How to Make Pig Feed Pellets At Home

The feed you give your pigs directly affects their growth. Powder or wet feed is cheap and easy, but it often lacks nutrition and leads to more waste. As commercial feed becomes more costly and less reliable, making your own pellets is a smarter choice. It offers balanced nutrition, reduces waste, and makes feeding easier, which suits small farms well.

Simple Steps to Make Pig Feed Pellets

Maybe you will worry that making pellet feed at home is complicated, but the process is actually quite simple. The machine runs without water or steam and doesn't require a boiler. Just one person can handle it with ease.

1. Prepare the Ingredients

Start by removing stones, nails, and other debris. Then grind corn, soybean meal, bran, or dried sweet potato until the particles are about 0.5 to 0.8 mm. This helps mix evenly and shape better in the pellet machine.

If you're raising a few pigs, it's easier to buy pre-crushed feed. If you have enough raw materials, a small grinder can save long-term costs.

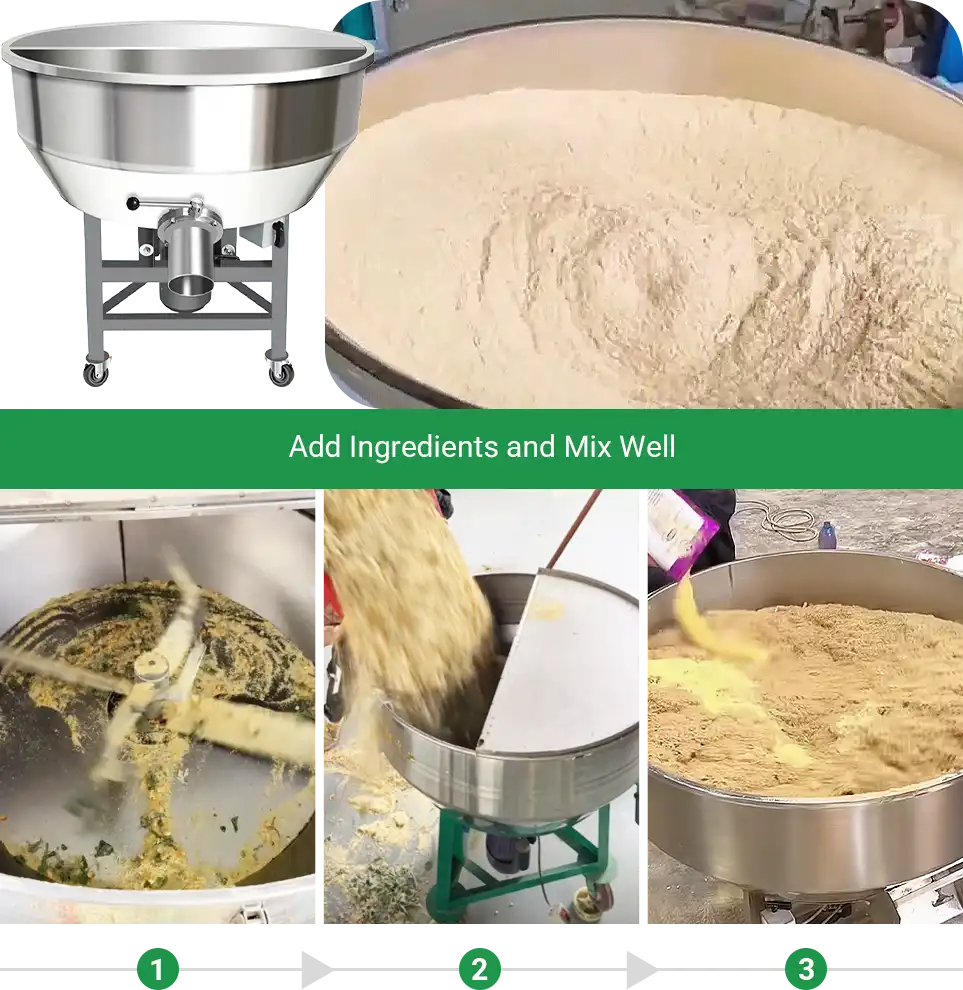

2. Mix the Feed

Hand mixing works for small batches, but it's hard to get it even when the volume increases. Additives like premix, calcium, or lysine need to be spread well.

To improve texture and reduce dust, mix in some bran or a little oil. It makes the feed taste better and helps with digestion. A small mixer makes this process faster and more consistent.

3. Start Pelletizing

Feed the mix into the pellet machine. The rollers press it into solid pellets. The heat during pressing (around 70°C) helps cook the feed, improves taste, and kills harmful germs. It's clean, safe, and easy to store.

| Pig Type | Suggested Pellet Diameter |

| Fattening pigs only | 4 to 6 mm |

| Mainly weaned piglets | 2 to 3 mm |

| Mixed, mostly nursery pigs | 3 to 4 mm |

4. Cooling and Drying

Freshly made pellets are usually hot and still hold some moisture. Just spread them out in a basin, on canvas, or a clean floor, and let them cool for about 10–20 minutes. This helps prevent mold during storage. Once cooled, they're ready to feed.

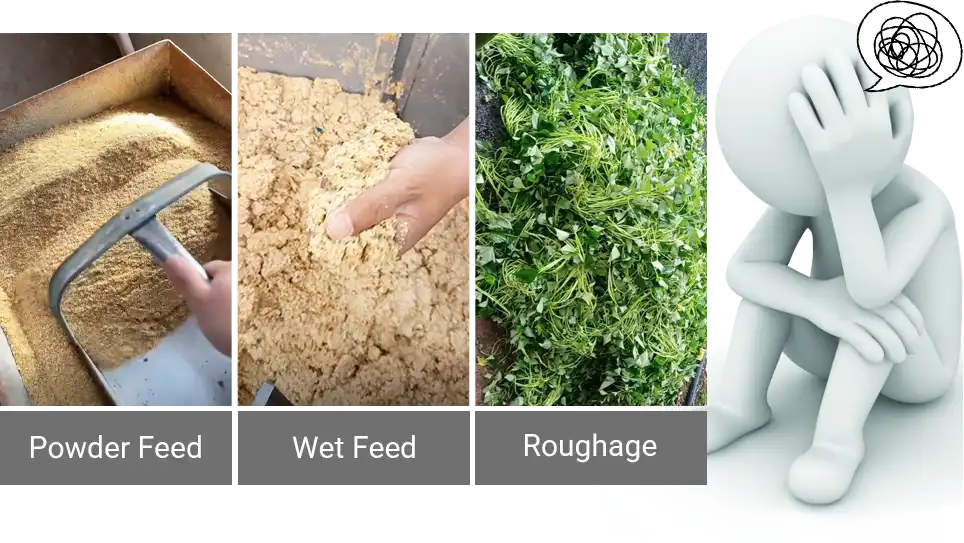

Common Feed Types Compared

In everyday swine farming, powder feed, wet mash, and roughage are still widely used.

They're simple and low cost, but each comes with its own set of problems.

Powder feed often gets pushed out of the trough, leading to waste. The dust can also irritate the swine's breathing.

Wet mash may be tasty, but it spoils quickly in the summer, clumps up in the winter, and the mix is hard to keep consistent. As for roughage like sweet potato or leafy greens, the nutrition provide enough nutrition and is best used as a supplement.

If you're wondering how powder feed compares to pellets in real use, we've laid out the details Here: Powder vs Pellet Feed for Swine, which is Better?

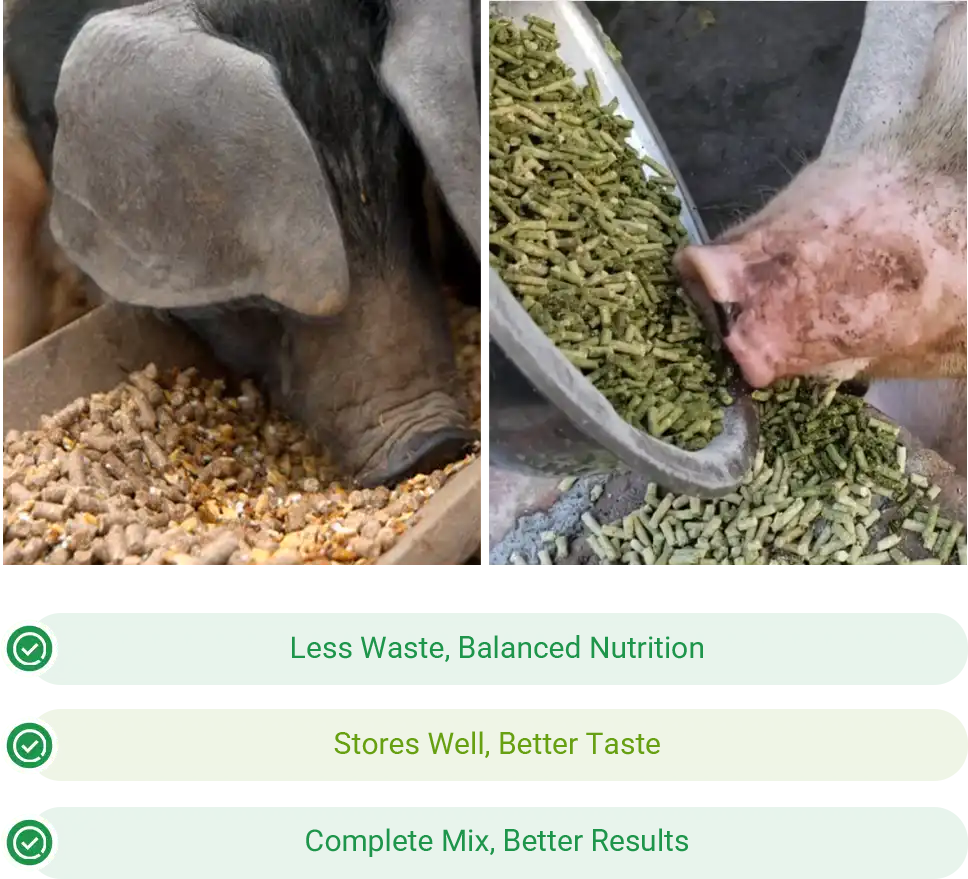

Why Choose Pellet Feed

Pellet feed stands out for its taste, balanced nutrition, and better digestion. After grinding and mixing, the ingredients are compressed into uniform pellets. Each one carries a full nutrient mix, which helps prevent picky eating and layering. The dense, dry texture makes them easier to store and transport. They also work well for controlled feeding and help improve daily weight gain while lowering the feed-to-meat ratio.

When Pellet Feed Works Best

- For piglets or finishing pigs that need fast growth and easy digestion

- When you want to cut down on feed waste and avoid picky eating

- In humid weather where feed is easy to spoil

- When there's not enough labor and feeding needs to be quick

- When you want better control over the feed mix and costs

Quick Comparison

| Feed Type | Main Issue | Pellet Feed Advantage |

| Powder Feed | Wastes easily, dusty | Less waste, balanced nutrition |

| Wet Feed | Spoils quickly, unstable | Stores well, better taste |

| Roughage | Low nutrition, slow growth | Complete mix, better results |

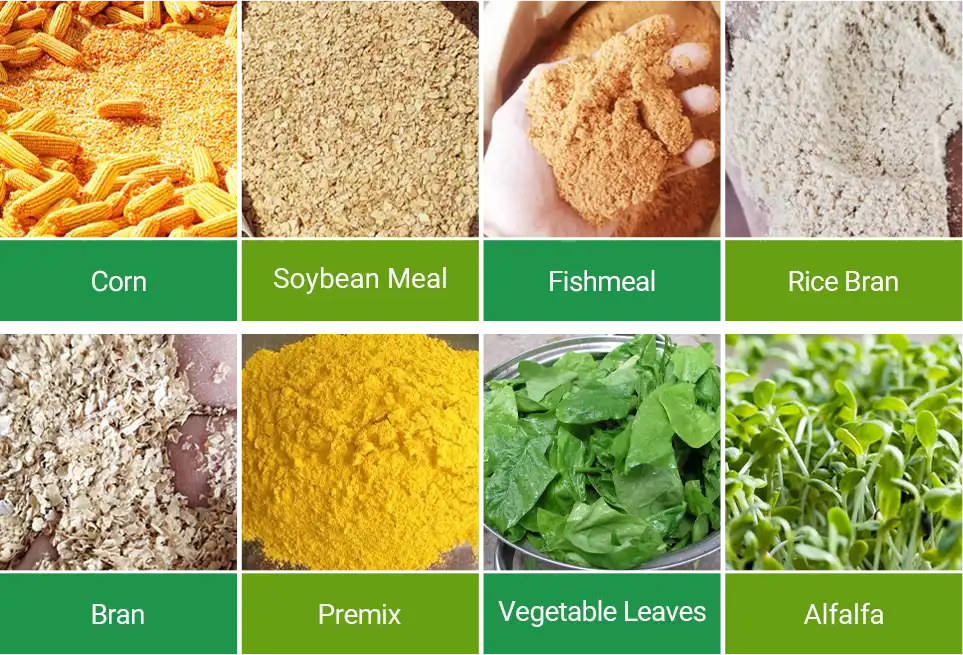

Pig Feed Ingredients

- For piglets, choose high-protein, easy-to-digest feed like soybean meal, fish meal, and whey powder to support early growth.

- Fattening pigs need energy-rich feed such as corn and sweet potato powder, with added protein to boost weight gain.

- For pregnant or lactating sows, focus on maintaining body condition with protein sources like soybean meal and rice bran, plus minerals for fetal growth and milk production.

Feeding the right formula at each stage improves efficiency, supports healthy growth, and helps pigs reach market weight faster.

Piggery Feed Formulation (per 100 kg)

| Growth Stage | Recommended Formula |

| Piglets (7–30 days) | Corn ~55%, Soybean meal ~25%, Fish meal 10%, Rice bran 5%, Premix 5% |

| Swine Starter (30–60 days) | Corn ~60%, Soybean meal ~22%, Rice bran 10%, Fish meal 5%, Premix 3–5% |

| Hog Grower (over 60 kg) | Corn ~65%, Soybean meal ~15%, Wheat bran 15%, Premix 5% |

| Gestating sows | Corn ~60%, Soybean meal ~20%, Wheat bran 15%, Premix 5% |

| Lactating sows | Corn ~55%, Soybean meal ~25%, Wheat bran 10%, Fish meal 5%, Premix 5% |

*Formula data based on Nutritional Requirements of Pigs

These formulas are for reference only. You don't need to follow the ratios strictly. Adjust based on local prices and available ingredients.

If fish meal is costly, replace part of it with soybean meal or bone meal. You can also use locally available low-cost ingredients like dried sweet potatoes, rapeseed cake, rice bran, vegetable leaves, or alfalfa as needed.

Equipment Selection and Setup Guide

Farm size, raw material handling, and feeding habits vary from one user to another. Here are a few practical equipment setups to help you choose the right feed pellet solution based on your needs.

Basic Single Machine Setup

This setup is ideal for small-scale swine farms. One pellet machine is enough to cover daily feed needs. You can mix ready-made powder or coarsely ground feed from a local store, then run it through the machine. It's low-cost, compact, and fits well in different farming setups.

Feed Pellet Machine for Sale

We also offer diesel-powered feed pellet machines, ideal for areas with unstable or no electricity.

| Model | KD-150 | KD-160 |

| Output | 80–150 kg/h | 130–200 kg/h |

| Power | 4.5 kW | 4.5 kW |

Small Feed Pellet Production Line

As the farm grows, a single pellet machine or manual mixing is no longer efficient enough. This setup adds a small feed mixer (with an optional screw feeder to improve loading efficiency), forming a practical and compact swine feed production line. It ensures more consistent mixing and faster output.

Recommended Equipment

| Model | Output (kg/h) | Power (kW) |

| KD-160 | 130–200 | 4.5 |

| KD-230 | 200–300 | 7.5 |

| KD-260 | 250–400 | 11 |

| Model | Mixing Capacity | Power (kW) |

| 50 | 70 kg | 3.0 |

| 120 | 120 kg | 3.0 |

| 150 | 180 kg | 3.0 |

| 200 | 230 kg | 3.0 |

More and more farmers are turning to homemade pig feed pellets. It helps reduce costs and allows greater flexibility in adjusting feed formulas to match actual needs.

If you're planning to set up your own feed line, feel free to contact us. Just let us know your farm size and raw materials, and we'll recommend the right machines and setup for you.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.