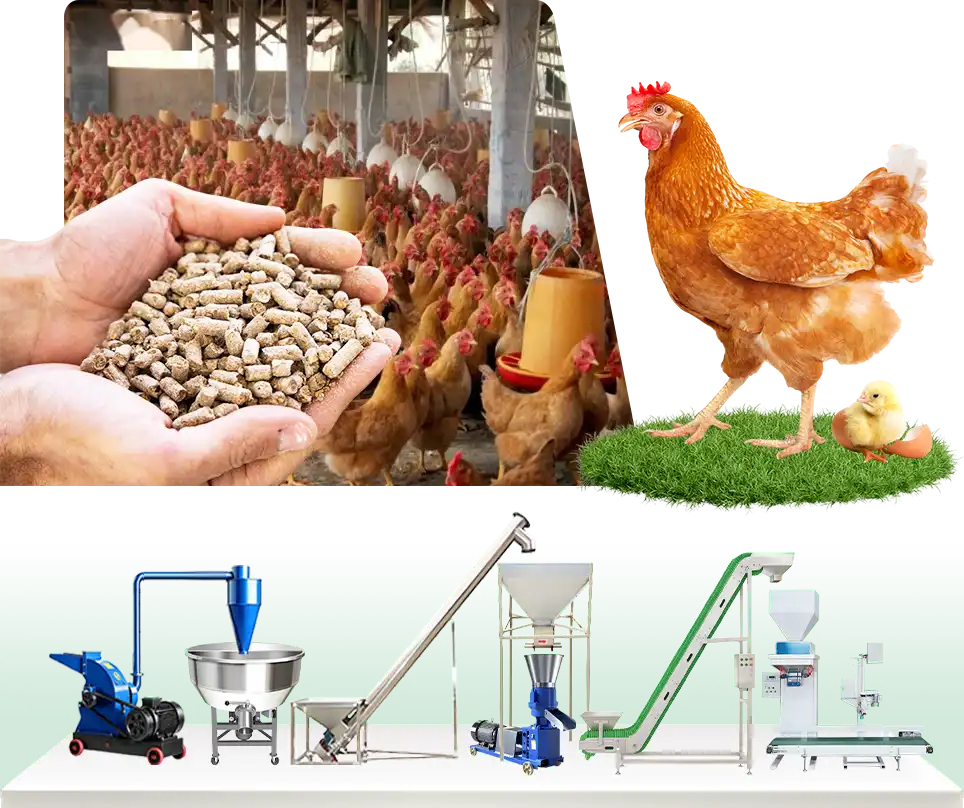

200-500kg/h Poultry Feed Production Line Setup & Price

The 200–500 kg/h chicken feed line is built for small and medium producers. It's compact, space-saving, and runs steadily for continuous feed production.

With a capacity to meet the daily feed needs of about 1,000-1500 chickens per hour, it offers a cost-effective and practical solution for farms and small feed mills looking to expand.

| Floor Area | Labor Required | Power Supply | Total Power |

| 30–60 m2 | 1–2 workers | 380 V / 50–60 Hz (customizable) | About 18–45 kW |

The complete production line includes crushing, mixing, pelletizing, cooling (optional), and commercial packaging.

It enables continuous and automated processing from raw materials to finished feed pellets.

Each machine is built for practicality and durability, with a compact design that's easy to use and maintain. The line can be tailored to your production scale and raw materials to meet different needs. The complete equipment list is as follows:

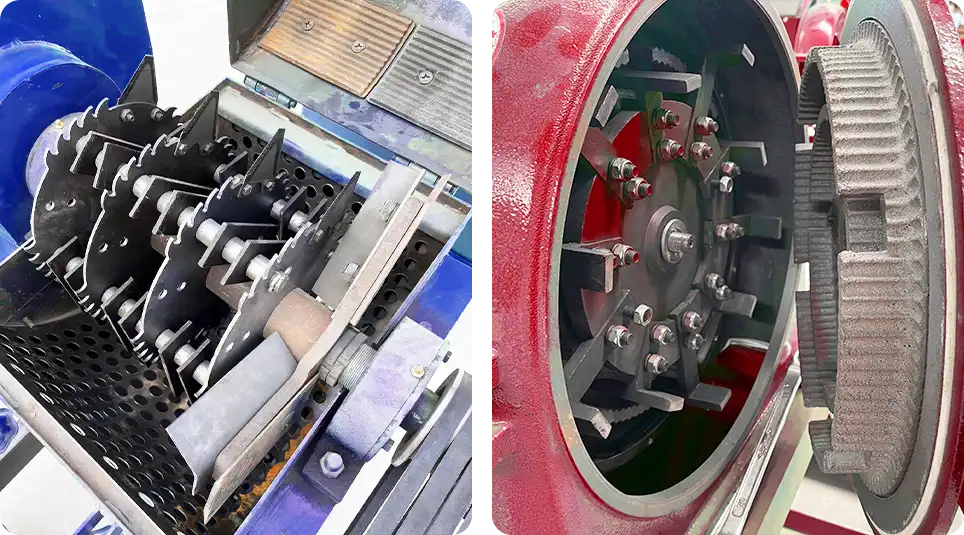

Crusher Machine

Feed corn, soybean meal, or wheat into the crusher. The high-speed hammers break the material by impact and friction, and particles smaller than the screen holes are discharged. Grinding size is adjustable by screen, usually 2–4 mm for chicken feed (1–10 mm optional).

Hammers and screens are made of wear-resistant alloy steel, lasting 800–1000 hours.

A self-suction model is also available for automatic feeding and dust reduction.

Crushing Machine Specs & Price

| Model | Capacity (kg/h) | Host power (kw) |

| 360 | 300-400 | 4.5 |

| 400 | 400-500 | 7.5 |

Factory Price from $ 300, Inquire Now!

Crushing Process Video Demo

Feed Mixer Machine

The mixer blends cornmeal, wheat bran, and soybean meal evenly to prevent layering. Vertical model uses cross blades at the bottom to move materials in a loop. It's simple, affordable, and best for light, dry, single materials like cornmeal or bran.

If your mix includes ingredients with different densities, a screw-lift vertical mixer works better for even blending.

Each batch takes only a few minutes. Check oil and blades regularly to keep it running smoothly and lasting longer.

Vertical Feed Mixer Specs & Price

| Model | Capacity (kg/Each stirring) | Volume(L) | Host power (kw) |

| 120 | 120 | 210 | 3 |

| 150 | 180 | 280 | 3 |

| 200 | 230 | 360 | 3 |

| 300 | 310 | 480 | 4.5 |

Factory Price from $ 300, Inquire Now!

Mixing Process Video Demo

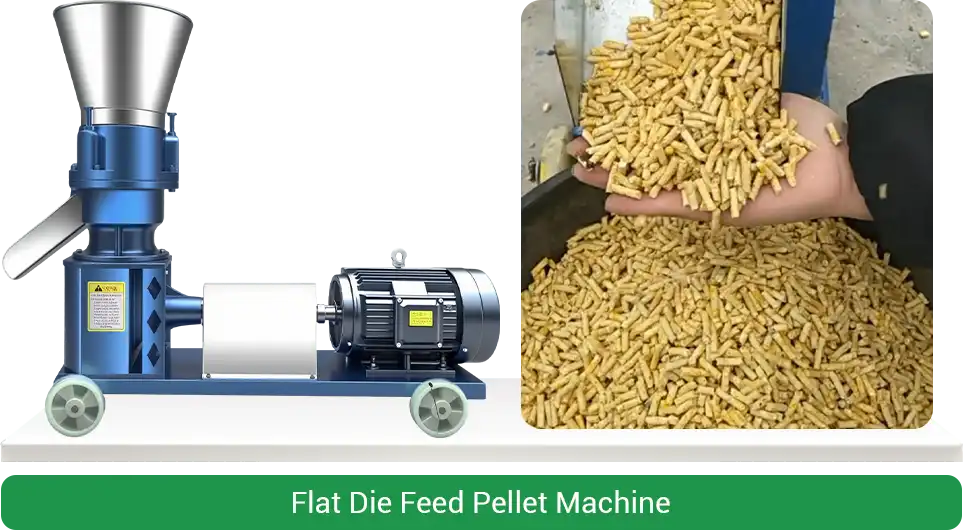

Chicken Feed Pellet Machine

The pellet machine is the core of the feed line, pressing mixed powder into firm, uniform pellets. For 200–500 kg/h output, a flat die model is ideal. It's compact, easy to use, and pellet size can be adjusted by changing the die (commonly 2.5–4 mm for different chicken stages).

The die and rollers are made of hardened carbon steel for high forming rate and wear resistance. Each die lasts about 800–1200 hours, and the machine can run over 8 hours continuously with low noise and smooth operation.

To keep it in good condition, clean residue after each shift, check roller clearance and grease every few days.

Feed pellet machine specs & price

| Model | Power (kw) | Capacity (kg/h) | Roller |

| KD-210 | 7.5 | 200-300 | 2 or 3 |

| KAD-230 | 11 | 250-400 | 3 |

| KD-260 | 15 | 300-500 | 3 or 4 |

Best Offer from $ 1,600, Order Now!

Pelletizing Process Video Demo

Auxiliary Equipment

In addition to the main machines, optional auxiliary devices can improve overall efficiency and keep the feed line running smoothly.

Screw conveyor

The screw conveyor automatically transfers powder materials between machines, serving as an essential link in the chicken feed line. It moves materials steadily and evenly, reducing manual handling and waste.

During feed production, light or powdery ingredients like cornmeal, soybean meal, and wheat bran often have poor flow and may cause clogging. The enclosed design of the screw conveyor prevents dust leakage and ensures continuous material flow.

Skirt belt elevator

The skirt belt elevator is designed to move finished chicken feed pellets smoothly to the cooling or screening section.

Its flexible edges prevent spillage and breakage, keeping pellets intact and clean while reducing labor and material loss.

Storage bin

The bin can store raw materials before crushing, ground feed, or finished pellets.

Since mixing takes time, adding a buffer bin before pelletizing helps keep material flow steady and continuous.

Fresh pellets usually reach 70–90°C. With natural air cooling in the bin, they cool and settle at the same time, saving energy and cost. This makes it a practical choice for small and medium-sized lines.

Packing machine (Commercial Use)

For users selling finished feed, this machine helps improve product appearance and brand image.

It's equipped with high-precision sensors, keeping weight error within ±0.2%. Sealing options include stitching or heat sealing, and operation is simple.

Video Demo

Production Line Showcase

This 200–500 kg/h chicken feed line combines cost efficiency with practical design. It runs smoothly and continuously, and each setup can be customized to your needs.

For industrial-scale commercial feed production, check the 0.5–1.2 T/H Complete Feed Line.

To explore different feed line options, check out our Top 5 Poultry Feed Production Line Solutions.

If you're planning to start or upgrade a feed line, contact us for a customized plan and quote.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.