Multifunction Chaff Cutter Operation Manual and Instructions

File Download

Get the full operation manual in PDF format.

The chaff cutter is a machine used for cutting green and dry forage such as grass, corn stalks, and straw. It chops materials evenly with high-speed blades while keeping fiber intact, helping animals digest feed efficiently. This manual outlines the machine's structure, operation steps, blade adjustment, and maintenance guidelines.

1. Product Overview

The chaff cutter efficiently cuts fresh grass, corn stalks, straw, and other forage for livestock feeding and silage making. It delivers even output for cattle, sheep, horses, and other herbivores.

The standard model handles both wet and dry materials. With a kneading or crushing system, it can be upgraded for finer feed processing.

Cutting length is adjustable, and the machine can be equipped with 4, 6, or 8 blades. Power options include electric or diesel drive to suit local conditions.

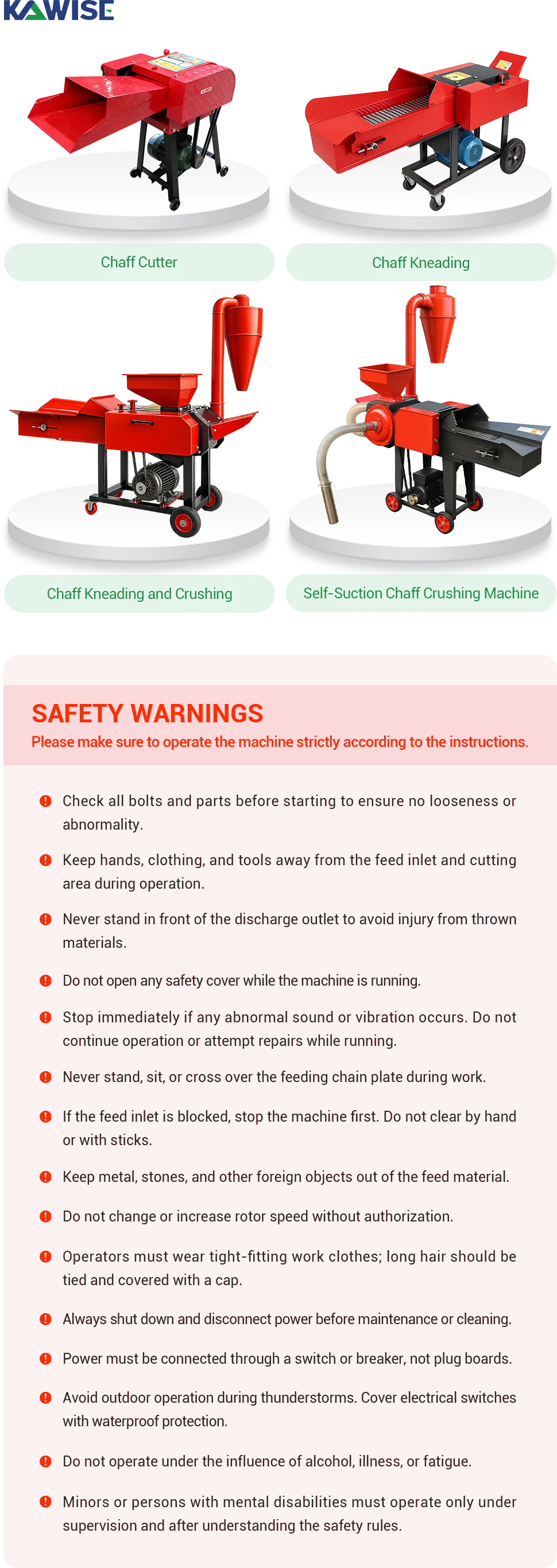

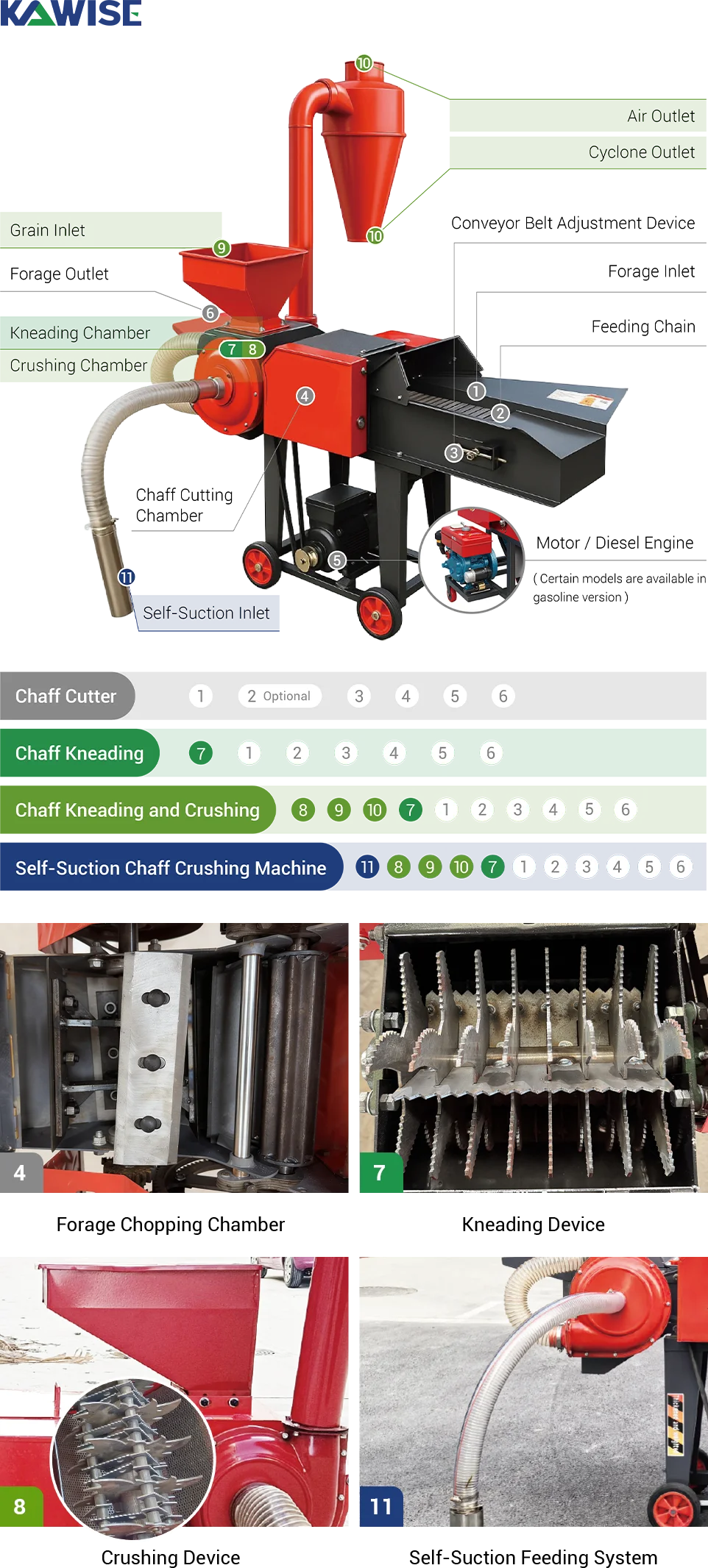

2. Main Model Introduction

All chaff cutter models are built for forage cutting as the basic function.

Based on this, different functional types can be extended to meet various feed processing needs, farming scales, and material handling requirements.

2.1 Chaff Cutter

The basic model is used only for cutting.

It suits direct chopping of fresh grass, corn stalks, straw, and other high-fiber forage.

2.2 Chaff Kneading

This model adds kneading rollers to the cutter. The fodder is pulled and pressed after cutting, making fibers soft and easy for ruminants to digest.

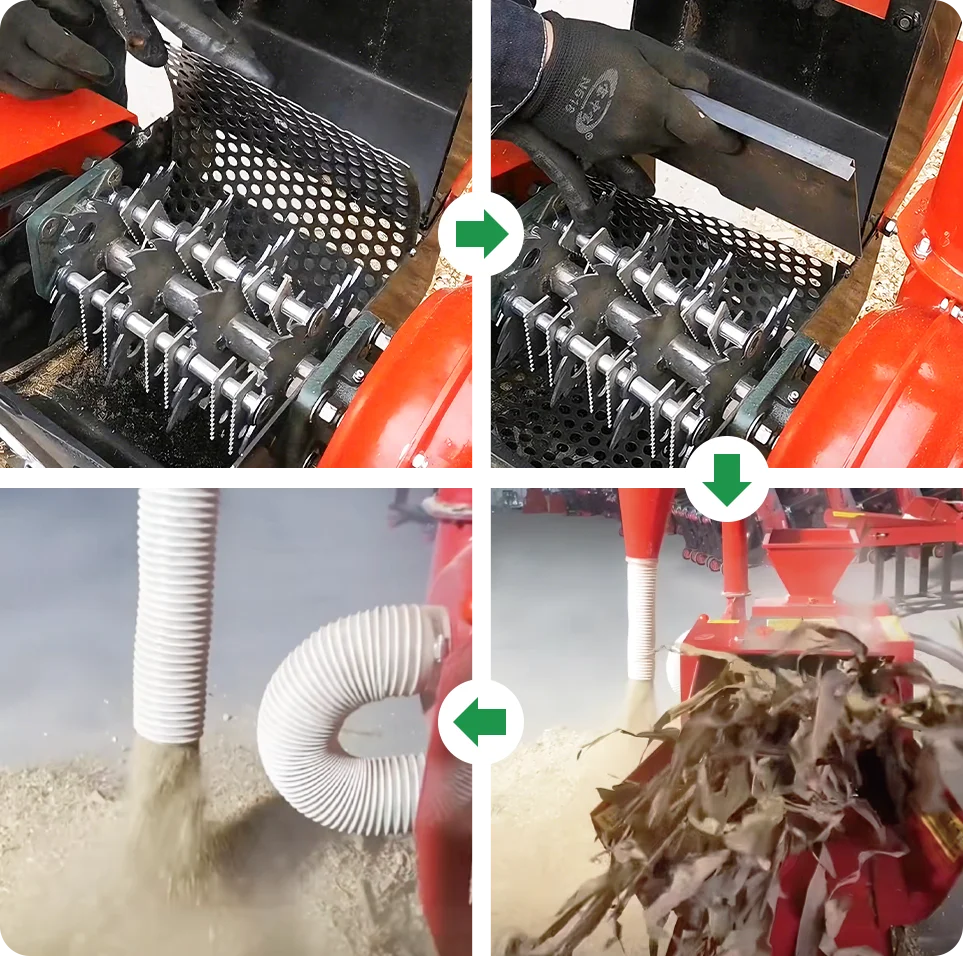

2.3 Chaff Kneading and Crushing

Based on the kneading model, this machine adds a crushing system.

After cutting and kneading, the material is crushed for finer processing. Suitable for straw, hay, grains, and vegetables. Output size is adjustable by screen.

Note: Crushing wet grass may cause blockage. Use this machine only for cutting and kneading.

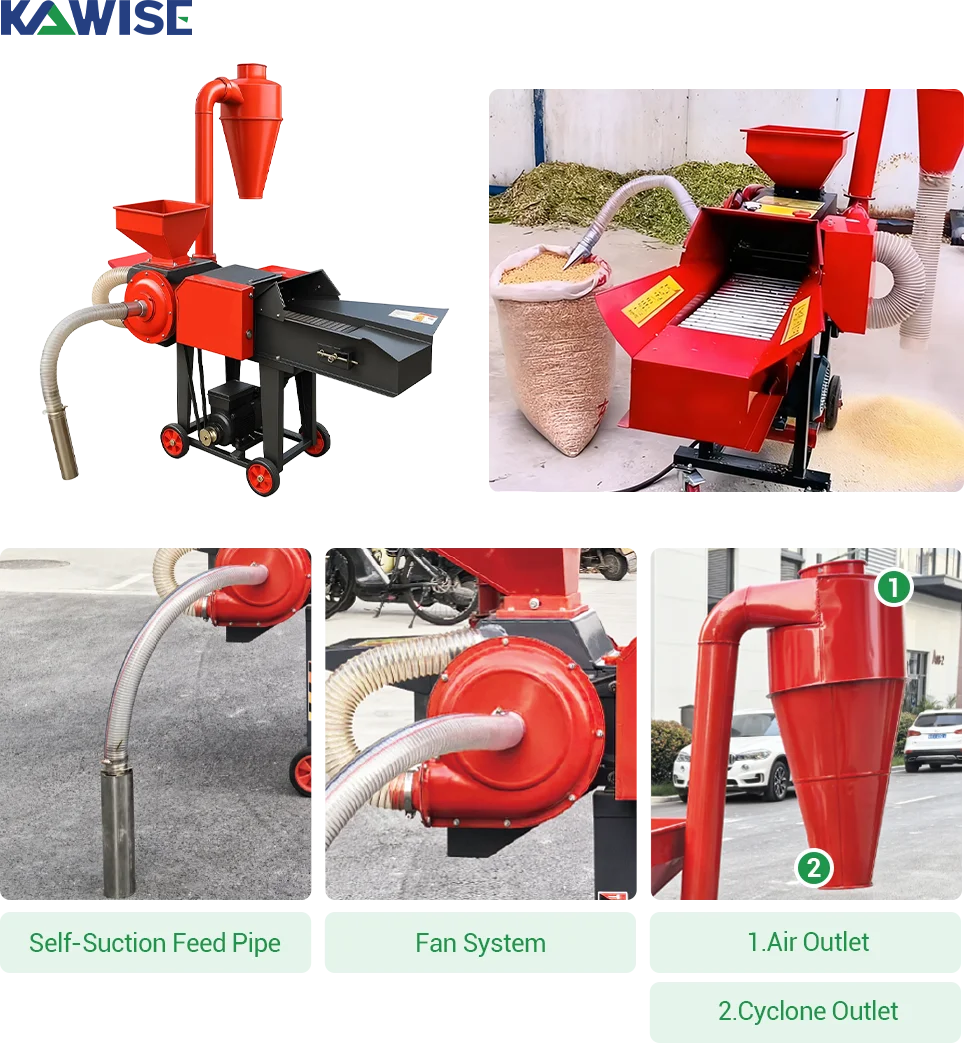

2.4 Self-Suction Chaff Crushing Machine

This model adds a self-suction feeding system to the crusher.

It automatically draws in loose materials such as corn, grains, beans, and straw fragments by airflow from a fan, reducing manual feeding work.

3. Main Components Display

4. Installation and Commissioning

Check that the power supply is above 200V and the cable is within 10 m.

Before use, ensure the power matches the equipment requirements and the cable is no longer than 10 meters.

Ground the machine securely and install a 60A breaker within 2 m of the power source for safety.

4.1 Equipment Installation

Step 1: Unpacking

Check all parts after unpacking. Confirm the frame, motor (or diesel engine), belt, guards, and pulleys are complete and undamaged.

Step 2: Assembly

Install the frame and motor. Adjust belt tension properly. Turn the pulley by hand to ensure smooth rotation.

Step 3: Lubrication

Before first use, lubricate bearings and gears to ensure smooth operation and reduce wear. (See 4.2 for details.)

Step 4: Tightness Check

After assembly, tighten all bolts and close the cover. Turn the pulley to confirm free rotation and correct motor direction.

Step 5: Blade Adjustment

Check bolts after transport. Adjust the gap between fixed and moving blades to 0.5–1 mm. (See 4.4 for adjustment steps.)

Step 6: Test Run

After installation, turn the pulley gently to ensure smooth movement. Check for friction, collision, or abnormal noise.

Installation Video (Electric Model)

Installation Video (Diesel Model)

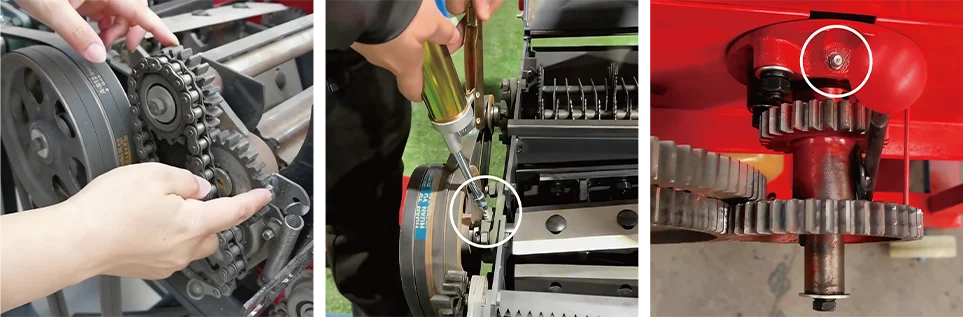

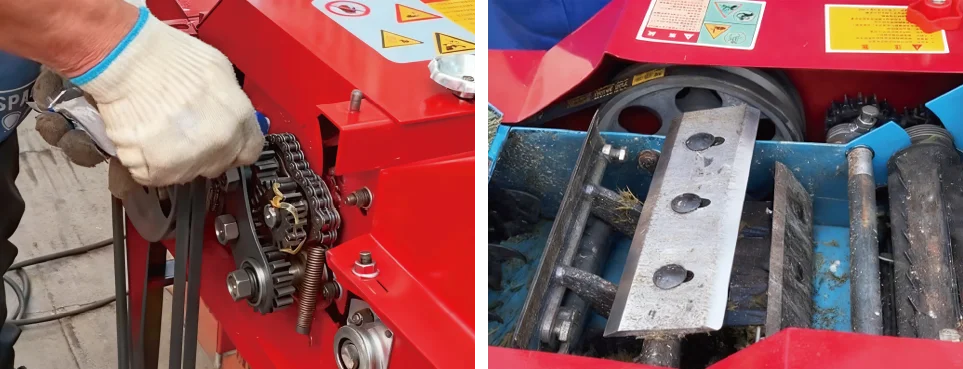

4.2 Transmission Lubrication

Before the first run, lubricate all transmission parts thoroughly.

- Remove the side guards and apply grease or oil evenly to gears and chains.

- Use a grease gun to fill the bearings until a small amount overflows.

- Apply grease to the feed gear, shift gear, and handle near the feed inlet.

- After lubrication, reinstall the guards and ensure all parts are secure for safe operation.

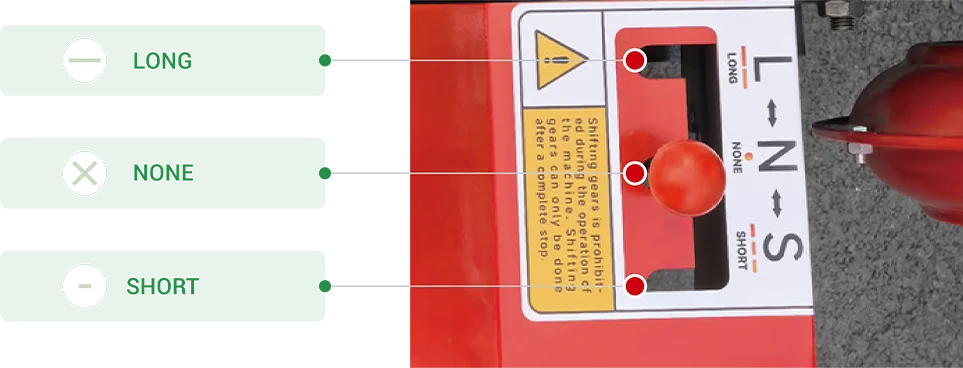

4.3 Forage Length Adjustment

The discharge length is adjusted using the Long–Short–Neutral handle.

This handle controls the transmission ratio between the feeding rollers and the main shaft (blade shaft), allowing the forage length to be changed.

Adjustment Method

Step 1: Make sure the machine is powered off or the engine is stopped before operation.

Step 2: Locate the Long–Short–Neutral handle on the side of the machine and select the desired gear:

- Long gear: larger feed rate, slower blade speed, longer forage pieces.

- Short gear: smaller feed rate, faster blade speed, shorter forage pieces.

- Neutral: disconnects the feeding system for idling.

Step 3: After adjustment, ensure the handle is firmly locked in position.

Step 4: Restart the machine and check if the discharge length meets requirements.

Cautions

Never shift gears while the machine is running to avoid gear damage.

Avoid frequent gear changes to keep the transmission system stable and reliable.

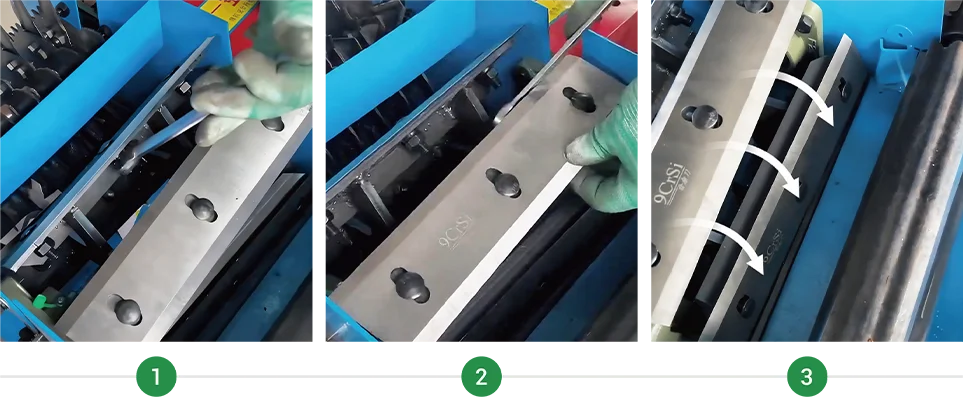

4.4 Blade Clearance Adjustment

The gap between the fixed and moving blades directly affects cutting performance and discharge quality.

- Too wide a gap may cause poor cutting and lower efficiency.

- Too narrow a gap may lead to blade collision or motor overload.

Adjustment Steps

- Ensure the equipment is powered off and disconnected.

- Loosen the fixed knife bolts.

- Place a wooden block on one side of the fixed knife holder and gently tap to adjust the fixed knife position, maintaining a 0.5–1 mm gap.

- Tighten the bolts after adjustment to secure the blade.

- Manually rotate the spindle to check if the knife operates smoothly. If any issues are found, adjust promptly.

Cautions

Wear gloves during adjustment to avoid cuts.

Do not strike the blades or holder to prevent edge damage or deformation.

Check blade wear regularly and sharpen or replace as needed.

5. Operation

After installation and inspection, operate the machine is as follows.

Note that functions and precautions may vary by model.

Do not run the kneading and crushing functions at the same time to prevent overload or damage.

Keep away from the discharge outlet while the machine is running.

5.1 Chaff Cutting (Kneading)

- Open the chaff cutter cover, install and secure the partition, then close the cover. (If equipped with a crushing function, insert the partitioninto the crushing inlet.)

- Open the discharge outlet cover, ensuring it is unobstructed.

- Set the cutting speed and discharge length.

- Feed material evenly to avoid overload.

- Stop feeding and turn off the power or engine after use.

- Clean the machine and remove residual material to keep it tidy.

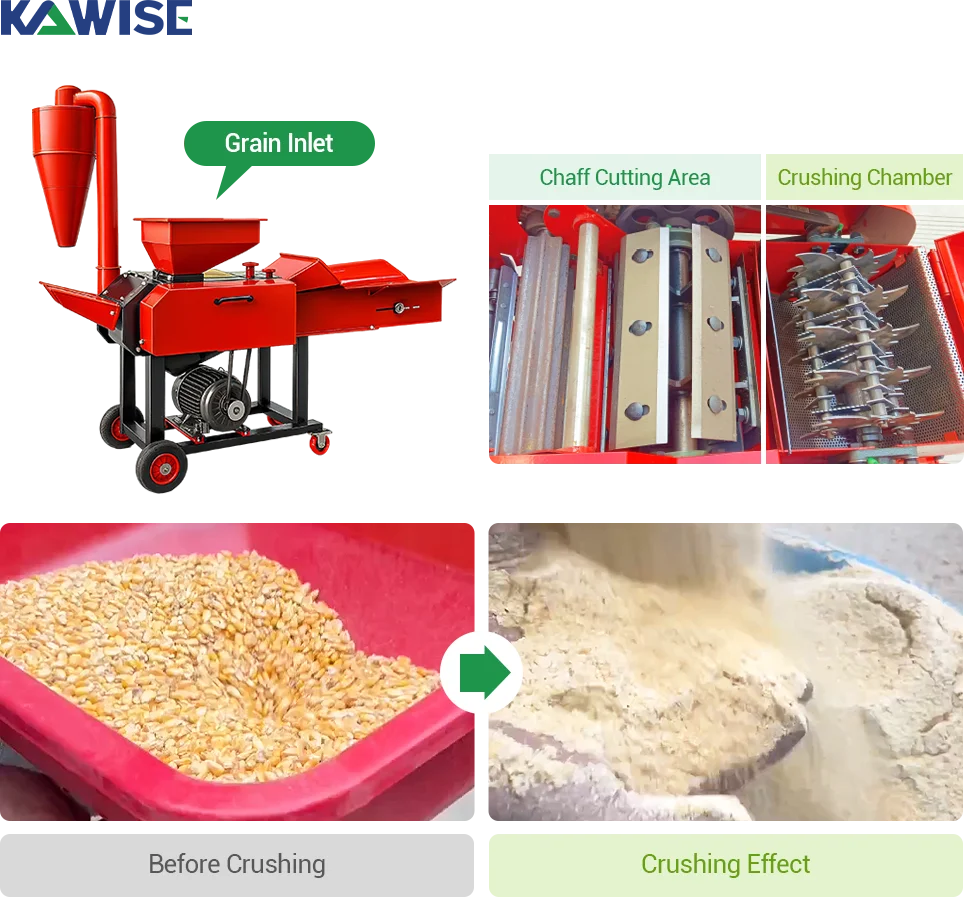

5.2 Crushing

Install a screen with proper hole size to adjust particle size.

Used for crushing corn, wheat, straw, and hay with low moisture after cutting or kneading.

Note: Before operation, keep the cutting length handle in Neutral to prevent system interference.

5.2.1 Grain Crushing

- Power off the machine and install a 2–5 mm screen at the bottom of the crushing chamber.

- Insert partition at the chaff inlet and outlet to seal the chamber.

- Open the grain inlet partition and feed material evenly to avoid overloading.

- Dust exits through the grain outlet, while powder is collected from the lower outlet.

- Stop feeding and turn off the power or engine after use.

- Open the chamber, clean the residue, and keep the equipment dry and clean.

5.2.2 Straw and Hay Crushing

- Open the crushing chamber cover, install a 5-30 mm screen at the bottom, secure it, and insert a partition at the discharge outlet. Close the cover. (For grain crushing models, insert a partition to seal the chamber.)

- Set the cutting speed and discharge length.

- Feed straw or dry hay evenly, ensuring continuous feeding to prevent overload.

- Crushed material exits through the grain outlet for collection.

- Stop feeding and turn off the power or engine after use.

- Open the chamber, clean the residue, and keep the equipment dry and clean.

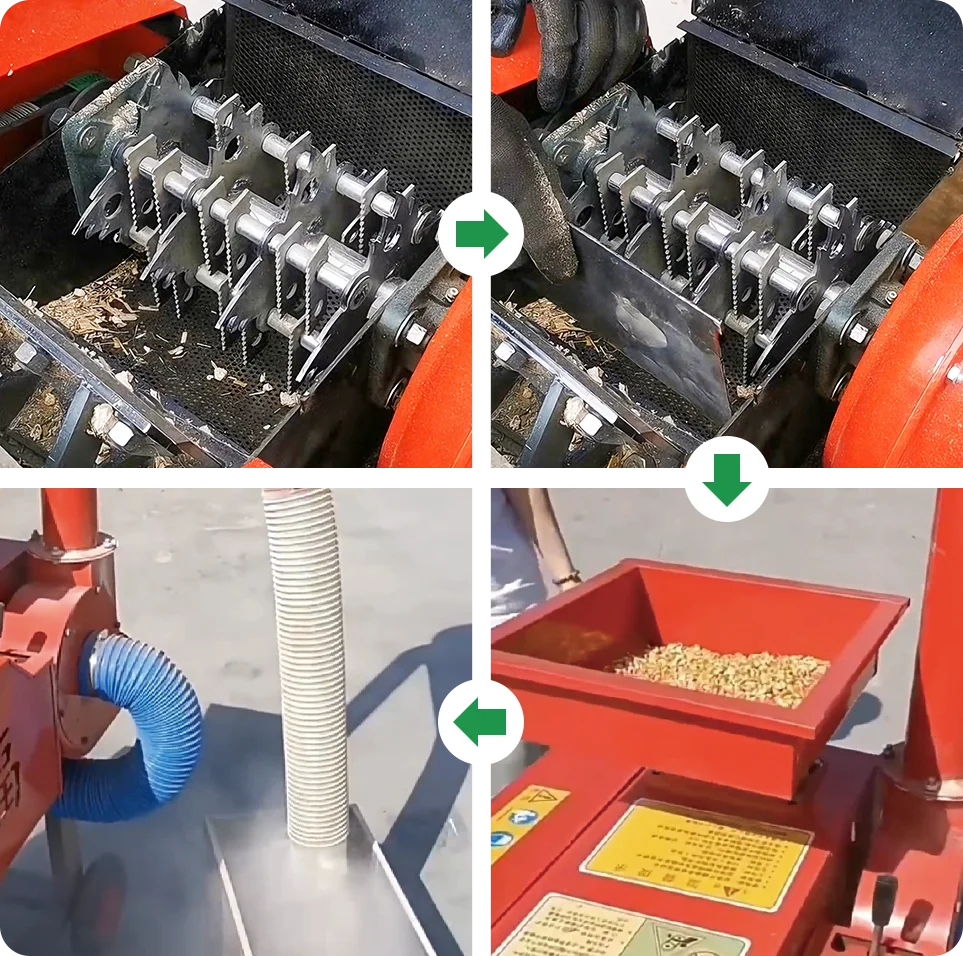

5.2.3 Self-Suction Feeding Crushing

- Power off and check the intake pipe, feed inlet, and connections for blockages.

- Install a 2–5 mm screen and insert partition at the inlets to seal the chamber.

- Power on and start once stable.

- Position the self-suction pipe for even material intake.

- Turn off power and clean the intake pipe and chamber after use.

6. Common Problems and Solutions

Low Efficiency / Poor Cutting

| Cause | Solution |

| Blades worn or dull | Sharpen or replace the blades |

| Blade gap incorrect | Adjust the clearance (see 4.4) |

| Shaft speed too low | Check and tighten the drive belt |

Blockage / Machine Stops

| Cause | Solution |

| Overfeeding overload | Stop the machine, clear blockage, and feed evenly |

| Feed inlet or system blocked | Power off, then remove the blockage |

Material Return (Self-Suction Model)

| Cause | Solution |

| Pipe or screen blocked | Clean the discharge pipe or replace the screen |

| Weak or wrong airflow | Check fan blades and air guide plate |

| Belt slipping | Adjust belt tension or replace if worn |

Vibration / Noise

| Cause | Solution |

| Bolts loose | Check and tighten all bolts |

| Frame unstable | Place machine on solid, level ground |

| Bearing worn or lacks grease | Replace or lubricate bearings (see 4.2) |

7. Maintenance and Care

Perform regular maintenance to keep the machine stable and extend its service life.

Always disconnect power before servicing to ensure safety.

Daily Maintenance

- After each use, check lubrication of all transmission parts and add oil if needed.

- Clean the surface and inside of the machine to keep it dry and tidy.

- Apply oil to the drive chain every 12 hours of work, and check bearings and gears regularly, adding grease when necessary.

Cutting and Kneading Parts

Check the fixed and moving blades, as well as kneading rollers, for wear.

Reverse or replace tooth plates when worn on both sides. If metal edges are worn, repair by welding and grind them smooth.

Rust Protection and Appearance

After operation, apply anti-rust oil to friction surfaces.

Repaint any areas with peeled coating to prevent rust and extend service life.

Technical Specifications

Chaff Cutter

| Model | Power | Horsepower |

| 3T | 4 kw | 6 hp |

| 3.8T | 4.5 kw | 6 hp |

| 4.8T | 5.5 kw | 8 hp |

| 5.8T | 5.5 kw | 8 hp |

| 6.8T | 7.5 kw | 12 hp |

Chaff Kneading Machine

| Model | Power | Horsepower |

| 3T | 4.5 kw | 6 hp |

| 3.8T | 4.5 kw | 6 hp |

| 4.8T | 5.5 kw | 8 hp |

| 5.8T | 5.5 kw | 8 hp |

| 6.8T | 7.5 kw | 12 hp |

Chaff Kneading and Crushing(with self-suction)

| Model | Power | Horsepower |

| 3.8T | 4.5kw | 6 hp |

| 4.8T | 5.5kw | 6 hp |

| 5.8T | 5.5kw | 8 hp |

The machine is equipped with a four-pole pure copper motor that meets national standards, with a rated speed of 1400 rpm.

The power cable should use standard copper core wire of at least 10 mm2.

*Voltage and frequency can be customized, or a diesel model can be selected as needed.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.