Profitable Biomass Fuel from Forest Residue Pelletizing

Forestry residues like branches, bark, and treetops are often left unused due to handling and transport challenges. They take up space, pose fire risks, and pollute when burned. But once shredded and pelletized, they become a clean, efficient fuel. With growing interest in low-carbon energy, this is a smart way to turn waste into value.

Pelletization Potential of Logging Waste

Forestry operations often produce large amounts of by-products, such as branches, bark, treetops, edge wood, stumps, and thinning small-diameter logs. These logging residues are widely distributed and produced in large quantities. While they typically don't enter the commercial timber product chain, they represent a highly promising resource for biomass energy development.

Concentrated and Abundant Raw Materials

According to FAO estimates, branches, bark, and other residues account for 30% to 50% of harvested timber.

In forestry-intensive regions like North America and Northern Europe, the proportion can be even higher. These by-products are often gathered in specific logging areas, creating a steady and centralized supply of raw materials for biomass pellet production.

The EU generates around 110 million tons of harvesting residues each year, with over 40% being economically valuable for pelletizing and biomass power. In countries like Finland and Sweden, these residues are often pelletized locally within 50 km, improving efficiency.

Suitable for Pelletizing

Branches, bark, and stumps are dense and rich in fiber, making them great for pellet production. After being shredded to under 6–8 mm, they dry easily and compress well. Since they contain less moisture than logs, drying uses less energy.

These materials also have high lignin content. When heated, lignin softens and naturally binds the material into pellets (no extra binders needed). That's why bark and branches are especially suitable for efficient pelletizing.

Burns Well and Cleanly

After logging, large amounts of branches and bark are often left behind or burned due to collection difficulties. In fact, these materials burn well and can be easily turned into clean, efficient biomass pellets.

| Material | Heat Value (MJ/kg, dry) | Ash Content (%, dry) | Moisture (%) |

| Branches | 18.5–20.5 | 1.5–3.0 | ≤10 |

| Bark | 17.5–19.0 | 4.0–8.0 | ≤10 |

| Stumps | 18.0–20.2 | 1.0–4.0 | 35–65 |

| Wood Chips (raw) | 18.3–19.0 | 1.0–2.8 | 30–55 |

Source:Grand View Research

Forest residues have solid fuel value, with energy levels close to or even above premium wood pellets (LHV 19.5–20.1 MJ/kg). While ash content is slightly higher, proper screening and feedstock control help reduce slagging and support stable boiler operation.

Environmental Benefits

As global temperatures rise and extreme weather worsens, the push for cleaner energy is stronger than ever. Converting wood waste into biomass pellets helps reduce methane emissions and replace fossil fuels like coal and diesel. Unlike open burning or landfilling, this process is cleaner and more climate-friendly.

Many countries, including the EU, US, and China, now offer subsidies and energy incentives to support biomass adoption.

Commercial Value of Wood Pellets

Wood pellets play a key role in the global biomass market. They are affordable, easy to source, and in high demand, making them a reliable option for clean energy use. Most raw materials come from sawmill dust and forestry residues. Sawmill dust provides better pellet quality, while forestry waste ensures a larger supply. With the growing push for renewable energy, wood pellets offer strong potential for producers and investors alike.

| Item | Data |

| Global wood pellet market size (2025) | USD 9–12.3 billion |

| Projected market size by 2035 | USD 15.7–23.6 billion |

| Annual growth rate (CAGR) | 6.2% to 6.7% |

| Share of forestry-based materials | About 60–70% (mainly logging residues) |

| Key markets | Europe, USA, Canada, Japan, South Korea |

| Top exporters | USA, Canada, Russia, Vietnam, China |

Source:Future Market Insights (FMI) & Allied Market Research

Beyond serving as a clean fuel for heating and power, logging residues also offer diverse commercial opportunities once pelletized.

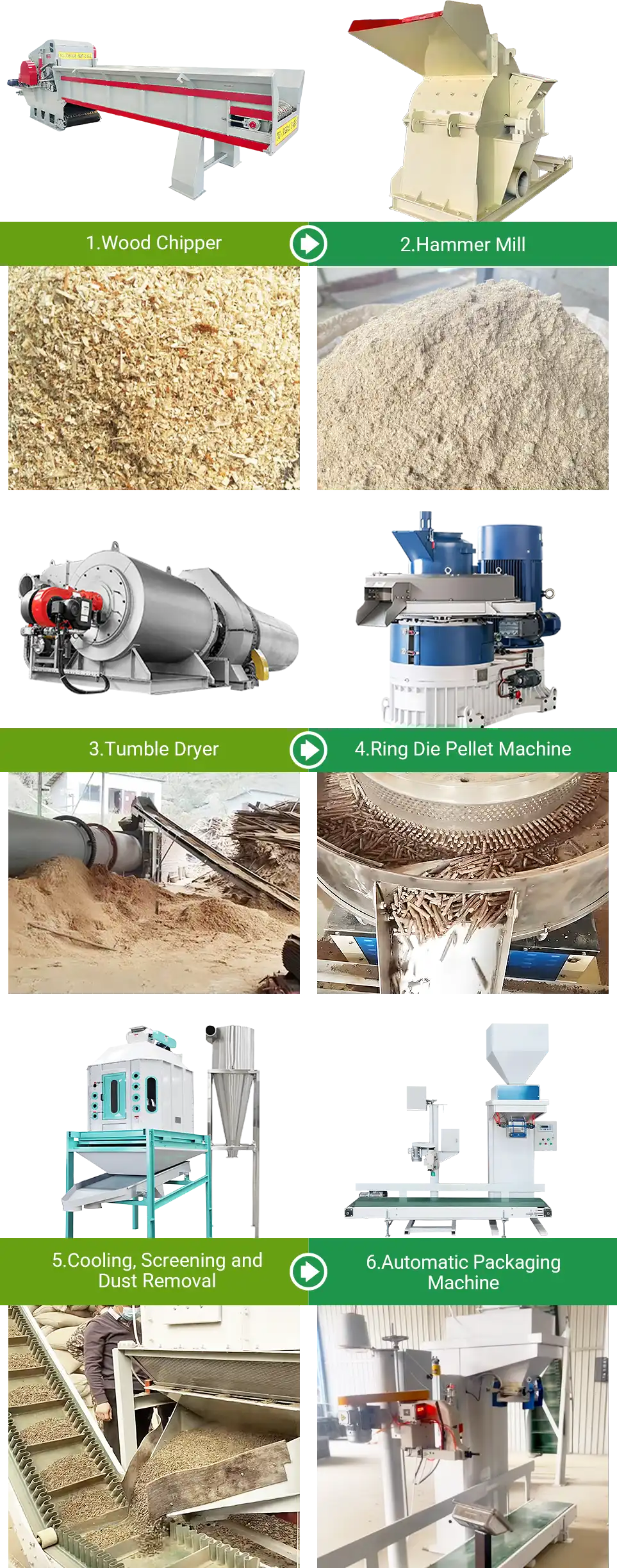

Pellet Production Process

Branches, bark, and treetops from logging are uneven, fibrous, and often too wet, making direct pelletizing difficult. To get good results, they need to be crushed, dried, and compressed. The process below is tailored for turning forestry residues into efficient fuel pellets.

Process & Equipment

When processing forestry residues, factors like raw material mix, supply stability, and site layout all directly affect production efficiency and cost. Here are some practical tips on these three aspects to help guide your operation.

| Step | Equipment |

| Coarse crushing | Wood crusher |

| Fine grinding | Hammer mill |

| Moisture control | Rotary dryer |

| Pelletizing | Ring die pellet mill |

| Cooling & Screening | Counterflow Cooler Screener |

| Dust removal | Dust collector |

| Bagging | Automatic packing machine |

Note:This is a standard setup. Configuration can be adjusted as needed.

Practical Tips & Considerations

To keep pellet production stable and cost-effective, it's important to plan ahead. Mix bark and branches with sawdust to improve pellet quality. Prepare enough storage for seasonal supply changes, and consider sourcing extra material from sawmills. Building your plant near raw material sources also helps cut transport costs and keeps operations efficient.

Case Study

Many users in China, Southeast Asia, and Africa are using our equipment to turn forestry waste into biomass pellets. Their projects run reliably, and the pellets perform well in actual use.

Forestry Waste Replaces Coal for Heating

In Northeast China, one customer used to rely on coal for heating during the harsh winter. With new restrictions and plenty of forestry waste around, they switched to a cleaner option. Using our wood crusher and KB-200 small pellet machine, they now turn branches and leaves into biomass pellets. It's a practical and affordable replacement for coal.

Indonesia Bamboo and Forest Residues Pelletizing Project

This customer is based in South Kalimantan, a major forestry and bamboo region in Indonesia. The area has many sawmills, plywood factories, and bamboo processors, offering a steady supply of low-cost raw materials like branches, wood scraps, bamboo shavings, and trimmings.

To make full use of these resources, the customer partnered with us to build a 3 TPH pellet line. The setup includes a KH-850 biomass pellet mill along with a wood crusher, rotary dryer, cooler, and automatic packing system. The plant layout was designed for smooth material flow and efficient pellet production.

Turning forestry residues into high-quality wood fuel pellets aligns with today's shift toward green energy and offers forestry businesses and energy investors a valuable path for added returns.

If you're planning a project to make use of forestry waste, feel free to contact us for customized pellet production lines and tailored solutions. Let's unlock more business potential together.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.