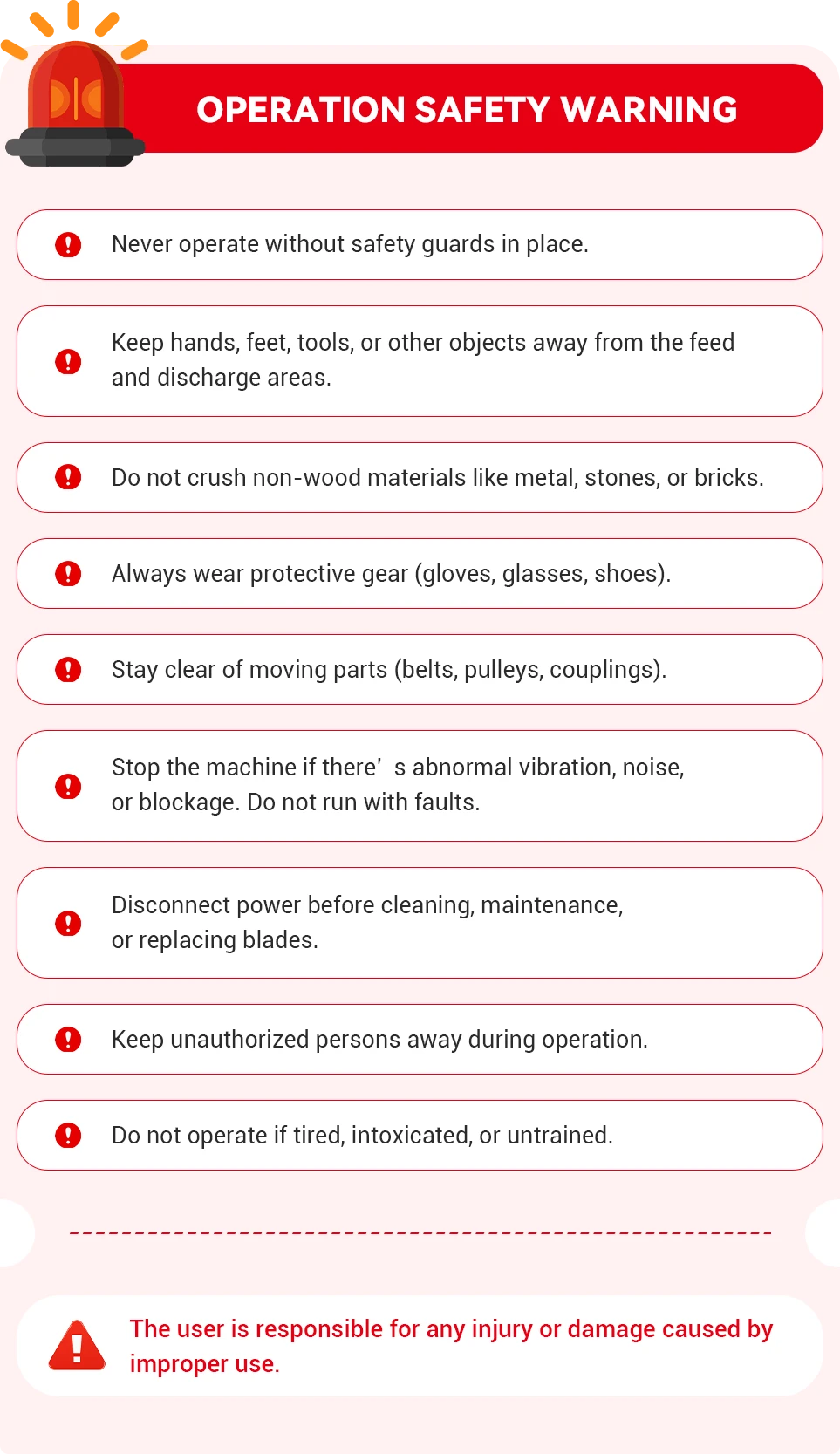

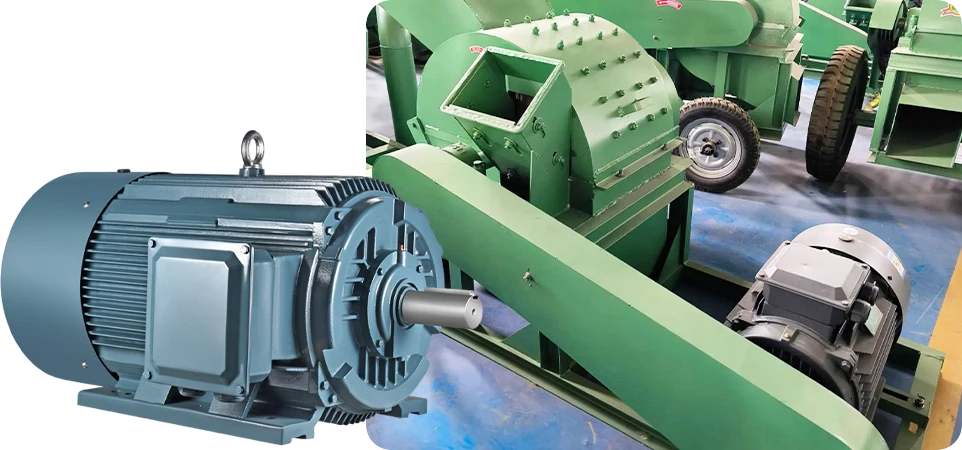

Wood Crusher Machine Operating Instructions

File Download

Get the full operation manual in PDF format.

This wood crusher is designed for cutting and crushing wood materials such as branches, wood strips, and wood scraps. It processes long materials into shavings or sawdust for easier collection, transport, and storage.

For safe and stable operation, please read and follow the instructions in this manual.

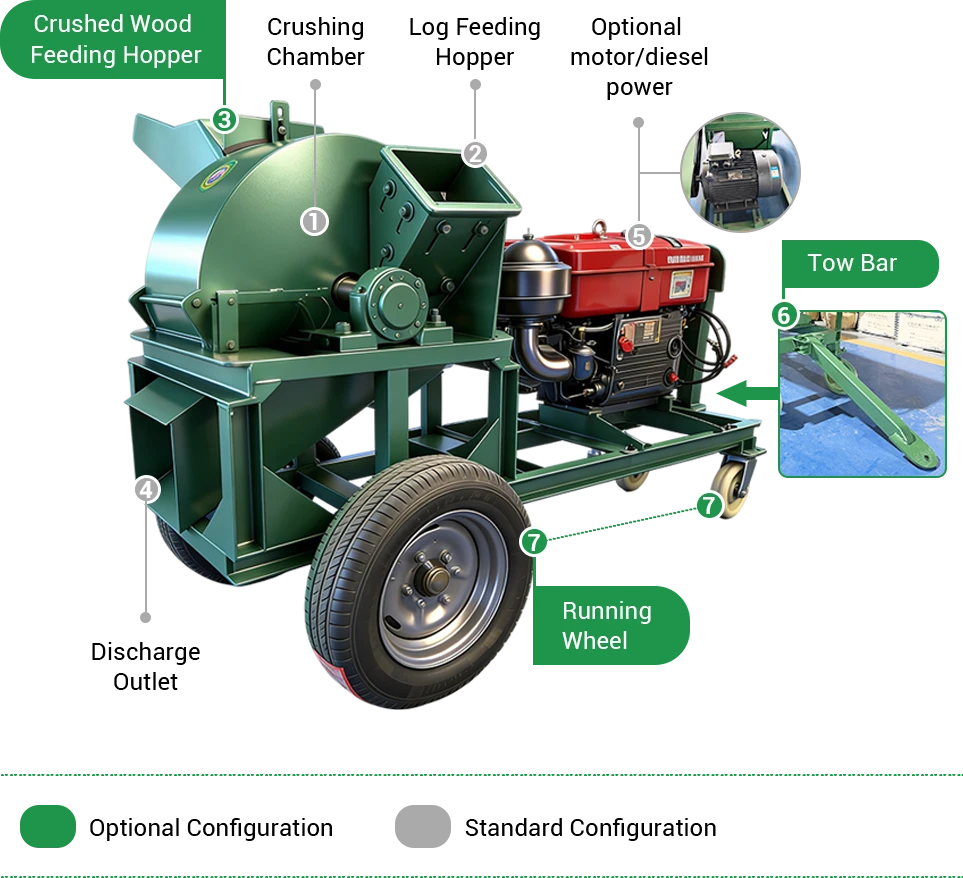

Equipment components

Installation and Inspection

Before first use or after long periods of inactivity, ensure the following installation and inspection steps are completed. Operations should be done with the equipment turned off.

Core component inspection

- Ensure the frame and casing are secure, with no looseness or damage.

- Check the feed inlet, crushing chamber, and discharge area for foreign objects or material residues.

- Verify the blades, hammers, and rotor are secure, with no wear or looseness.

Installing the belt

Place the belt into the motor and spindle pulley grooves, ensuring it is not twisted and fully seated. Align both pulleys to prevent the belt from slipping.

After installation, check the belt tension and rotate the pulley by hand to ensure smooth movement without friction or collision, ensuring no slippage during operation.

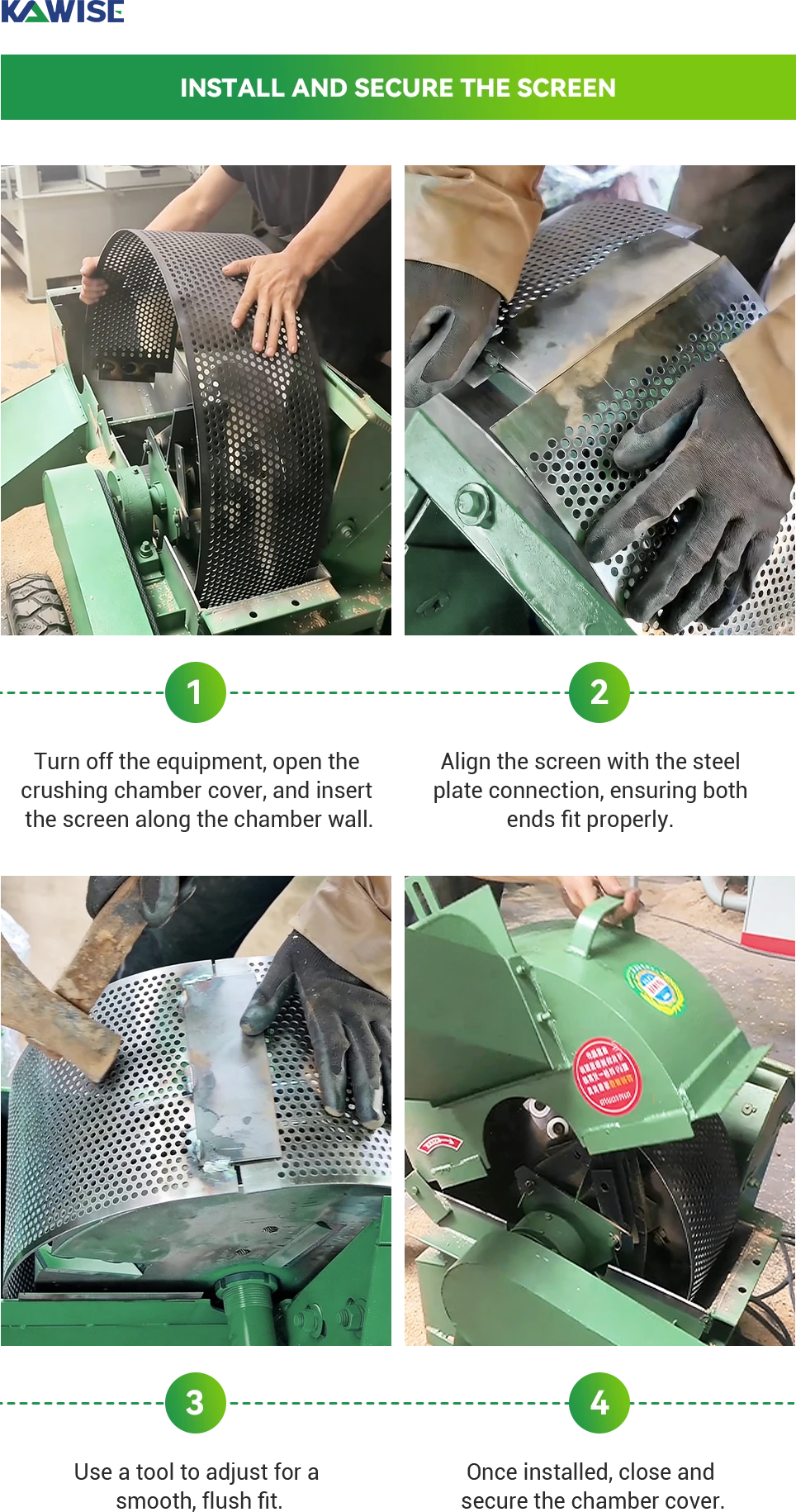

Install and secure the screen

The screen needs to be installed by the user as the equipment is shipped without it.

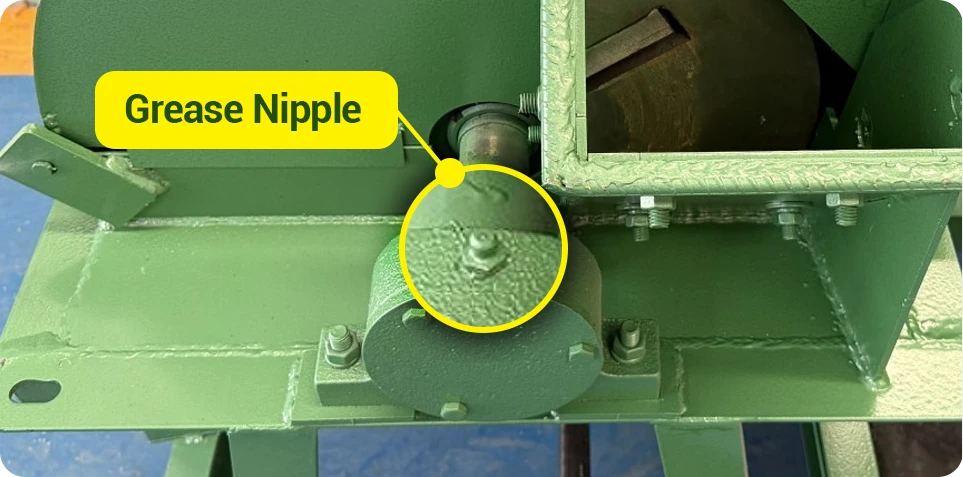

Bearing lubrication

The bearing housing has a grease nipple. Use a grease gun to inject grease into the nipple, applying gradual pressure until a small amount of grease flows from the bearing seal.

Check for unusual noises

Before starting the equipment, manually rotate the rotor to ensure the claws, hammers, and rotor move smoothly and are securely fixed. Check for any collisions or interference in the crushing chamber.

Also, verify that the rotor's rotation direction matches the labeled direction and check the lubrication of the power system.

Starting Method

Depending on the drive type, the equipment supports both electric start and diesel drive.

Single-phase wiring

Before wiring, install an air switch near the equipment for easy operation, then connect the equipment to the power supply through the air switch.

After ensuring all connections are secure and properly grounded, proceed with powering on and starting the equipment.

Three-phase wiring

It is recommended that a professional electrician perform the wiring for three-phase equipment. Before use, ensure the following electrical protection and control devices are properly installed:

- Air switch

- Three-phase motor protector

- Star-delta starter (or equivalent starter)

Diesel start

For detailed startup procedures, refer to the Diesel Engine Pellet Mill Startup and Maintenance Guide.

Operating Steps

Startup

- Connect the power and start the equipment.

- Run the equipment without load for about 2 minutes after starting.

- Once smooth operation is confirmed, with no abnormal vibrations or noises, begin feeding materials.

- Maintain continuous and even feeding during operation.

- The crushed material is discharged from the outlet and should be collected promptly.

When processing logs or long wood, feed through the main inlet and close the auxiliary inlet flap (for models with dual inlets). When processing wood blocks, chips, or scraps, feed evenly through the auxiliary inlet.

Shutdown

- Stop feeding materials before finishing, allowing the equipment to run idle for a moment.

- After all material is discharged, turn off the power switch and disconnect the power.

- Clean any remaining material from the crushing chamber promptly.

If any abnormalities occur during operation, immediately stop feeding and shut down the equipment for inspection.

Common Faults and Solutions

| Fault | Possible Cause | Solution |

| Severe vibration | Unbalanced or improperly installed blades/rotor | Reinstall blades, check and adjust rotor balance |

| Unusual noise in crushing chamber | Hard objects, loose or damaged parts | Remove hard objects, shut down, inspect and replace damaged parts |

| Significant decrease in productivity | High material moisture, worn blades, fast feeding | Dry material, replace blades, control feeding speed |

| Motor overload or tripping | Overfeeding, loose or slipping belt | Control feeding, adjust or replace belt |

| Difficulty starting engine | Fuel contamination, clogged filter, ignition system failure | Replace filter, repair ignition system |

| Poor discharge or blockage | Clogged screen, uneven material size | Clean screen, pre-treat material |

Regular maintenance and proper operation are key to ensuring the efficient and safe operation of the wood shredder. We hope this manual will assist you in using your equipment.

If you encounter any issues during use or need further support, please feel free to contact us. Our team is here to provide you with professional assistance and guidance.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.