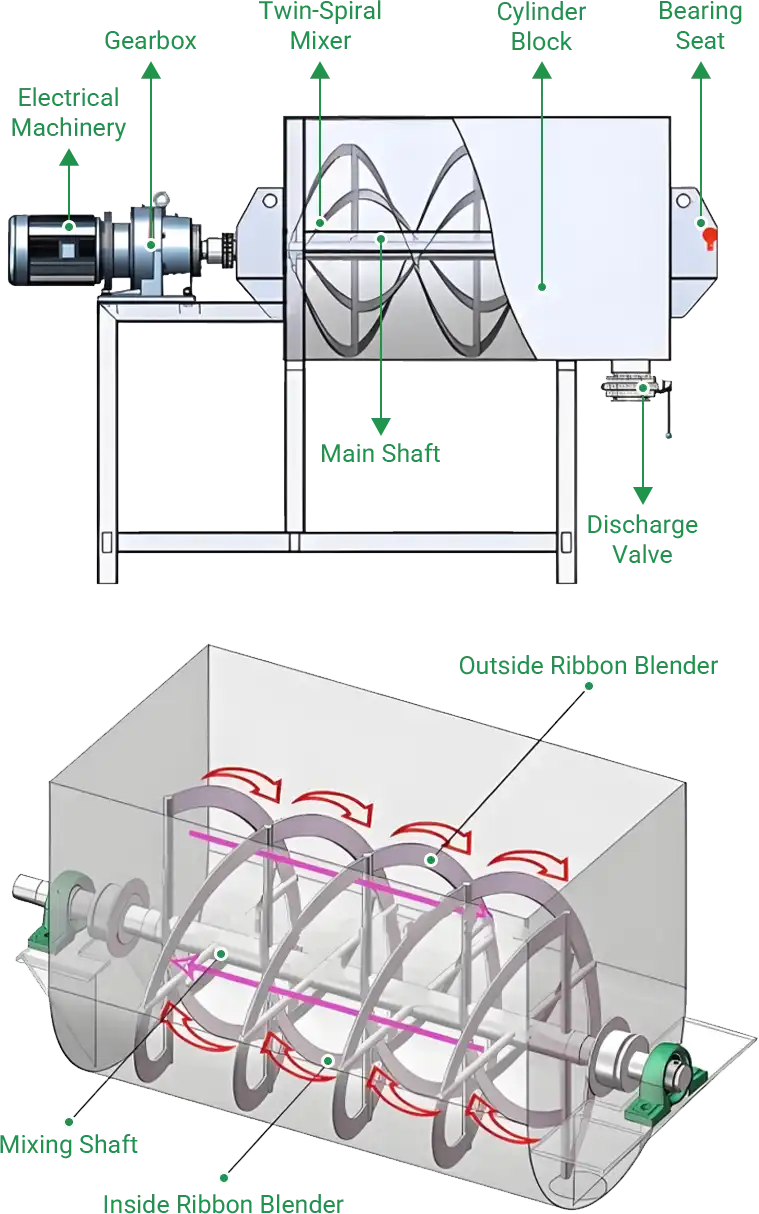

Horizontal Feed Mixer

The horizontal feed mixer is ideal for users who need precise, even mixing. It's great for premix, expanded feed, or feeds with additives. Compared to vertical mixers, it offers better blending, handles more material, and discharges faster. It's well-suited for farms or feed mills with higher precision needs.

The ribbon structure helps mix and move materials evenly in a short time. The tank is slightly tilted, so materials don't stick easily. Discharge can be set on the side or bottom, making it easy to run continuously.

The carbon steel model is suitable for dry feed. If you work with wet or fermented feed, or need easy cleaning, the stainless steel version is a better fit.

Whether used on a small farm or in a larger feed line, this mixer improves efficiency and keeps feed quality stable.

Video

Product Parameters

| Model | Volume(m3) | Host power (kw) |

| 100 | 1 | 5.5 |

| 150 | 1.5 | 5.5 |

| 200 | 2 | 7.5 |

| 250 | 2.5 | 11 |

| 300 | 3 | 11 |

| 400 | 4 | 15 |

| 500 | 5 | 22 |

FAQ?

How do I choose between a horizontal and vertical mixer?

If you need accurate mixing and want to avoid layering, a horizontal mixer is a better choice. It's ideal for blending formulas with additives or multiple ingredients. Vertical mixers are simpler and take up less space, better for single ingredients or tight areas.

What kind of materials can it handle?

It can mix common feed ingredients such as cornmeal, premix, expanded feed, fermented feed, and additives. Both dry and wet materials are supported.

Will feed stick inside the mixing tank?

Not likely. The tank has a sloped design with side or bottom discharge, and the ribbon mixing helps reduce buildup. It's also easy to clean after use.

Does it have automatic discharge?

The mixer uses a manual discharge gate, but if you prefer automatic control, an electric discharge option is available.

Can I add a dust cover?

Yes, a sealed cover is available. It helps control dust and keeps the feed clean, which is especially useful in cleaner work environments.

Can it connect to a pellet machine?

Yes. The outlet can link to a conveyor so the mixed feed can go directly into the pellet machine without extra setup.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.