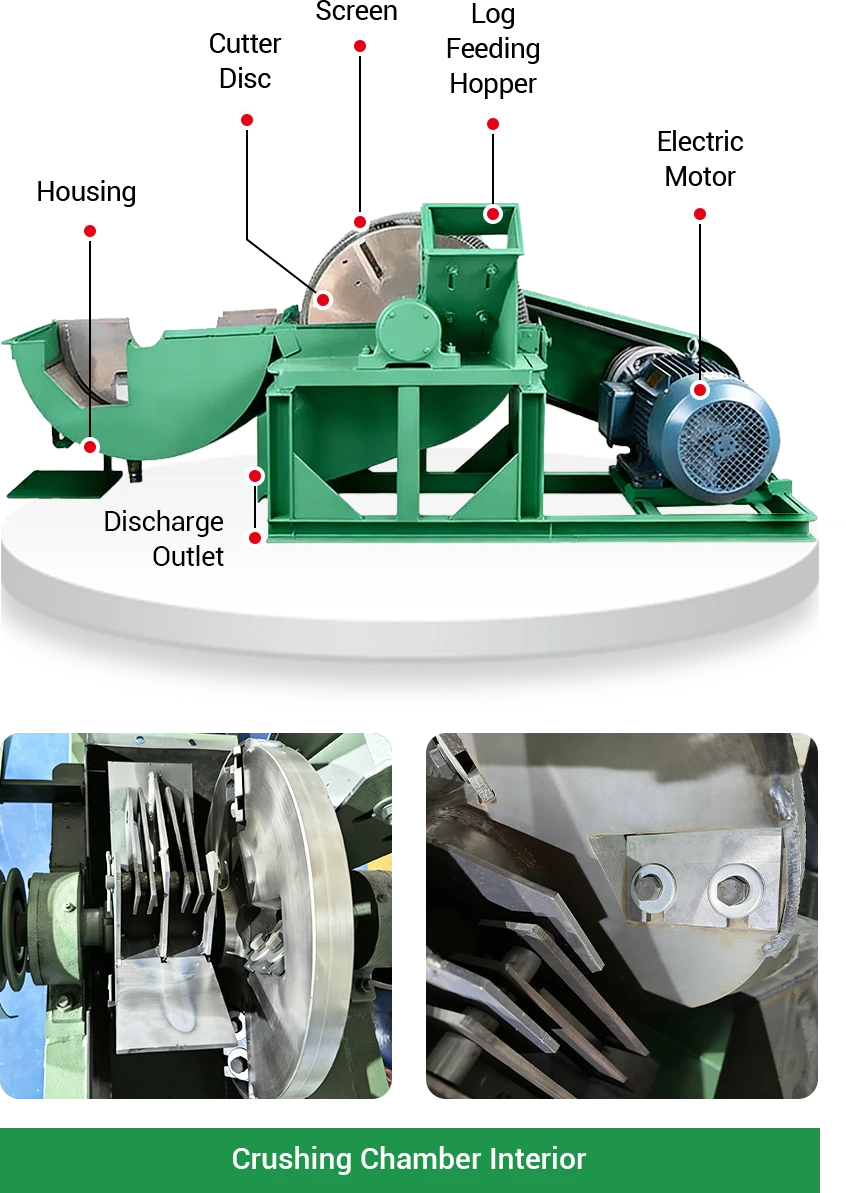

Wood Crusher

Wood crusher, also known as a wood chipper or shredder, uses a high speed blade system to process logs, branches, and wood waste into uniform chips or powder. It is widely used in biomass energy processing, landscaping applications, and wood recycling projects.

After logs enter the feed inlet, they are first cut by high-speed blades, then pass into the crushing chamber for further crushing by hammers.

The screen controls the discharge size. Material that meets the required size is discharged, while oversized material continues to be crushed.

Without a screen installed, the output is typically wood shavings.

The machine supports electric and diesel drive options to suit different power conditions, with an optional tractor PTO for easy mobility and on-site operation.

Common Materials Processed

- Logs and wood blocks

- Wood board offcuts

- Branches and forestry waste

- Used wooden pallets and packing wood

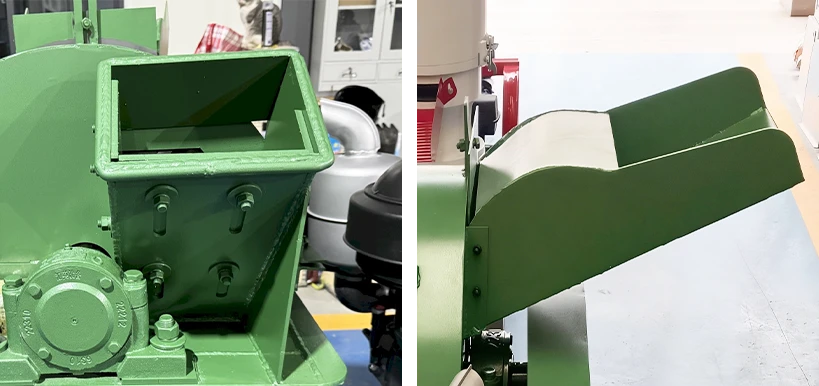

For board waste and other non-branch materials, a larger feed inlet can be added. The material feeds directly into the hammer crushing area for efficient processing.

Output Size with Different Screens

![output size with] different screens](https://www.kwmach.com/i/images/output-size-with-different-screens.webp)

Product Advantages

- Enlarged dual feed inlet for larger material sizes

- High power motor with optional diesel drive

- Thickened durable blades for long service life

- Screen sizes from 3 to 50 mm for flexible output

- Optional bottom wheels for easy movement

Video

Product Parameters

Motor driven models

| Model | Motor Power (KW) | Capacity (T/H) | Inlet Size (MM) | Crushing Diameter (MM) | Blade Diameter (MM) | Number of Blades |

| 420 | 11 | 0.8-1 | 180*150 | 120 | 420 | 4 |

| 500 | 22 | 1.5-2 | 200*180 | 150 | 500 | 4 |

| 600 | 30 | 2-3 | 230*200 | 160 | 600 | 4 |

| 700 | 37 | 3-4 | 240*200 | 180 | 600 | 6 |

| 900 | 55 | 4-5 | 270*250 | 250 | 750 | 8 |

| 1000 | 55 | 5-6 | 280*260 | 300 | 750 | 8 |

| 1200 | 90 | 6-8 | 380*360 | 400 | 1000 | 8 |

Diesel driven models

| Model | Diesel Power (HP) | Capacity (T/H) | Inlet Size (MM) | Crushing Diameter (MM) | Blade Diameter (MM) | Number of Blades |

| 420 | 18 | 0.8-1 | 180*150 | 120 | 420 | 4 |

| 500 | 28 | 1.5-2 | 200*180 | 150 | 500 | 4 |

| 600 | 35 | 2-3 | 230*200 | 160 | 600 | 4 |

FAQ?

Does moisture content affect crushing performance?

Yes. The recommended moisture content of raw materials is 15% to 30%. Excessive moisture can reduce crushing efficiency and increase machine load as well as wear on wearing parts.

How to adjust the final particle size?

The size can be changed by replacing the screen. We offer multiple options from 3 to 50 mm. Additional screens can be purchased to meet different production needs.

How often should blades and hammers be replaced?

Alloy blades can be resharpened 2–3 times, lasting about 3–6 months under normal use. Hammer life depends on material type and working hours, usually replaced every 4–8 months.

Is there much dust during operation?

Some dust will be produced. A dust collection system (bag filter or or a cyclone with a rotary discharge) can be added to reduce dust, keep the workspace clean, and extend equipment life.

What causes a drop in output?

First check blade sharpness, screen blockage, rotor build up, belt tension, and motor load condition.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.