4–6T/H Layer Feed Production Line Launched in China

The client from Shaanxi, China saw that while layer farming has grown rapidly, most feed on the market is still for broilers or general use, which cannot fully meet the nutritional needs of laying hens. After market research, they identified this demand and decided to invest in a 4–6 t/h feed production line dedicated to layers.

Through industry contacts, they learned about us and, after discussions and on-site visits, recognized the value of our design and equipment. They finally chose to cooperate with us to build this production line.

The production line includes five main steps: grinding, mixing, pelletizing, cooling and screening, and packaging. For clarity, we group them into three sections for introduction.

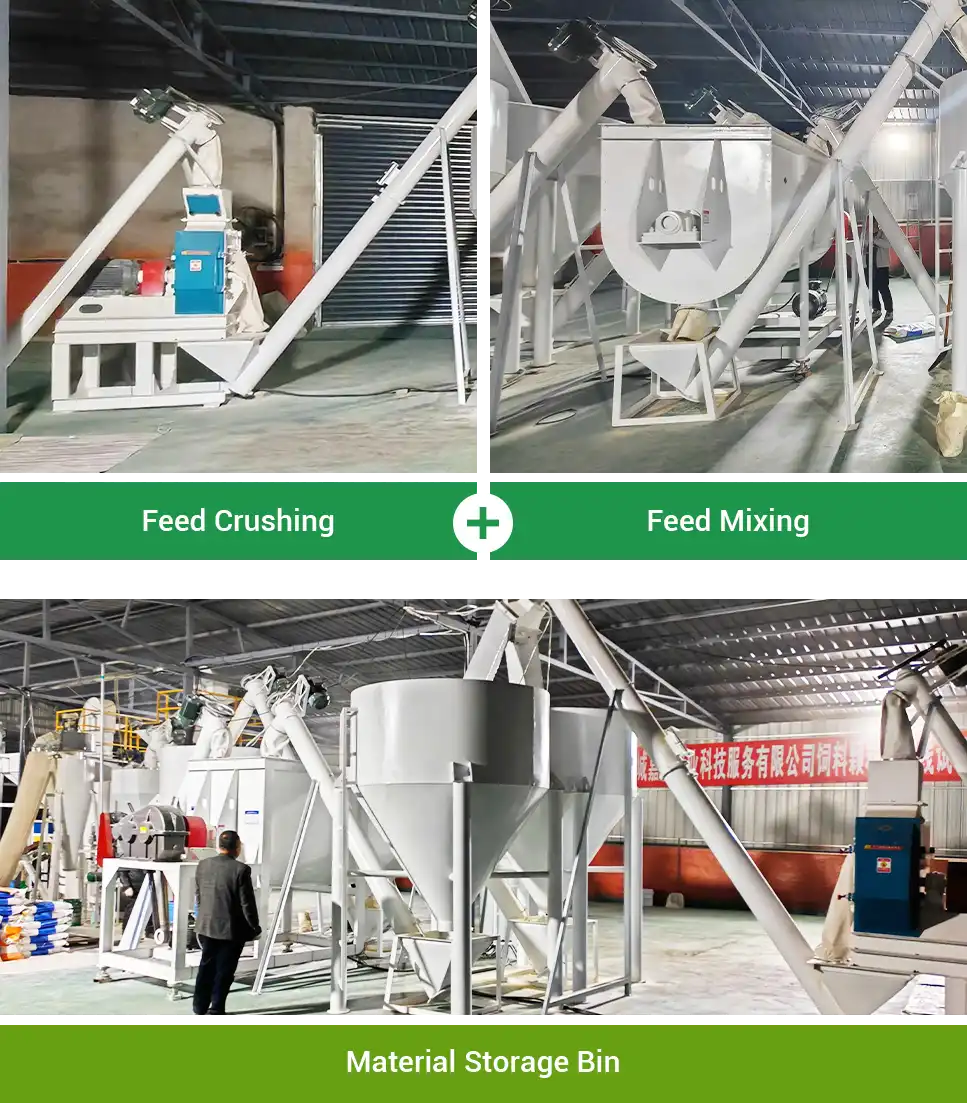

Crushing and Mixing System

To improve feeding efficiency, a ground-level pit is used. Raw materials are lifted by a screw conveyor and sent to the water-drop hammer mill for grinding.

Since corn and bran are the main ingredients, two storage bins are placed after grinding. They allow separate storage, precise dosing, and continuous production between grinding and batching.

To meet the mineral and trace element needs of layer feed, an extra feeding unit is added at the mixer for limestone powder, dicalcium phosphate, salt, and premix. This ensures a complete formula.

Crushing & Mixing Equipment List

| Equipment | Model/Specification | Power (kW) | Quantity |

| Water-drop Hammer Mill | Model 40 | 37 | 1 |

| Raw Material Storage Bin | 6 cube | - | 2 |

| Horizontal Feed Mixer | Model 2000 | 18.5 | 1 |

| Screw Conveyor | - | 3 | 4 |

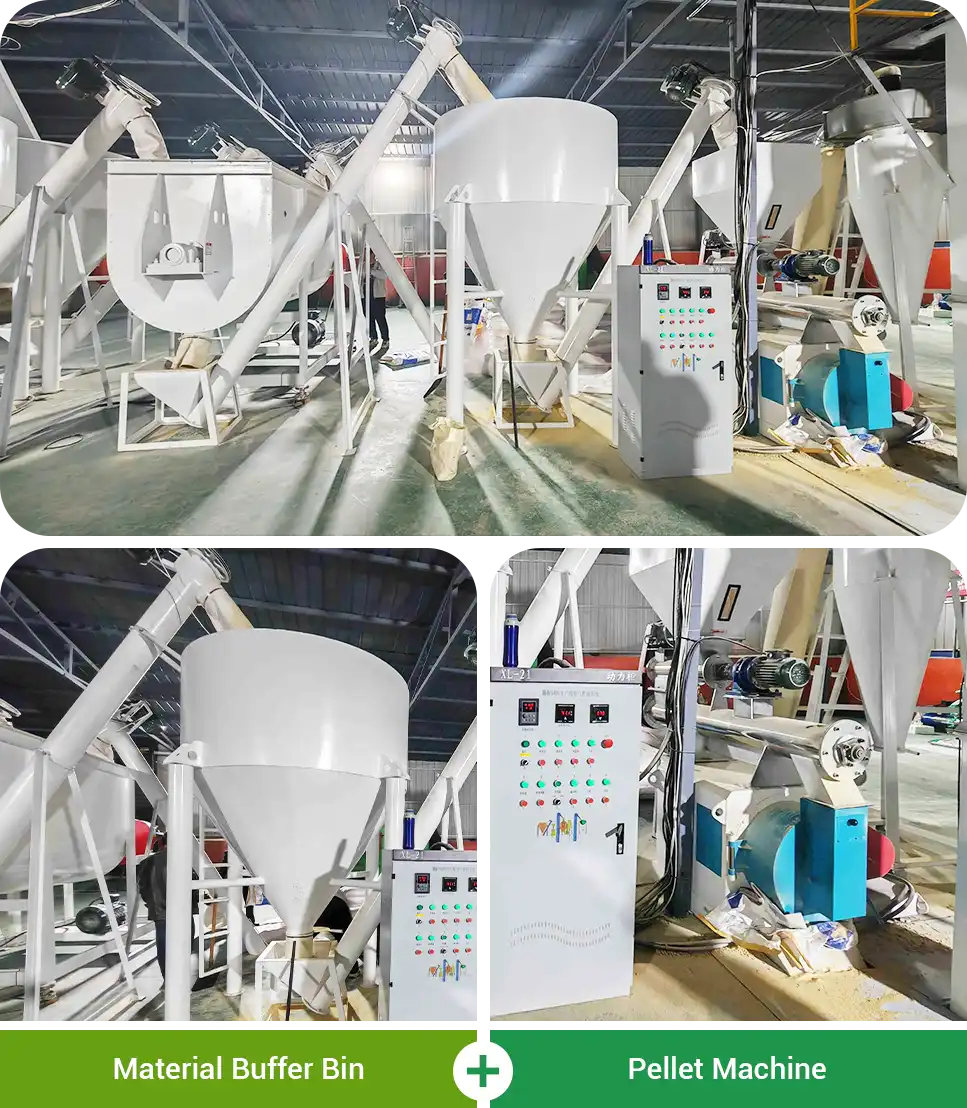

Pelletizing System

Since each mixing batch takes time, a buffer bin is added before pelletizing to store mixed materials and ensure continuous operation.

The biomass feed pellet mill is equipped with a steam system for conditioning. Before pressing, the feed is adjusted to proper temperature and moisture, producing firm pellets that resist crumbling.

Starch is partially gelatinized, nutrients become easier to absorb, and harmful bacteria are reduced. This helps improve egg production, shell quality, and extend peak laying periods.

Pelletizing Equipment List

| Equipment | Model/Specification | Power (kW) | Qty |

| Raw Material Buffer Bin | 5 cube | - | 1 |

| Ring Die Feed Pellet Mill | Model 350 | 60 | 1 |

| Screw Conveyor | - | 3 | 2 |

| Steam Boiler | 1.0 t/h rated capacity | - | 1 |

Note: The steam boiler in this project uses biomass fuel for steam heating.

Cooling & Packaging System

Pellets leave the pellet mill at high temperature and can soften or clump if not treated promptly. A bucket elevator transfers the hot pellets to the counterflow cooler, where they are cooled and then screened to remove fines and irregular pieces.

The cooler is equipped with a pulse dust collector that removes hot air and dust during cooling, ensuring both fast cooling and a clean workshop environment.

Qualified pellets are then sent to the automatic packing machine for weighing and sealing. A finished product bin above the packer serves as a buffer to keep packaging continuous.

Cooling & Packaging Equipment List

| Equipment | Model/Specification | Power (kW) | Qty |

| Bucket Elevator | - | 3 | 2 |

| Counterflow Cooler (with pulse dust collector) | 1700 × 1700 | 14 | 1 |

| Vibrating Screen | 1 m × 2.5 m | 3 | 1 |

| Automatic Weighing & Packing Machine | - | 1.5 | 1 |

Electrical Control System

To improve efficiency and safety, the production line uses two control cabinets.

The first manages grinding and mixing, while the second controls pelletizing, cooling, and packaging. This division ensures balanced power distribution, smoother process flow, easier maintenance, and reliable operation.

The production line was put into operation at the end of 2024. By sourcing local raw materials at low cost, the client quickly gained a market advantage.

The pellets produced have low powder content and good palatability, attracting many repeat customers. Sales are now growing steadily, the brand is taking shape, and the client has shared plans for further expansion.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.