6 Types of Animals Feed Pellet Machine for Sale

Every animal has unique requirements for pellet formula, size, and texture, which directly influence feed intake and health. The right pellet mill enhances efficiency, reduces costs, and ensures animal well-being. Here are our expert recommendations for different livestock.

- Poultry Feed Pellet Machine

- Pig Feed Pellet Machine

- Livestock Feed Pellet Machine

- Fish Feed Machine

- Rabbit Feed Pellet Machine

- Horse Feed Pellet Mill

Poultry Feed Pellet Machine

Poultry feed is mainly made of ingredients like corn and soybean meals, so pellets should be softer for better digestion. When selecting a pellet mill, the compression ratio should be moderate to ensure good pellet palatability.

Pellet size also affects poultry growth and feed intake. For chicks (broilers and layers), smaller pellets are more effective as their beaks are not fully developed.

Recommended Pellet Sizes

| Animal | Starter | Grower | Finisher |

| Chicken | 1.0-2.0 mm | 3.0 mm | 3.5-4.0 mm |

| Duck | 2.5-3.0 mm | 3.5-4.0 mm | 4.0-4.5 mm |

| Goose | 3.0-3.5 mm | 4.0-4.5 mm | 5.0 mm |

The size of the pellets can significantly affect poultry performance. To explore this further, read our blog on Feed Pellet Size and Its Effect on Poultry Performance.

Small-Scale & Backyard Farming

For small-scale or backyard poultry farmers, a small flat die poultry pellet mill is the best choice. This equipment is simple in structure, energy-efficient, and has adjustable die hole sizes.

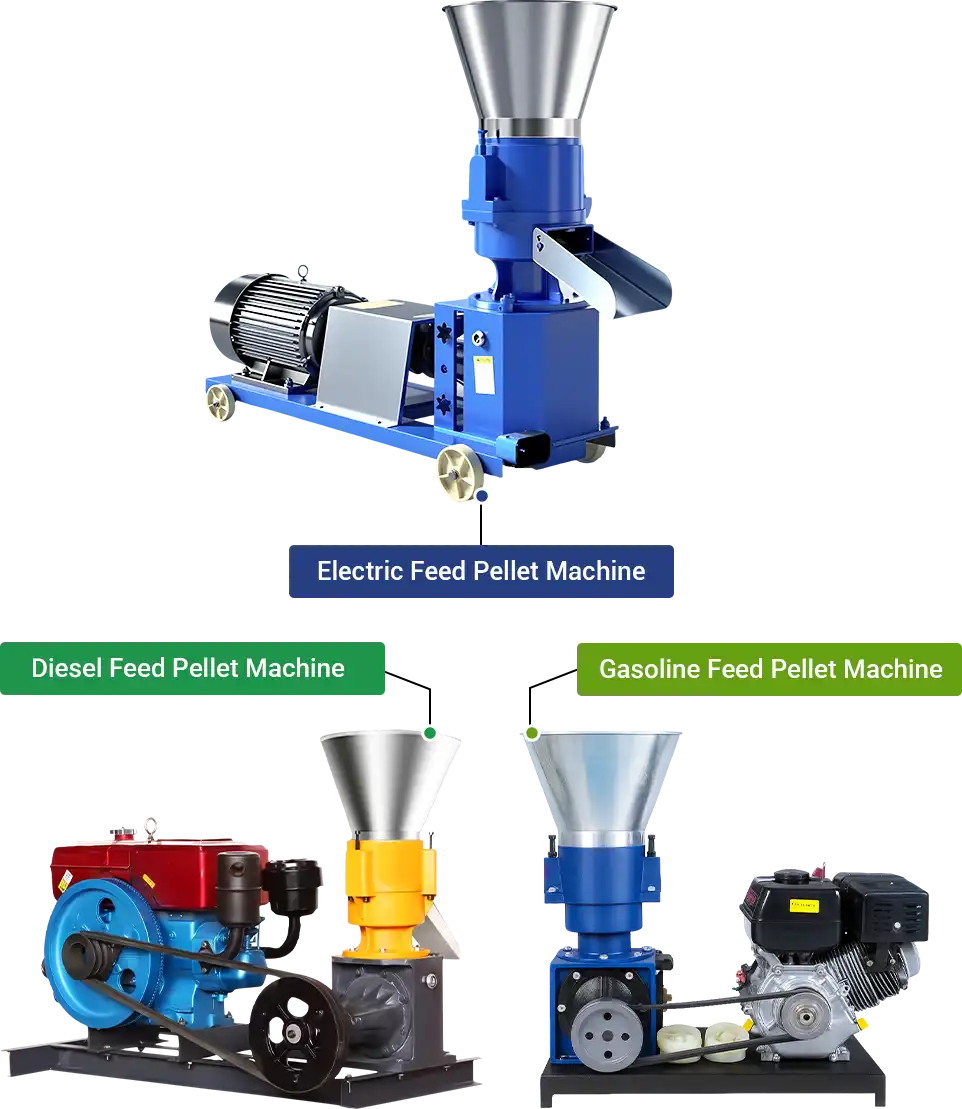

Depending on the specific usage scenario, equipment selection may vary.

- For users with reliable power supply and low-cost investment, an electric pellet mill is recommended, as it is easy to operate and maintain.

- For outdoor or off-grid use, a diesel or gasoline pellet mill is more suitable.

Livestock Pellet Machine for Sale

| Model | Power (kw) | Power (HP) | Capacity (kg/h) |

| KD-125 | 4.5 | - | 60-100 |

| KD-150 | 4.5 | 8 | 80-150 |

| KD-160 | 4.5 | 15 | 130-200 |

FOB Price from $340 | Ask us on WhatsApp.

Commercial Farming

For large-scale poultry farms, cooperatives, or feed processing plants, small equipment may not have sufficient capacity to meet daily demands. When selecting equipment, the focus should be on high output and stable feed supply.

Livestock Pellet Machine for Sale

| Model | Power (kw) | Capacity (kg/h) |

| KD-300 | 22 | 500-700 |

| KD-400 | 37 | 900-1200 |

FOB Price from $1630 | Ask us on WhatsApp

Feed Mills

For large-scale poultry feed production, the line should ensure high capacity and proper pellet conditioning.

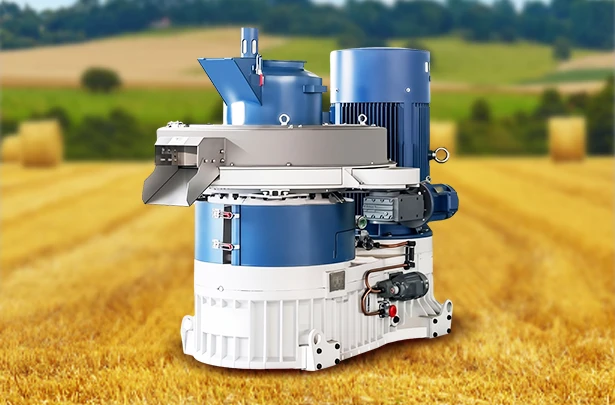

We recommend using ring die pellet mills with efficient steam conditioning systems to improve pellet quality. Integrating equipment like grinders, mixers, coolers, screens, and packagers creates a stable, high-efficiency production line.

👉Feel free to inquire about equipment and pricing.

Pig Feed Pellet Machine

In pig feed production, pellet hardness and durability matter.

Soft pellets break easily, wasting feed and creating dust that harms pigs' health. Pelletizers need enough pressure, especially with high-fiber ingredients.

Mold size should match pigs' feeding habits, affecting pellet size, palatability, and digestion.

| Stage | Recommended Pellet Size |

| Piglets | 2–3 mm |

| Weaner Pigs | 3–4 mm |

| Finishing Pigs | 4–6 mm |

| Breeding Pigs | 6–8 mm |

Free-range & small-scale farming

Small-scale farmers have low feed needs and can use a small pellet mill for production. Ingredients like corn meal, soybean meal, and wheat bran are easy to pellet.

Pig Pellet Machine for Sale

| Model | Power (kw) | Capacity (kg/h) |

| KD-160 | 4.5 | 130-200 |

| KD-210 | 7.5 | 200-300 |

Price Start $ 380 | Contact for for details!

If the formula includes high-fiber ingredients like hay or alfalfa, which are harder to pellet, it's recommended to use a roller-turned pellet mill for better results.

| Model | Power (kw) | Capacity (kg/h) |

| KR-190 | 5.5 | 200-260 |

| KR-190P | 7.5 | 200-300 |

| KR-210 | 11 | 250-400 |

Price Start $ 410 | Chat on WhatsApp now!

Large-scale farming

Finishing pigs eat 2.5–3.5 kg of feed daily. As the farm grows, a single small pellet mill can't meet the demand, even with continuous operation. Frequent feeding, transfer, and mixing can also affect pellet quality.

A high-capacity pellet mill (0.5-1 ton per hour) with a crusher, mixer, and screw feeder is a better choice. This improves efficiency and reduces labor costs.

Ring die pellet mills produce more, but they take up more space and need a full production line, which makes them expensive. They're not the best option for medium to large farms.

Pig Pellet Machine for Sale

| Model | Power (kw) | Capacity (kg/h) |

| KD-300 | 22 | 500-700 |

| KD-400 | 37 | 900-1200 |

FOB Price from $1630 | WhatsApp for details.

| Model | Power (kw) | Capacity (kg/h) |

| KR-260 | 18.5 | 500-700 |

| KR-300 | 30 | 700-900 |

| KR-400 | 45 | 1000-1200 |

This equipment delivers higher pressure, lower energy use, and a better price at high output (compared to motor models).

FOB Price from $1200| WhatsApp for details!

Feed mills

For high-output pig feed production, a ring die biomass pellet mill with a complete production line ensures efficient production and consistent pellet quality.

It meets high-pressure requirements for pellet durability and supports continuous, large-scale production with conditioning, cooling, screening, and packaging.

👉Contact us for production line setup and pricing!

Livestock Feed Pellet Machine

When selecting a ruminant pellet machine, focus on its ability to handle high-fiber materials and ensure pellet stability.

Given the high proportion of forage in the feed, the machine should have sufficient pressure and durable molds for long-term, stable operation.

Mold hole size should be based on the feeding habits of cattle and sheep, with a compression ratio recommended between 1:5 and 1:8. This ensures strong, durable pellets while maintaining palatability and digestibility.

Recommended Pellet Size

| Animal | Mature Size | Young Size |

| Cattle | 6–10 mm | 4–6 mm |

| Sheep | 4–6 mm | 3–4 mm |

| Deer | 3–5 mm | 3–4 mm |

For small-scale or family farms, ruminants mainly consume high-fiber feed like straw and hay, which is harder to pellet. In this case, machine pressure is more important than output.

For mostly roughage, a roller-driven pellet machine is best, offering stronger pressure for smooth pellet formation. For feeds with more concentrates, a regular small pellet machine works fine.

* Choose electric or diesel models based on farm needs for stable and efficient pelletizing.

| Model | Power (kw) | Capacity (kg/h) |

| KR-190 | 5.5 | 200-260 |

| KR-190 P | 7.5 | 200-300 |

| KR-210 | 11 | 250-400 |

* Check and replace rollers and molds regularly to maintain performance and pellet quality.

Price from $410 | Ask us on WhatsApp

Large-scale farming

In large farms, untreated high-fiber materials like straw and hay can affect pellet quality.

Using a chaff cutter, mixer, and screw conveyor in a simple production line improves efficiency and reduces labor.

👉Contact us for updated price!

Feed mills

In feed mills, forages like alfalfa, oat hay, and straw require machines that handle low-density, elastic, and abrasive materials.

Pair a hay bale crusher or chaff cutter with a hammer mill for fine grinding, then use a ring-die pellet machine to prevent blockages. Finally, cool, sieve, and package the pellets.

👉 Contact us for production line options and a tailored quote.

Fish Feed Machine

In aquaculture, pellet feed works best when the formula is balanced and the machine suits the fish's feeding habits.

Choose equipment based on the species: use an extruder for floating feed and a pellet mill for sinking feed.

Sinking Fish Feed

Flat die pellet mills make harder pellets that stay firm in water, so fish have more time to eat. For most farms, this type is enough. The machine is simple, affordable, and easy to use.

Ring die mills give higher output but need bigger investment, which suits larger feed plants. For planned production, using a high-capacity flat die mill with a full line can keep efficiency while saving cost.

Recommended Fish Pellet Sizes

| Size | Typical Species |

| 0.8–2 mm | Shrimp, Lobster, Eel |

| 2–3 mm | Crucian Carp, Common Carp, Large Yellow Croaker, Softshell Turtle |

| 3–5 mm | African Catfish, Channel Catfish, Grouper, Sea Bass |

| 5–6 mm | Carp, Softshell Turtle, Abalone (cylindrical pellets) |

| 6–8 mm | Sturgeon, Large Cyprinids, Large Softshell Turtles |

Data Reference: PMC and Global Seafood

Sinking Fish Feed Machine for Sale

| Model | Power (kw) | Capacity (kg/h) |

| KD-150 | 4.5 | 80-150 |

| KD-160 | 4.5 | 130-200 |

| KD-210 | 7.5 | 200-300 |

| KD-230 | 11 | 250-400 |

| KD-260 | 15 | 300-500 |

| KD-300 | 22 | 500-700 |

| KD-400 | 37 | 900-1200 |

Price Start from $ 350 | Ask us on WhatsApp

Floating Fish Feed

An extruder uses high temperature and pressure to turn powder feed into pellets. The process creates a porous structure, lowers density, and lets the pellets float in water for a long time.

By adjusting settings, the extruder can also make sinking feed. Extruded pellets are well cooked and easy to digest, making them suitable for many species and for large farms or feed plants.

Floating Fish Pellet Machine for Sale

| Model |

Capacity (kg/h) |

Host power (kw) |

| KP-40 | 40-60 | 5.5 |

| KP-50 | 60-80 | 11 |

| KP-60 | 100-150 | 15 |

| KP-70 | 150-200 | 18.5 |

| KP-80 | 200-250 | 22 |

| KP-90 | 250-300 | 30 |

👉 For the latest prices, get in touch with us now!

Rabbit Feed Pellet Machine

Rabbit feed is mostly grass and grains. Pellets should be firm and hard to wear down teeth. Keep dust low, as rabbits are sensitive.

Note

As rabbits grow, reduce pellets and give more hay and vegetables. Too many pellets may cause obesity and other health problems, so adjust feeding with age.

Recommended Pellet Size

| Rabbit Stage | Pellet Size |

| Young | 2–4 mm |

| Growing | 3–5 mm |

| Adult | 4–6 mm |

Forage vs Concentrates

For high fiber feed like alfalfa or hay, use a roller-driven pellet mill. It has strong pressure and makes firm pellets.

For concentrates like soybean meal or corn flour, a small flat die pellet mill works well. It gives good taste and offers flexible power options.

👉Message us for the current price and special offers!

Capacity

For small and medium farms, a flat die pellet mill is practical. It is low cost, easy to use, and improves feed quality.

Large farms can choose a high-capacity flat die mill with crushers, mixers, and conveyors. With more budget, a ring die mill gives higher output and better quality.

At any scale, add a dust system to keep feed safe.

👉Contact us for equipment and pricing details!

Horse Feed Pellet Mill

Horse feed is mainly high-fiber materials like forage and hay, so the pellet machine needs enough pressure for coarse fibers. A 1:5 to 1:7 compression ratio ensures pellets are firm but not too hard, maintaining palatability.

Given horses' chewing habits and dust sensitivity, choose mold hole size based on growth stage, and control dust during production for safe, palatable feed.

Recommended Pellet Size

| Life Stage | Recommended Pellet Size |

| Foals (0-6 months) | 2-4 mm |

| Yearlings (6 months-2 years) | 4-6 mm |

| Adult Horses (2 years and above) | 6-8 mm |

| Senior Horses (15 years and above) | 4-6 mm |

Horse Farm

For small horse farms with wet forage or silage, a roller pellet machine improves pellet hardness and stability by adapting to moisture.

For larger farms, a high-output small flat-die pellet machine is ideal. Additional equipment can be added to boost efficiency and stability if needed.

Horse Pellet Machine for Sale

| Model | Power (kw) | Capacity (kg/h) |

| KR-190 | 5.5 | 200-260 |

| KR-190P | 7.5 | 200-300 |

| KR-210 | 11 | 250-400 |

| KR-260 | 18.5 | 500-700 |

| KR-300 | 30 | 700-900 |

| KR-400 | 45 | 1000-1200 |

FOB Price from $690 | Ask us on WhatsApp

Feed mills

For horse feed production lines, dust control is a top priority due to horses' sensitivity to dust.

The production line is centered around a ring-die pellet machine, with dust control carefully managed during crushing, mixing, cooling, and screening to ensure high performance and quality.

👉Click to see the latest production line setups and prices

If you have any questions about equipment selection or production setup, we are here to offer expert advice and full support.

Contact us for more details and a customized quote!

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.