5 Poultry Feed Production Line Solutions

Selecting the right feed line for self production or expansion requires careful consideration. Capacity, equipment, and cost vary with scale and farming objectives. We provide five poultry feed pellet line solutions to guide new projects and capacity upgrades.

- Home Farm Economy Feed Line(80-200kg/h)

- Small Enhanced Production Line(200–500 kg/h)

- Small to Medium Scale Practical Line(0.5–1.2T/h)

- Stable Production Layer Feed Line(2–4 T/H)

- High-Efficiency Broiler Feed Line(4–6 T/H)

Home Farm Economy Feed Line (80-200kg/h)

Designed for individual farmers and small farms, this line delivers daily feed production with ease. Low investment and a compact footprint make it a smart choice for fast, cost effective farming.

Applicable Chicken Types

For backyard, free range, native breeds, and small flocks of broilers or pullets.

Running 1–2 hours daily supplies feed for 500–1300 birds, fresh and consistent.

Key Equipment

| Equipment | Power (kW) |

| Feed Mixer (Vertical) | 3.0 |

| Screw Conveyor | 2.2 |

| Flat Die Feed Pellet Mill | 4.5–5.5 |

Total Power: 10–11 kW (Supports home use power)

Pellet Size: 2.5 / 3 / 4 mm

Features & Application

The line is suitable for small farms, allowing flexible, small batch feed production.

Pellets can be fed right after cooling, ensuring freshness and good intake. The equipment is simple in design, easy to clean and maintain.

Limitations

Raw materials must be pre crushed, and pellets still need manual cooling. Output is best for small scale farming.

For expansion, additional equipment or a higher capacity line should be considered.

Guide Price: 1000–1300 USD

enquire now

Small Enhanced Production Line (200–500 kg/h)

This line is for small to medium farms and cooperatives. It supports daily self use as well as larger scale production, offering higher output, better efficiency, and more stable feed than the economy line.

Applicable Chicken Types

For medium to small flocks of layers and broilers, also applicable to native and specialty breeds. One hour of operation can supply daily feed for about 1300–3300 birds.

Key Equipment

| Equipment | Power (kW) |

| Hammer Mill | 4.5 |

| Feed Mixer (Vertical) | 3.0 |

| Screw Conveyor | 2.2 |

| Flat Die Feed Pellet Mill | 7.5–15 |

| Cooling & Screening Machine (Optional) | 1.3 |

*Diesel engine option for areas without three phase power

Total Power: 19–26 kW

Recommended Die Size: 2.5 / 3 / 4 mm

Guide Price: 1600–2300 USD

enquire now

Features & Application

This line builds on the economy model with added crushing and cooling screening. Materials can be processed directly on site, cutting costs and improving flexibility.

After cooling and screening, pellets are uniform and stable, with better intake and storage. No manual drying is needed, saving both time and labor.

Small to Medium Scale Practical Line (0.5–1.2 T/h)

This line is built for small to medium farms and regional feed mills.

With moderate capacity, it covers standard poultry feed needs. The design emphasizes practicality and cost control, keeping only essential steps to ensure stable pellets, balanced nutrition, and lower costs.

Suitable Poultry

For commercial layers and broilers at medium scale, also applicable to some breeder farms.

Best for users focusing on standard feed formulas, stability, and cost efficiency.

| Equipment | Power (kW) |

| Pre-cleaner with De-ironing Device (Optional) | 6.0 |

| Hammer Mill | 7.5 |

| Batching Scale (Optional) | 3.0 |

| Horizontal Feed Mixer | 4.5 |

| Screw Conveyor | 2.2 |

| High Output Flat Die Pellet Mill | 15–37 |

| Counterflow Cooler & Screener (Optional) | 1.3 |

| Automatic Packing Scale (Optional) | 1.5 |

Total Power: 35–57 kW (three phase required)

Recommended Pellet Size: 2.5 / 3 / 4 mm

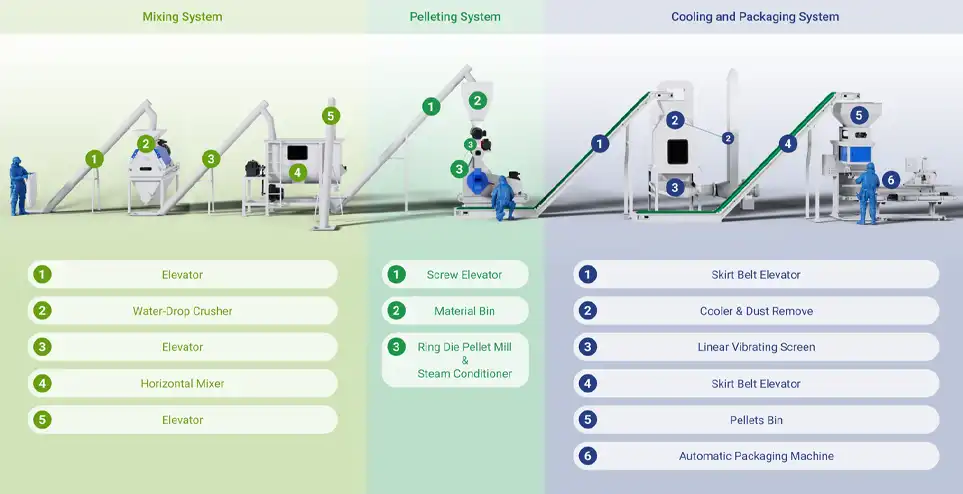

Complete Process Flow

Raw Material Receiving → Grinding → Batching & Weighing → Mixing → Pelleting → Cooling → Screening → Finished Product Packaging

Line Features

This line is an upgrade of the small advanced model, with higher output and less reliance on manual work.

For users with larger budgets or higher requirements for pellet conditioning and nutrition, optional conditioning and spraying systems can be added for further expansion.

Stable Production Layer Feed Line (2–4 T/H)

This line is tailored to the nutritional needs of layers, with precise control of calcium and protein to support shell quality and stable egg production.

It suits layer farms, cooperatives, and small to medium feed mills, providing reliable feed across all stages.

Floor Space Required: 100–150 m2 | Height: 6–7 m | Power: 108–120 kW

Key Equipment

| Equipment | Power (kW) |

| Raw Material Silo | - |

| Pre-cleaner with De-ironing Device | 2.2 |

| Water-drop Hammer Mill | 22.0 |

| Batching Scale (3–4 bins) | 1.5 |

| Double Screw Mixer (Horizontal) | 22.0 |

| Steam Conditioner (Single Layer) | 2.2 |

| Boiler | Optional Energy |

| Ring Die Pellet Mill | 39– |

| Counterflow Cooler & Dust Removal | 10.5 |

| Crumbler (Optional) | 4.0 |

| Finished Product Silo | - |

| Automatic Packing Scale | |

| Belt Bucket Elevator | 3.0 |

Recommended Pellet Size

| Stage | Age (weeks) | Pellet Diameter |

| Starter | 0–6 | 2.0 mm |

| Grower | 7–18 | 3.0 mm |

| Layer | 19+ | 3.5–4.0 mm |

Chickens require different pellet sizes at each growth stage. To learn how pellet size affects performance, you can check out Feed Pellet Size and Its Effect on Poultry Performance.

Complete Process Flow

Raw Material Receiving → Pre-cleaning & Magnetic Separation → Grinding → Dosing & Batching → Mixing → Conditioning → Pelletizing → Cooling → Screening / Crumbling → Finished Product Packaging

Line Highlights and Considerations

This line delivers precise nutrition for layers at every stage, with pellet size tailored to bird growth. The result is better feed intake, stronger laying performance, and reliable product quality that drives higher productivity and profitability.

Limitations

High calcium formulas cause faster die wear. For future capacity expansion, adding parallel lines is recommended to ensure efficiency and stability.

Contact us for detailed solutions.

High-Efficiency Broiler Feed Line (4–6 T/H)

Engineered for rapid growth and high feed efficiency, this line delivers dense, well-sized pellets from starter to finish. With post-spray technology enhancing palatability and daily gain, it is the smart choice for large-scale broiler farms and regional feed mills

Floor Space: 100–150 m2 | Height: 6–7 m | Power: 108–120 kW

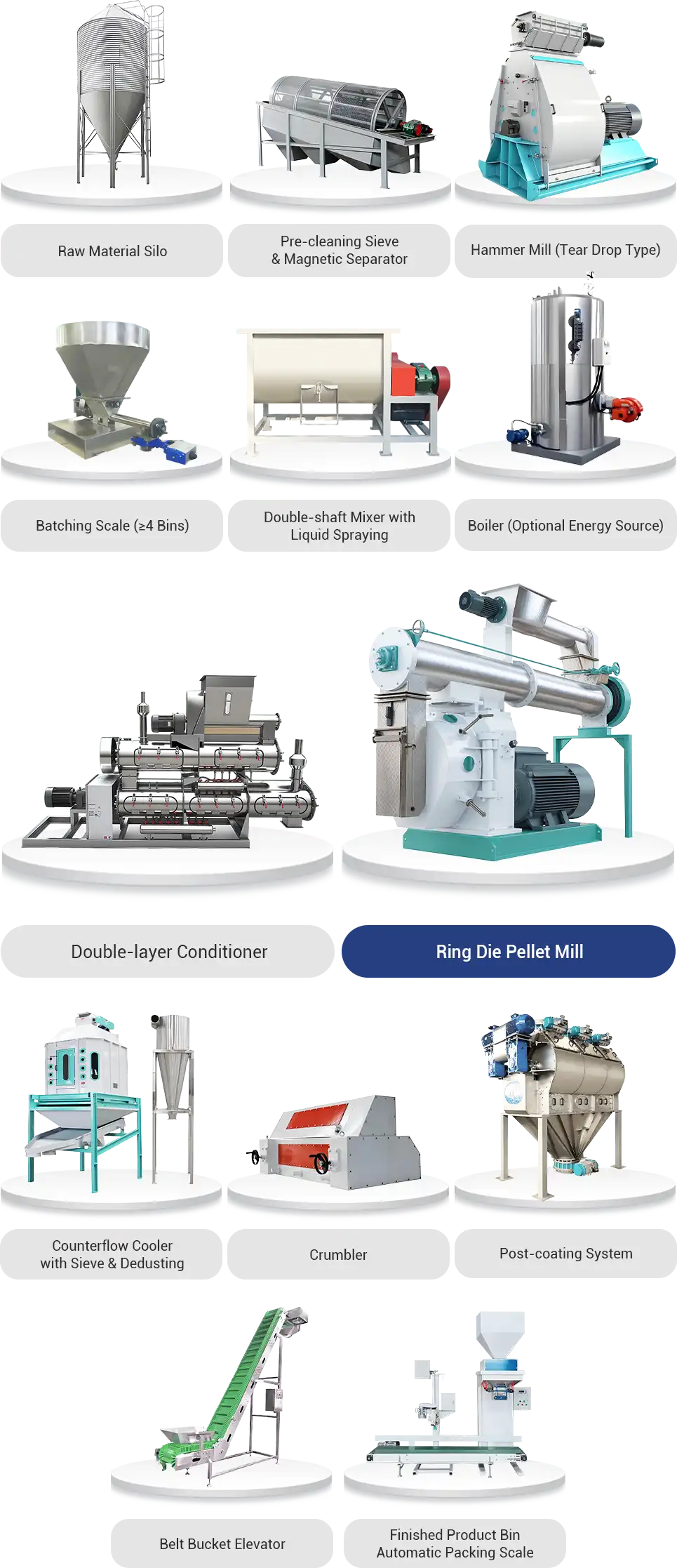

Key Equipment

| Equipment | Power (kW) |

| Raw Material Silo | - |

| Pre-cleaning Sieve & Magnetic Separator | 5 |

| Hammer Mill (Tear Drop Type) | 37 |

| Batching Scale (≥4 Bins) | 3 |

| Double-shaft Mixer with Liquid Spraying | 22 |

| Boiler (Optional Energy Source) | - |

| Double-layer Conditioner | 4 |

| Ring Die Pellet Mill | 50.5 |

| Counterflow Cooler with Sieve & Dedusting | 14 |

| Crumbler | 5.5 |

| Post-coating System | 4 |

| Finished Product Bin | - |

| Belt Bucket Elevator | 3 |

| Automatic Packing Equipment | 1.5 |

Recommended Pellet Size

| Stage | Age (weeks) | Pellet Diameter |

| Starter | 0–3 | 1.5–2.0 mm (mainly crumbled) |

| Grower | 4–6 | 2.5–3.0 mm |

| Finisher | 7+ | 3.0–3.2 mm |

Complete Process Flow

Raw Material Receiving → Pre-cleaning & Magnetic Separation → Grinding → Dosing & Batching → Mixing → Conditioning → Pelletizing → Cooling → Screening / Crumbling → Finished Product Packaging

Line Highlights and Considerations

This line is designed for efficient broiler production, delivering dense pellets that support rapid growth, better feed conversion, and consistent product quality.

Broiler feed needs finer grinding and conditioning, leading to higher energy use and maintenance. For future expansion, parallel crumbling and coating units help keep output and quality stable.

Chat with us on WhatsApp for details.

Whether you're planning to expand capacity or reduce long-term feed costs, having a clear goal and production scale is key to choosing the right solution.

For detailed specs or customized configuration advice, feel free to contact us for tailored recommendations.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.