0.2–1 t/h Goat & Sheep Feed making Equipment Recommend

Goat and sheep feed equipment should match the diet type. Proper selection improves efficiency and helps reduce costs. The sections below outline practical low-cost setups for different feeding programs.

Recommended Processing Equipment

| No. | Forage Based Diet | Concentrate Based Diet |

| 1 | Chaff cutter | Chaff cutter with crushing function |

| 2 | Stainless steel mixer | Stainless steel mixer |

| 3 | Roller type pellet machine | Feed pellet machine |

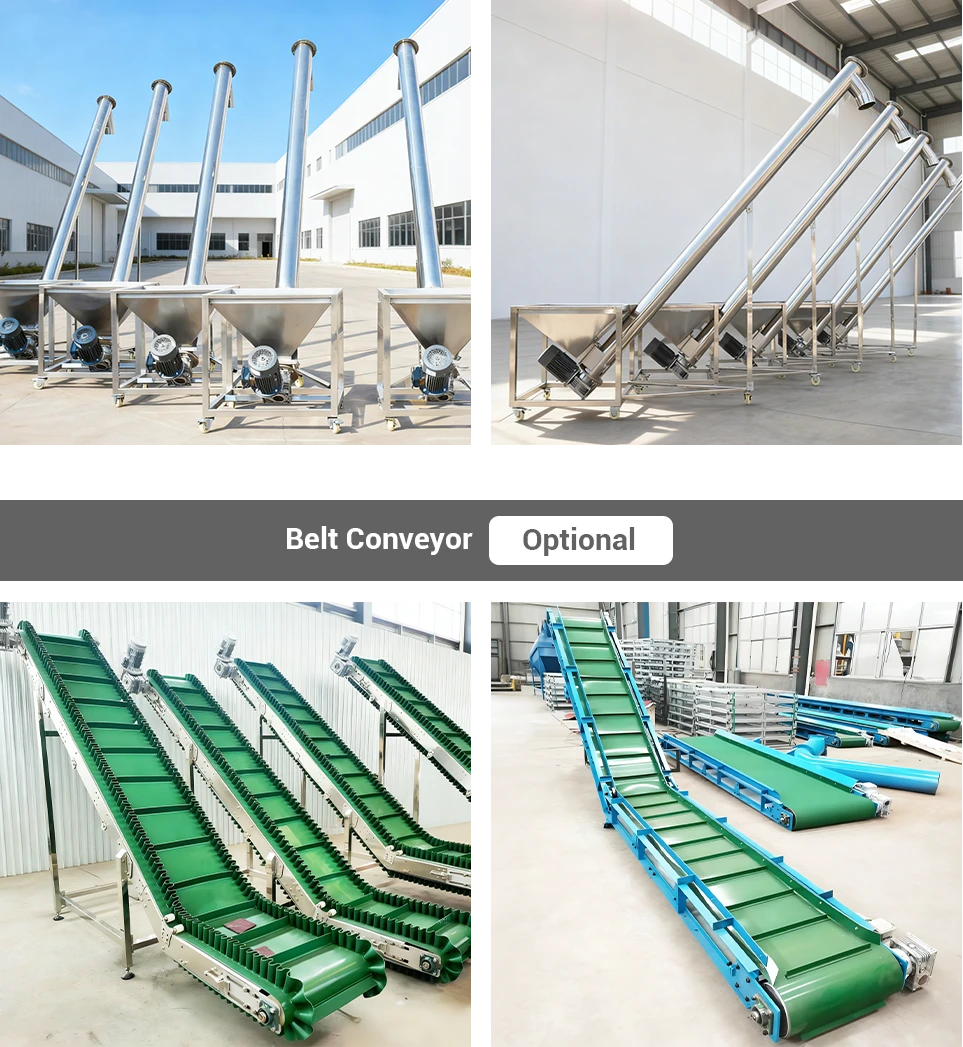

| 4 | Belt conveyor (optional) | Screw conveyor |

1. Chaff Cutter

The chaff cutter prepares rough forage such as grass, hay, and straw by cutting and conditioning it to improve fiber structure, palatability, and digestion. High speed blades ensure stable chop length for feeding or further processing.

- For forage based diets, it is mainly used for forage cutting and conditioning.

- For concentrate based diets, a crushing function is recommended so one machine can handle both forage and grain, reducing equipment count and investment cost.

Chaff Cutter Specifications

| Model | Power (kW) | Capacity (kg/h) |

| 3T | 4 | 500–3000 |

| 3.8T | 4.5 | 900–3500 |

| 4.8T | 4.5 | 1000–4000 |

Chaff cutters are available with diesel or electric drive options, allowing flexible selection based on local power conditions.

From USD 250 ( price varies by capacity and configuration )

2. Stainless Steel Mixer

The stainless-steel mixer blends forage with concentrates such as corn and bran to ensure a consistent ration. Its stainless-steel construction offers corrosion resistance and easy cleaning, making it suitable for continuous operation.

- For forage-based diets, it mixes forage with small amounts of concentrates.

- For concentrate based diets, it plays a key role in achieving uniform mixing and maintaining feed consistency.

Equipment Specifications

| Model | Motor Power (kW) | Blender Diameter (mm) | Volume (L) |

| C50 | 3 | 550 | 120 |

| C75 | 3 | 620 | 160 |

| C100 | 3 | 680 | 200 |

| C150 | 3 | 900 | 260 |

Using the C50 model as an example, one batch of 5 to 10 minutes can mix about 80 kg of material.

From USD 280 ( price varies by capacity and motor power )

3. Feed Pellet Machine

Pelletizing compresses powdered or mixed feed into stable pellets, reducing feed loss and sorting while improving ration consistency and ease of management. The benefits of pelletizing are most evident in diets with a high concentrate ratio or where long-term storage is required.

- For concentrate based or mixed diets, standard feed pellet machines are sufficient, with a focus on stable operation and good pellet quality.

- When forage or grass meal content is high, roller type pellet machines are preferred, as they provide stronger compression and better pellet stability for high fiber materials.

Pellet Machine Spec (Stand Model)

| Model | Power (kW) | Capacity (kg/h) |

| KR-190 | 5.5 | 200–250 |

| KR-190P | 7.5 | 200–300 |

| KR-210 | 11 | 250–400 |

| KR-260 | 18.5 | 500–700 |

| KR-300 | 30 | 700–900 |

| KR-400 | 45 | 1000–1200 |

Electric motor models operate on 380V 50Hz three phase power. When electricity is limited, diesel driven options are available.

Roller Type Pellet Machine Spec

| Model | Power (kW) | Capacity (kg/h) |

| KR 190 | 5.5 | 200 to 250 |

| KR 190P | 7.5 | 200 to 300 |

| KR 210 | 11 | 250 to 400 |

| KR 260 | 18.5 | 500 to 700 |

| KR 300 | 30 | 700 to 900 |

| KR 400 | 45 | 1000 to 1200 |

From USD 360 ( price varies by capacity and motor power )

4. Screw Conveyor

The screw conveyor is used to handle powdered or finely crushed materials, mainly in concentrate based or continuous pelletizing lines.

Its compact and stable design ensures consistent feeding when working with mixers and pellet machines, helping improve pelletizing efficiency and reduce manual feeding variation.

Screw Conveyor Specifications

| Attribute | Range |

| Screw Diameter | 100–300 mm |

| Conveying Length | 3–5 m |

| Conveying Speed | 0.5–2 m/s |

| Conveying Capacity | 1–2 t/h |

| Conveying Angle | 30°–60° |

| Power | 0.75–45 kW |

Screw diameter, conveying length, and inclination angle can be customized to match site layout and capacity requirements.

For small to medium scale production, selecting the right equipment based on diet structure allows the full feed process to be completed at a low cost.

If your raw materials, feeding volume, or expansion plans are clear, we can optimize the configuration to better match your production needs.

Online Contact

Online Contact Send Message

Send Message

Need Some Help?

Contact us quickly and we will reply you within 24 hours. We will not disclose your information.