Rabbit Feed Processing Equipment for Small Scale Home Use

To reduce feed costs, more farmers are using equipment for self-processing. The right setup impacts efficiency and experience. Here, we offer practical rabbit feed processing equipment recommendations for small-scale farms, ensuring efficiency and minimizing costs.

Recommended Equipment

Raw material properties vary, and feed processing needs change across different rabbit growth stages. Equipment selection should match these specific requirements. Below are commonly used machines for small scale rabbit feed production.

Multi-functional Chaff Cutter

Hay makes up about 85% of a rabbit's diet. The chaff cutter can cut roughage like grass and alfalfa hay into smaller pieces, aiding in better digestion for rabbits.

If power supply is limited or standard household voltage (220 V, 50 Hz) cannot meet demand, a diesel driven option is available.

Beyond basic cutting, the multifunction chaff cutter can be configured with fiber shredding or grinding functions based on processing needs.

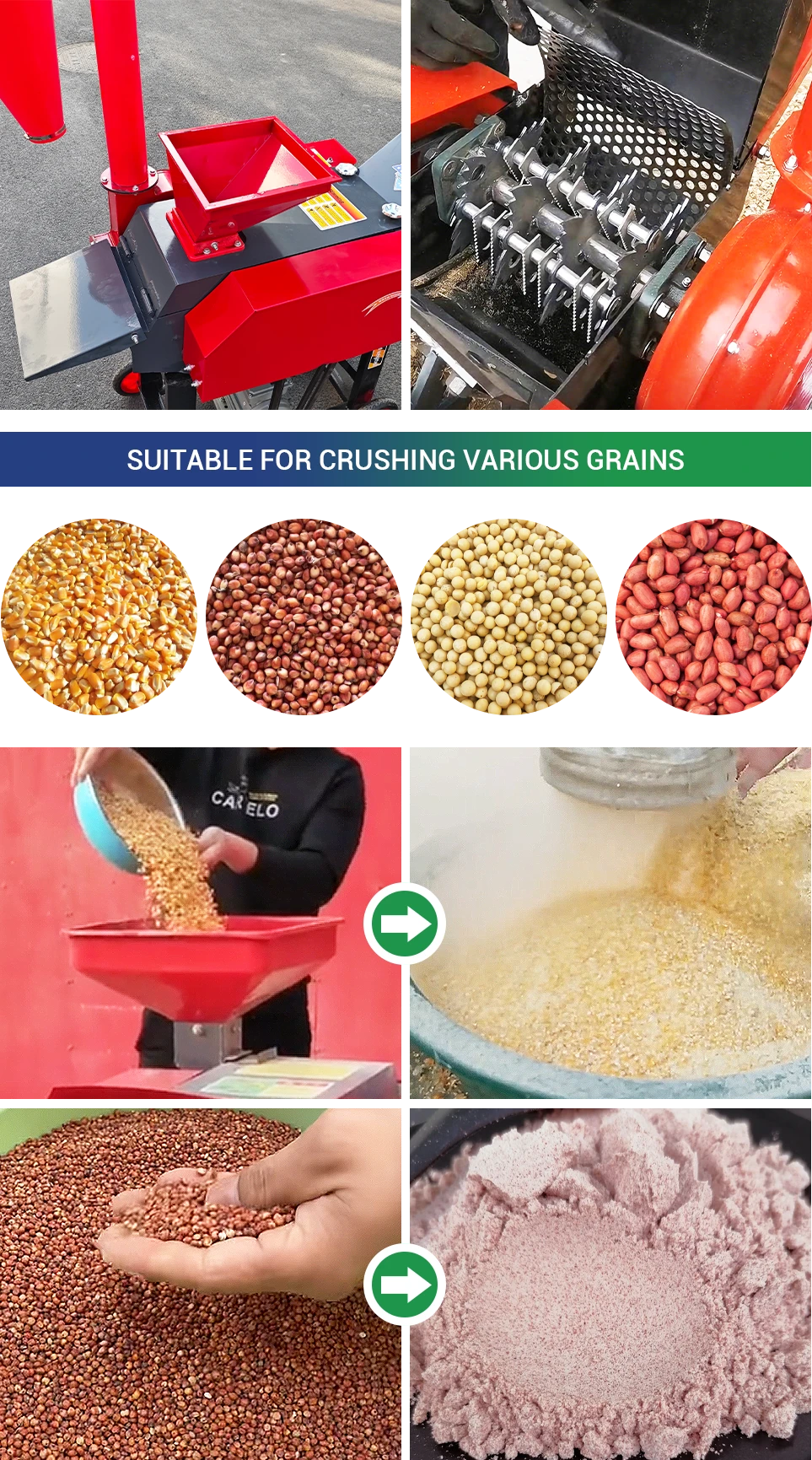

In addition to forage, it handles grains such as corn bran and soybean meal, helping materials blend more evenly with grass powder during mixing and pellet forming, which improves overall rabbit feed consistency.

If your application focuses only on grain grinding, a hammer mill is the more efficient choice.

Feed Mixer

Rabbit feed formulas typically include grains and small amounts of additives in addition to forage. Because these materials differ in density, particle size, and ratios, insufficient mixing can reduce feed quality and feeding performance.

A feed mixer blends chopped or ground forage with grains in a short time, improving overall processing efficiency. Consistent mixing helps maintain feed uniformity and reduces waste and feeding fluctuations caused by uneven ratios.

Rabbit Feed Pellet Machine

Pelleted feed offers concentrated nutrition, stable structure, and easier management, making it widely used in rabbit farming. For young and growing rabbits with limited intake, pellets help ensure consistent nutrient supply.

Compared with mash or loose feed, finished pellets are denser, easier to store, and less prone to moisture absorption and spoilage.

When power supply is limited or standard household voltage (220 V, 50 Hz) is insufficient, the machine can be configured with diesel or PTO drive.

The latest model features a rotating roller design that delivers higher pressing force, making it well suited for rabbit feed with high grass powder and fiber content.

Our Advantages

- Direct factory supply with cost efficient pricing

- Simple operation and low maintenance requirements

- Proven compatibility with forage and common grain ingredients

- Adjustable pellet size for different rabbit growth stages

- Energy efficient design that delivers stable output and lower operating cost

Optional Basic Support Equipment

For users producing rabbit feed pellets in house, the equipment above already covers the main processing steps. Adding a few simple tools can further refine the workflow and improve final pellet quality.

After pelletizing, a small amount of fines or broken pellets is usually present. Excess fines can lead to selective feeding and dust, affecting intake stability and respiratory health.

Simple screening with a metal or handheld sieve removes fines for reprocessing, reducing waste and improving pellet quality.

Screen Mesh

After pelletizing, finished feed usually contains a small amount of fines or broken pellets. Excess fines can cause selective feeding and dust, which affects intake consistency and respiratory health.

Simple screening with a metal mesh or handheld sieve separates fines for reprocessing, reducing waste and improving overall pellet quality.

Small Cooling Rack

Fresh pellets exit the machine at a higher temperature. If they are stacked or bagged immediately, moisture buildup and caking can occur.

Using a small cooling rack for spreading and natural air cooling allows pellets to cool gradually, improving short term storage stability and overall feed performance.

Simple Pellet Crushing Tool

In large scale production lines, a crumble is commonly used to break finished pellets into smaller sizes for young rabbits.

For home or small scale operations, a simpler method can be used. Without changing pellet dies, small batches of pellets can be lightly pressed with a thick wooden or metal plate to produce particles around 1–2 mm, suitable for feeding young rabbits.

By choosing and configuring the right equipment for small scale rabbit feed processing, you can boost efficiency, control operating costs, and fine tune feed formulas for each growth stage.

We supply a complete range of feed processing equipment to support a more efficient workflow. Contact us anytime for a solution tailored to your operation.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.