Shrimp Feed Cost and Stability Challenges in Southeast Asia

In Southeast Asian shrimp farming, feed influences growth performance, water quality, and farming risk. With higher stocking densities and rising costs, dependence on commercial feed alone is becoming less effective, placing greater emphasis on feed management.

Shrimp Farming in Southeast Asia

Southeast Asia has long been an important region for global shrimp farming and exports. Its development path largely reflects the transition of aquaculture from traditional practices to high density, large scale production.

Since the 1970s, countries such as Thailand, Vietnam, Indonesia, the Philippines, and Malaysia have leveraged tropical climates and coastal resources to gradually establish export oriented shrimp farming systems, becoming major suppliers in the global market.

Major Shrimp Producing Countries in Southeast Asia (2024–2025)

| Country | Key Highlights |

| Vietnam | ~1.19 million tons; Mekong Delta as the core production area. |

| Indonesia | 2024 target: 578,000 tons; modern estates alongside traditional ponds. |

| Thailand | 250,000–300,000 tons annually; intensive systems with strong biosecurity focus. |

Data source: Shrimp Outlook 2025; Easyfish(2025)

Asia accounts for over 80% of global shrimp farming output, but increasing competition from Latin America, particularly Ecuador, is reshaping the global market.

Ecuador's large scale low-density ponds, optimized local breeding programs, and lower energy and labor costs have created sustained price pressure on Asian producers.

In response to growing price pressure, shrimp producing countries in Southeast Asia are adopting different production strategies:

- Vietnam is targeting value added products, using strong peeling and cooked processing capacity to serve premium markets in Europe, the US, and Japan.

- Indonesia is advancing the Shrimp Estates model under government leadership to scale production in new regions such as Sumatra, Java, and Papua.

- Thailand is prioritizing biosecurity and recirculating aquaculture systems (RAS) to maintain its position in global trade standards.

Core Feed Demand Analysis

In intensive shrimp farming systems, feed has become a key factor affecting production stability and cost control.

In Southeast Asia, feed typically accounts for 50–60% of total farming costs, meaning that even small improvements in feed conversion ratio (FCR) can deliver significant economic gains.

Protein and Amino Acid Requirements

As crustaceans, shrimp require significantly higher protein levels than terrestrial livestock.

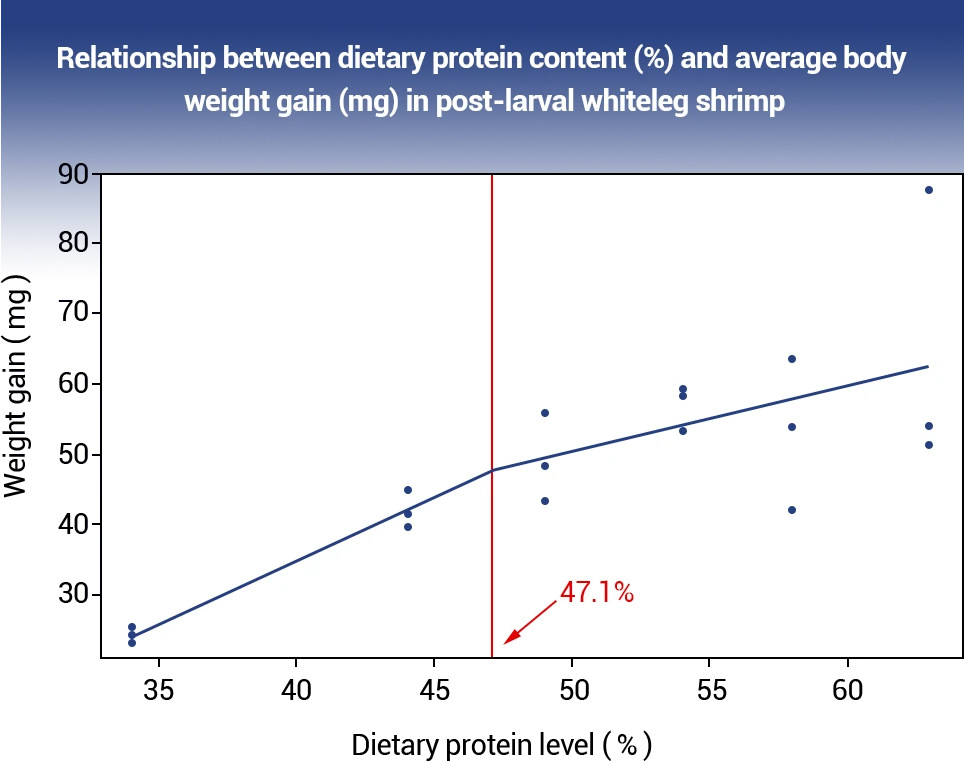

White shrimp have stage specific protein requirements. During the nursery stage, crude protein levels of 47.1–54% are required, while levels below 34% can reduce growth, weaken antioxidant capacity, and increase mortality during pond transfer.

During the grow out stage, when biofloc or natural feed is sufficiently available, dietary protein levels can be maintained at 30–35%, with microbial sources within the system supplying part of the protein requirement.

Lipids and Micronutrients

Lipids play a critical role in shrimp physiology, as shrimp cannot synthesize cholesterol and must obtain sterol precursors from feed to support normal molting hormone production.

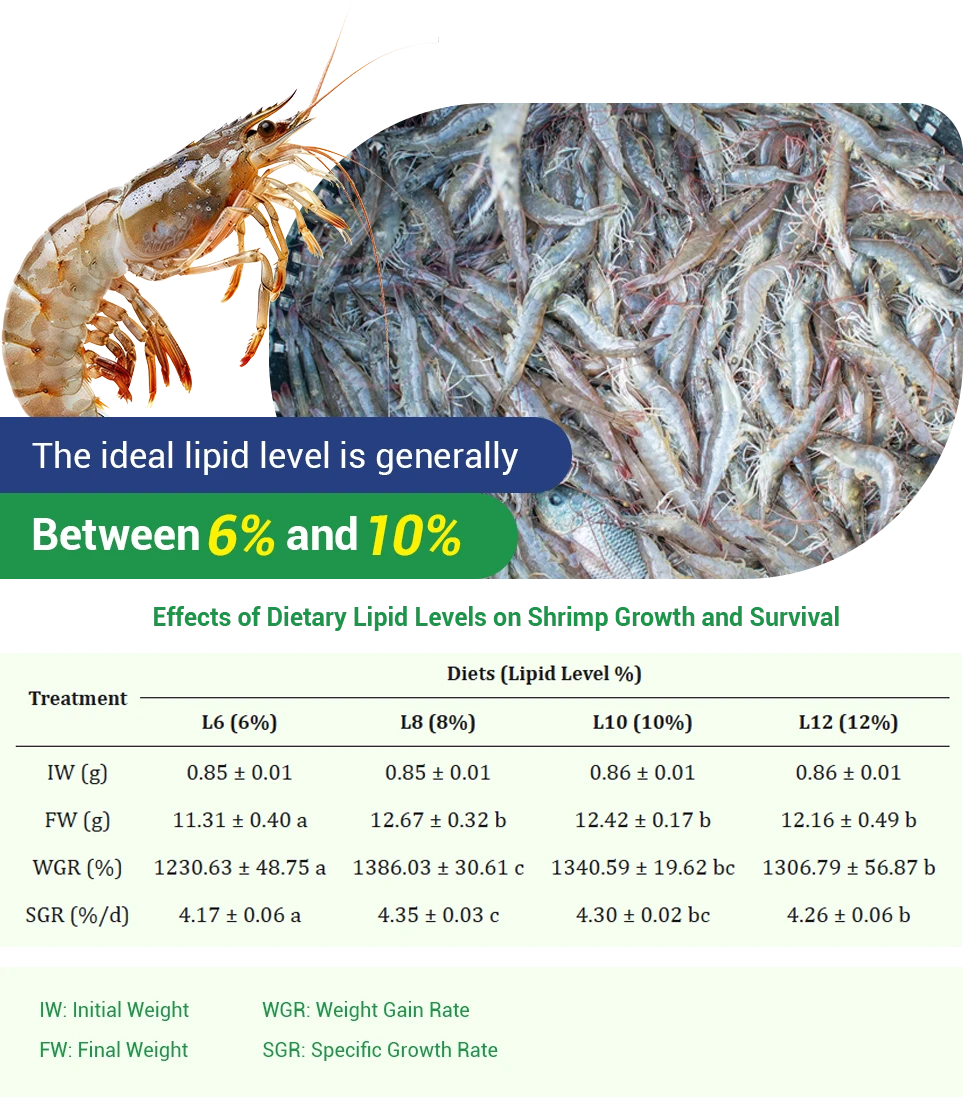

Optimal lipid levels typically range from 6–10%. Excessive lipid levels (above 11%) do not improve growth and may cause lipid accumulation in the hepatopancreas, reducing resistance to pathogens such as Vibrio.

Vitamins and minerals, though required in small amounts, are essential for enzyme function. Shrimp must obtain them through feed, as deficiencies can disrupt molting and immunity. Mineral absorption is also affected by pond salinity.

In low salinity inland systems (2–5 ppt), dietary supplementation of magnesium, potassium, and calcium is required to offset osmoregulatory mineral losses.

Different Feed Processing Methods

Feed physical properties directly affect performance in water. Because shrimp are bottom dwelling and feed slowly, feed must have high water stability and remain intact after at least two hours of immersion, without significant nutrient loss.

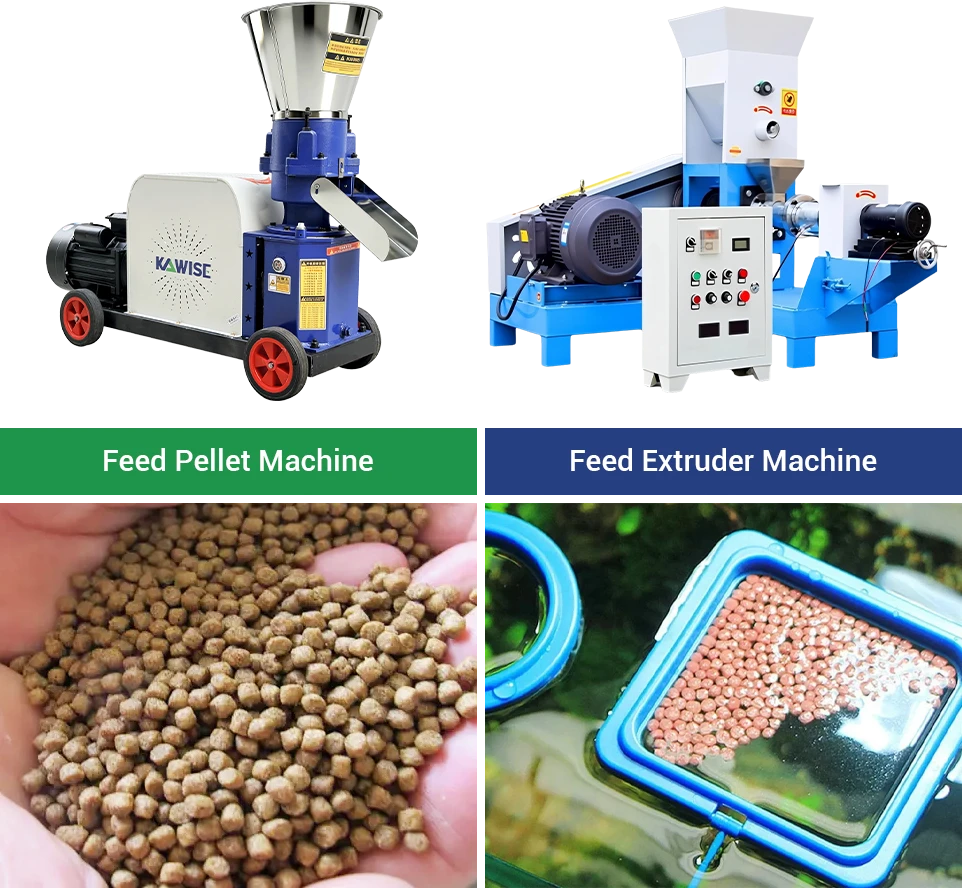

Two feed processing methods are commonly used in Southeast Asia.

One method is pelleting, which forms sinking pellets at lower cost with minimal impact on heat sensitive vitamins.

The other method is extrusion, which improves digestibility and allows floating or slow sinking pellets through starch gelatinization.

Pelleting vs. Extrusion

| Item | Pelleted Feed | Extruded Feed |

| Starch gelatinization | Low, binder needed | High, natural binding |

| Water stability | 2–4 h | 6–8 h |

| Vitamin retention | Higher | Lower |

| FCR | 1.5–1.8 | ~1.2–1.4 |

| Equipment cost | Lower | Higher |

| Typical use | Lower, small to mid-scale use | Higher, large scale use |

We provide shrimp feed processing equipment for various farming needs, with tailored solutions available based on your specific conditions.

Current Challenges

Under current farming and supply conditions, shrimp producers in Southeast Asia face practical challenges related to feed stability, cost control, and supply structure.

Pellet stability and water quality

In shrimp farming areas such as the Mekong Delta and coastal Thailand, farming season water temperatures often reach 28–32°C, with high feeding frequency. Under these conditions, pellet stability in water directly affects water load.

If pellets soften or break down soon after entering the water, uneaten feed forms fine residues, accelerating organic buildup and increasing the difficulty of ammonia and nitrite control.

High protein feed limits

When water temperatures remain above 30°C, shrimp digestion and metabolism are limited, and higher protein levels do not improve absorption efficiency. Excess nutrients enter the water, increasing water quality pressure and affecting farming performance.

In practice, simply increasing protein content rarely leads to more stable results.

Local ingredient processing limits

In Southeast Asian shrimp farming regions such as Southeast Asia, local by products like rice residues, cassava waste, fish scraps, and shell meals are widely available.

However, limited processing capacity makes consistent and standardized use difficult, leaving most farms dependent on commercial feed.

Strategies and Recommendations

To address these challenges, self-feed processing offers greater control and flexibility than fixed commercial formulas, allowing adjustments in formulation, processing, and feeding schedules.

In practice, self-processed feed offers clear advantages:

- Flexible formula adjustment based on actual needs

- Improved water stability through proper binder use

- Protein levels adjusted to farming conditions

- Better use of local ingredients to reduce long term feed costs

With rising feed price volatility and tighter farming margins, self feed processing has become a practical way to improve control and reduce risk.

By aligning processing methods and equipment with your operation scale, you can build a more stable feed system. Contact us to explore suitable solutions.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.