Common Chaff Cutter Problems and Solutions

During daily operation, chaff cutters may experience issues such as material blockage, machine jamming, failure to rotate, or unstable discharge. Based on real operating conditions, the following section summarizes common problems and practical solutions for quick reference during use.

Operating Notes

Before inspecting, adjusting, or servicing the chaff cutter, always prioritize safety. To prevent personal injury or equipment damage, observe the following precautions during operation.

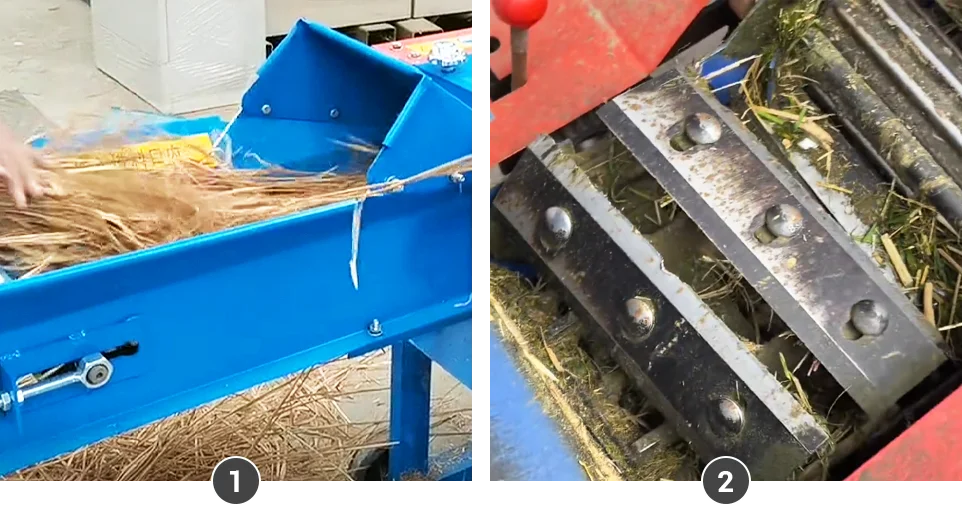

1. Blockage and Jamming During Operation

Blockage or jamming may occur when material conditions change, feeding is uneven, or the cutting system does not match the material. Increased resistance leads to material buildup in the cutting chamber.

Extended high load operation can reduce cutting efficiency, causing material to stay longer in the cutting area. Insufficient or mismatched motor power may also result in blockage or jamming.

Solution

- Shut off the power immediately to protect the motor and ensure safety.

- Open the chaff cutter working chamber.

- Wear gloves and remove the blocked material carefully to avoid contact with the blades.

- Adjust the discharge plate height to allow smooth material flow.

- Restart the machine after inspection and resume normal operation.

2. Machine Not Rotating or Abnormal Startup

After startup, power is transferred from the motor or drive source to the main shaft and rotating components. If the rotation system is blocked, the machine may fail to start or stop suddenly during operation.

This issue is mainly related to two causes:

- Material, fibers, or foreign objects wrapped around the cutter shaft or roller shaft, increasing resistance and preventing normal rotation.

- Worn or damaged bearings after long term use, causing poor rotation and abnormal startup or operation.

Solution

- Cut off power before inspection.

- Check the cutter shaft and roller shaft for wrapped material or debris and remove it.

- Rotate parts by hand to check for resistance or abnormal noise.

- Replace worn or damaged bearings if needed.

- Test run the machine after confirming smooth rotation.

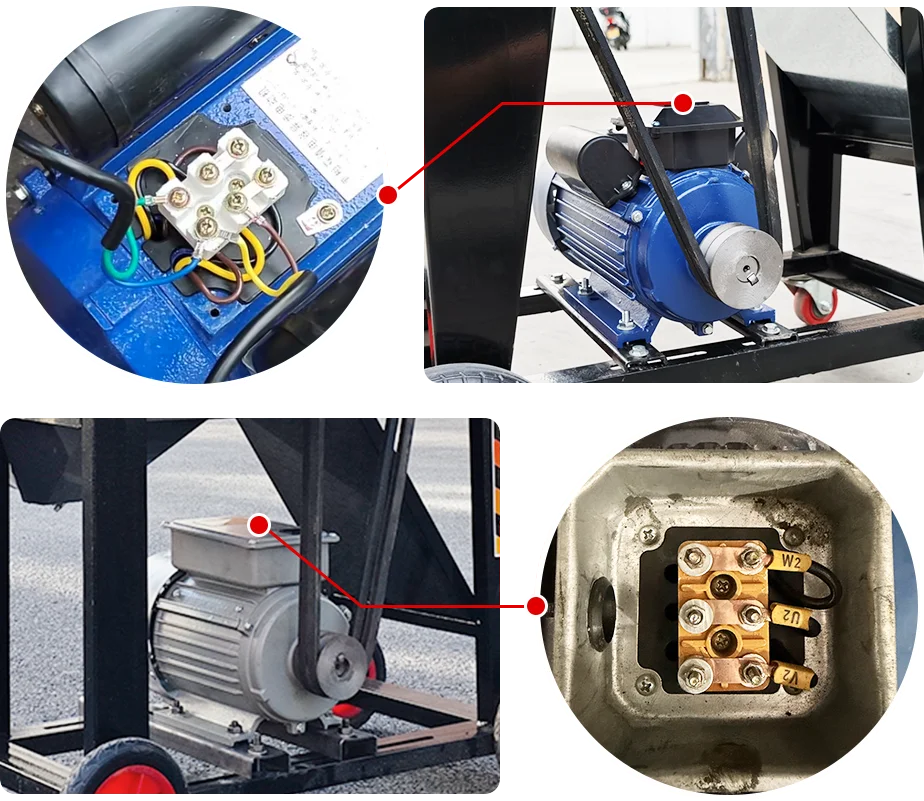

3. Motor Reverse Rotation

If the motor runs after startup but material cannot be fed or cut properly and instead piles up at the inlet or is pushed back, the motor is likely rotating in reverse.

Although motor direction is checked before delivery, wiring may loosen during transport or change during installation, connection, or maintenance, causing reverse rotation.

Note

When troubleshooting, confirm the machine was not set to reverse by mistake and check that the drive components are installed correctly, with motor rotation matching the cutter direction.

Adjustment Method

Chaff cutters usually use single phase or three phase motors.

- Single phase motor: Check and correct the wiring of the main and auxiliary windings.

- Three phase motor: Swap any two power supply wires to change the rotation direction.

We have a dedicated article that explains motor reverse rotation adjustment in detail for reference. How to Adjust Flat Die Pellet Mill Reverse Rotation Correctly

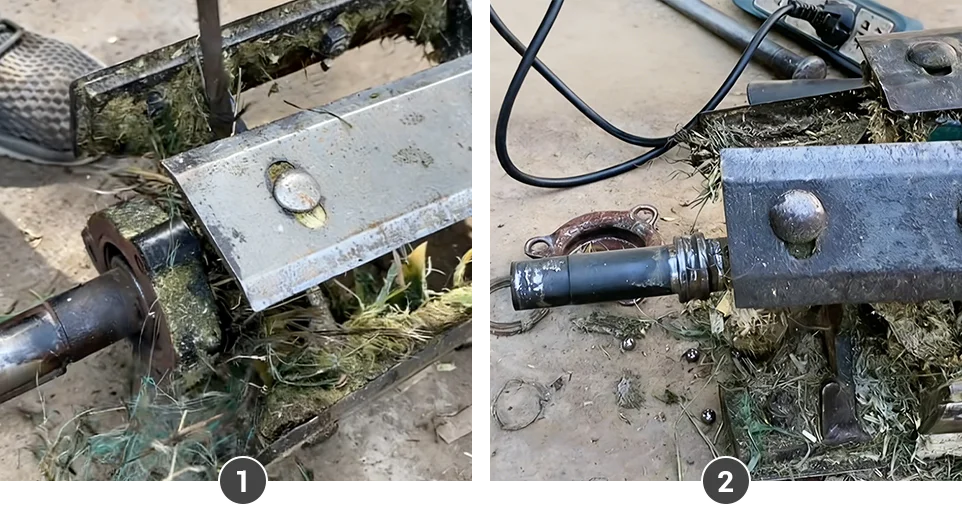

4. Feed Roller Rotation or Pressure Issues

If material is difficult to feed into the cutting chamber, feeding becomes uneven, or material builds up at the inlet and requires frequent manual assistance, the issue is usually related to abnormal feed roller rotation or insufficient pressing force.

Solution

- Turn off the power and remove the side protective covers.

- Open the machine chamber door.

- Remove the fixing bolts on both sides of the feed roller. Apply lubricant if the bolts are tight.

- Check the springs for damage, deformation, or blockage by debris.

- Replace damaged springs or remove any obstruction.

- Reinstall all parts and confirm the feed roller rotates normally.

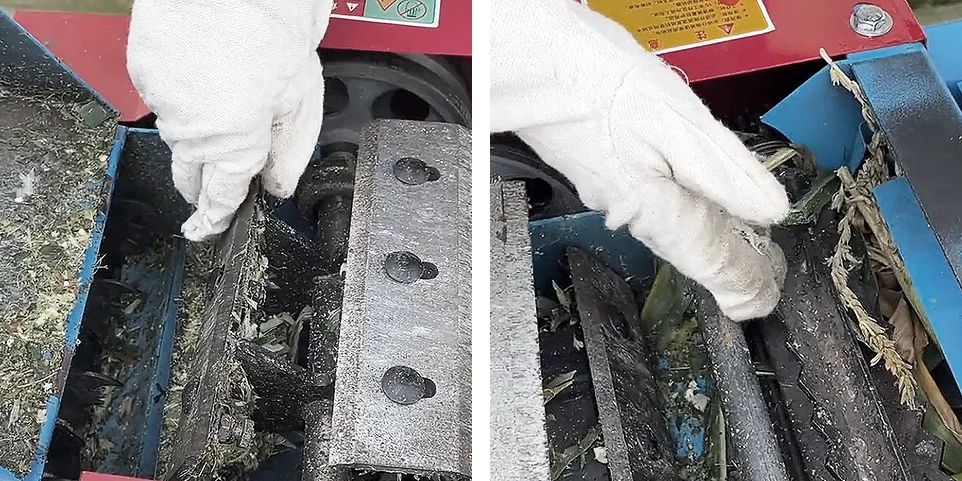

5. Blade Wear and Sharpening

Over time, blades gradually wear, reducing cutting efficiency and output quality. Blade handling generally falls into two options depending on wear level.

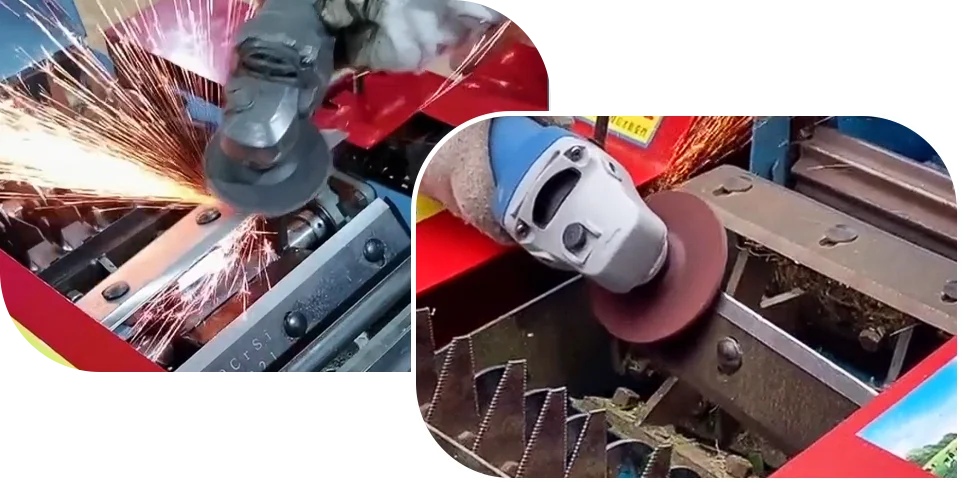

5.1 Sharpening with an angle grinder

When wear is minor and the blade edge remains intact without chips or deformation, sharpening with an angle grinder can restore cutting sharpness. This method suits light wear.

5.2 Blade replacement

When blades show heavy wear, visible damage, deformation, or fail to perform after repeated sharpening, replacement is recommended. Timely replacement helps restore normal operation and prevents extra load on other components.

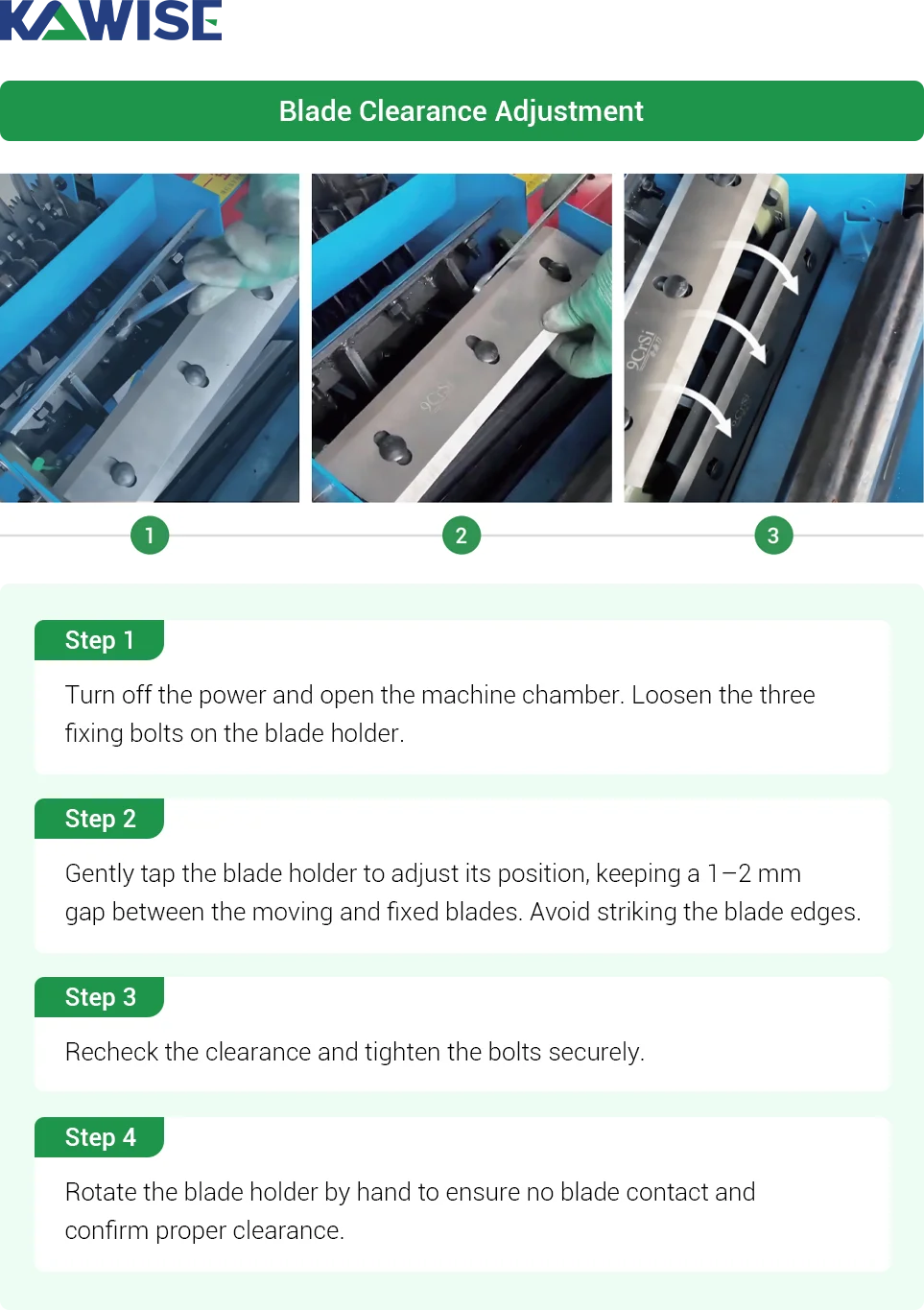

After installing a new blade set, readjust the blade clearance.

6. Uneven Cutting Length

Uneven output length or poor discharge performance is usually caused by unstable cutting rhythm. In most cases, this results from inconsistent manual feeding or improper blade clearance and blade wear.

6.1 Improve Manual Feeding Rhythm

Keep feeding steady and continuous. Avoid sudden changes in speed or feeding large amounts at once. Adjust feeding when material conditions change to maintain consistent output.

6.2 Adjust Blade Clearance

7. Abnormal Noise During Operation

Abnormal noise usually indicates changes in the condition of transmission components. In most cases, it comes from the chain or bearings. Loose chains, poor lubrication, or worn bearings can all cause unusual sounds during operation.

Solution

- Check whether the drive chain is loose, misaligned, or rubbing against the guard. Adjust the tension if needed.

- If the chain runs dry or produces friction noise, apply lubricant evenly.

- Rotate the chain and bearings by hand to check for sticking, noise, or rough movement.

- After confirming proper tightening and lubrication, reconnect power and run a test to see if the noise is eliminated.

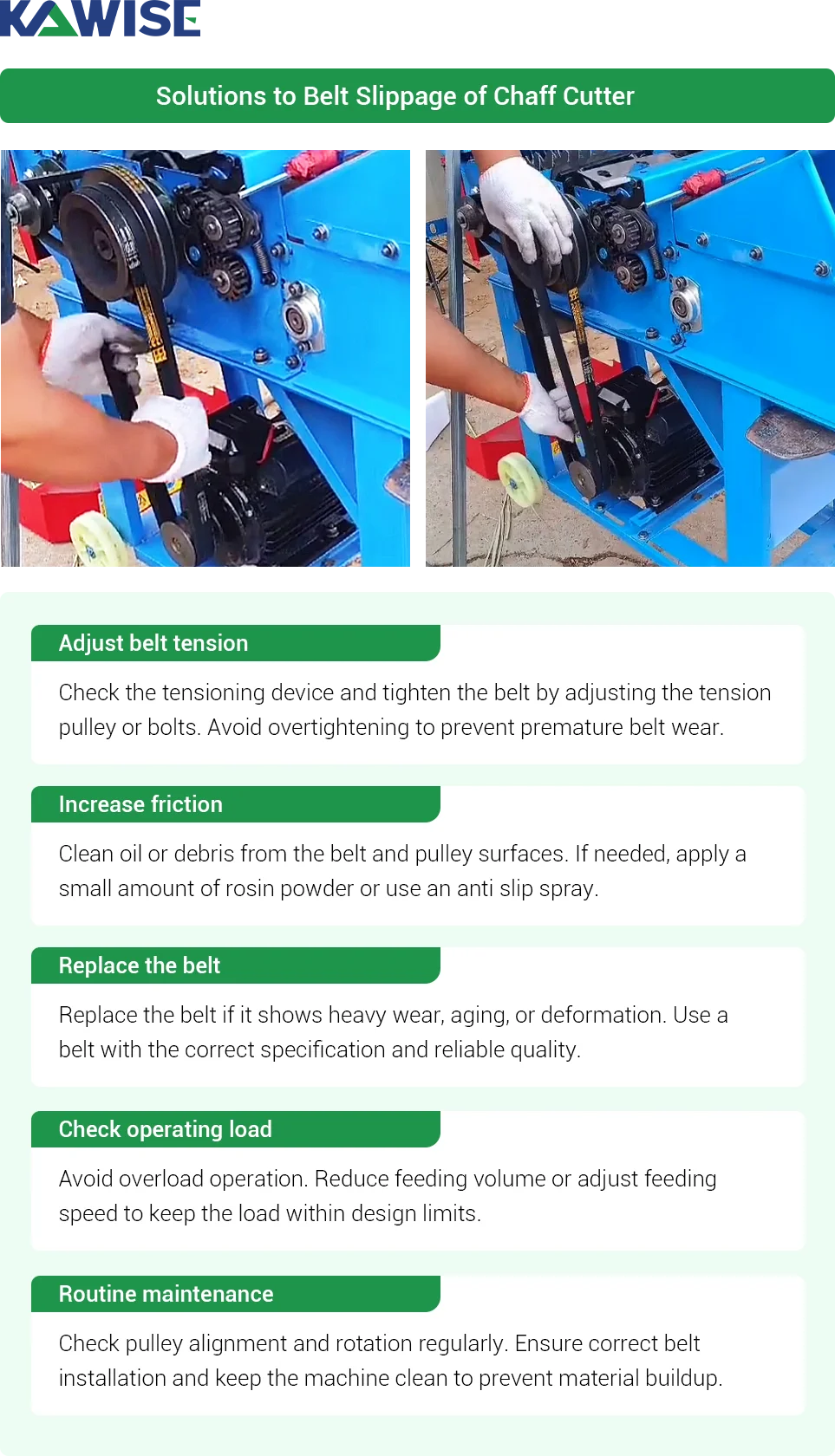

8. Belt Slipping

After a period of use, belts may loosen or wear, reducing contact with the pulley and causing slipping. Fast feeding or sudden load increases can further raise belt stress and lead to slippage.

The following measures can help resolve this issue.

Most chaff cutter issues can be addressed with proper inspection and correct operation. If the fault is unclear, professional service is recommended.

As a direct manufacturer, we provide cost-effective machines with flexible configurations and a one-year warranty under normal use.

For further questions, feel free to contact us.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.