500–1200 kg/h Semi-automatic pig feed production line

This line is suitable for farms with moderate scale and higher expectations for automation and feed quality. It supports a capacity of 500 to 1200 kilograms per hour. The sections below outline the process and recommended equipment to guide users planning a new setup or expand production.

Line Features

A market pig of 60-80 kilograms needs about 2.64 kilograms of feed per day to gain one kilogram.

This production line can support the feed needs of roughly 150 to 400 pigs per hour. It suits farms that already operate at a moderate scale, and the equipment combination can be adjusted based on actual production needs.

Line Advantages

- Flexible configuration for different production goals

- Semi-automatic design that reduces manual work

- Compact layout for easy installation

- Energy efficiency to lower operating costs

- Scalable for future expansion

More pig farms now mix their own feed to keep costs under control as prices fluctuate.

Based on common price ranges for corn, soybean meal, and wheat bran, producing feed on site can save about 0.12–0.20 USD per kilogram. For farms with high daily feed usage, this difference adds up to a substantial overall saving.

Price Reference: Global Monthly Commodity Prices

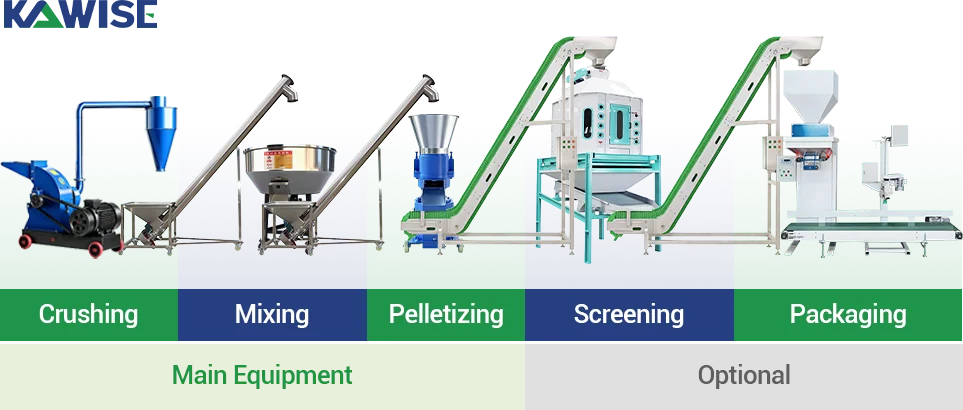

Core Equipment and Price Reference

| Process | Equipment |

| Crushing | Hammer mill |

| Feeding support | Screw conveyor / Skirt belt elevator |

| Mixing | Stainless steel mixer |

| Pelletizing | Flat die feed pellet machine |

| Cooling and screening(Optional) | Counterflow cooler with screening |

| Raw material / Finished feed storage | Hopper or storage bin |

Hammer Mill

For pig feed formulas based mainly on corn, soybean meals, wheat, and wheat bran, a hammer mill is a cost-effective choice with good crushing efficiency.

The particle size can be adjusted by changing the screen size, and a 1 to 3 millimeter screen is recommended for pig feed production.

If the budget allows, a water drop hammer mill can be considered for finer grinding.

Recommended Hammer Mill Models

| Model | Power (kW) | Capacity (kg/h) | Total Weight (kg) |

| 400 | 7.5 | 500 to 600 | 85 |

| 420 | 11 | 800 to 1000 | 95 |

| 420 dual inlet | 11 | 800 to 1000 | 130 |

Video Demo

Guide PriceFrom USD 490

Stainless Steel Mixer

For higher output needs, a larger capacity mixer is required. The recommended model offers higher efficiency and can mix about 140 kilograms of powder in roughly 15 minutes. The stainless steel build is durable, easy to clean, and supports liquid additives when needed.

This mixer provides high efficiency at a relatively low cost, making it a good fit for medium-scale farms.

If you plan to mix corn, wheat, or other grain materials for direct feeding, a cone type mixer is recommended.

Recommended Mixer Models

| Model | Capacity per Batch (kg) | Volume (L) |

| C150 | 140 | 260 |

| C200 | 180 | 320 |

| C300 | 280 | 480 |

Video Demo

Guide PriceFrom USD 360

Pig Feed Pellet Machine

For users with a 500 to 1200 kilogram per hour capacity need, a flat die pellet machine is recommended.

It compresses powder into pellets under high pressure, which improves feed quality and digestibility. The heat generated during pelletizing also helps with sterilization and enhances feed safety.

This model offers stable performance and delivers the required output while keeping overall investment cost effective.

Recommended Pellet Machine Models

| Model | Power (kW) | Capacity (kg/h) |

| KD-280 | 15 | 500 to 600 |

| KD-300 | 22 | 600 to 700 |

| KD-400 | 37 | 900 to 1200 |

Video Demo

Guide PriceFrom USD 920

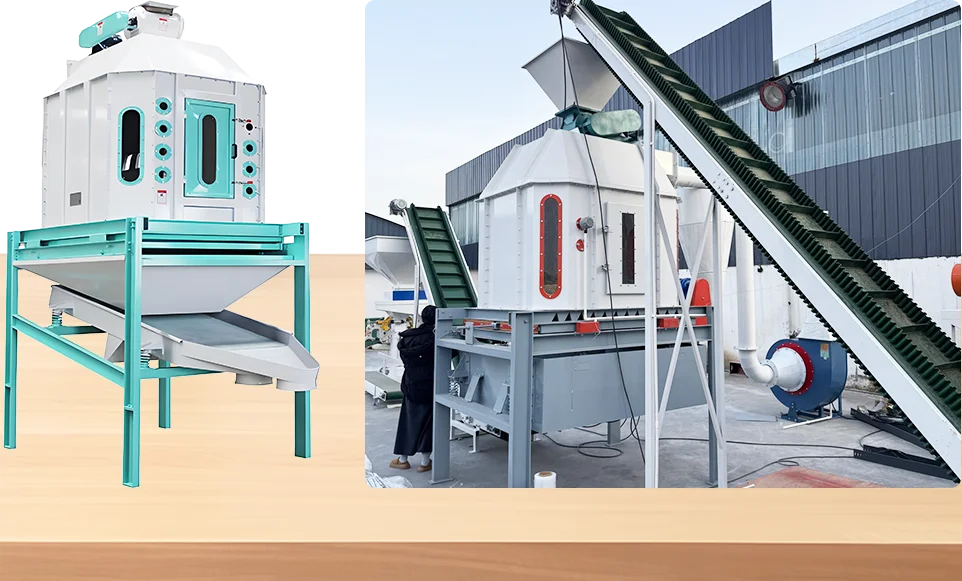

Counterflow Cooler with Screening

Fresh pellets come out at a high temperature and need proper cooling. This machine uses an air-cooling system to cool large batches quickly and efficiently.

After cooling, the pellets pass through a vibrating screen that removes undersized or incomplete pellets for reuse. This reduces material waste and helps maintain consistent feed quality.

Cooling and Screening Machine Spec

| Model | Capacity (t/h) | Trough Volume (m3) | Power (kW) |

| NL2.5 | 5 | 2.5 | 0.75 + 0.55 |

Video Demo

Feeding Support Equipment

This includes the screw conveyor and the skirt belt elevator, which function as auxiliary equipment in the production line.

The screw conveyor transports powder materials. Its sealed design reduces manual feeding and helps prevent dust leakage and material waste.

The skirt belt elevator transfers pellets after pelletizing, and the raised skirt structure helps minimize spillage and product loss.

*Both the conveyor length and lifting angle can be customized as needed.

If you have a larger budget or prefer a higher level of automation, you can refer to: Pig Feed Production Line Equipment and Full Processing Flow

The configuration shown above is for reference only. You can adjust the equipment setup based on your production needs.

If you would like more information or a quotation, feel free to contact us. We can provide a customized solution tailored to your requirements.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.