Goat and Sheep Feed Processing Equipment Recommendations

Goats and sheep differ in growth traits, feeding habits, and diet structure, which leads to different requirements in feed preparation. The forage to concentrate ratio plays a key role and directly guides equipment selection. Processing equipment should match the intended feed use and formulation.

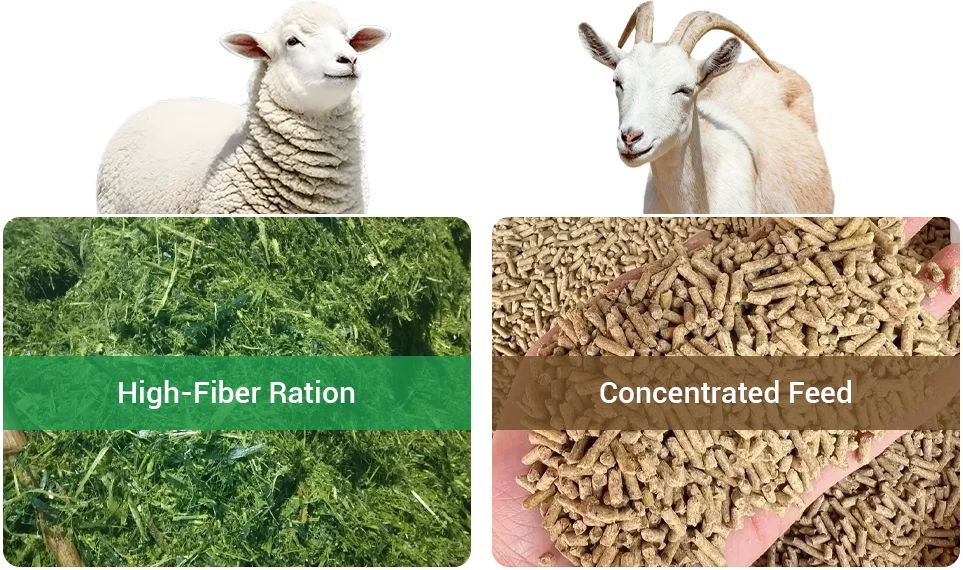

Goat vs Sheep Feed Structure Differences

Their feeding behavior, fiber utilization, and dependence on concentrates vary.

- Sheep utilize high fiber forage more efficiently.

- Goats require more concentration and are more sensitive to energy intake during finishing.

For detailed comparison, you can see: Nutritional and Feed Differences Between Goats and Sheep.

Diet structure determines the required processing method, so equipment selection should start with assessing the forage to concentrate ratio.

Feeding for Weight Gain

Meat focused goats and sheep require higher energy density during the finishing phase. These rations rely heavily on concentrates and prioritize nutrient density, palatability, and consistent intake.

To achieve the intended feeding results, concentrate ingredients need proper processing to control particle size, mixing uniformity, and palatability.

Under these diet characteristics, the processing workflow centers on concentrate handling:

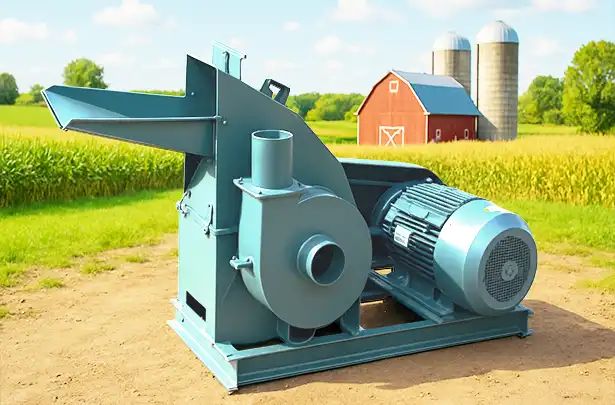

Grain Crusher

High energy diets require controlled particle size, as corn and soybean meal fineness affects energy absorption. Goats are more sensitive to concentrate fineness, and sheep also need efficient energy use during finishing.

A grain crusher helps achieve the required particle size, which can be adjusted by changing the sieve. Finishing rations typically use a 1.5 to 3 millimeter sieve.

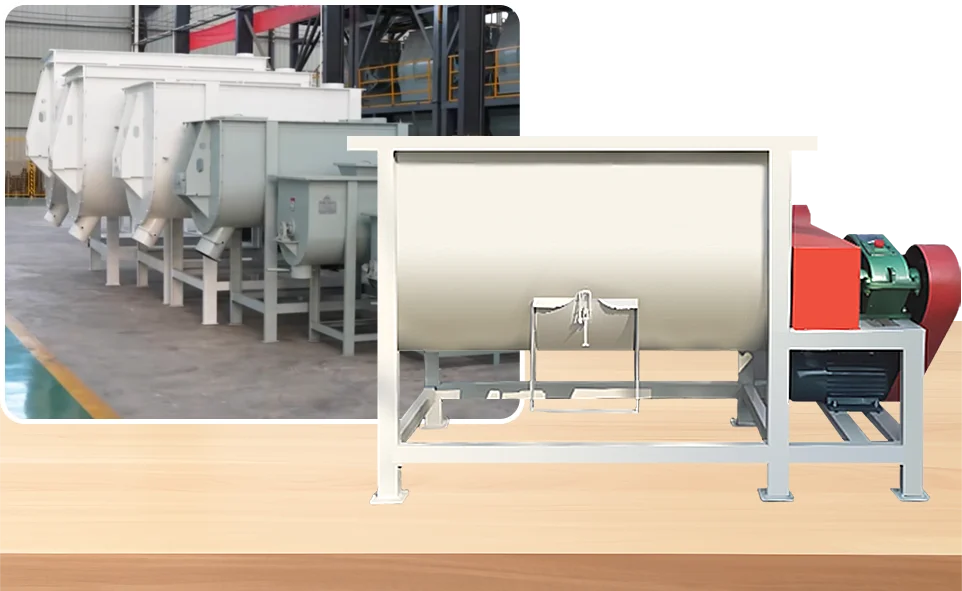

Feed Mixer

Sheep in the finishing stage are sensitive to diet variation. Consistent nutrient supply is important for weight gain, and goats are especially prone to selective feeding, which leads to unstable energy intake. Sheep are more stable, but inconsistent rations still reduce growth performance.

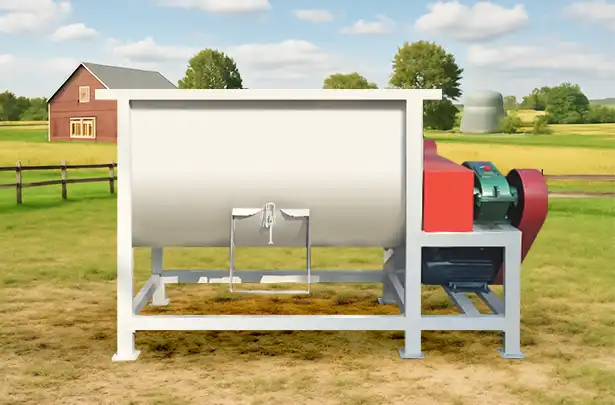

For small and medium farms, stainless steel mixers offer a compact and cost-efficient option. They mix crushed ingredients evenly and allow the addition of oils or molasses to support finishing results.

For higher output or continuous processing, horizontal mixers provide greater capacity and mixing efficiency.

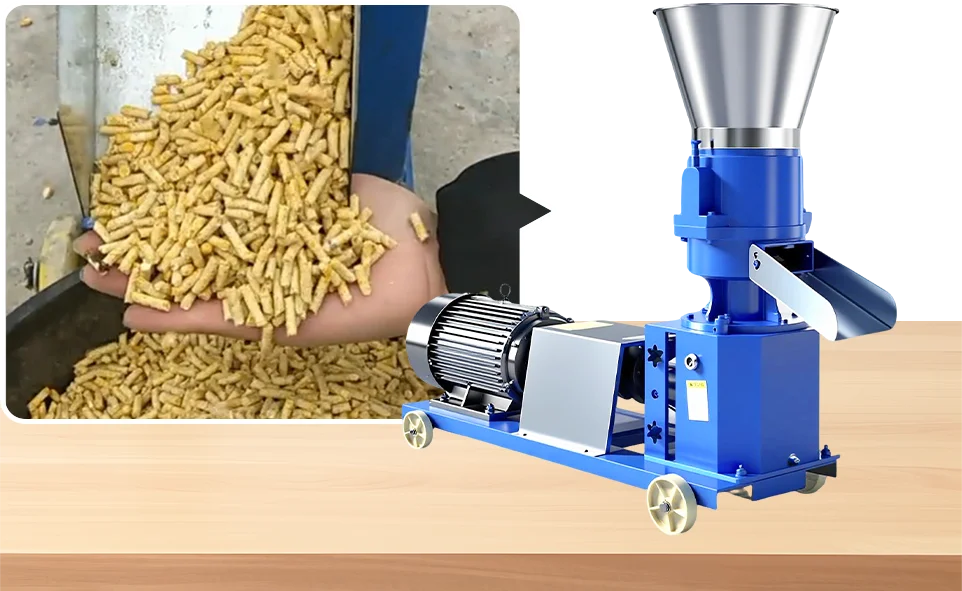

Feed Pellet Machine

Studies show that pelleted feed improves intake and reduces selective feeding. Compressing powders into uniform pellets increases palatability, feed density, and digestive efficiency, which often leads to better daily weight gain.

Pellets also reduce waste during storage, transport, and feeding, making them suitable for finishing diets that require fast intake improvement.

- Flat die pellet machines offer low cost, simple operation, and a small footprint for small and medium farms.

- Ring die pellet machines suit larger production lines, providing higher output and continuous processing.

Feeding for Milk Production

Dairy goats and sheep need stable, nutrient dense rations. Any change in energy, protein, or minerals during lactation can affect milk yield and composition, so concentrates take a larger share of the diet and must stay palatable to support steady intake.

Hammer Mill

Higher energy demand increases the need for consistent concentrate processing. Stable particle size helps prevent intake decline.

For larger dairy farms, water drop hammer mills provide higher efficiency and more uniform grinding, making them suitable for continuous concentrate production.

Mixer

Lactation diets often include minerals, vitamins, oils, and buffering additives, which require a high level of mixing uniformity.

Horizontal mixers provide stable, non-separating blending and suit dairy farms that need continuous or large batch feeding. This supports steady intake and stable milk yield.

Feed Pellet Machine (Optional)

Pelleting in lactation is optional and aims to stabilize concentrate intake when formulas separate easily or when mechanized or night feeding is needed. Pellet form helps maintain consistent intake and supports milk performance.

Equipment selection follows the same principles as weight gain diets, with tighter control of particle size and uniformity for dairy rations.

Forage Based Diets for Wool Production

Wool producing sheep rely heavily on fiber, so forage makes up a larger share of the ration. Adequate effective fiber supports rumen function and wool fiber growth, making forage quality, length, and palatability more important, while concentrates serve mainly as supplements.

Chaff Cutter

High forage diets require proper forage length, as it directly affects intake and rumen performance. A chaff cutter reduces hay or alfalfa to easier to consume lengths, improving fiber utilization and supporting wool growth.

.webp)

Additional functions can be selected based on feeding needs:

- Rubbing creates softer, more palatable forage for young animals or flocks needing higher intake.

- Grinding shortens fiber further and allows better mixing with concentrates, useful in diets that require precise fiber control.

TMR Mixer

Forage based diets separate easily, especially when grass powder, concentrate powders, and additives are combined. A mixer improves uniformity, reduces separation, and limits selective feeding, helping maintain stable fiber and nutrient intake.

A TMR mixer integrates chopping and mixing, handles baled forage efficiently, and allows additives to be added during processing, offering higher overall throughput than standard stainless steel or horizontal mixers.

Roller Driven Pellet Machine (Optional)

Direct feeding of forage often causes waste and selective intake. Pelleting grass powder reduces loss, improves palatability, and simplifies storage and feeding.

New roller driven machines provide stronger compression, producing dense, low fine pellets from grass, straw, and other high fiber materials.

Equipment Selection by Feeding Goal

| Feeding Goals | Key Focus | Small to Medium Scale | Higher Output |

| Weight Gain (Goats / Sheep) | Energy use | Hammer mill, stainless steel mixer, flat die pellet machine | Water drop hammer mill, horizontal mixer, ring die pellet machine |

| Milk Production (Goats / Sheep) | Formula stability | Grinder, stainless steel mixer, optional flat die pellet machine | Water drop hammer mill, horizontal mixer, optional ring die pellet machine |

| Wool Production (Sheep) | Fiber intake | Chaff cutter, stainless steel mixer, roller driven pellet machine | TMR mixer, reinforced roller pellet machine |

Feeding structure and feed processing vary across sheep types, so equipment should be selected based on the ration and production goal.

For tailored advice on equipment or system setup, feel free to message us.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.