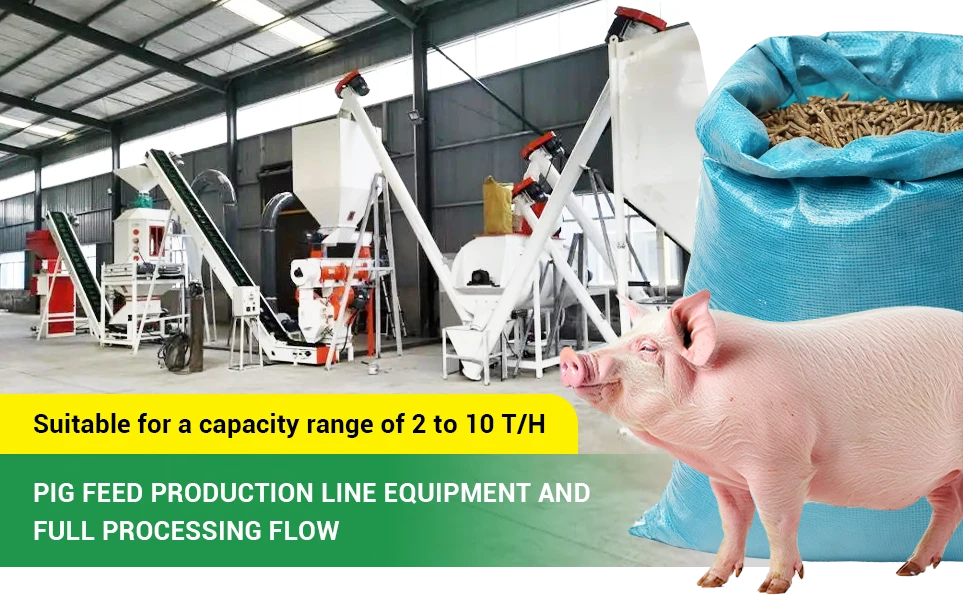

Pig Feed Production Line Equipment and Full Processing Flow

In pig feed production, a full line stands out for its steady and continuous workflow. It keeps crushing, mixing, and pelleting running smoothly, reduces manual errors, and improves product consistency. The sections below follow the production flow and give you a quick look at how each part works together as one system.

Production line design overview

A well designed pig feed line focuses on smooth process coordination. A continuous and standardized flow helps achieve:

- Accurate ingredient ratios

- Stable grinding, mixing, and pelleting

- Reduced manual work

- Higher feed conversion and consistent pellet quality

- Easier batch control and traceability

This setup suits pig farms and feed producers seeking reliable, long-term performance.

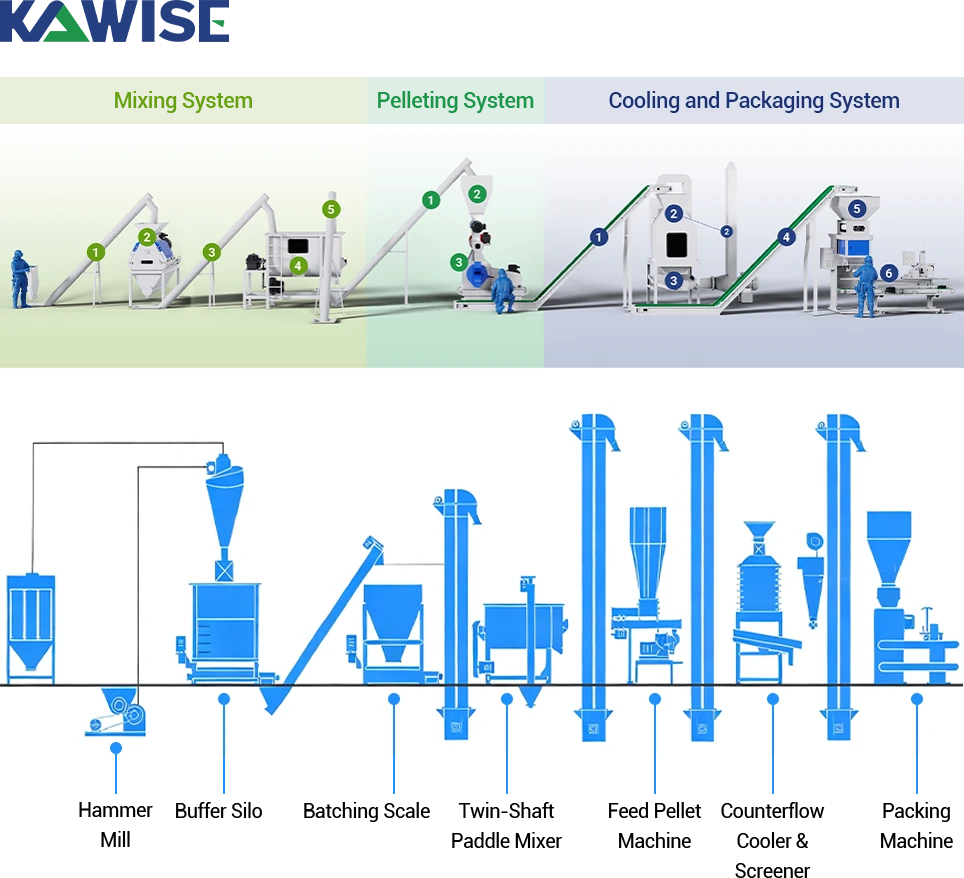

Process flow and key equipment

Pig feed pellets are produced through several stages, and each step relies on dedicated equipment.

| Production Process | Corresponding Equipment |

| Raw Material Reception | Raw Material Silo / Storage Tower |

| Impurity Removal | Impurity Separator / Magnetic Separator |

| Weighing & Dosing | Multi-bin Dosing System |

| Grinding | Hammer Mill / Water-drop Hammer Mill |

| Mixing | Twin-shaft Paddle Mixer |

| Raw Material Buffering | Buffer Silo |

| Conditioning (Optional) | Conditioner (with steam connection) |

| Pelletizing | Ring Die Pellet Mill |

| Cooling | Counter-flow Cooler |

| Screening | Vibrating Screen |

| Storage / Packaging | Finished Product Silo, Automatic Packaging Machine |

| Auxiliary Equipment | Screw / Belt Conveyor |

| Control Equipment | Centralized Control Cabinet |

1. Raw material receiving and storage

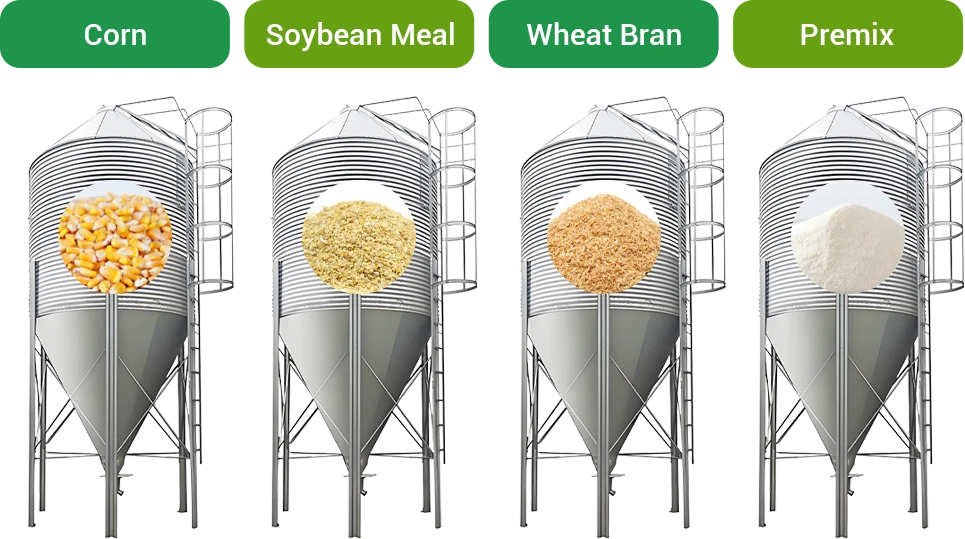

Pig feed ingredients like corn, soybean meal, wheat bran, and premix vary in density and flowability. Storing them separately in silos helps avoid cross contamination. Before grinding, the materials should pass through impurity removers to ensure smooth operation and stable feed quality.

Recommendation

Because pig feed uses many different ingredients, we suggest 3 to 5 silos with an automatic dosing system, and selecting bucket elevators or screw conveyors based on capacity to keep feeding continuous.

2. Grinding section

The grinding section reduces corn, soybean meal, wheat bran, and other ingredients to the particle size required for pig feed. This ensures stable mixing and pelleting. Hammer mills or water drop hammer mills are commonly used, and particle size is controlled by changing the screen.

- Hammer mill: Simple structure, lower cost, suitable for routine grinding of standard materials.

- Water drop hammer mill: Improved chamber design for higher efficiency and more consistent particle size, ideal for continuous production.

Pig feed is sensitive to particle size. Coarse particles reduce digestibility, while overly fine particles create dust and increase energy consumption. The typical target size is 0.8 to 2.0 mm for good digestibility and pelleting performance.

The grinding system is usually equipped with air suction or dust removal to keep the workspace clean and improve efficiency.

3. Mixing section

The mixing stage ensures ingredients with different densities and particle sizes are blended evenly without segregation.

Pig feed requires high uniformity, so a double shaft paddle mixer is commonly used. Through lifting and convection, it reaches a stable uniformity (CV ≤ 5 percent) in about 5 to 10 minutes.

At this stage, small amounts of oil, enzymes, vitamins, minerals, or other liquid additives can be added to improve palatability or meet nutritional needs.

Powder Feed Line Extension

After mixing, the line can be extended to produce powder feed by adding two discharge outlets: one for pelleting and the other for direct packaging via belt or screw conveyor

This design enhances flexibility, enabling both pellet and powder production.

4. Conditioning (optional)

Conditioning is optional but has a clear effect on pellet density and durability.

Since pig feed does not require very hard pellets, conditioning mainly helps the mash absorb heat and moisture so it forms a stable structure in the die.

Steam conditioning improves plasticity and stabilizes pelleting, but small scale lines can also pellet directly. In that case, pellet density and durability depend more on the die design and compression ratio.

5. Pelleting section

Pelleting is the final forming step, and pigs at different stages require different pellet sizes and firmness.

To support long, stable production, ring die pellet mills are typically used.

In the chamber, material is compressed by the rollers and pushed through the die, creating pellets. The heat generated provides mild sterilization and produces firmer pellets that pigs accept more easily.

Pellet size is determined by the die. For pig feed, a 4 to 6 mm die is recommended.

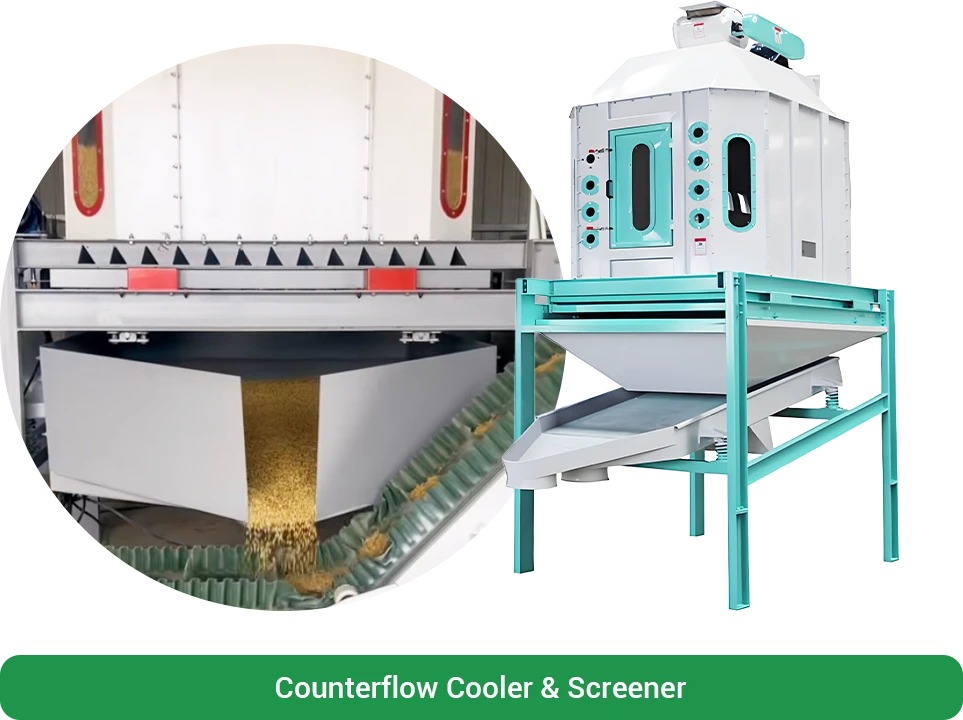

6. Cooling and screening section

After pelleting, the hot pellets need to be cooled to near room temperature for storage.

A counterflow cooler removes heat and moisture gradually, preventing rehydration and caking.

The pellets are then screened to separate fines and broken pieces. Fines can return to the pelleting process to improve usage.

A combined counterflow cooler and screener reduces footprint and simplifies the layout.

7. Finished product packaging and storage

After cooling and screening, pellets move into a buffer bin and are then bagged by a packing scale as needed.

This stage keeps the discharge flow stable and prevents backup when the line is running continuously. Packed feed can be stored directly, and the buffer bin helps manage batches and improve loading or feeding flexibility.

Automated packaging offers:

- Accurate dosing

- Faster bagging

- Fewer manual errors

- Better commercial appearance

- Batch, weight, and output records

With automation, the workload at the final stage drops significantly, and one to two operators can manage the whole line.

Common Factory Layouts

Production lines can be arranged in different layouts:

Linear Layout

- Ideal for narrow factories

The most common layout, where materials flow sequentially from raw material reception to packaging, ensuring clear and efficient movement.

L-shaped Layout

- Ideal for medium-sized factories

Raw material reception and finished product packaging are placed in separate directions, reducing logistics overlap and improving cleanliness and area management.

Case Reference

2–3 T/H Cattle and Sheep Feed Pellet Production Line in Turkey

Multi-level Layout

- For limited ground space

By utilizing floor height, materials move between processes by gravity, reducing the frequency of material lifting and lowering the energy consumption of lifting equipment.

A well-designed production line enhances efficiency and long-term profitability. We can customize a solution based on your materials, space, and budget to help you quickly start or upgrade your feed processing.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.