3 Types of Pig Feed Pellet Production Line Solution

Pellet feed is becoming a smart choice for pig farms and feed mills. It's easy to handle, store, and transport, and can improve feed efficiency by 5–8%. Below are three feed pellet line options with setup and price tips to guide your investment.

Content

Small Economic Feed Line (60–220 kg/h)

| Area Required | Operators | Total Power | Guide Price |

| 20–30 m2 | 1 person | 8–18 kW | From USD 650 |

Ideal for small pig farms or households, this line offers low investment and easy operation for daily feed pellet production.

Production Process

Powdered raw materials are mixed → conveyed → pelletized → naturally cooled

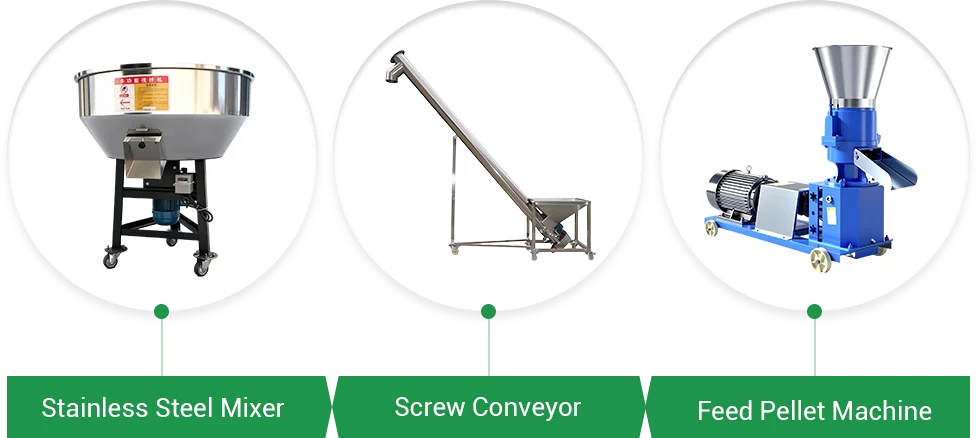

| Function | Equipment |

| Mixing | Stainless Steel Mixer |

| Material Conveying | Screw Conveyor |

| Pelletizing | Feed Pellet Machine |

Pig Feed Pellet Machine

A flat die pellet machine is ideal for small pig farms. It can produce enough feed per hour for 20–70 pigs (100–120 kg each). The machine is easy to use, clean, and maintain, and its compact design saves space.

It presses ingredients like corn, soybean meal, and wheat bran into firm pellets. Pellet size can be changed by using different dies; 6 mm dies are recommended for pig feed.

Feed pellet machine spec

| Model | Power (kW) | Capacity (kg/h) |

| KD-125 | 4.5 | 60–100 |

| KD-150 | 4.5 | 80–150 |

| KD-160 | 5.5 | 130–200 |

| KD-180 | 5.5 | 150–220 |

*Supports 220V single-phase power or optional diesel/gasoline engine.

Pellet Machine Working Video

Stainless Steel Feed Mixer

This mixer blends cornmeal, wheat bran, rice bran, soybean meal, and additives evenly to keep feed uniform and nutritious.

It mixes large batches quickly and efficiently, saving time compared with manual methods.

Made of stainless steel, it's durable, easy to clean, and helps keep the feed safe and hygienic.

Feed mixer spec

| Model | Capacity (kg/Each Stirring) | Host Power (KW) |

| 50 | 45 | 3 |

| 75 | 70 | 3 |

| 100 | 90 | 4 |

Feed mixer video demo

Screw Conveyor (Auxiliary Equipment)

The screw conveyor automatically feeds mixed powder into the pellet machine, reducing manual work. Its enclosed design minimizes dust and feed loss during transfer, keeping the process clean and efficient.

Screw conveyor spec

| Model | Power (kW) | Length (m) |

| L140-2 | 2.2 | 2 |

| L140-2.5 | 2.2 | 2.5 |

| L140-3 | 2.2 | 3 |

All conveyors feature a 140 mm pipe diameter with a lifting capacity of 1–2 m3/h.

Screw conveyor video demo

Semi-Automatic Feed Line (500–1200 kg/h)

| Floor Area | Operators | Total Power | Guide Price |

| 60–80 m2 | 1–2 persons | 45–50 kW | From USD 1800 |

Designed for medium-scale farms and feed processors, this line features a simple and stable design for continuous pellet production. It supports optional cooling, screening, and packing units, suitable for both self-use and commercial feed making.

Production Process

Raw Material Grinding → Mixing → Pelletizing → Cooling & Screening → Finished Product Packing (optional for commercial use)

| Process Stage | Equipment Name |

| Raw Material Grinding | Hammer Mill Grinder |

| Mixing | Stainless Steel Mixer |

| Material Conveying | Screw Conveyor |

| Pelletizing | Feed Pellet Machine |

| Cooling & Screening (Optional) | Air-Cooling Dryer |

| Packing (Optional) | Automatic Packing Machine |

Feed Hammer Mill

It efficiently grinds corn, soybean meal, and wheat bran,ideal for pig feed production.

The particle size can be adjusted by changing the screen (1–3 mm recommended for pig feed).

Feed grinder spec

| Model | Power (KW) | Capacity (KG/H) | Total Weight (KG) |

| 210 | 3 | 300–600 | 85 |

| 230 | 3 | 400–800 | 95 |

| 300 | 4 | 800-1200 | 130 |

Feed hammer mill video demo

Stainless Steel Mixer

This stainless-steel mixer has a larger capacity, ideal for higher-volume pig feed production.

Each batch takes about 15 minutes to mix evenly, preventing separation and ensuring consistent feed quality for pelletizing.

Feed mixer spec

| Model | Capacity (kg/Each stirring) | Volume(L) |

| 150 | 140 | 260 |

| 200 | 180 | 320 |

| 300 | 280 | 480 |

Pig Feed Pellet Machine

This line is equipped with a high-output flat die pellet machine designed for medium-scale feed production. It delivers strong power, stable performance, and supports continuous operation.

With a capacity of 500–1200 kg/h, it meets the daily feed processing needs of pig farms.

Animal feed pellet machine spec

| Model | Power (kW) | Capacity (KG/H) |

| KD-280 | 15 | 500-600 |

| KD-300 | 22 | 600-700 |

| KD-400 | 37 | 900-1200 |

* Supports 380V 50Hz three-phase power, with optional diesel or gasoline engine configuration.

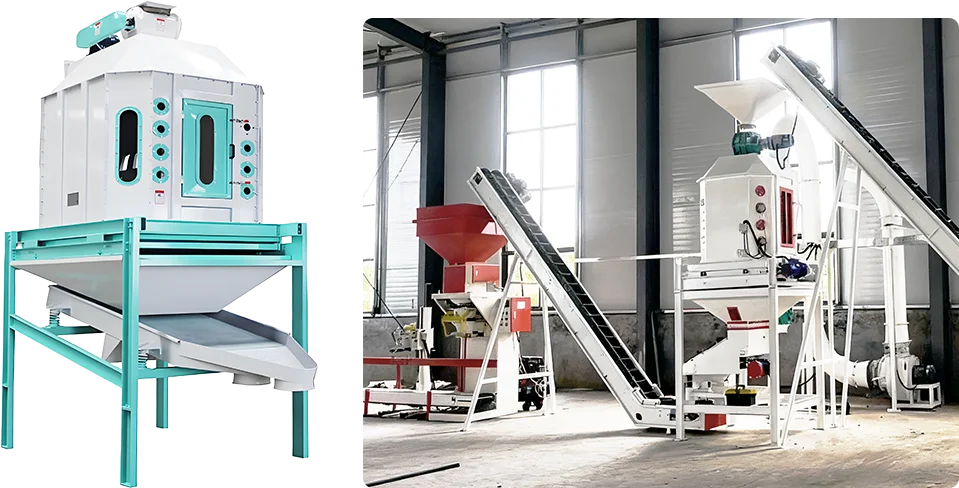

Air-Cooling Dryer & Sifter (Optional)

This machine cools pellets to room temperature quickly, preventing moisture, clumping, and mold. It also removes powder and unformed pellets to improve product quality and appearance.

Ideal for users needing better feed stability or appearance. For self-use or smaller budgets, natural cooling is also suitable.

Air-Cooling Dryer Parameters

| Model | Capacity (t/h) | Trough Volume (m3) | Power (kW) |

| NL2.5 | 5 | 2.5 | 0.75 + 0.55 |

Counterflow Cooler & Screener Video

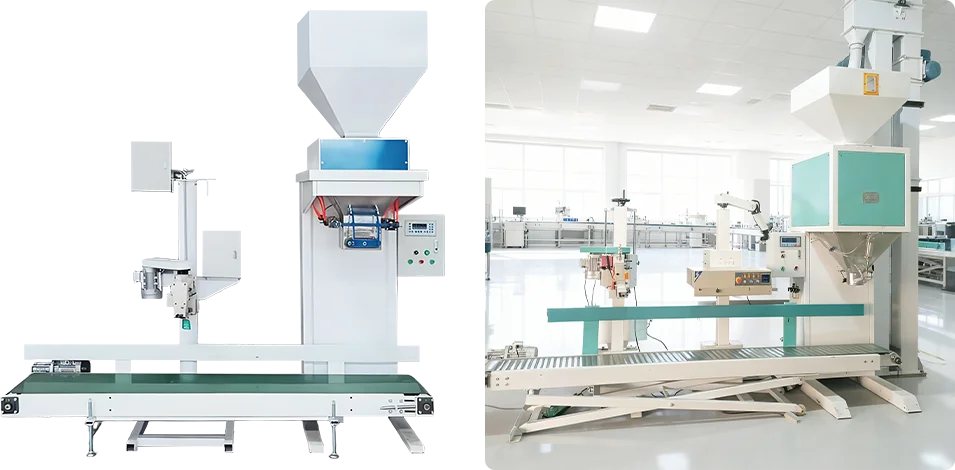

Packing Equipment

For users planning to sell finished pig feed but working with a limited budget, a manual sewing machine is a cost-effective choice for bag sealing.

For higher packaging efficiency and a better product appearance, an automatic weighing and packing machine is recommended. It enables fast, accurate bagging and improves consistency.

Automatic Weighing & Packing Machine Spec

| Item | Specification |

| Packaging Speed | 3–6 bags/min (25 kg/bag) |

| Packaging Weight | 5–50 kg |

| Weighing Accuracy | ±0.1% |

| Power | 1.5 kW |

Automatic packing machine video demo

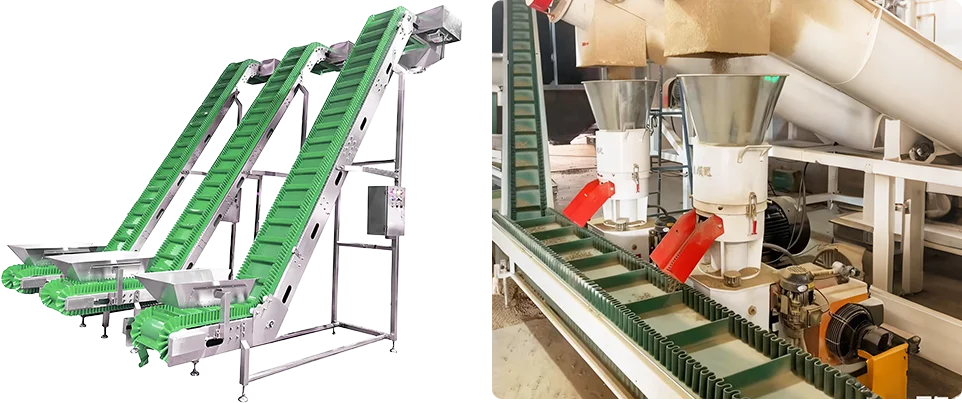

Feeding Equipment (Auxiliary Unit)

The screw conveyor delivers mixed feed powder to the pellet machine for continuous, stable feeding.

With a packing system, a skirt-belt conveyor can be added to transfer cooled pellets to the packing station without damage for faster bagging.

Skirt-belt conveyor video

Both length and pipe diameter can be customized to fit your plant layout.

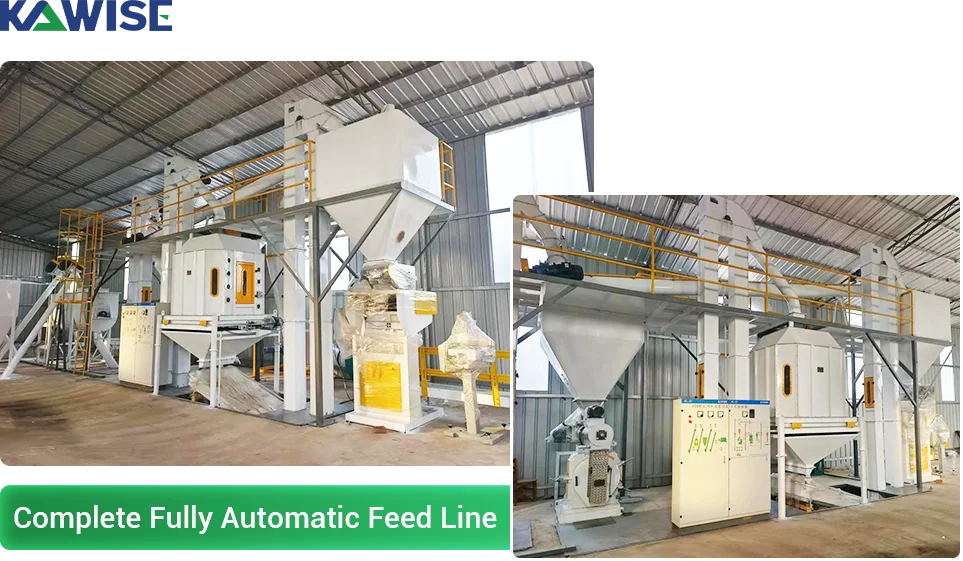

Complete Fully Automatic Feed Line (2–4 t/h)

This production line is designed for large farms, feed mills, and feed trading companies.

It supports mass production of pig feed for different growth stages (piglet, grower, finisher, and sow feed) with a high level of automation.

| Floor Area | Operators | Total Power | Guide Price |

| 250–300 m2 | 2–3 persons | 75–90 kW | USD 16,000–30,000 |

Production Process

Raw Material Silos (Multi-bin + Dosing System) → Grinder → Mixer → Buffer Bin → Conditioning & Pelletizing → Cooling & Screening → Finished Feed Silo → Packing

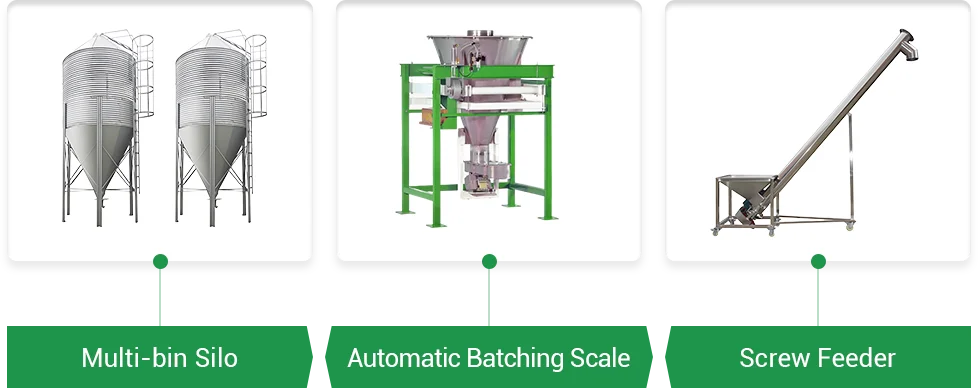

1. Raw Material Storage & Dosing System

Raw materials are fed into separate silos by a screw conveyor. Each ingredient is automatically weighed and dosed to keep the mix accurate and balanced.

The automated system allows quick formula changes for different pig feed types, ensuring smooth, continuous production.

Equipment List

| Equipment | Function |

| Multi-bin Silo | Stores different raw materials. |

| Automatic Batching Scale | Weighs and feeds ingredients precisely. |

| Screw Feeder | Transfers materials to silos or batching bins. |

| Electric Valve System | Controls discharge for automatic batching. |

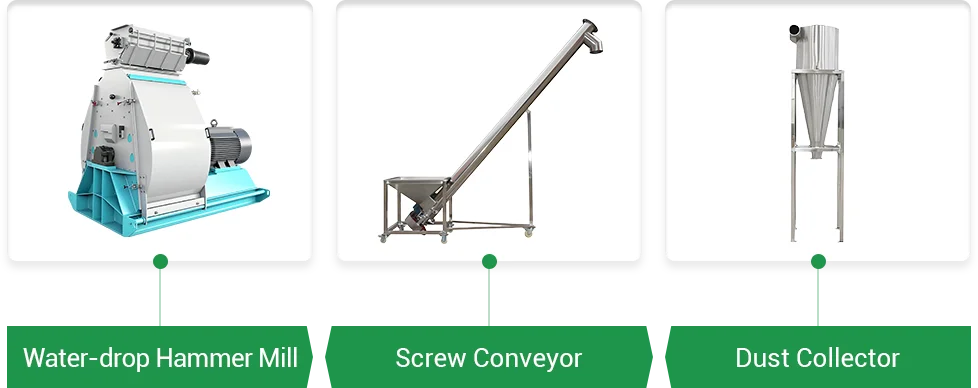

2. Grinding Section

The water-drop hammer mill grinds corn, soybean meal, and other materials to below 2 mm, improving digestibility and feed quality.

The uniform particle size also enhances mixing and pelletizing consistency.

Equipment List

| Equipment | Function |

| Water-drop Hammer Mill | Grinds materials into fine powder. |

| Screw Feeder | Feeds automatically, reducing labor. |

| Dust Collector | Removes dust to keep the area clean. |

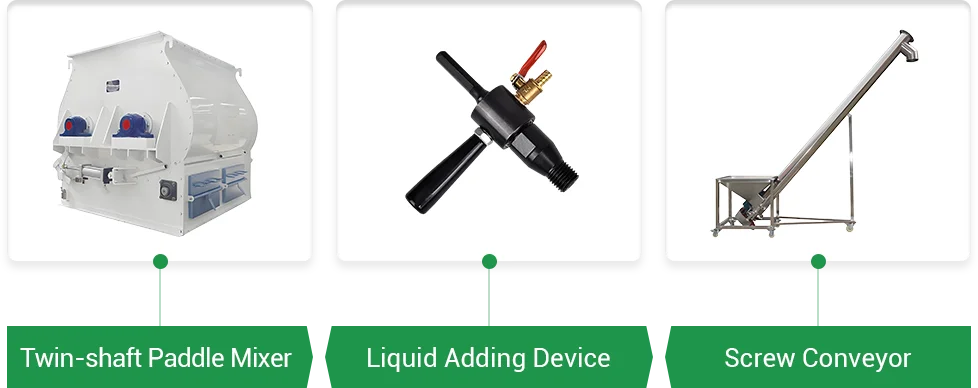

3. Mixing Section

After batching, ground corn, soybean meal, and additives are fed into the mixer.

The twin-shaft paddle mixer achieves high uniformity (CV ≤ 5%) within 2–3 minutes, ensuring consistent nutrition in every batch.

Liquid ingredients like oil, vitamins, and amino acids can also be added to boost feed energy and nutrient balance.

Equipment List

| Equipment | Function |

| Twin-shaft Paddle Mixer | Mixes ingredients quickly and evenly. |

| Liquid Adding Device | Sprays oil or liquid additives. |

| Screw Conveyor | Transfers mixed feed to the next stage. |

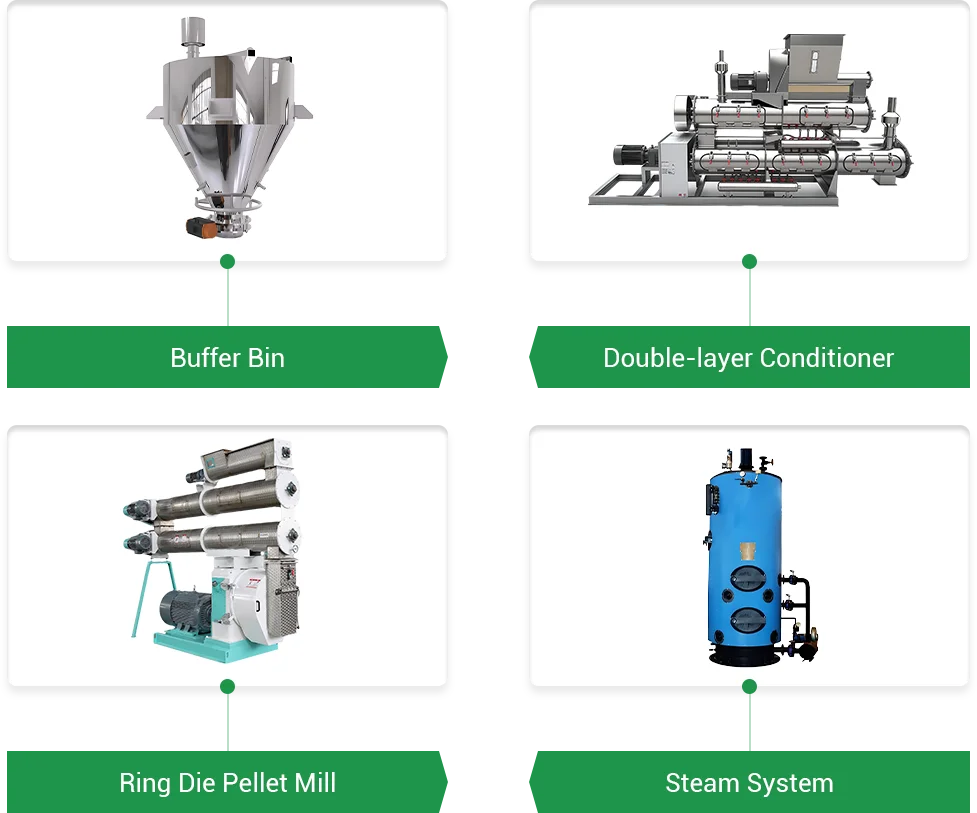

4. Conditioning & Pelletizing Section

The mixed feed is stored temporarily in a buffer bin to ensure continuous feeding to the pelletizer.

After steam conditioning, the material enters the ring die pellet mill. Steam treatment improves feed gelatinization, pellet density, and palatability.

Equipment List

| Equipment | Function |

| Buffer Bin | Holds feed for continuous supply. |

| Double-layer Conditioner | Uses steam to condition the feed. |

| Ring Die Pellet Mill | Compresses feed into pellets. |

| Steam System | Provides heat for conditioning. |

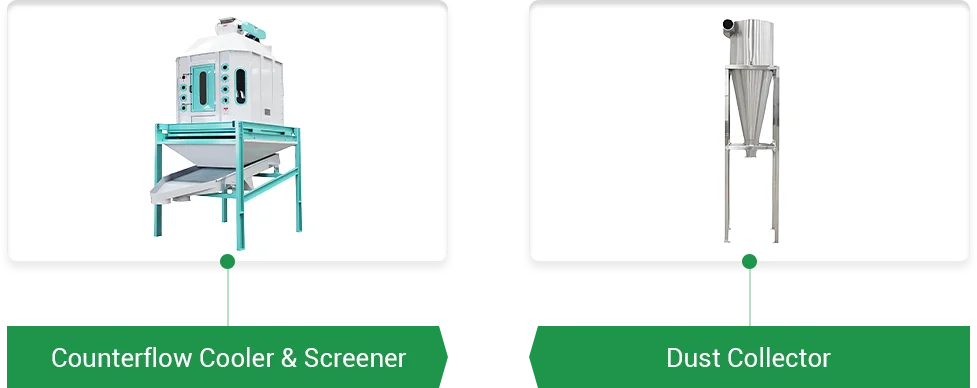

5. Cooling & Screening Section

Fresh pellets with high temperature and moisture are cooled by a counterflow cooler, then screened to remove powder and broken pellets, ensuring uniform quality.

Equipment List

| Equipment | Function |

| Counterflow Cooler & Screener | Cools and separates finished pellets. |

| Dust Collector | Keeps the environment clean. |

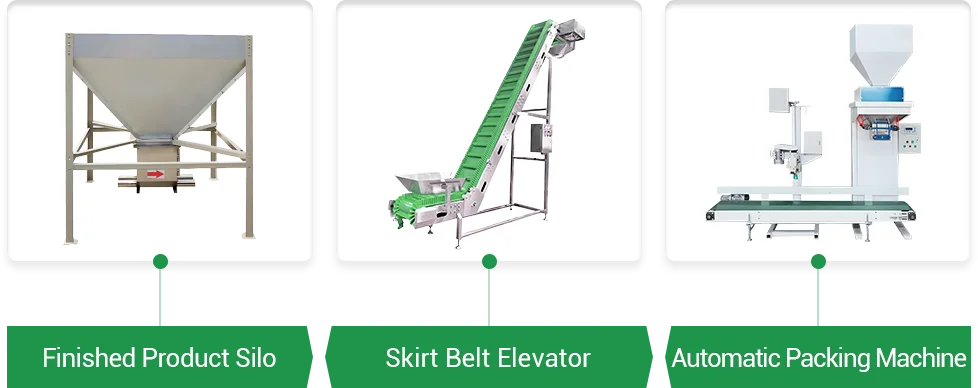

6. Finished Product Storage & Packing

Cooled pellets are lifted to the finished feed silo for temporary storage, then automatically weighed, bagged, and sealed by the packing system.

Equipment List

| Equipment | Function |

| Finished Product Silo | Stores cooled pellets. |

| Skirt Belt Elevator | Lifts pellets to the packing section. |

| Automatic Packing Machine | Weighs, bags, and seals the feed. |

Central Control Cabinet

The cabinet centrally manages the entire production line, allowing quick monitoring of each machine's status, automatic start/stop control, formula switching, and alarm management.

The production line configuration should be selected based on actual output needs and investment budget. The above plan is for reference only.

For detailed equipment or process design, please contact us for a customized solution.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.