0.5 - 1.2 T/H Complete Poultry Feed Line Setup

This poultry feed line balances output and cost. Its compact, end-to-end layout and high automation enable steady, continuous operation. On an 8-hour shift it produces about 4–10 metric tons, suitable for medium and large-scale farms and commercial feed mills.

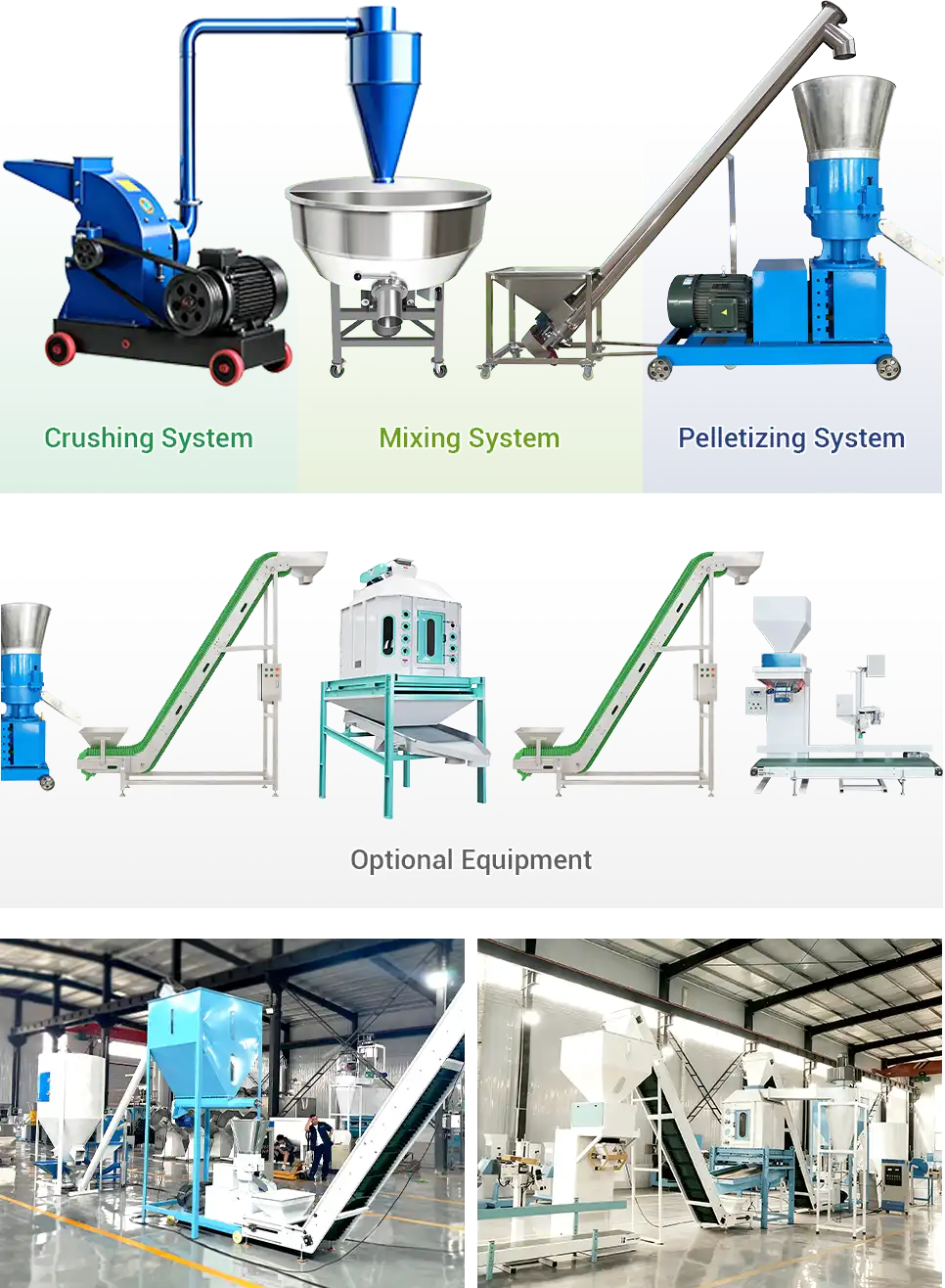

Line Options & Process Flow

For the 0.5 to 1.2 t/h poultry feed line, choose from two configurations: Economy and Commercial. Both deliver the same capacity.

The Economy package focuses on cost control, while the Commercial package emphasizes efficiency and uptime. Select based on your space, raw materials, and budget.

Economy Package

| Floor Area | Labor | Power Supply | Total Power | Guide Price |

| 120 to 150 m2 | 1 to 2 people | 380 V | 45 to 55 kW | USD 5,500 to 13,000 |

Process Flow

Grinding → Mixing → Pelleting → Cooling and screening → Packaging

Commercial Package

| Floor Area | Labor | Power Supply | Total Power | Guide Price |

| 180 to 250 m2 | 3 to 4 people | 380 V | 70 to 85 kW | USD 15,000 to 30,000 |

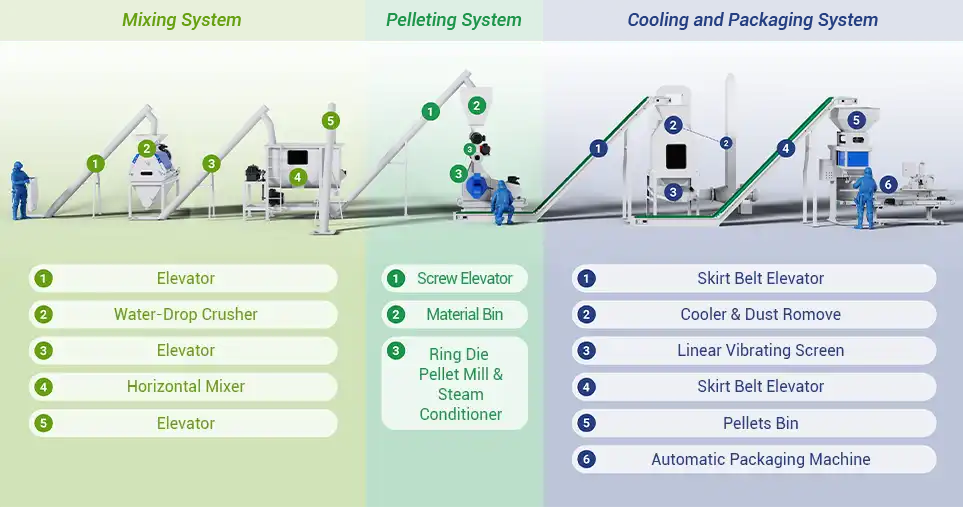

Process Flow

Raw material silo → Grinding → Mixing → Conditioning (with steam boiler) → Pelleting → Cooling and screening → Packaging

Raw Material Storage

To keep the line running continuously, plan storage and transfers carefully.

Silos

Store corn meal, soybean meal, and wheat bran in separate silos. This prevents moisture pickup and cross-mixing, and it makes ratio dosing and batching more accurate.

| Item | Recommended Spec |

| Number of silos | 3 to 4 |

| Capacity per silo | 5 m3 |

| Total storage | 15 to 20 m3 (about 8 to 11 tons) |

| Height | 5 m |

| Diameter | 2.2 to 2.5 m |

Grinding System

Proper size reduction improves downstream mixing, boosts pelleting efficiency, and helps animals digest nutrients better. Depending on your output needs and budget, choose hammer mill or water drop mill designs.

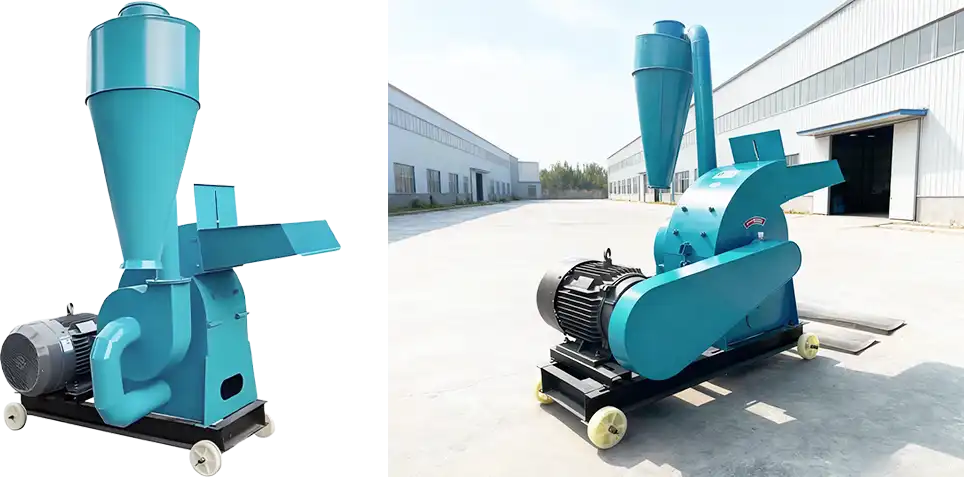

Hammer Mill (Economy option)

A hammer mill uses rapidly rotating hammers to impact and shatter the material, turning common poultry feed ingredients such as corn, soybean meal, and wheat bran into fine powder.

It offers high throughput and uniform discharge at a lower purchase cost, making it a solid choice for budget-conscious users who still value grinding efficiency.

Hammer Mill Specifications

| Model | Capacity (kg/h) | Motor Power (kW) |

| 400 | 500–600 | 7.5 |

| 420 | 800–1,000 | 11 |

| 500 | 1,000–1,500 | 15 |

Performance Demo

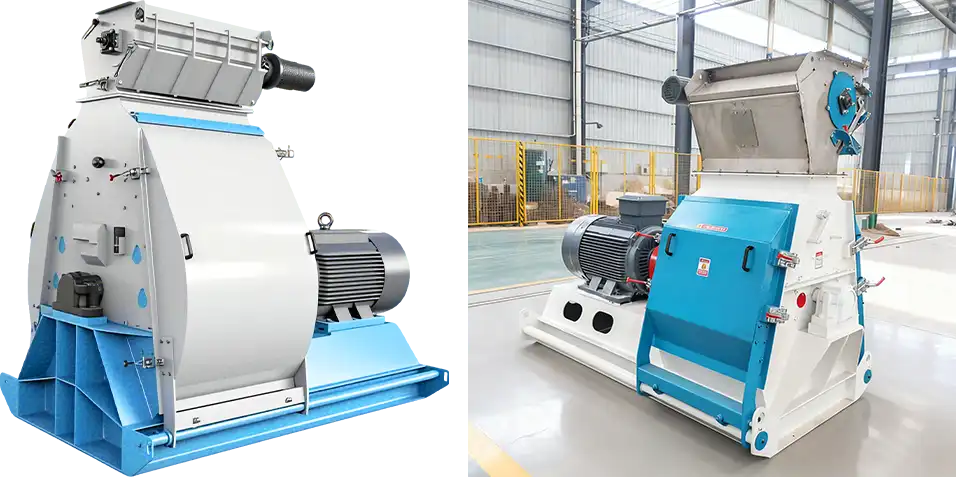

Teardrop Hammer Mill (Commercial option)

The water drop hammer mill upgrades the grinding chamber to a teardrop profile, reducing airflow resistance and improving efficiency and particle uniformity.

It outperforms a standard hammer mill but costs more, making it a better fit for commercial plants and higher automation needs.

Teardrop Hammer Mill Spec

| Model | Power (kW) | Coarse ≥ 3.0 mm (t/h) | Fine ≤ 2.5 mm (t/h) |

| SFSP56*30 | 22 | 1 to 3 | 0.5 to 1.5 |

Performance Demo

Mixing System

This stage blends milled ingredients with additives to ensure a uniform nutrient profile, feeding the pellet mill with a consistent mix. Mixing uniformity directly affects pellet quality and animal intake.

Stainless Steel Mixer (Economy option)

This mixer is simple, compact, and easy to operate. Screw blades provide continuous recirculation: horizontal for powders and vertical for larger particles.

It delivers stable mixing with low cost and low energy use, ideal for small and medium farms and for in-house poultry feed lines.

Stainless Steel Mixer Specifications

| Model | Batch size (kg) | Volume (L) | Motor power (kW) |

| 200 | 230 | 360 | 3 |

| 300 | 310 | 480 | 4.5 |

| 500 | 550 | 890 | 4.5 |

Mixing Performance

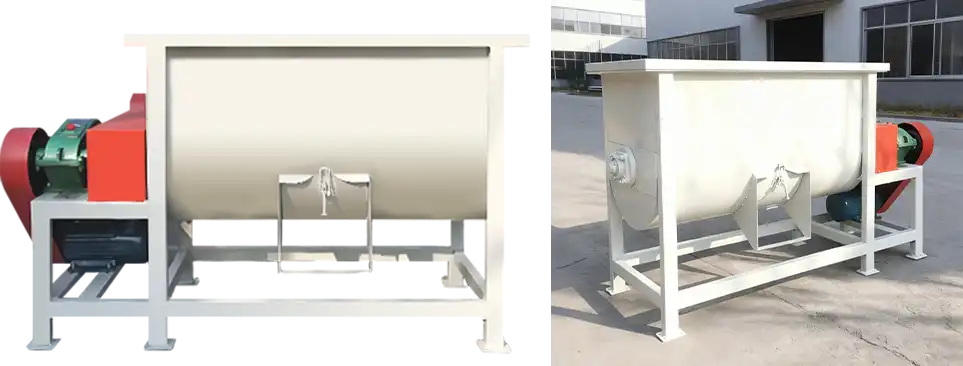

Horizontal Mixer

Larger loading space and higher mixing accuracy than a vertical stainless mixer. Single shaft or twin shaft paddles deliver fast, uniform mixing with stable efficiency. Suited to commercial poultry feed lines.

Horizontal Mixer Specifications

| Model | Volume (m3) | Motor power (kW) |

| 100 | 1.0 | 5.5 |

| 150 | 1.5 | 5.5 |

Mixing Performance

Conditioning and Pelleting

Conditioning and pelleting are the core steps of a poultry feed line. They press mixed materials into firm and uniform pellets, affecting hardness, cooking degree, and taste.

Equipment and conditioning options can be selected based on capacity and feed quality to balance cost and product performance.

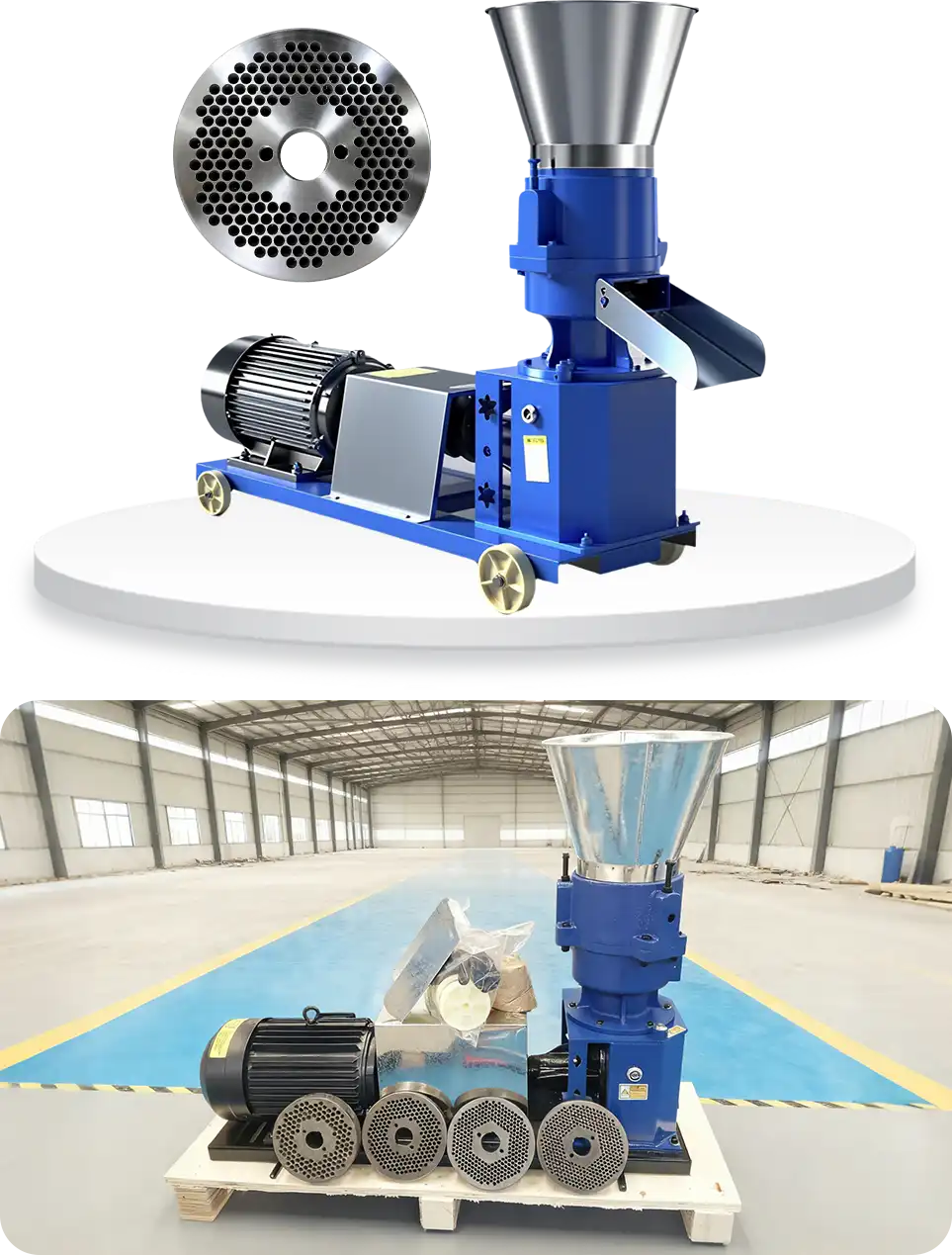

Flat Die Pellet Mill (Economy option)

The flat die pellet mill is simple to use and maintain. It supports cold pelleting without steam conditioning.

Pellets are firm and well formed, suitable for layer and broiler feed where high cooking is not needed.

Its low cost makes it a practical choice for small and medium farms or on-site feed production.

If you're looking for a more cost-effective solution, take a look at the 80–200 kg/h Chicken Feed Pellet Line Setup and Price.

Flat Die Pellet Mill Specifications

| Model | Power (kW) | Capacity (kg/h) |

| KD-300 | 22 | 500 to 700 |

| KD-400 | 37 | 900 to 1200 |

Work Video Demo

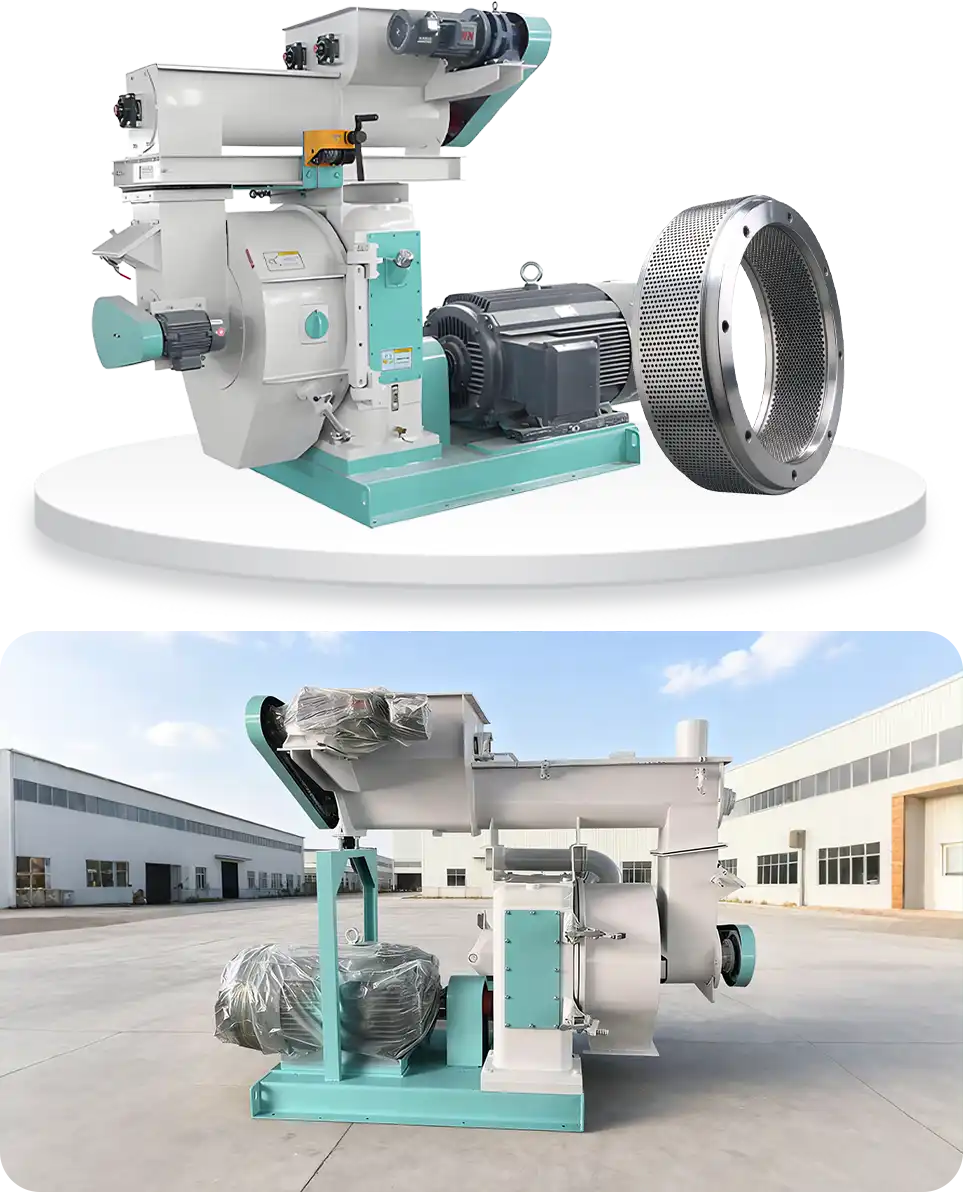

Ring Die Pellet Mill

The ring die pellet mill suits large scale continuous production with high output and dense, well-formed pellets.

Used with steam conditioning, it produces smoother, fully cooked pellets that are easier to digest and more hygienic, making it ideal for commercial poultry feed plants.

Ring Die Pellet Mill Specifications

| Model | Power (kW) | Capacity (t/h) |

| SZLH250 | 22 + 2.2 + 1.5 | 0.5 to 1.5 |

Pelleting Performance

Conditioner (Optional)

For higher feed quality, a single layer conditioner can be added for steam heating and moisture adjustment before pelleting.

It improves material softness and starch gelatinization, enhancing pellet hardness and feed digestibility.

Steam Boiler (Optional)

The steam boiler provides a stable heat source for the conditioning system, essential for high quality pelleting.

Steam Boiler Specifications

| Steam output (kg/h) | Pressure (MPa) | Temperature (°C) | Fuel type |

| 100 to 200 | 0.4 to 0.6 | 160 to 175 | Gas / Electric |

Cooling and Screening System

Freshly pelleted feed is hot and moist, which can cause breakage, clumping, or reabsorption of moisture if not cooled promptly.

This stage lowers temperature and humidity, removes fines and unqualified pellets, and ensures a clean, uniform product ready for packaging.

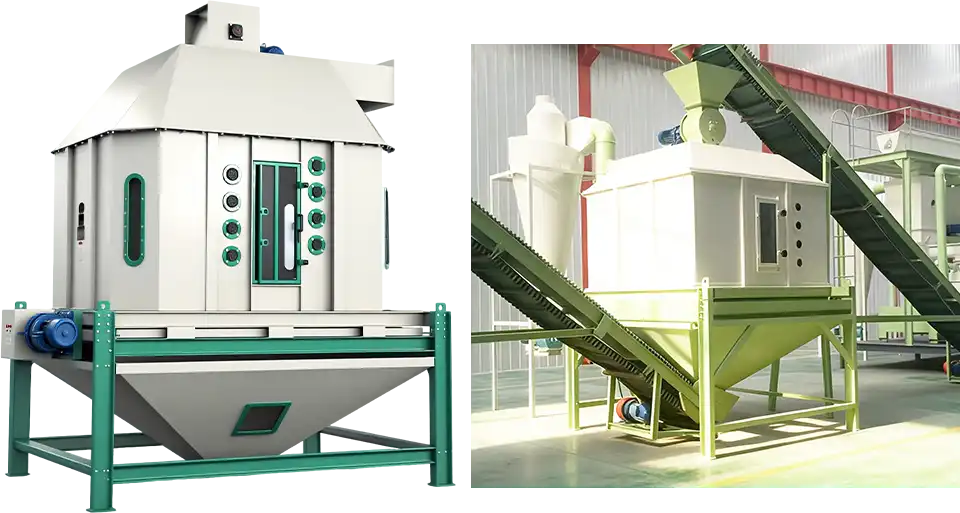

Counter Flow Cooler

After pelleting, the feed passes through a counter flow cooler where cool air moves upward through the pellet bed, quickly removing heat and moisture.

The cooled pellets are firm, smooth, and resistant to cracking or deformation.

Counter Flow Cooler Spec

| Model | Capacity (t/h) | Trough Volume (m3) | Power (kW) |

| NL2.5 | 5 | 2.5 | 0.75 + 0.55 |

Operating Demo

Vibrating Grading Screen

The vibrating screen precisely separates qualified pellets from fines and irregular particles. Finished pellets go directly to the product bin, while the fines are collected and returned for re-pelleting.

Vibrating Screen Specifications

| Screen Size (m) | Power (kW) |

| 1.0 × 2.0 | 3 |

Conveying Equipment

Connects each part of the line for smooth, automatic material flow. Compact and reliable, it helps improve efficiency.

Screw Conveyor (Powders)

The screw conveyor moves powdered feedstocks steadily and evenly between machines, enabling automatic feeding and cutting manual handling.

Its sealed housing prevents leaks and dust escape, keeping the plant cleaner while improving line continuity and overall efficiency.

Specifications

| Attribute | Range |

| Screw diameter | 165 mm |

| Conveying length | 3 to 6 m |

| Conveying speed | 1.0 to 1.5 m/s |

| Conveying capacity | 0.8 to 2 t/h |

| Conveying angle | ≤ 45° |

| Power | 2.2 to 4 kW |

Video Showcase

Skirt Belt Elevator (Pellets)

Used for conveying pellets before and after cooling. The flexible skirts on both sides prevent feed loss and breakage, keeping the pellets intact and reducing waste.

Skirt Belt Elevator Specifications

| Attribute | Recommended Range |

| Skirt belt width | 300 to 400 mm |

| Conveying length | 3 to 5 m |

| Belt speed | 0.8 to 1.5 m/s |

| Conveying angle | 15° to 35° |

| Power | 1.5 to 5.5 kW |

Packaging System

For commercial poultry feed production, various packaging options are available depending on output and automation level.

Choose between a portable sewing gun or an automatic sealing machine.

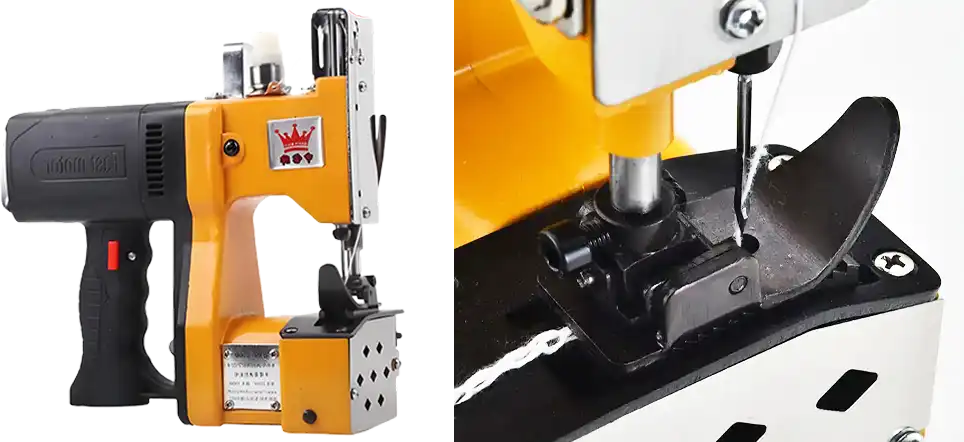

Manual Sewing Gun

Compact and easy to use, the sewing gun is ideal for small and medium farms or decentralized packaging.

It quickly seals feed bags, saving labor and cost. However, as it relies on manual operation, its efficiency is lower and not suitable for large scale continuous production.

Automatic Weighing and Packaging Machine

This unit integrates automatic weighing, bag filling, and sealing. It offers high efficiency and accuracy, making it suitable for large scale or continuous production lines.

Automatic Packaging Machine Spec

| Packaging Speed | 3–6 bags/Min (25 kg/ bags) |

| Packaging Weight | 5 – 50 Kg |

| Weighing Accuracy | ±0.1% |

| Power | 1.5 kW |

Automatic Packaging Machine Working Video

All configurations above are recommended based on a complete production process and can be adjusted to meet your specific needs.

Whether you're building a new feed line or upgrading an existing one, we can tailor an efficient, reliable solution to your needs. Contact us for details and a quote.

If you'd like to explore more production line setups, take a look at Top 5 Poultry Feed Production Line Solutions.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.