Key Pre Operation Steps for Flat Die Feed Pellet Machine

File Download

Get the full operation manual in PDF format.

Step 1. Add Gear Oil First

Before starting the machine, add gear oil to the gearbox through the oil inlet.

Do not start the machine without oil or with insufficient oil, as this can cause serious gear wear.

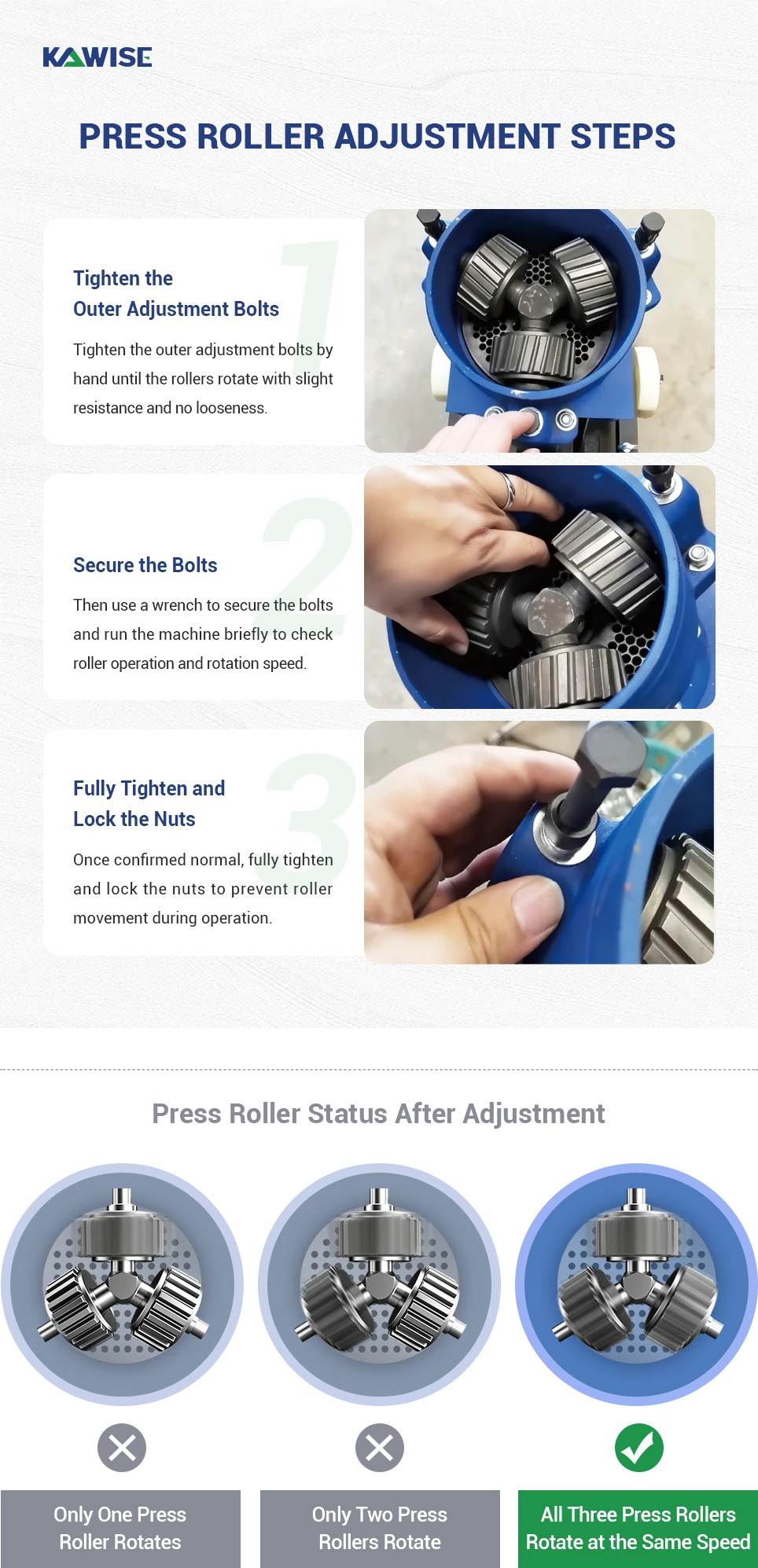

Step 2. Adjust the Rollers

Note: The adjustment method is the same regardless of the number of rollers.

Running the machine without proper roller adjustment may cause poor pellet formation, abnormal load, and accelerated wear.

Step 3. Add a Small Amount of Material

After startup, let the machine run idle for 1–2 minutes to confirm normal roller operation, then feed material slowly in small amounts. Do not cover the rollers.

Note: Keep material moisture at 10%–18%.

Use a moisture meter or hand test material forms a ball and does not fall apart.

Stop operation immediately if roller rotation is abnormal.

If discharge is unstable at startup, reuse the ground material.

Once the die and rollers warm up, pellets form smoothly with slight white smoke, normal feeding can begin.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.