Sheep/Goat 1-3 T/H Feed Pellet Production Line

Goat and sheep diets are made up of grass, alfalfa, grains, minerals, and vitamins. As farm sizes grow, manual mixing becomes less efficient. Automated feed production lines are essential for improving efficiency, ensuring quality, and supporting long-term operations.

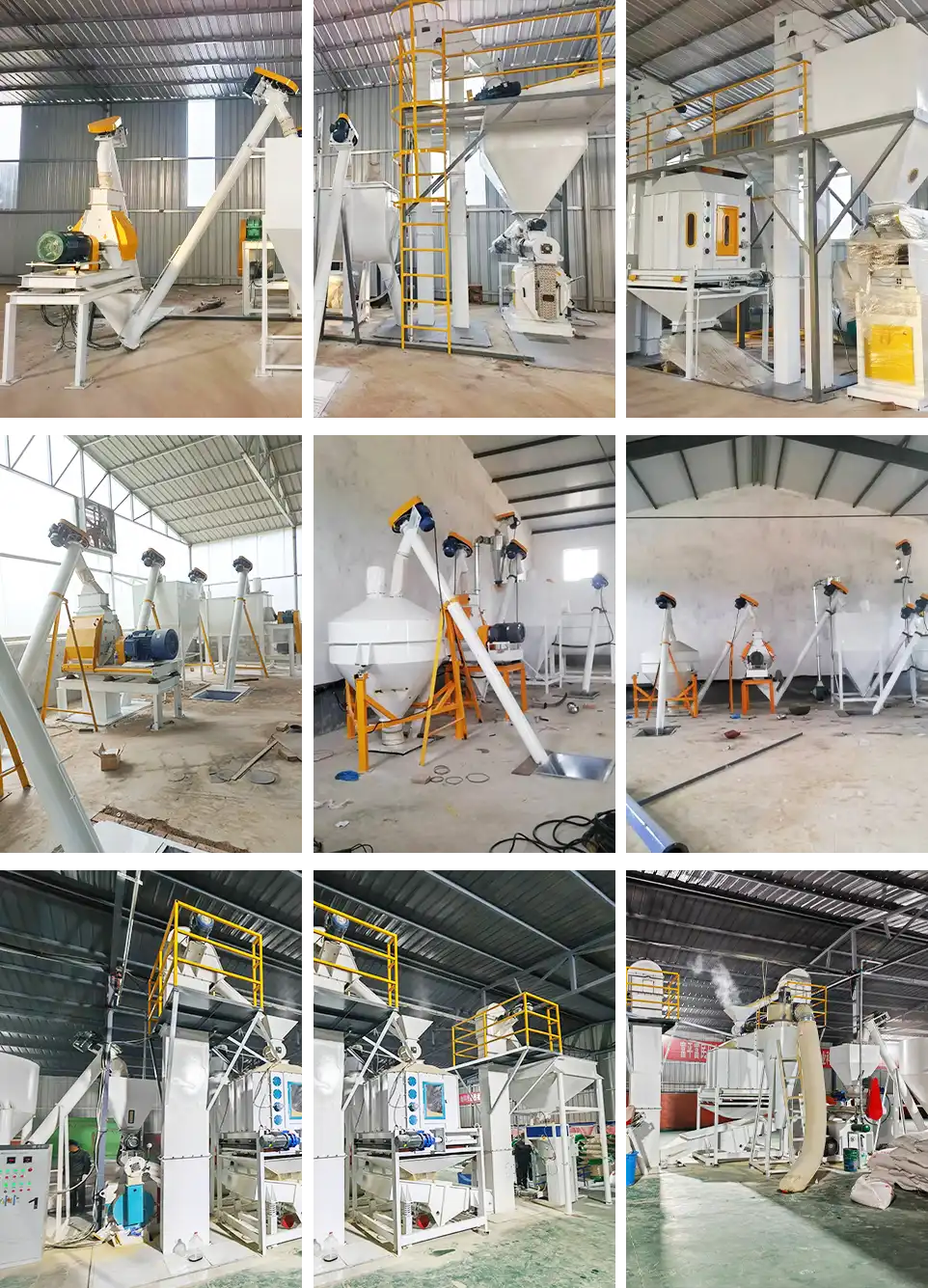

Production Line Overview

This production line is ideal for large-scale farms and commercial feed mills.

| Capacity | Area | Operators | Estimated Price |

| 1-3 T/H | 150 – 300 m2 | 2-3 people | $20,000 - $50,000 |

The production line is highly flexible, allowing customization to suit different farm sizes and production requirements. It meets diverse market demands and can be adjusted and tailored based on your raw material characteristics.

Equipment List

| Required Equipment | Function and Purpose |

| Cleaning Screener | Removes impurities from hay, alfalfa, and grains. |

| Hammer / Drop-Type Crusher | Crushes grains to ensure uniformity and quality. |

| TMR Mixer | Mixes and crushes dry and wet feed ingredients. |

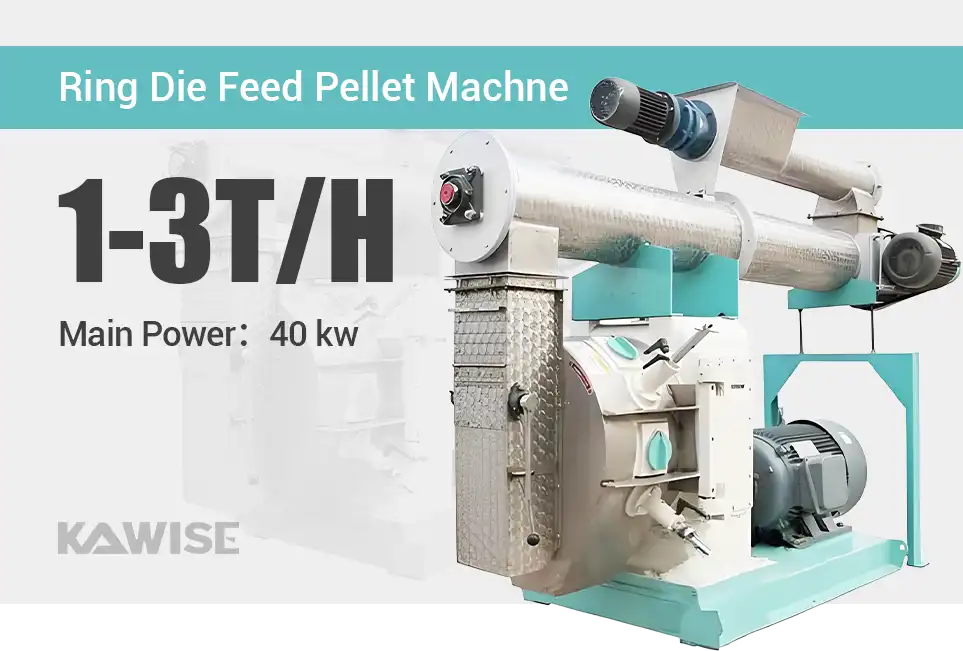

| Ring Die Pellet Mill | Forms pellets for improved digestion and storage. |

| Counterflow Cooler & Screener | Cools and separates quality pellets. |

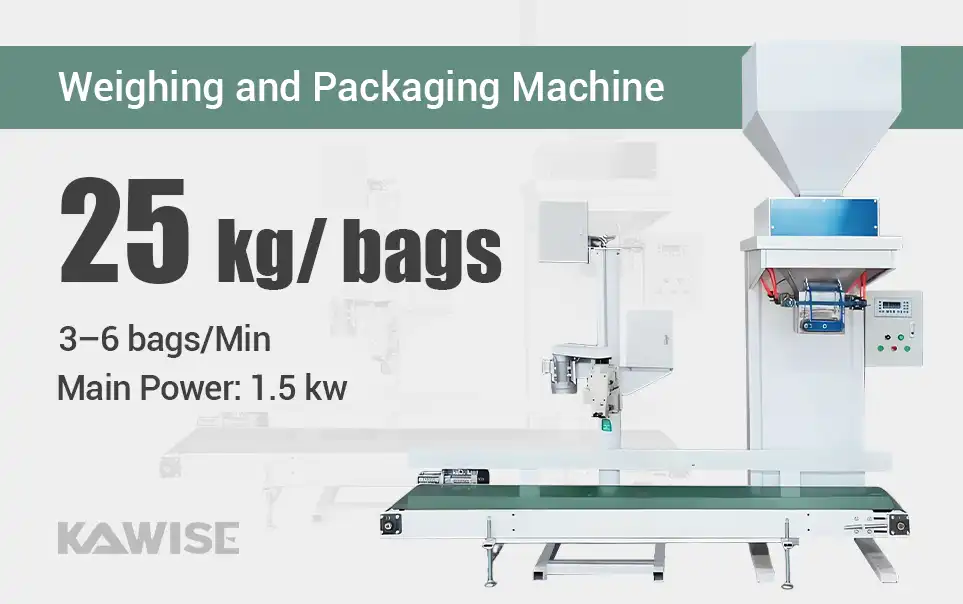

| Automatic Weighing & Packing Machine | Weighs and packs feed automatically. |

| Screw / Skitrted Belt Conveyor | Transports crushed or mixed feed. |

| Buffer Storage Bin | Stores raw materials to ensure continuous operation. |

Production Process

The 1-3 T/H goat and sheep feed production line uses automated equipment to ensure efficient production from raw material processing to final product. Each step is designed to enhance feed quality, save time, and maintain consistent production.

1. Raw Material Cleaning & Preprocessing

Before moving to the next processing stages, raw materials must be free of impurities. In this step, hay, alfalfa, grains, and other materials are cleaned to remove weeds, stones, dust, and other contaminants.

This ensures smooth operation of subsequent equipment and improves feed quality.

2. Grain Crushing

Grains need to be crushed before pelletizing to improve mixing and processing. Crushed material is stored in a buffer bin for further processing.

Hammer mills are cost-effective and versatile, while water-drop hammer mills offer higher precision, ideal for high-quality feed and reducing waste.

3. Rough Feed Crushing & Mixing

Hay, straw, silage, and other roughage are loaded into the TMR mixer, where they are crushed and mixed with other ingredients. Crushed grains are then conveyed to the mixer, ensuring thorough blending.

The equipment automatically adds additives like protein and vitamins for balanced nutrition.

Each mixing cycle takes 5-10 minutes, reducing manual work and improving efficiency and consistency.

4. Pelletizing

The mixed feed is compressed into dense pellets using a ring die feed pellet mill.

During this process, the feed is treated with high temperature and pressure, turning it into pellet form, which enhances digestion and makes it easier to store and transport.

Pellet size and hardness can be adjusted to meet the specific needs of different animals, ensuring palatability and nutritional value.

5. Cooling & Screening

After pelletizing, the feed pellets are hot and need to be cooled using a counterflow cooler and screener.

Cooling helps reduce pellet temperature, preventing breakage from overheating, while improving stability and hardness. The screening function removes substandard pellets, ensuring consistency and quality in the final product.

6. Packaging (Commercial Sales)

Standard feed pellets are automatically weighed and packaged using an automatic weighing and packing machine. This ensures consistent weight for each bag, making transportation and storage easier.

For commercial feed production, bulk packaging is also available to facilitate sales and distribution.

Investment Value of the Production Line

Building a production line not only improves efficiency and reduces costs but also provides long-term, stable returns for farms or commercial feed mills.

For large-scale producers, the return on investment is relatively quick. Compared to manual production, an automated line increases output and greatly enhances the standardization and professionalism of feed processing.

How to Choose the Right Production Line

Choosing the right production line impacts efficiency and costs. Focus on these key points:

- Define capacity needs to avoid underuse or insufficient output.

- Select equipment based on raw material types and required automation.

- Ensure equipment stability, and consider maintenance and support.

- Plan for future expansion and balance long-term investment and returns.

- Stay within budget and manage procurement and operating costs.

For a goat feed pellet production line, selecting a reliable supplier is essential for improving efficiency, reducing maintenance, and ensuring stable long-term operation.

With years of experience in feed production equipment, we are dedicated to providing high-quality animal feed processing machinery and customized solutions tailored to your needs.

Feel free to contact us for a personalized production line configuration.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.