Diesel Engine Pellet Mill Startup and Maintenance Guide

File Download

Get the full operation manual in PDF format.

This guide applies to diesel engines used with pellet machines for feed and biomass processing. It focuses on single cylinder diesel engines with manual and electric start, explaining correct startup practices to reduce operating issues.

Main Components

Some components may be disassembled for transport. Before operation, refer to the diagrams and ensure all parts are properly installed.

A diesel engine works by compressing air to a high temperature. When fuel is injected into the cylinder, it ignites automatically, driving the piston and crankshaft to deliver power to the pellet machine.

During startup, single cylinder diesel engines use a decompression mechanism to reduce resistance and are started either manually or electrically, depending on the power source.

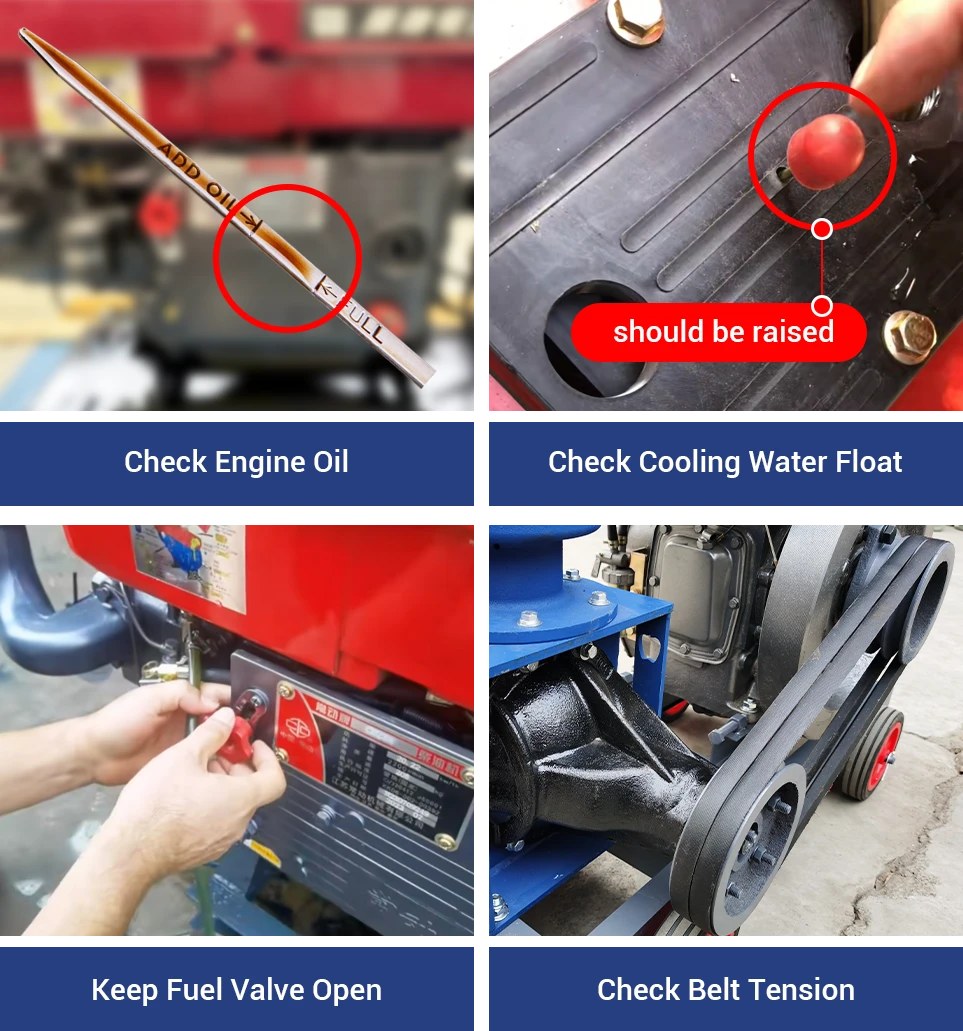

Pre-Start Checks

Before each start, complete the following checks to prevent machine damage.

- Check engine oil and keep the level within the marked range.

- Ensure cooling water is sufficient. Never run without water.

- Make sure diesel fuel is sufficient and the fuel valve is open.

- Check belt tension and adjust if necessary.

- Keep the area around the flywheel and belts clear. Keep people away from moving parts.

- Recommended engine oil CN40 for high temperatures and CN30 for low temperatures.

- Use clean, soft cooling water. In cold environments, add ready to use antifreeze directly.

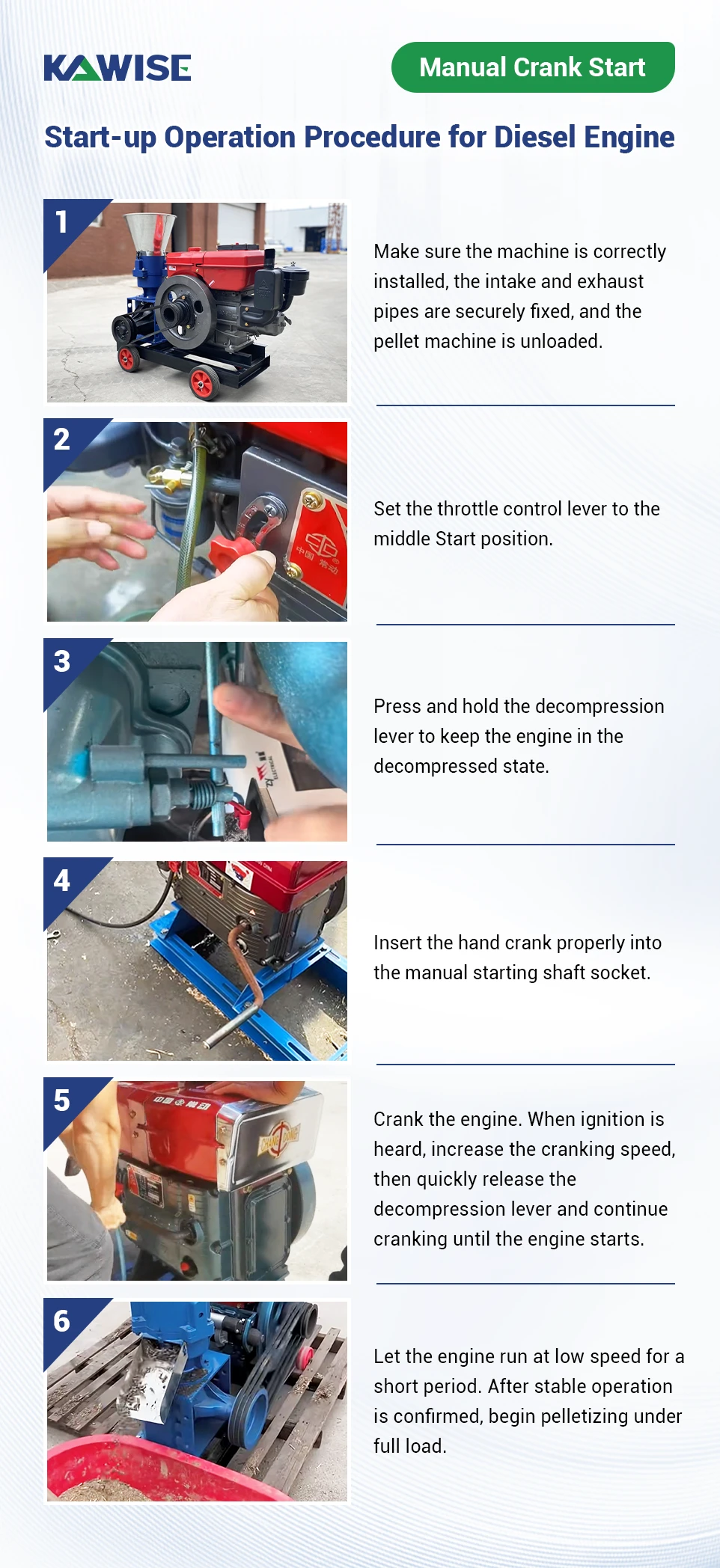

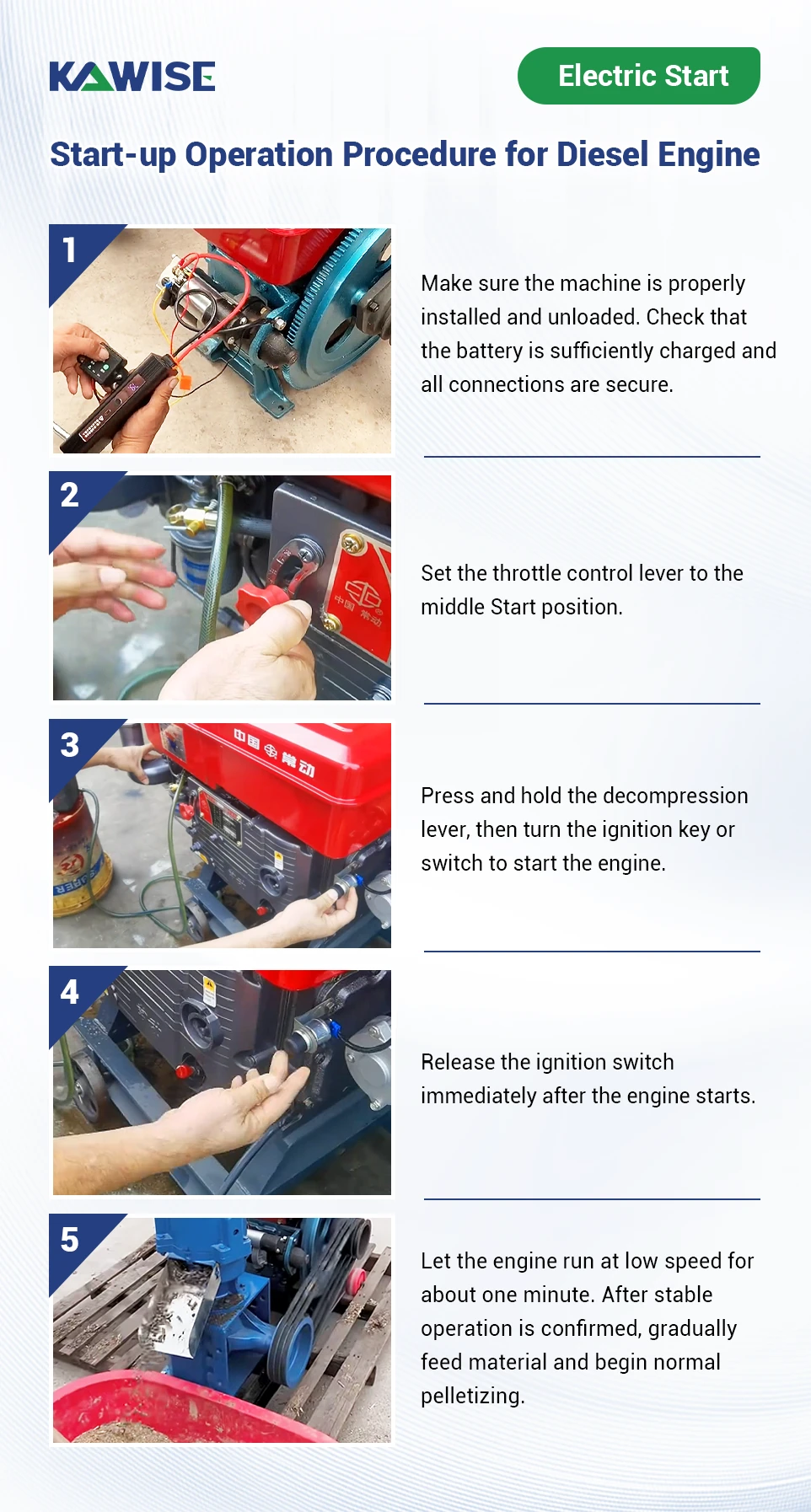

Starting Procedure

Manual and electric starting methods are available. Follow the corresponding procedure based on the machine configuration.

Manual Starting

Note: After the engine starts, the hand crank will disengage automatically. Do not release the hand crank immediately after starting.

Operation Video

Electric Starting

Operation Video

Common Problems During Starting and Operation

The following are common issues that may occur during the starting and operation stages, along with recommended corrective actions.

Starting with no exhaust smoke

Possible Causes

- Fuel shut off valve is closed or fuel level is insufficient

- Air present in the fuel line

- Fuel filter is clogged

- Throttle control lever is in the stop position or set too low

- Decompression device not used during manual starting

- Insufficient battery power during electric starting

Solution

- Make sure the fuel shut off valve is open and fuel supply is sufficient

- Bleed air from the fuel line

- Clean or replace the fuel filter

- Set the throttle control lever to the middle position

- Use the decompression device correctly according to the starting method

- Check battery charge level and power connections for electric starting

Black exhaust smoke and low engine speed

Possible Causes

- Excessive load on the pellet machine or feeding too quickly

- Clogged air filter causing restricted air intake

- Improper throttle adjustment resulting in poor combustion

Solution

Avoid starting the engine under load, run at no load before gradual loading, control the feeding rate, clean or replace the air filter, and adjust the throttle according to the load.

Abnormal engine knocking noise

Possible Causes

- Injection timing too advanced, causing excessive combustion impact

- Low engine oil level or insufficient lubrication

- Engine temperature too high

- Loose belts or components

Solution

Check that the engine oil level is within the normal range, inspect the cooling system and avoid continued operation at high temperature, and perform a general inspection to repair or replace any damaged or loose components.

Maintenance Notes

Proper daily maintenance ensures stable diesel engine operation and extends service life under pellet machine operating conditions.

Daily cleaning and maintenance

- Keep the engine clean and ensure proper cooling.

- Check for oil, fuel, and coolant leaks.

- Drain the fuel filter regularly.

- Close the fuel valve and clean around the engine after shutdown.

Maintenance and replacement

| System | Component | Maintenance Action | Interval |

| Air Intake | Air Filter (1) | Clean dust from the filter to ensure smooth air intake | 50–100 h |

| Fuel System | Fuel Filter (10) | Replace filter and drain water and impurities | 100 h |

| Lubrication | Engine Oil (8) | Check oil level daily; replace if oil deteriorates | Daily |

| Cooling | Water Tank (4) | Check water level and clean scale regularly | Daily |

Note: Maintenance intervals may vary depending on operating conditions.

Long Term Storage

If the equipment (such as a seasonally used pellet machine) will be shut down for an extended period

1. Drain engine oil

Drain the used oil while the engine is warm, then refill with fresh oil.

2. Seal intake and exhaust

Cover the air filter and exhaust pipe with plastic to prevent moisture from entering the cylinder and causing rust.

3. Rotate the crankshaft

Manually turn the crankshaft several times each month to maintain an oil film on internal components.

This operating guide also applies to other diesel engine driven equipment, such as chaff cutters, feed mixers, and grinding machines.

This guide is intended as a practical reference to help users understand diesel engine starting methods and key operating points.

If operating conditions or equipment configurations differ, please contact us for further assistance.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.