and relatively inexpensive, making corn cob pellets a cost-effective fuel option.

These pellets provide a calorific value of around 16 to 18 MJ/kg and have an ash content ranging from 1.5% to 3%. Corn cob pellets work well in industrial boilers, biomass power plants, and multi-fuel systems, particularly when used with equipment that has strong ash-handling capabilities.

For household heating, they should be burned in specialized stoves equipped with effective ash removal systems. They are not recommended for long-term use in standard residential pellet stoves.

As you can see, different types of biomass pellets vary widely in terms of energy output and ash content. The following table offers a quick comparison of their key characteristics and common applications.

| Type | Calorific Value (MJ/kg) | Ash Content | Reference Price (USD/t) | Household Heating | Industrial/Power Use | Raw Material Availability |

| Wood Pellets | 15.9–19.3 | 0.3–1% | 180-240 | ✓ | ✓ | ✓ |

| Straw Pellets | ~18 | 2–3% | 80-120 | × | ✔︎ (Blended) | ✓ |

| Paper Pellets | 12–18 | 1–5% (depends on material) | 100-130 | ◐ | ✔︎ (Blended) | ✓ |

| Corn Pellets | ~16.3 | 1–1.5% | 200-245 | ◐ | × | ✓ |

| Bamboo Pellets | 18.4–20.1 | 0–1% | 140-150 | ✓ | ✓ | △ |

| Rice Husk Pellets | 15–16 | 6–7% | 75-120 | × | ✔︎ (High Ash Removal) | ✓ |

| Bagasse Pellets | 14.2–17.6 | ~6.1% | 160-260 | × | ✓ | △ |

| Corn Cob Pellets | 16–18 | 1.5–3% | 150-180 | × | ✓ | ✓ |

Note: ✔︎ = Suitable ✖︎ = Not recommended

◐ = Limited use under certain conditions

△ = Region-specific material, must be concentrated or located near factories to be economically viable.

(Prices are reference ranges and may vary depending on raw material source, regional transportation, processing standards, and market demand.)

In addition to the eight types listed above, other promising biomass fuel materials include peanut shells, cotton stalks, palm kernel shells, algae, coffee grounds, sludge, and waste fabrics. While these materials are less commonly used today, they still hold potential, especially in specific regions or for particular applications.

When selecting fuel pellets for everyday use, choosing the right type can greatly improve equipment efficiency. Whether for home heating, industrial heating, or emerging new energy projects, the combination and application of these materials should be continuously optimized.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.