How a Chaff Cutter Can Benefit Your Farm

The way coarse feed is processed directly affects animals' intake and health. To enhance feed palatability, many farmers use chaff cutters to chop the forage, making it easier to consume and reducing waste. Whether for small family farms or large-scale operations, proper forage handling significantly improves feeding quality.

Function and Purpose of the Chaff Cutter

The core function of the chaff cutter is to cut large forage or straw into lengths suitable for animals to consume and digest. By chopping the feed, it significantly improves animals' feeding efficiency and enhances their health.

The chaff cutter operates by using an electric motor to drive rotating blades, which quickly slice the forage into predetermined lengths, ensuring it is easy for animals to eat and digest.

| Processed Materials | Examples |

| Forage Feed | Dry hay, elephant grass, fresh pasture, oat hay, etc. |

| Crop Straws | Wheat straw, rice straw, corn stover, peanut vines, sugarcane leaves, etc. |

| Leguminous Feeds | Alfalfa, clover, and other high-protein forages |

| Silage Materials | Silage corn, silage grass, etc., which can undergo pre-cut processing |

Based on material hardness and fiber length, the chaff cutter uses an adjustment lever to change cutting length, ensuring the forage meets different feeding needs.

How to Boost Farm Efficiency with a Chaff Cutter?

For farms with high coarse feed needs, processing forage to improve palatability and digestibility is crucial for better feed quality. A chaff cutter helps increase forage utilization, reduce waste, and optimize time and labor, improving overall farm efficiency.

1. Improved efficiency, Time savings

Traditional forage processing is time-consuming and inefficient, relying on manual labor. A chaff cutter automates the cutting process, greatly improving efficiency and reducing labor.

For large farms, it saves time and allows owners to focus on other tasks, boosting overall farm productivity.

2. Reducing feed waste

Long fibers in forage often lead to waste during feeding, with some leftover in the trough. After being cut or shredded by a chaff cutter, the forage is more palatable, reducing waste and making feeding more efficient, while also easing cleaning.

3. Easier storage and transport

Cut forage takes up less space, making it easier to store and transport. For large farms, this reduces storage needs and prevents spoilage, cutting storage and transport costs.

4. Better digestion, Increased productivity

Cutting forage increases surface area, helping animals digest and absorb nutrients more effectively. This enhances digestion, increases milk production, or accelerates meat growth, improving overall animal productivity.

5. Versatile use, Suitable for various animals

The chaff cutter can process forage for different animals like goats, sheep, dairy cows, beef cattle, and horses, making it ideal for farms with diverse livestock.

Return on Investment for Equipment

The cost of a chaff cutter is relatively low. While there is an initial investment, the payback period is short due to reduced feed waste and lower labor costs in daily feeding.

For farms with high forage consumption, the chaff cutter's consistent cutting ability and easy operation make feed processing more centralized and feeding more efficient, improving overall operations and providing clearer returns on investment.

Choosing the Right Chaff Cutter

Different farms have varying forage types, handling volumes, and feeding methods, so the chaff cutter configuration should be customized. We offer several options to help you choose the best equipment for your needs:

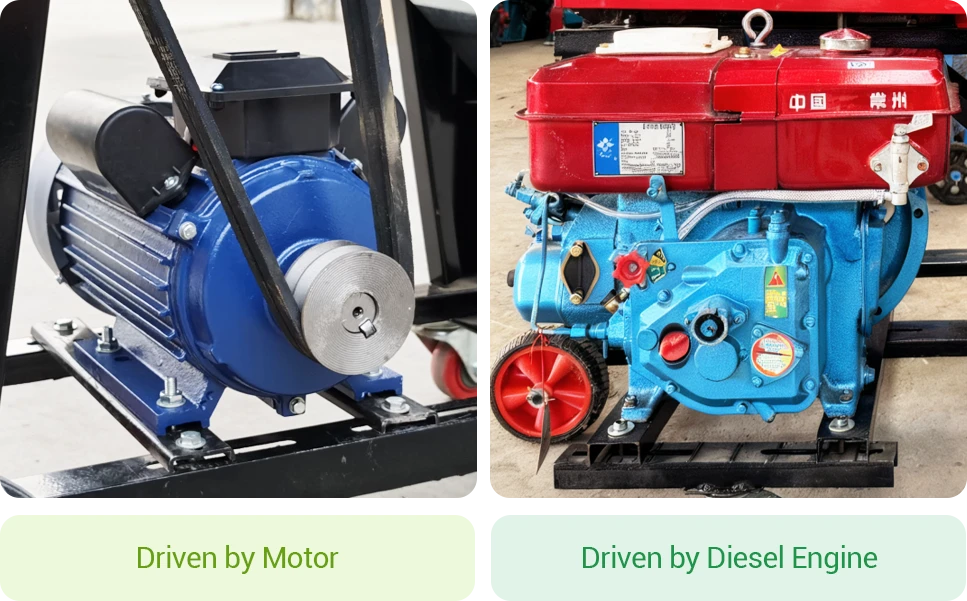

Motor or Diesel Engine Options

Choose between a motor or diesel engine based on your farm's power supply. The motor version is ideal for stable electricity, while the diesel version is better for areas with limited power or outdoor operations.

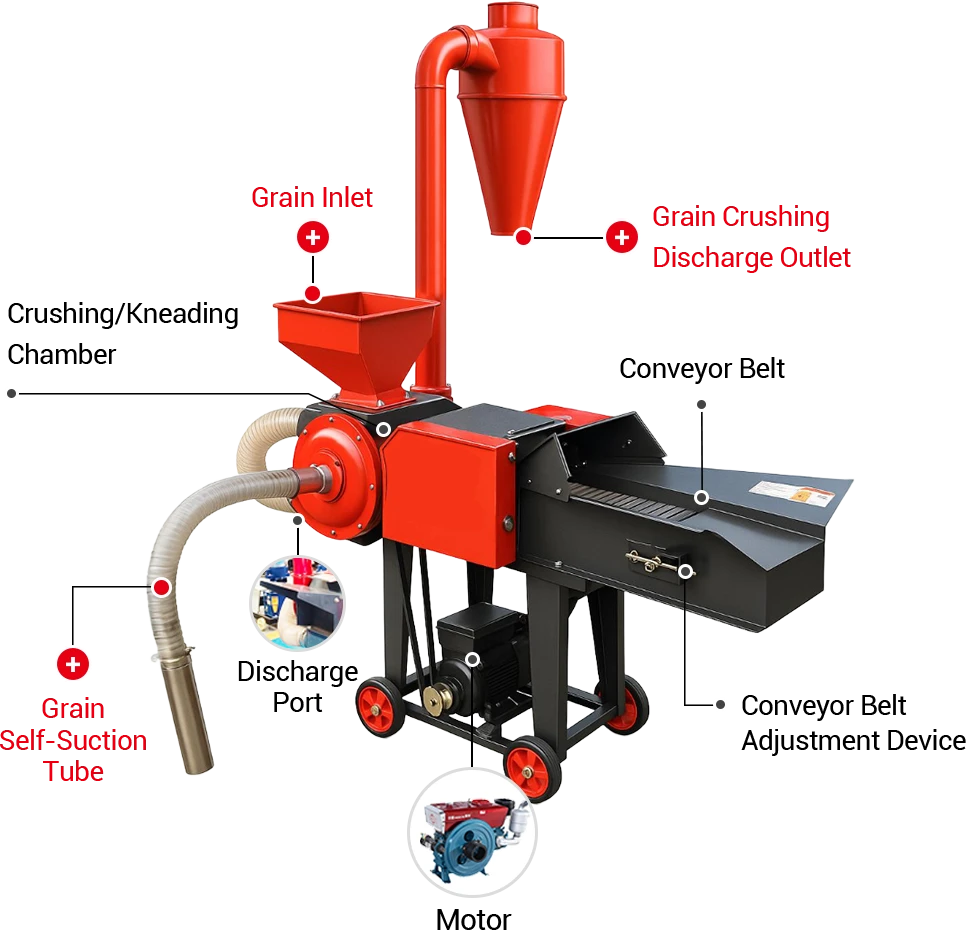

Optional Crushing and Shredding Functions

The machine offers optional grinding or crimping functions alongside basic cutting. Grinding is ideal for grains and can include a self-priming feed inlet. The crimping module loosens the forage, making it easier for animals to eat and mix.

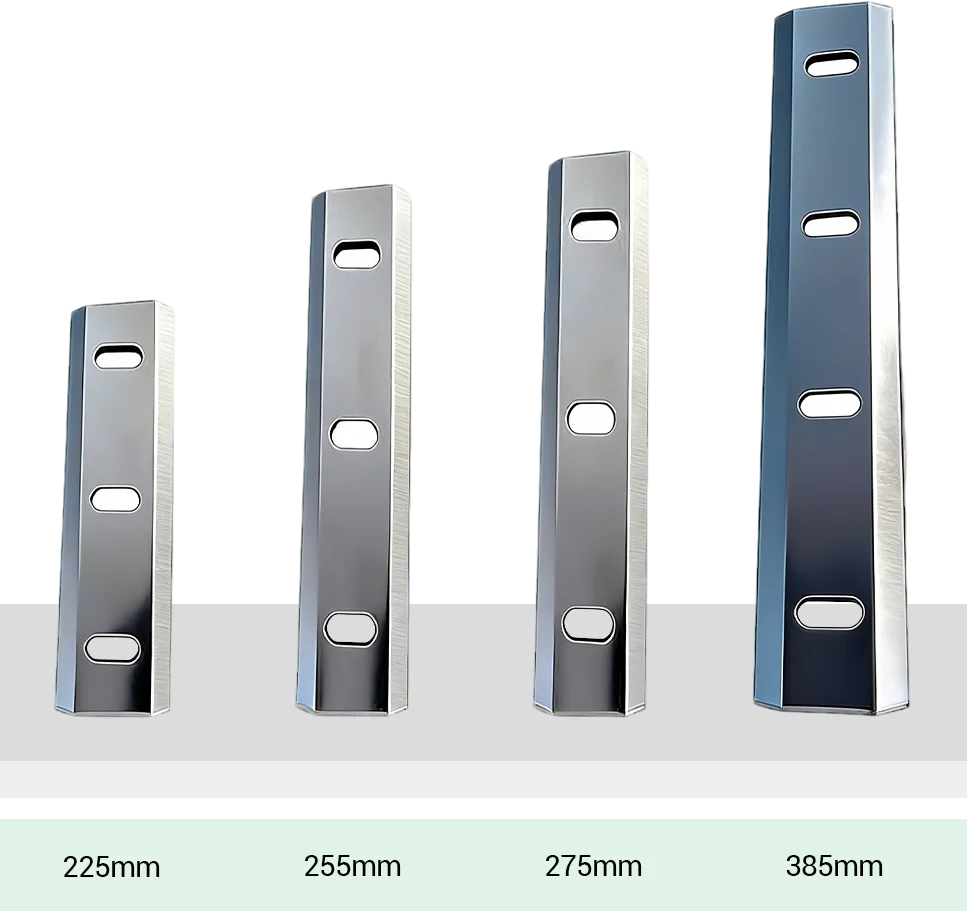

Customizable Blade Length and Output

The equipment supports different blade lengths (e.g., 225mm, 255mm, 275mm, 385mm). Longer blades offer higher output and wider cutting width. Select based on your daily needs, and some models allow additional blades for improved efficiency.

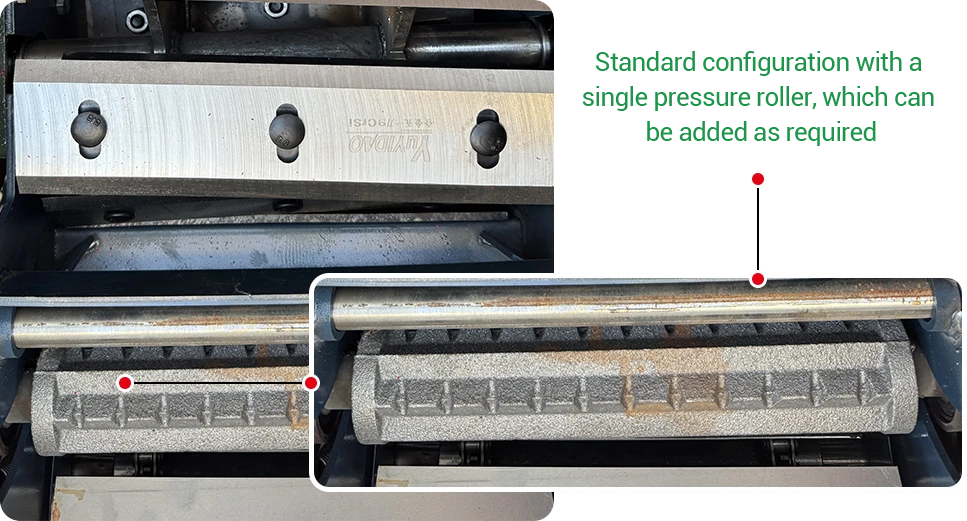

Adjustable Rollers

Add extra rollers for tougher or more fibrous materials to improve feed handling and ensure smoother cutting.

Customizable Discharge Options

The discharge port can be adjusted to suit your feeding system, such as extending (high spray), changing direction, or adding more outlets, reducing handling steps.

Optional Stand

For farms needing greater stability or frequent mobility, an optional stand can reduce vibrations and enhance stability during operation.

FAQ

How much does a high-quality chaff cutter cost?

Prices vary based on model, configuration, and output. We offer customizable options, such as blade length and power configuration, to fit different farm needs. Contact us for a detailed quote based on your requirements.

Can a chaff cutter handle high-moisture forage?

Yes, by adjusting the blade gap, the chaff cutter efficiently handles high-moisture forage, preventing clogs and improving cutting performance.

How often do the blades need to be replaced?

Blade replacement depends on forage hardness and usage frequency. For tougher materials like straw or bark, blades wear faster and should be checked and replaced more often.

Can processed forage be used directly for feeding?

Yes, processed forage is more uniform and easier to digest. It can also be mixed with other ingredients to optimize the feed formula for different animals.

What is the lifespan of a chaff cutter?

With regular maintenance, a chaff cutter can last for many years. Routine blade replacement, cleaning, and lubrication help extend its lifespan.

For more detailed information on the installation, maintenance, and servicing of the chaff cutter, please refer to our:

Multifunction Chaff Cutter Operation Manual and Instructions

If you want to simplify feed preparation, reduce waste, and boost livestock productivity, a chaff cutter is a worthwhile investment. By efficiently processing forage, it saves time, improves animal health and productivity, and leads to higher profitability.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.