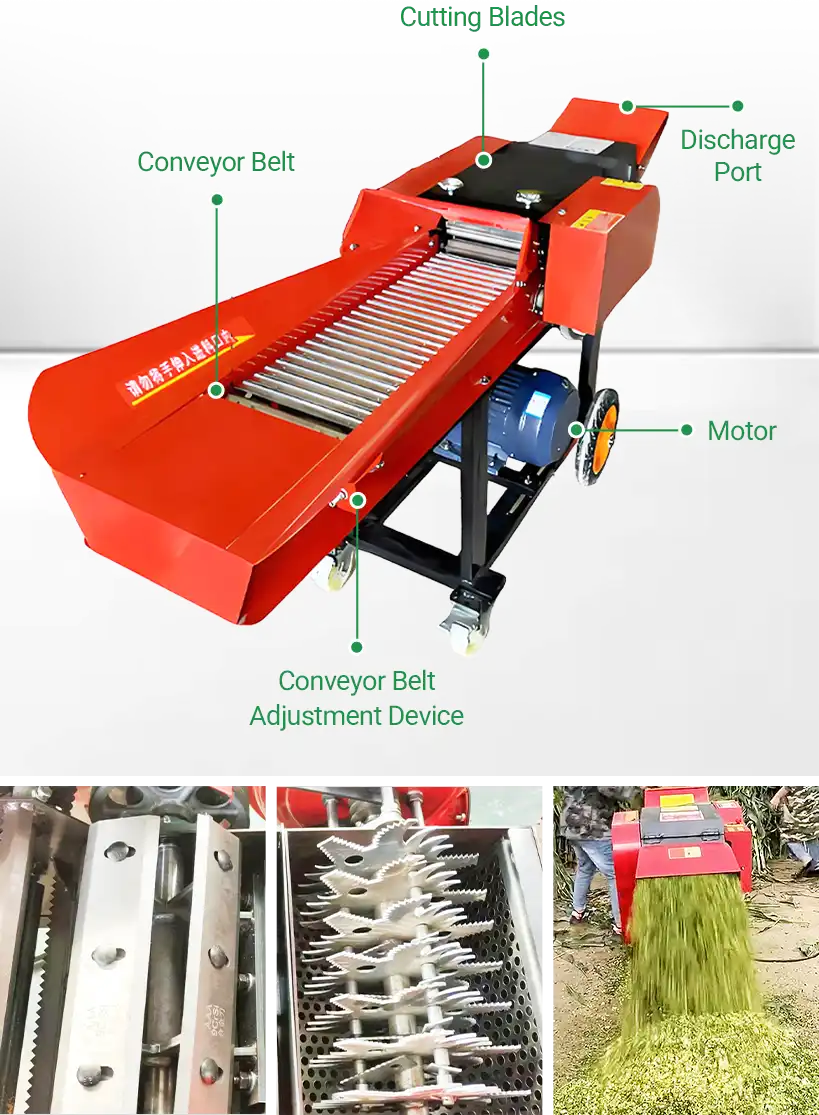

Chaff Cutter Grinder Machine

This machine is suitable for crushing hay, silage, straw, and corn cobs. The crushed material can be used directly for ruminant feed or pelletizing. It has a compact design, small size, high output, and works with both dry and wet materials. Ideal for crop processing and small to medium farms.

The material enters the crushing chamber through the feed inlet. High-speed blades cut and strike the fibers, quickly breaking them down. The crushed material exits through the bottom screen. The process is fast and continuous, ideal for tough, fibrous materials like hay, straw, and corn stalks.

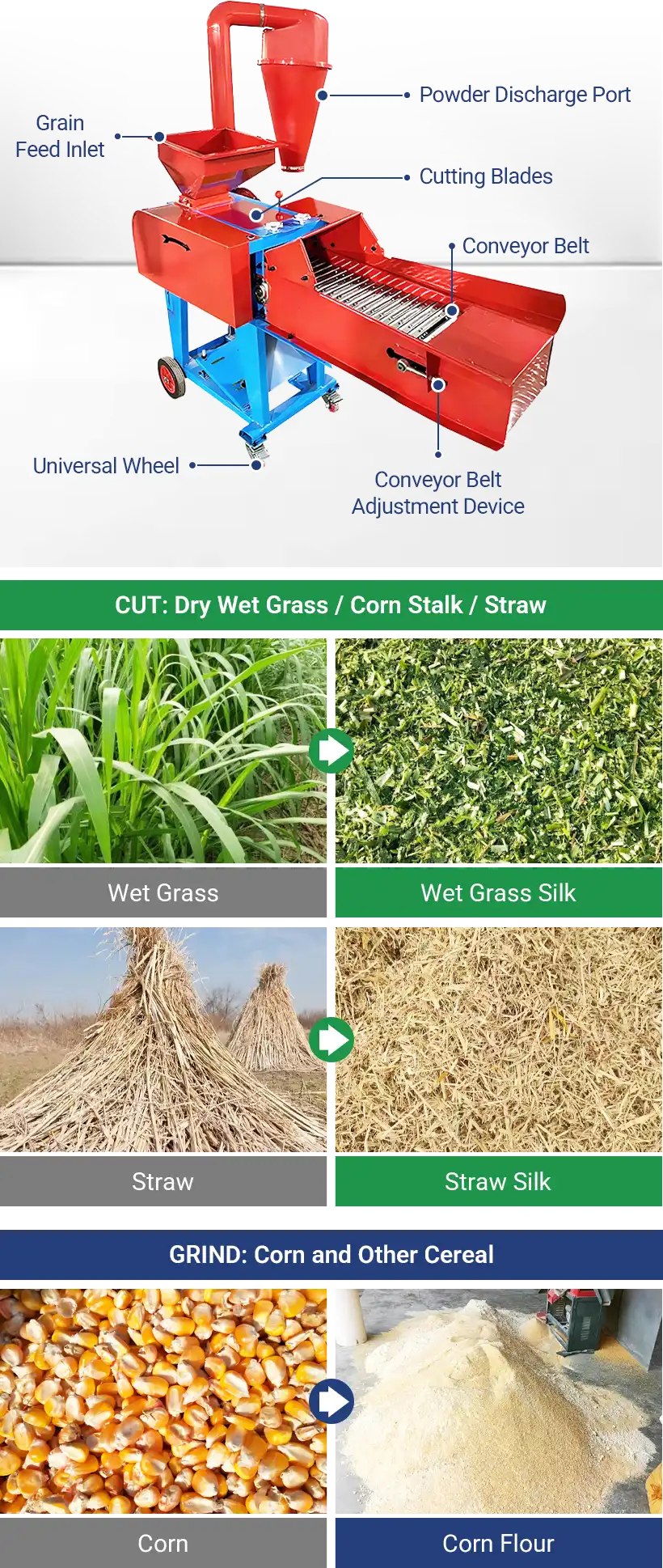

Upgraded Model

This model adds separate inlets and outlets with a hammer or disc crusher for high-speed grinding. Unlike the basic rear-discharge type, it uses bottom discharge for cleaner, easier collection.

In addition to processing fibrous materials like pasture grass and crop stalks, it can also crush corn, soybean meal, wheat bran, and dried sweet potatoes. This makes it ideal for mixed feed production such as silage or fine powder, and suitable for a wider range of applications.

The machine comes with several practical features

- Electric or diesel option for different power needs

- Durable alloy blades and hammers, easy to replace

- Adjustable screen for different output sizes

- Copper motor, supports local voltage

- Swivel wheels make moving the machine easy

- Optional belt for continuous feeding

Video

Product Parameters

Basic model (Electric)

| Model | Power (kw) | Capacity (kg/h) | Total Weight (kg) |

| 3T | 4kw | 500-3000 | 120 |

| 3.8T | 4.5kw | 900-3500 | 150 |

| 4.8T | 5.5kw | 1000-4000 | 160 |

| 5.8T | 5.5kw | 1100-5000 | 205 |

| 6.8T | 7.5kw | 1500-6000 | 292 |

Upgraded model (Electric)

| Model | Power (kw) | Capacity (kg/h) | Total Weight (kg) |

| 3.8T | 4.5kw | 500-3000 | 159 |

| 4.8T | 5.5kw | 900-3500 | 190 |

| 5.8T | 5.5kw | 1000-4000 | 225 |

FAQ?

What materials can it crush?

This machine works with various fibrous materials like hay, fresh grass, silage, alfalfa, Sudan grass, straw, corn stalks, sorghum, cotton stalks, wheat straw, bean vines, and weeds.

The upgraded model also crushes corn, soybean meal, bran, dried sweet potatoes, broken grains, rice bran, and peanut shells. It is well suited for mixed feed processing.

How often to change blades or hammers?

Check the blades or hammers every 3 to 6 months, depending on use and material. Replace them if they are dull or deformed to keep performance steady.

Does it clog? Can it run continuously?

The machine runs smoothly with both forage and grain materials. It supports continuous use for 1–2 hours without clogging, if the feed is even. For wet or long materials, drying or cutting them beforehand helps prevent blockages.

Can it cut and grind at the same time?

Yes. The chaff cutter and grinder are separate systems powered by the same motor. You can use them independently or together, depending on your needs.

How often should I clean the screen?

Clean the screen daily after use. For silage or wet grass, clean more often. Use a brush to avoid damaging the screen.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.