How to Start a Profitable Broiler Poultry Farm for Beginners

For those new to poultry farming, broiler production is relatively easy to start. With a short growth cycle and fast results, broilers can deliver stable returns in a shorter time under proper management. Beginners should focus on basic preparation, daily management, and common rearing practices.

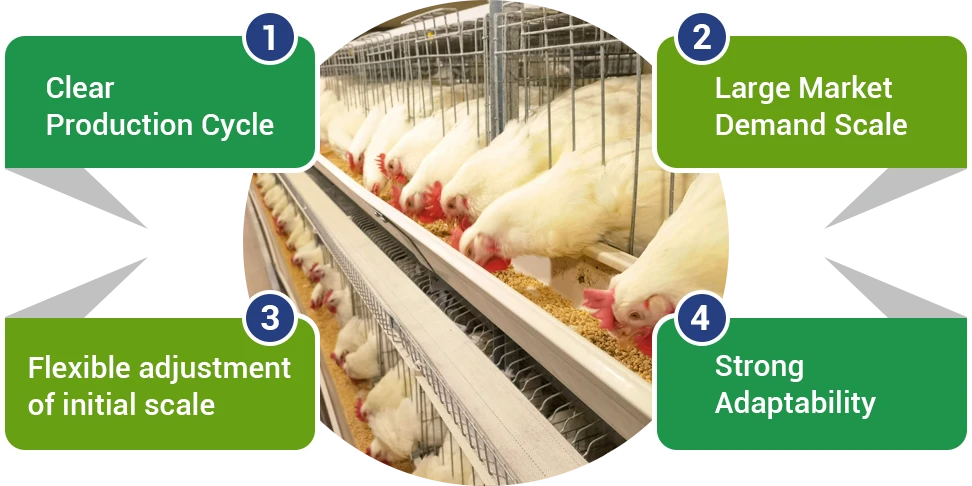

Why Choose Broiler Farming

Broiler farming offers clear advantages in production cycle, market demand, and investment structure, making it a highly practical option among livestock and poultry projects.

Key advantages include:

- A clear production cycle that supports stable planning and turnover

- Strong market demand with a continuing growth trend

- Flexible starting scale that can be adjusted to available resources

- Good adaptability to location and site conditions, with fewer restrictions

What to consider before getting started

Before construction and setup, several key issues must be addressed. These factors directly affect future operations, efficiency, and long-term sustainability.

1. Farming goals and scale planning

Set a clear production scale based on market demand, available capital, and risk tolerance. Initial investment should stay within budget while allowing room for future adjustment or expansion.

2. Site selection and construction

The site should meet basic requirements for ventilation, drainage, and biosecurity. Avoid damp or poor environments to protect flock health and ensure stable long-term production.

3. Initial budget and financing

Prepare a detailed budget covering housing, equipment, and feed. Reserve funds for unexpected costs to prevent cash flow issues from disrupting operations.

4. Feed supply and cost control

Work with reliable feed suppliers and assess long-term price stability. Adjust feed formulas by growth stage to control costs and maintain performance.

5. Risk management and contingency planning

Plan for disease control, market changes, and equipment failure. Clear response measures help reduce losses and maintain operational stability during disruptions.

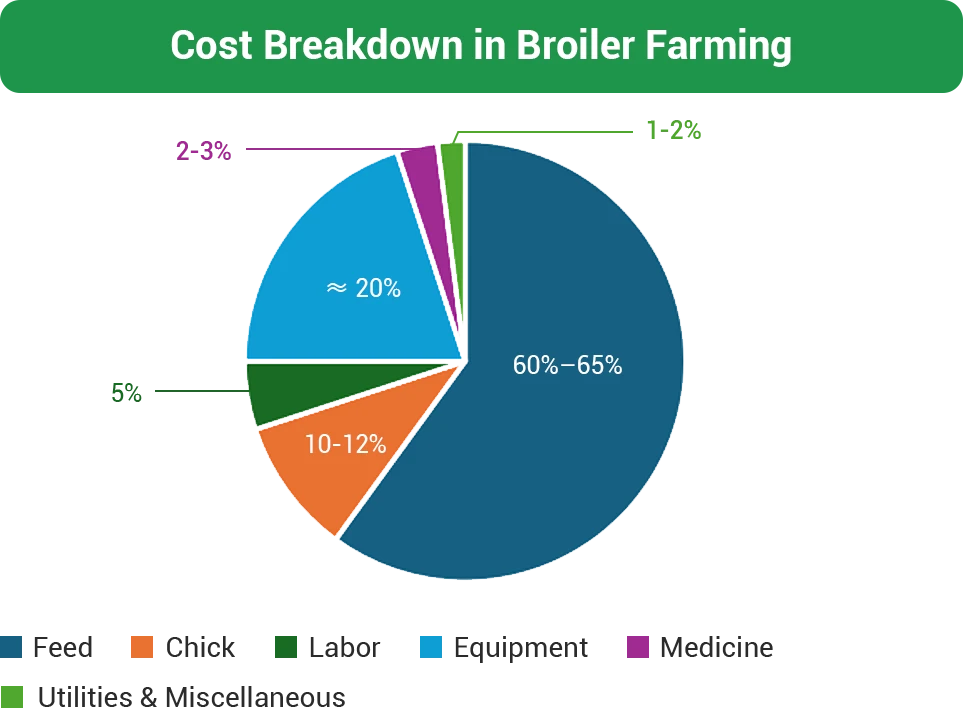

Understanding cost structure

Cost control drives profitability. The chart below shows the main cost components of broiler farming, based on data from Polish farms and cooperative broiler operations in Indonesia.

The table highlights major cost items, while actual operations also involve hidden costs such as maintenance, energy, and material loss. Cost control is essential for both profitability and long-term sustainability.

Choosing the Right Equipment Setup

Equipment selection and configuration directly affect efficiency, labor costs, and overall operations. Different farm sizes require equipment setups tailored to actual production needs.

For small to medium scale farms

For small farms, especially at the startup or trial stage with limited capital, equipment selection should focus on saving space and reducing costs. As production gradually expands, automation can be introduced step by step.

Poultry house construction

Use simple frame structures with moisture resistant materials, and ensure adequate space and proper ventilation inside the poultry house.

Choose manual or automatic feeding systems based on budget and farm planning. Adjust feed amounts according to flock size and feeding needs to avoid overinvestment, as feed waste can significantly increase costs.

A well-designed drinking system is essential to provide a stable and sufficient water supply. Manual drinkers are suitable at the early stage, while automatic systems can be added if budget allows. Water quality and supply should be checked regularly.

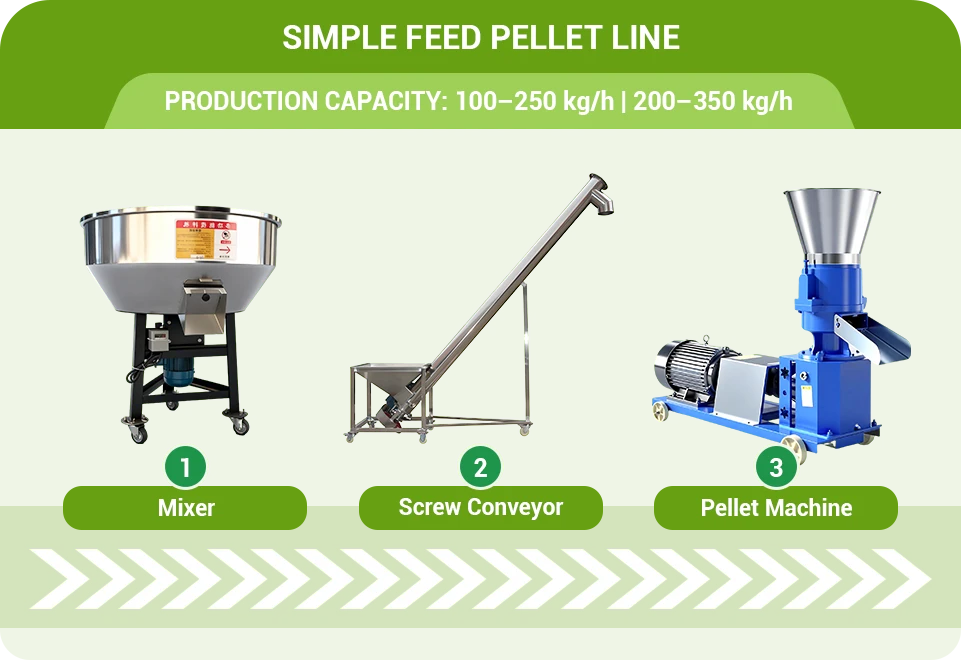

Feed processing equipment

Broiler feed is mainly supplied as pellets or mash, with crushed pellets suitable for chicks. Compared with mash, pellets reduce feed waste and improve feed efficiency.

For small scale farms, choosing suitable feed processing equipment can greatly improve daily feed preparation efficiency while keeping equipment costs affordable.

We offer compact broiler feed production lines that are cost effective, space-saving, and easy to operate. Feel free to contact us for more equipment details.

For large scale farms

For large scale farms, equipment setup should focus on automation and smart management. Efficient production equipment and environmental control systems help improve overall efficiency and reduce labor costs.

Housing construction

For large scale farms, poultry house design must balance bird comfort with production requirements and local climate conditions.

- The house should provide effective ventilation to maintain air circulation and limit harmful gas buildup. Proper insulation is essential to prevent heat loss or overheating, especially in cold regions

- Chicks require reliable heating to support normal growth. Heating capacity and insulation levels should be calculated based on local winter conditions to ensure performance under extreme weather.

- Heating sources should be selected based on cost efficiency, environmental compliance, and local availability, such as natural gas, solar energy, or biomass.

- Environmental monitoring systems should track temperature, humidity, and gas levels in real time to enable timely adjustments.

Feed storage and processing systems

Feed is the main cost in poultry production. Proper storage is essential to prevent moisture, mold, and nutrient loss. Sealed feed silos and conveying systems help protect feed from moisture and contamination.

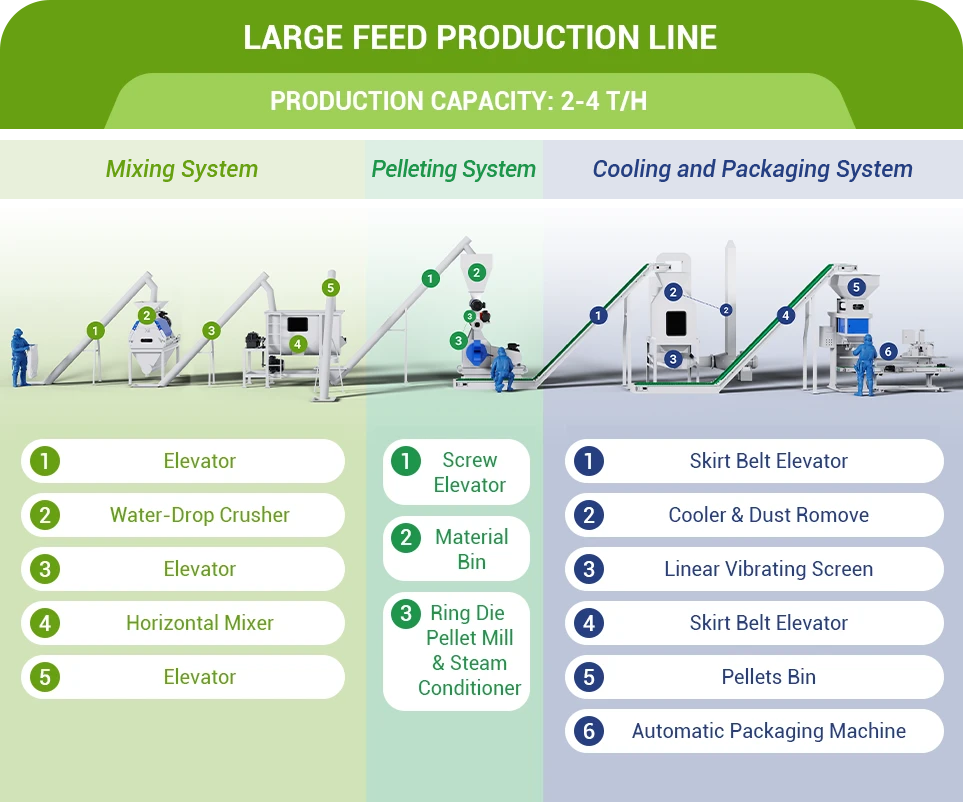

In large scale feed production, the process typically includes grinding, mixing, pelleting, and cooling. Each stage relies on coordinated equipment to maintain production efficiency.

Homemade vs Purchased Feed

Producing feed in house with bulk raw materials lowers cost per ton, especially as scale increases. Purchased feed requires less upfront investment, but long-term reliance on suppliers often leads to higher costs.

We offer a range of broiler feed processing equipment and custom production line solutions to help reduce costs and improve efficiency. Contact us for more details.

Broiler farming requires upfront investment, so careful evaluation of market demand, risks, local conditions, and regulatory requirements is essential. Insights from experienced farmers and on-site visits can support better decisions.

For broiler feed processing equipment or production line solutions, feel free to contact us for practical reference and support.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.