Make Biodegradable Cat Litter: Process & Equipment List

Cat litter is a daily essential for cat owners, and demand keeps growing. In recent years, biodegradable litter has become more popular for being dust-free, non-stick, and eco-friendly. By 2024, the global market passed $14 billion, with biodegradable types gaining more share. For anyone looking to enter this space, it's a great time to start. This guide will walk you through the production process and equipment options.

Why Invest in Biodegradable Cat Litter Production

Wondering why it's becoming so popular? Here's what makes it stand out:

- It breaks down naturally, making it more eco-friendly

- Low dust means a healthier cat and a cleaner home

- No sticking to the litter box, so cleanup is easier

- Lightweight and odor-free, which cats tend to prefer

- Can be flushed down the toilet, saving time and effort

What Is the Best Cat Litter

Before choosing raw materials, it's a good idea to understand what products are doing well in the market. These are some of the most popular options:

Tofu Cat Litter

Made from soybean residue or pea fiber, tofu litter is one of the fastest growing products. It clumps quickly, controls odors well, and produces very little dust. This type is especially favored by cat owners in cities who care about cleanliness, smell, and ease of use.

Corn Pellet Cat Litter

This type is made from cornmeal, corncobs, or related by-products. It has a natural color, mild scent, and good absorbency. It's a good choice for users who are sensitive to strong smells and prefer eco-friendly materials.

Wood Pellets Cat Litter

Typically made from pine or sawdust, wood litter absorbs liquid quickly and helps control odor. It is usually formed into pellets with low dust and minimal sticking, making it suitable for homes with multiple cats. The raw materials are widely available and support large-scale production.

Paper Cat Litter

Made from recycled paper or industrial pulp, this litter is soft, lightweight, and nearly dust-free. It's easy to flush and ideal for cats with special needs, such as older or recovering pets. The raw material is easy to source and can be part of a recycling-based production model.

Each type has its own strengths. When planning your production, it's worth considering the materials you have access to and what your target customers are looking for.

Equipment Needed for Cat Litter Production

Below is a list of key equipment used in producing biodegradable cat litter. The cat litter manufacturing process includes everything from raw material handling to final packaging. While specific setups may vary depending on the type of litter (such as tofu, corn, wood, or paper-based), the overall workflow is generally similar.

Raw Material Preparation

| Equipment | Function |

| Crusher | Grinds raw materials into 1–5 mm pieces |

| Sieve | Removes large debris and unwanted particles |

| Dryer | Lowers moisture to suitable level for processing |

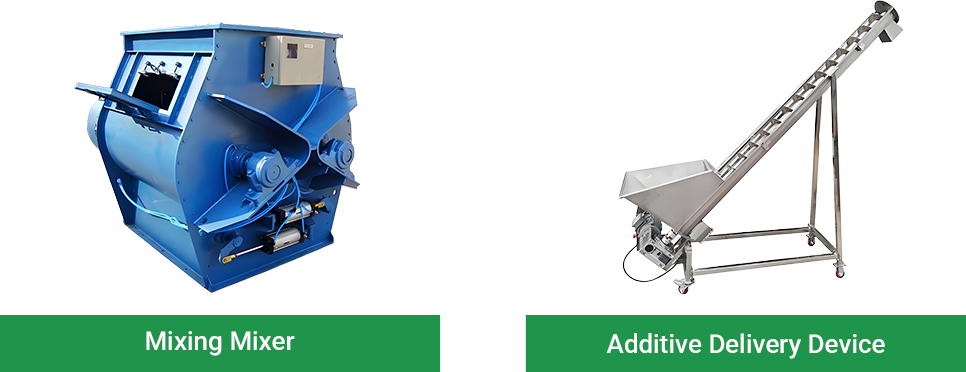

Mixing

| Equipment | Function |

| Mixer | Blends raw materials and binders |

| Additive Feeder | Adds small ingredients with precise dosing |

Pelletizing

| Equipment | Function |

| Screw Feeder | Feeds material evenly into the pellet machine |

| Pellet Mill | Presses material into solid pellets |

Pelletizing is the key step. The right pellet machine gives you better shape, hardness, and less waste. Want to know which model fits your needs? Talk to our team for tailored advice.

Drying and Cooling

| Equipment | Function |

| Dryer | Dries finished pellets |

| Cooler | Lowers temperature for storage |

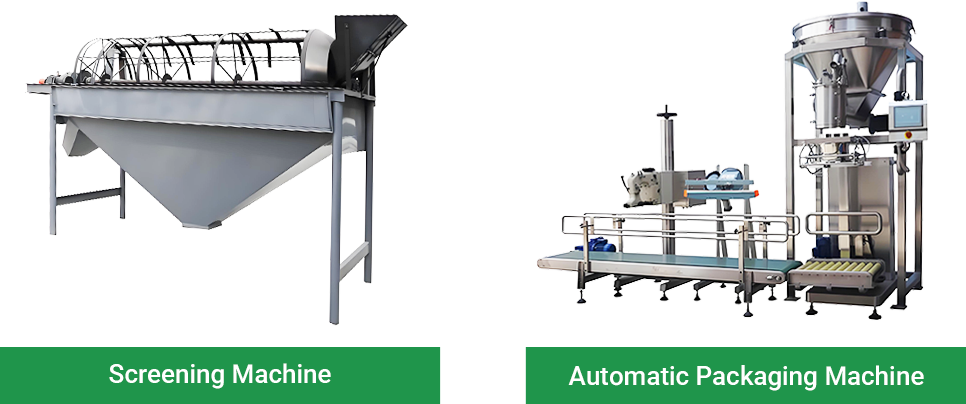

Final Processing

| Equipment | Function |

| Screener | Removes dust and broken pieces |

| Packing Machine | Weighs, bags, and seals pellets |

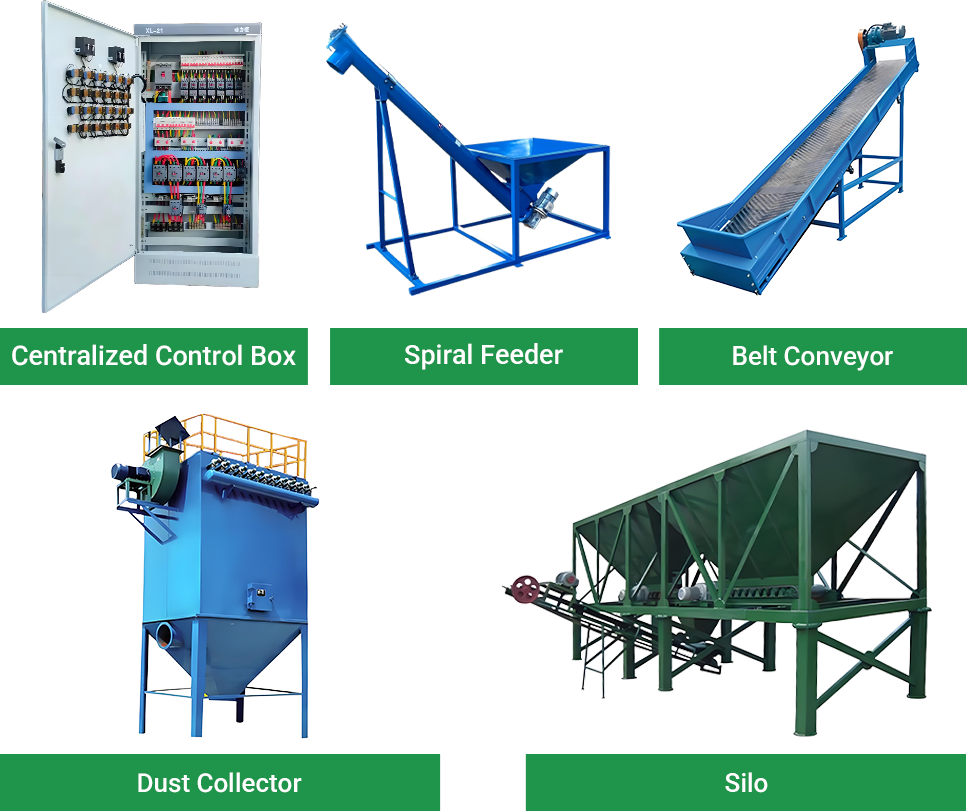

Other Optional Supporting Equipment

| Equipment | Function |

| Control Panel | Manages all machine operations |

| Screw Conveyor | Moves powder to the next step |

| Belt Conveyor | Transfers pellets to the packing area |

| Dust Collector | Keeps air clean during processing |

| Storage Bin | Holds raw or finished material |

These machines make up a complete cat litter production line. The exact models and setup may vary depending on your production scale and product type. It's best to choose equipment based on your material, output needs, and budget.

Common Production Line Setups

Not every project requires a full set of machines. It's more practical to choose equipment based on your production goals, budget, and available raw materials. Below are two typical setup options for your reference.

For Small-Scale or Low-Budget Production

Output: 200–1000 kg/h

This setup is ideal for users with limited budget or space. It includes the essential machines, keeps costs low, and is easy to operate. Suitable for soft materials like tofu residue, paper pulp, or corn powder. Some steps may require manual work.

| Equipment | Suggested Model |

| Crusher | Model 500 |

| Horizontal Mixer | 300 L |

| Screw Conveyor | Φ165 × 3 meters (adjustable) |

| Flat Die Pellet Mill | KB-300 to KB-550 |

| Vibrating Screener | 800 mm, single layer |

| Control Box | Includes stop switch, overload protector, and inverter |

For Higher Output and Better Pellet Quality

Output: 1–4.5 tons/hour

This line is designed for larger operations with stable raw material supply. It suits users who plan to produce in bulk for retail, wholesale, or export. With high automation and strong material adaptability, it produces uniform pellets suitable for long-term production.

| Equipment | Suggested Model |

| Crusher | 56×40 cm |

| Twin-Shaft Mixer | 1000 L (paddle type) |

| Screw Conveyor | Φ219 × 3 m (sealed, with inverter) |

| Ring Die Pellet Mill | KH-450 to KH-880 |

| Multi-layer Screener | 1000 × 3000 mm, double layer |

| Belt Dryer | Multi-layer, 12 meters |

| Cooler | Vertical cooler or air tunnel |

| Automatic Packing Machine | Dual-scale, fully automatic |

| Control System | Full control cabinet with inverters and buttons |

Note: Equipment models may vary depending on your production capacity.

The two setups above are for reference. Your final production line should be tailored to your raw materials, output goals, and budget. If you're planning to set up a cat litter pellet line or need help choosing the right equipment, feel free to contact us anytime.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.