Low Cost Pig Feed Pellet Machine and Equipment Prices

Many pig farmers look for a simple and affordable way to make feed pellets. This guide lists budget friendly pellet mills and basic equipment that offer low investment, easy maintenance, and steady output for small and medium farms.

Feasibility of Low-Cost Pelletizing Solutions

Pig feed production is relatively simple. Common ingredients like corn, soybean meals, and wheat bran are easy to grind, mix, and pelletize, so the equipment does not require high power or strong compression. This makes low-cost machines a practical option for pig farms.

For small farms, making pellets on site is often cheaper than buying commercial feed. Raw material prices are steady, and formulas can be adjusted based on seasonal supply.

Once you understand the basic ingredient structure, preparing your own feed becomes straightforward.

For more detailed diet ratios, you can refer to Feed Formulation Reference for Different Animals, which offers ready to use formulas for different growth stages.

Recommended Pig Feed Pellet Equipment

Making your own feed relies on the right machines. Here are a few cost effective and practical options suited for small pig farms.

Hammer Mill

Grinding is a key step in pig feed production. Finer particles increase the surface area of the ingredients, which improves enzyme action and nutrient absorption.

Studies show that reducing particle size by about 0.1 millimeter can raise feed efficiency by roughly 1 percent, offering a clear benefit for feed conversion.

Single Inlet / Double Inlet / Self Priming

A hammer mill can efficiently grind corn, wheat, bran, soybean meal, and other pig feed ingredients to the required particle size, which is adjusted by changing the screen.

If you want to reduce manual feeding, a self-priming model can grind and pull in material at the same time.

- Self-priming model can handles a wide range of ingredients and works well with formulas that include alfalfa or other roughage.

- For grain only, a self-priming mill is the better option.

Single inlet hammer mills are suitable for grains, while double inlet models can process both grains and forage such as fresh grass or straw.

If cost is the main concern, buying pre ground materials for pelletizing is also a practical choice.

Hammer Mill Spec and Price

| Model | Power (KW) | Capacity (KG/H) |

| 360 | 300-400 | 4 |

| 400 | 500-600 | 7.5 |

Hammer mill working demo

Guide Price: From USD 240

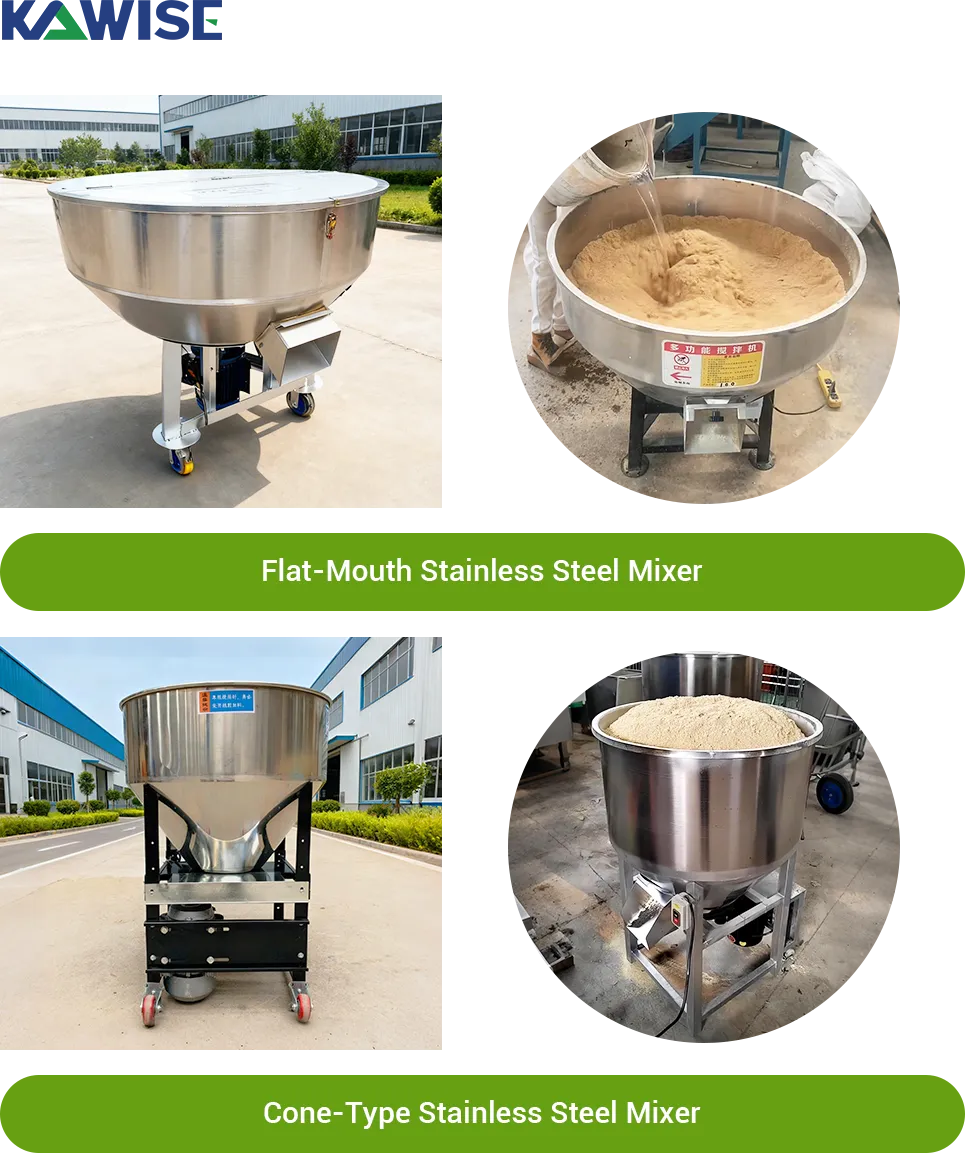

Stainless Steel Mixer

Pig feed ingredients such as corn, soybean meal, and wheat bran vary in density, particle size, and moisture absorption.

A stainless steel mixer uses efficient blades to blend these materials evenly. In about five minutes, it can mix powders and additives into a uniform batch, helping ensure consistent nutrient distribution in the final feed.

The stainless steel mixer has a smooth interior that prevents sticking, making it ideal for fine materials like corn flour, bran, soybean meal, and premix. Its corrosion resistant build handles moisture and oils well, reduces residue, and helps maintain clean and stable feed.

Stainless Steel Mixer Spec and Price

| Model | Host Power (kw) | Blender Diameter(mm) | Volume (L) |

| C50 | 3 | 550 | 120 |

| C75 | 3 | 620 | 160 |

| C100 | 3 | 680 | 200 |

| C150 | 3 | 900 | 260 |

Stainless steel mixer working demo

Guide Price: From USD 270

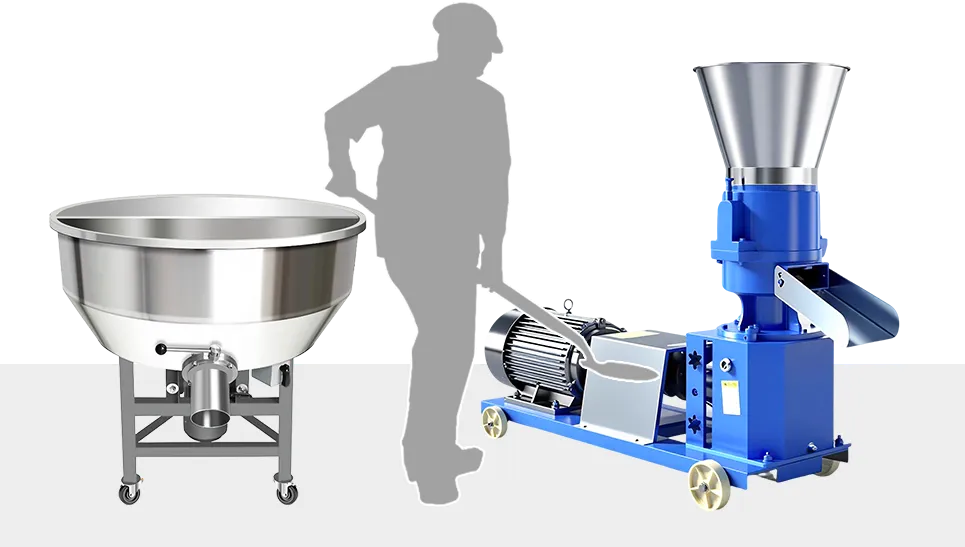

Pig Feed Pellet Machine

This is the core equipment in pellet production. During pelletizing, pressure and friction generate heat that helps kill pathogens and improve feed hygiene, reducing disease risks in the herd.

Pellets are compact and less likely to scatter, making them easier for pigs to eat while reducing waste and keeping the pen cleaner.

Finished pellets come out at a high temperature, around 60 to 80 C, and need to cool down. For users with a limited budget who do not need a cooler, natural cooling is a simple and cost saving option.

Pellet Machine Spec and Price

| Model | Power(KW) | Capacity(KG/H) |

| KD-125 | 4.5 | 60-100 |

| KD-150 | 4.5 | 80-150 |

| KD-160 | 5.5 | 130-200 |

| KD-180 | 5.5 | 150-220 |

Pellet machine working demo

Guide Price: From USD 340

Both electric and diesel options are available, allowing you to choose based on your site conditions and power supply.

For a full guide on pig feed pellet production, you can see: How to Make Pig Feed Pellets at Home.

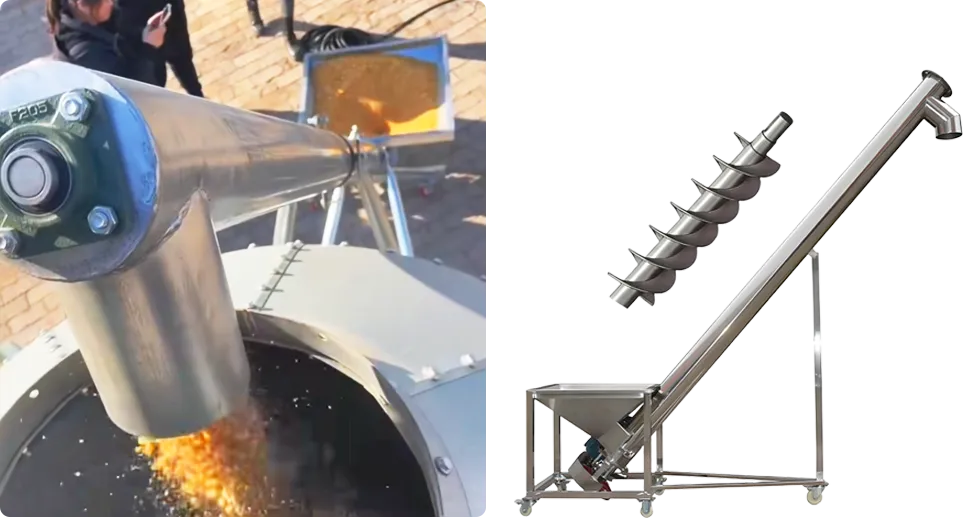

Screw Conveyor

A screw conveyor is mainly used for moving feed powder in pig feed production. As an auxiliary feeding device, it reduces manual handling and improves overall efficiency.

Its enclosed design prevents spillage and helps keep the conveying process clean and consistent.

Screw Conveyor Specifications

| Model | Power | Length (Meters) | Pipe diameter (mm) | Lift Quantity/Hour |

| L140-2 | 2.2KW | 2 | 140 | 1-2m3 |

| L140-2.5 | 2.2KW | 2.5 | 140 | 1-2m3 |

| L140-3 | 2.2KW | 3 | 140 | 1-2m3 |

| L140-4 | 3KW | 4 | 140 | 1-2m3 |

*The screw conveyor's length, angle, and tube size can be customized as needed.

A screw conveyor is mainly used to move feed powder in pig feed production.

It reduces manual work and improves efficiency, while the sealed design prevents spillage and keeps the process clean.

Screw conveyor working demo

Guide Price: From USD 280

Budget Friendly Production Line Options

Here are three recommended low cost setups that you can choose based on your raw materials and daily production needs.

Option 1: Mixing and Pelletizing

This setup suits users with a strict budget and simple formulas with only a few raw materials. It covers basic feed processing at the lowest cost, but requires manual feeding.

Equipment: Stainless steel mixer, small flat die pellet machine

Option 2: Mixing, Conveying, and Pelletizing

This setup is suitable for users who want better efficiency while keeping costs low. It works best when using pre-ground materials.

Equipment: Stainless steel mixer, screw conveyor, small flat die pellet machine

Option 3: Grinding, Mixing, Conveying, and Pelletizing

This setup fits users who work with multiple raw materials and need higher feed quality. Adding a grinder allows finer particle control and improves overall efficiency.

Equipment: Hammer or grain mill, stainless steel mixer, screw conveyor, small flat die pellet machine.

Producing your own pellets gives you more control over feed costs. I hope this equipment recommendations help support your farm.

If you have any questions or need guidance on equipment options, feel free to reach out.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.