How to Make Alfalfa Pellets for Feed

Alfalfa, the king of forages, is nutrient-dense and a top protein feed for ruminants like cattle, sheep, horses and rabbits. Rich in organic matter and nitrogen, it also serves as an organic-fertilizer input, and pelletizing preserves nutrients while improving storage and handling.

Natural benefits of alfalfa

Alfalfa pulls nutrients from deep soil and delivers about 16–20% crude protein plus vitamins and minerals, making it an excellent feed for ruminants.

Rich in organic matter and nitrogen with an NPK of about 3-1-2, it also serves as high quality organic fertilizer that improves soil and plant performance.

To make full use of alfalfa and simplify storage and feeding, it is processed into pellets through a few key steps. Here is the standard production flow for alfalfa feed pellets.

1. Fresh alfalfa drying and dehydration

Newly cut alfalfa can contain 60–70% moisture and must be dehydrated first.

Lay it in a ventilated, shaded area to let excess moisture evaporate, then use low temperature hot air drying. Keep drying temperature around 55–60°C to remove water while preserving chlorophyll and protein.

Aim for a final moisture of 12–15%.

2. Foreign matter removal

Dried alfalfa often contains soil, stones, weeds or metal fragments. If not removed, these cause equipment wear or pellet contamination.

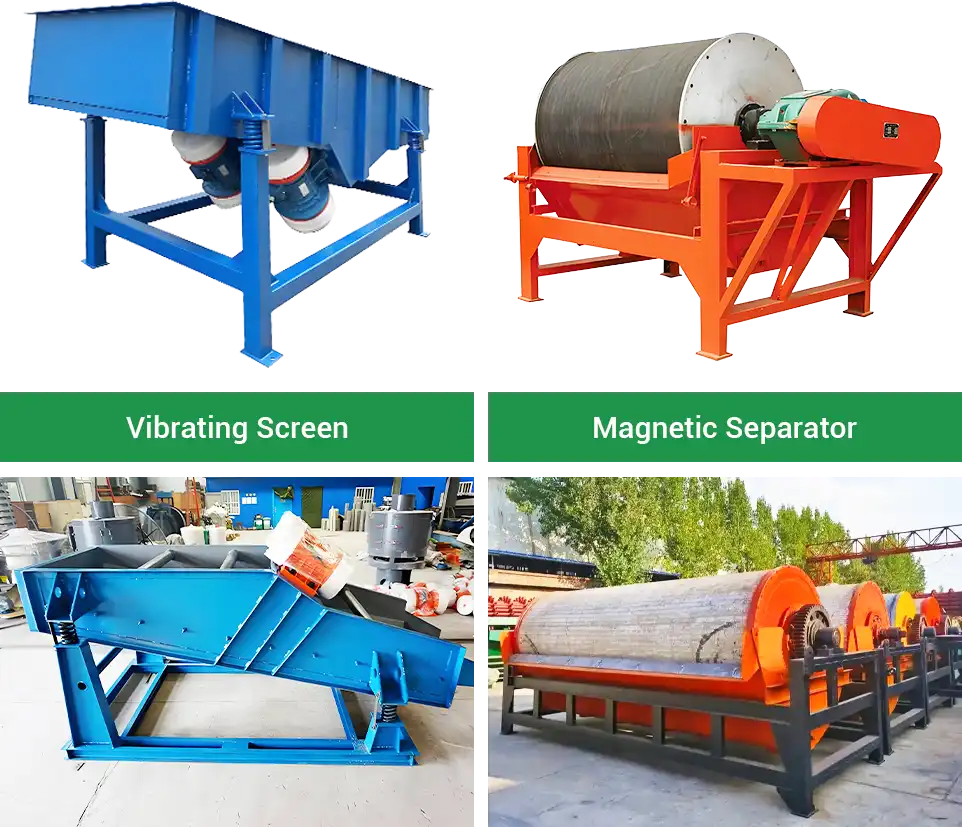

Remove debris by hand picking and vibration screening. Add magnetic separation if iron fragments are present.

3. Grinding and milling

Alfalfa stems are stiff and fibrous. Use a hammer mill or chaff cutter to reduce fiber length to about 3–5 mm.

If you buy preground alfalfa meal you can skip grinding, but still check moisture and uniformity. If the powder is too fine and pellets lack density, add a small amount of bran or coarse meal to improve forming.

4. Pelletizing of alfalfa meal

Before feeding ground alfalfa into the pellet mill, add up to 3% molasses or vegetable oil as a binder and to improve palatability.

Die hole for ruminant feeds is typically 4 to 6 mm and can be adjusted by species.

Choose equipment by capacity and purpose

- Flat die pellet mill for small to medium scale. Simple to operate and easy to move.

- Ring die pellet mill for continuous production. Provides more stable pellet density and higher output.

5. Cooling and screening

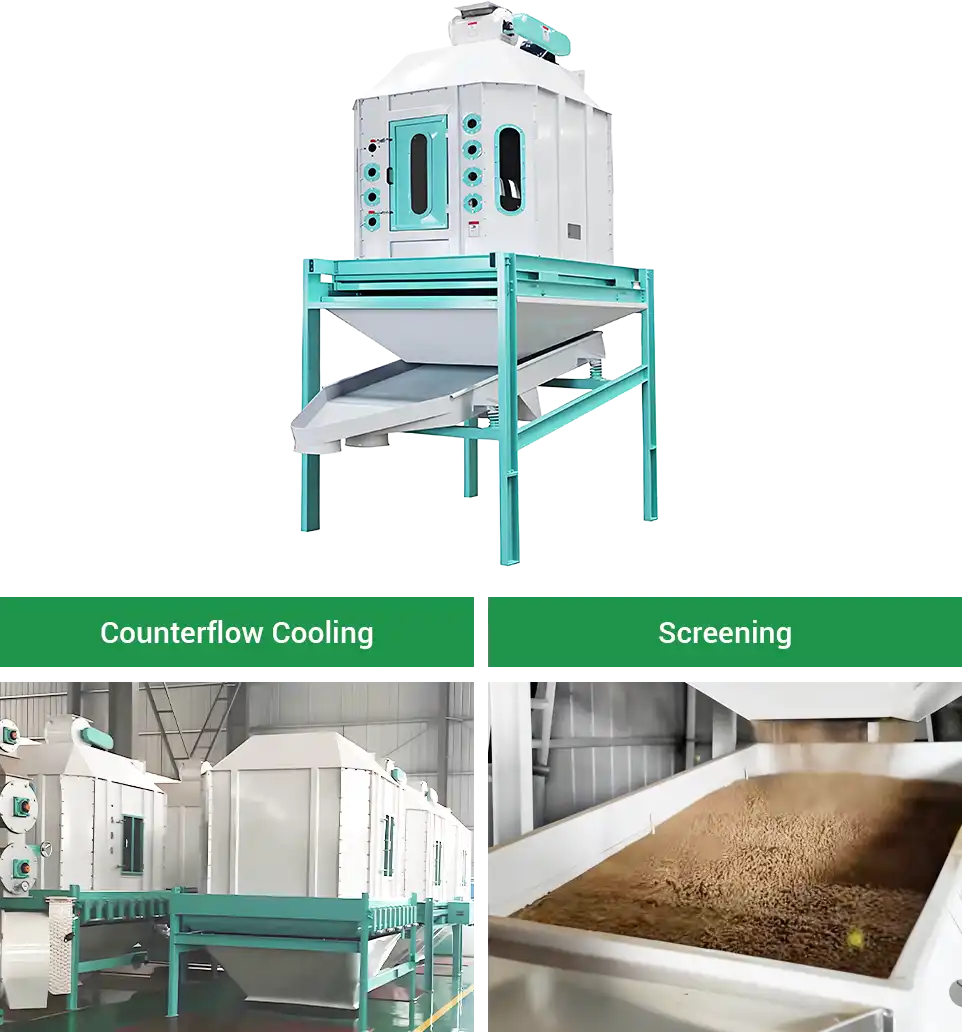

Pellets exit the machine at about 85 to 90 °C. If not cooled quickly they may reabsorb moisture, deform or develop mold. Cool to room temperature near room temperature by natural cooling or with a counterflow cooler.

In humid areas add a low temperature secondary drying step to remove residual moisture.

After cooling, screen the pellets and return fines and broken pieces to the pellet machine for recycling.

Process steps & equipment

| Step | Main equipment |

| Drying | Hot air dryer, drying racks |

| Cleaning | Vibrating screen, magnetic separator |

| Grinding | Hammer mill, chaff cutter |

| Pelleting | Flat die mill for small to medium scale; ring die mill for large continuous lines |

| Cooling and screening | Counterflow cooler, vibratory screener |

| Packing and handling | Mixer, automatic feeder, packing machine, conveyors |

Alfalfa blocks vs pellets

Alfalfa blocks are made by compressing whole dry plants. Density about 90–180 kg/m3. They keep high fiber and lengthen chewing time, so they suit high-roughage diets. Blocks absorb moisture and can mold in damp storage. Typical loss rates range from 10 to 30%.

Pellets are made by grinding, mixing and pressing into dense pellets, about 550–700 kg/m3. Pellets are easier to store and transport and resist moisture. They can be formulated for different animals to improve palatability and cut selective feeding and waste.

Common uses of alfalfa pellets

1. Ruminant feed and protein supplement

Alfalfa pellets supply 16–20% protein and effective fiber. They support rumen function, rumination and saliva production.

2. Roughage base

Used as main roughage or a base in concentrates for rabbits, deer and camels. It boosts protein intake, coat health in rabbits and eases digestion in larger herbivores.

3. Ingredients for poultry and aquafeeds

Ground alfalfa adds plant protein, vitamins and pigments. It can improve yolk color in layers and provide fiber in fish and shrimp diets.

4. Raw material for organic fertilizer

Rich in organic matter and nitrogen, alfalfa is blended with manure or straw and composted into organic fertilizer pellets.

5. Soil improvement

Alfalfa pellets release nutrients slowly, ideal for poor or saline soils and for long-term turf and soil restoration.

Choosing the right pelleting equipment noticeably improves production efficiency and pellet quality.

If you plan to start alfalfa pelleting, feel free to contact us for equipment and process advice.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.