Hardwood Biomass Pellets: Materials, Properties, and Uses

Hardwood pellets are a popular form of biomass fuel. They are known for their high energy content, low ash levels, and clean combustion. These qualities make them widely used in residential heating, biomass boilers, and industrial power generation. Hardwood pellets serve as a valuable alternative to traditional fossil fuels like coal.

The raw materials mainly come from hardwoods. However, the density and chemical composition of different tree species can vary, which affects the pellets' energy content, ash levels, and combustion properties.

If you're planning to start a related business, understanding the performance characteristics of different tree species is key to developing an effective production plan and ensuring pellet quality.

Common Hardwood Materials and Pellet Performance biomass fuel

Common hardwood pellet materials include four main types:

1. Oak

Oak primarily grows in temperate regions of the Northern Hemisphere, with a broad distribution across Europe (such as France, Germany, and Eastern Europe) and North America. Oak species are also found in parts of Northeast and Southwest China.

It is a medium-to-high-density hardwood, with a dry density ranging from 700 to 800 kg/m3. Its chemical composition is well-balanced, with cellulose making up about 40%, hemicellulose 25%, and lignin 20%. This composition helps form solid pellets. Oak pellets are dense and high in energy.

In terms of combustion, oak pellets have a calorific value of up to 18.7 MJ/kg. They burn steadily with a long-lasting flame. After removing the bark, the ash content can be as low as 0.5%–0.7%, ensuring a cleaner combustion process.

Oak's excellent physical and combustion properties make it popular in export markets and high-demand fuel applications.

(Learn more: Complete Process for Oak Pellet Fuel Production Line)

2. Birch

Birch is widely distributed in the cold temperate regions of the Northern Hemisphere, including Russia, Scandinavia, Canada, and Northeast China.

As a medium-density hardwood, birch typically has a dry density ranging from 620 to 650 kg/m3. This makes it easier to form pellets, reducing the pressure during pellet formation, which helps lower energy consumption and minimize mold wear. Its chemical composition consists of about 40% cellulose, 36% hemicellulose, and 20% lignin, providing a stable structure that supports pellet formation.

Birch pellets have a calorific value of approximately 17–18 MJ/kg. Although slightly lower than oak pellets, they burn evenly, produce a bright flame, and release heat steadily. The ash content is higher than that of oak pellets, around 1% (increasing when the bark is included).

Birch pellets ignite quickly because of their thin bark and high oil content. They ignite quickly and heat up fast, making them ideal for daily heating, especially for home stoves that require a rapid temperature rise or intermittent use.

3. Beech

Beech is a common hardwood in Europe, known for its hard, dense wood and thin bark. Its dry density ranges from 650 to 750 kg/m3. Beech contains about 44–49% cellulose, 22–24% lignin, and 22% hemicellulose. This makes it a compact wood that enhances pellet quality and energy density.

Beech pellets have excellent combustion performance. Their calorific value ranges from 17–18 MJ/kg, with ash content between 0.5% and 1.2%. The pellets burn steadily, with minimal slag, making them a popular clean fuel in the EU market. They are widely used in home fireplaces and high-end biomass boilers.

4. Maple

Maple refers primarily to species such as sugar maple and other hard maple types. With a dry density of around 660 kg/m3, it is considered a medium-to-high-density hardwood. Its cellulose content is about 50%, hemicellulose 19.4%, and lignin 25.5%, giving it excellent properties for pellet formation. Maple pellets are strong and resistant to breakage. However, due to the high lignin content, strict temperature control is necessary during pelletizing to prevent mold burning or clogging.

Maple pellets have a calorific value of approximately 17–18 MJ/kg. When burned, they produce a steady flame and stable heat output. The thin bark and oil content release a mild wood fragrance, similar to maple syrup. This makes them especially popular in North America, particularly in areas with abundant sugar maple resources, such as Eastern Canada and the Northeastern United States.

It is important to note that medium-to-high-density hardwoods, such as oak, beech, and maple, typically require higher compression pressures during pelletizing, which can result in more wear on the molds. In production, equipment parameters should be adjusted based on the type of wood, with careful control of temperature and humidity.

The following table compares the key parameters of pellets made from different tree species. This comparison can help you identify the most suitable raw materials and target markets based on your specific needs.

| Material | Density (kg/m3) | Cellulose (%) | Hemicellulose (%) |

Lignin (%) |

Pellet Calorific Value (MJ/kg) |

Pellet Ash Content (%) |

Optimal Application |

| Oak | 700–800 | 40 | 25 | 20 | 18.7 | 0.5–0.7 | High-end Export / Industrial Boilers |

| Birch | 620–650 | 40 | 36 | 20 | 17–18 | ~1.0 | Home Fireplaces / Quick Heating |

| Beech | 650–750 | 44–49 | 22 | 22–24 | 17–18 | 0.5–1.2 | Low-Slag Boilers |

| Maple | ~660 | 50 | 19.4 | 25.5 | 17–18 | <1.0 | North American Residential Market |

Additionally, in addition to focusing on the wood's characteristics, the consistent availability of raw materials is also crucial to the success of biomass pellet production.

Raw Material Sourcing Channels

The raw materials for hardwood pellets mainly come from wood processing by-products and forestry waste. Common raw material sourcing channels include:

Wood Processing Plant By-products

Furniture factories, flooring manufacturers, and wood door/window producers generate a large amount of scrap material during processing, such as sawdust, wood shavings, and wood chips.

These by-products are key sources of high-quality hardwood pellets. They are mainly derived from cutting waste of dried hardwood planks, which are pure in wood quality and have low moisture content, making them ideal for direct pelletizing.

Sawmill and Plywood Plant Waste

Sawmills and plywood plants are also important sources of raw materials for hardwood pellets.

During the sawing and processing of wood, these plants produce significant amounts of sawdust, wood chips, and shavings. Since these wastes are usually untreated, have pure wood quality, dry quickly, and are easy to crush, they are well-suited for pellet fuel production.

These two types of processing waste are typically sourced through partnerships with local furniture factories, sawmills, and other processing companies. Alternatively, they can be procured centrally by recyclers.

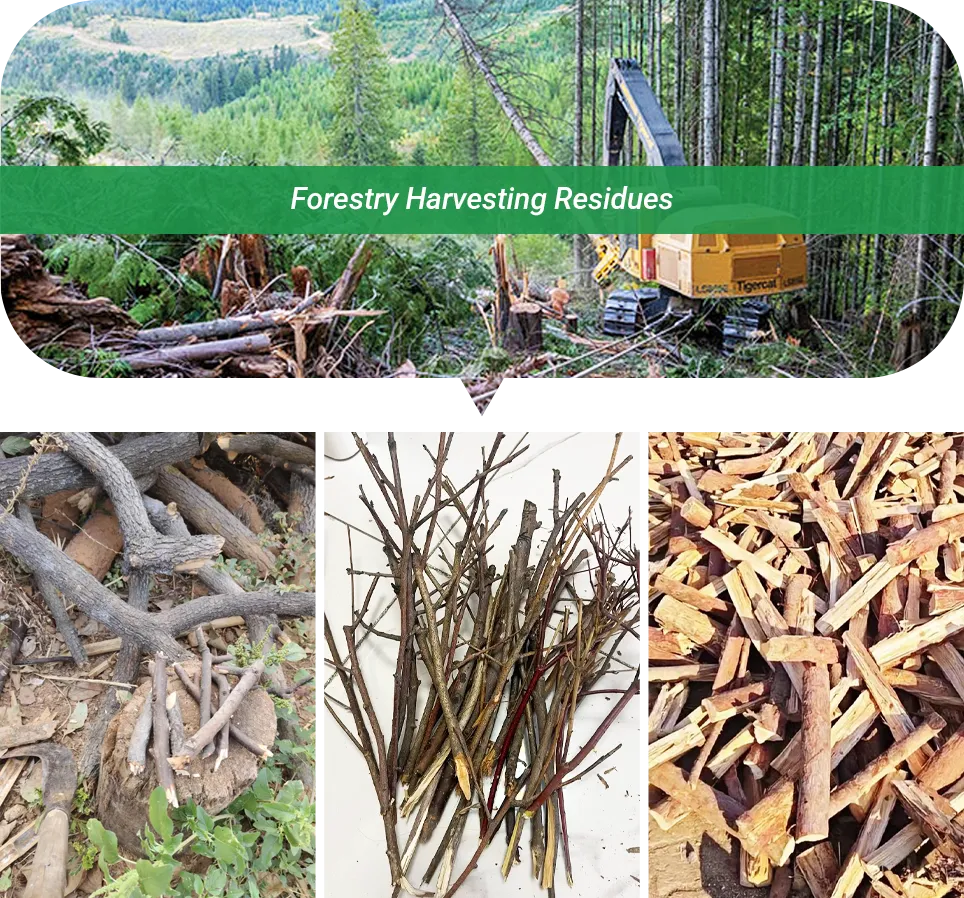

Forestry Harvesting Residues

During forest harvesting, materials such as tree tops, branches, wood scraps, and bark are often left behind as residues. After being crushed and dried, these materials can also serve as raw materials for hardwood pellets.

These harvesting residues are typically sourced through partnerships with forestry farms or logging companies that hold harvesting rights. This makes them suitable for large-scale collection and use. For small to medium-sized producers, these resources can also be obtained from raw material recyclers or third-party procurement companies.

In addition to the three common sources, waste wood from urban landscaping and orchard trimming are also used as supplementary materials.

It is important to note that not all wood waste is suitable for pelletizing. Only untreated, natural wood can be used for production.

Raw Material Selection Considerations

To produce high-quality hardwood pellet fuel, the following factors should be considered when selecting and preparing raw materials for processing:

Cleanliness and Purity

The raw materials must be clean and pure, free from sand, metal, plywood, or other chemically treated materials. Otherwise, pellet quality may be affected, and equipment wear may increase. During collection, screening and magnetic separation should be performed, especially for urban recyclables, which require more thorough sorting.

To achieve pellets with low ash content, the amount of bark should be reduced as much as possible, as it contains higher levels of ash and minerals.

Avoid Glue and Coatings

Wood containing glue, paint, or preservatives should not be used in pellet production. These materials release harmful gases when burned and can easily clog machinery.

Therefore, mixed hardwood waste should be carefully inspected. If the surface contains coatings or adhesives, they must be removed or shaved off, leaving only the clean wood portion.

Preventing Mold

Raw materials should be kept dry and clean to prevent mold growth. Moldy materials have reduced calorific value and may release harmful substances that affect air quality. Sawdust, especially when stored in humid environments, tends to clump and mold, so it must be thoroughly dried before pelletizing.

It is recommended to store materials in a well-ventilated, moisture-proof environment and use them as soon as possible to avoid decay and deterioration.

Controlling these factors ensures the raw materials are dry, pure, and free of impurities, improving pellet quality.

Choosing the right raw materials not only affects pellet quality but also influences your market direction and equipment selection. If you'd like to create a tailored production plan based on your needs, feel free to contact us for a custom solution.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.